ASME B 18.6.3 (1998)

-

Upload

iqzaragoza82 -

Category

Documents

-

view

4.725 -

download

335

Transcript of ASME B 18.6.3 (1998)

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

The American Society of Mechanical Engineers

A N A M E R I C A N N A T I O N A L S T A N D A R D

MAIHINE SCREWS AND MACHINE

SCREW NUTS

ASME B1 8.6.3-1 MM8 [Revision 01 ANSI B18.6.3-1972(R1997)]

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

STDmASME BLB.b.3-ENGL L998 m 0759b70 ObL4Lb4 T39 W

Date of Issuance: November 30, 1999

The 1998 edition of this Standard is being issued with an automatic addenda subscription service. The use of an addenda allows revisions made in response to public review comments or committee actions to be published as necessary. The next edition of this Standard is scheduled for publication in 2004.

ASME is the registered trademark of The American Society of Mechanical Engineers.

This code or standard was developed under procedures accredited as meeting the criteria for American National Standards. The Standards Committee that approved the code or standard was balanced to assure that individuals from competent and concerned interests have had an opportunity to participate. The proposed code or standard was made available for public review and comment, which provides an opportunity for additional public input from industry, academia, regulaton/ agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item, construction, proprietary device, or activity.

ASME does not take any position with respect to the validity of any patent rights asserted in connection with any items mentioned in this document, and does not undertaketo insure anyone utilizing a standard against liability for infringement of any applicable Letters Patent, nor assume any such liability. Users of a code or standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, is entirely their own responsibility.

Participation by federal agency representative(s) or person(s) affiliated with industry is not to be interpreted as government or industry endorsement of this code or standard.

ASME accepts responsibility for only those interpretations issued in accordance with governing ASME procedures and policies which preclude the issuance of interpretations by individual volunteers.

No part of this document may be reproduced in any form, in an electronic retrieval system or otherwise,

without the prior written permission of the publisher.

The American Society of Mechanical Engineers Three Park Avenue, New York, NY 10016-5990

Copyright O 1999 by THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved Printed in U.S.A.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

STDOASME BLB.b.3-ENGL L998 m 0757670 ObL4Lb5 975 m

FOREWORD

American National Standards Committee B 18 for the standardization of bolts, screws, nuts, rivets, and similar fasteners was organized in March 1922, as Sectional Committee B18 under the aegis of the American Engineering Standards Committee (later the American Standards Association, then the United States of America Standards Institute and, as of October 6, 1969, the American National Standards Institute, Inc.), with the Society of Automotive Engineers and the American Society of Mechanical Engineers as joint sponsors. Subcommittee 3 ' was subsequently established and charged with the responsibility for technical content of standards covering slotted and recessed head screws.

An American Standard setting forth slotted head proportions was approved and published in April of 1930. Over the years following the Issuance of this document, the need for standards more comprehensive than head configurations became apparent. At a meeting held on April 14, 1942, Subcommittee 3' was reorganized and enlarged, and the following operating scope was established:

The scope of Subcommittee 3' shall consist of the development and promulgation of American Standards embracing screw products variously known as machine screws, wood screws, tapping screws, slotted head cap screws, slotted headless set screws, and machine screw nuts. The standards shall comprise complete product standards covering all dimensions and tolerances required for the specification and production of the products. Details shall include boundary dimensions, such as nut width and thickness; screw head dimensions; slot and recess dimensions; body dimensions; thread classification or thread detail, as required; thread length; point design; chamfers; underhead fillets; and supporting general specifications covering the quality, finish, and the acceptable tolerances and limits as well as any information that may be necessrtry to insure satisfactory application of the products.

Several meetings of the Subcommittee over the ensuing 3 years resulted in the development and acceptance of a proposed revision containing complete product standards coverage for slotted and recessed head machine, tapping and wood screws; slotted head and hexagon head cap screws; and slotted headless set screws. Following approval by the B18 Committee and sponsor organizations, this proposal was forwarded to the American Standards Association and declared an American Standard, ASA B 18.6, on April 12, 1947.

Recognizing the need for further refinements, Subcommittee 3' at a meeting held on February I , 1951, established three standing working subgroups: one to develop details pertinent to tapping screw threads; a second to review, revise, and develop head dimensions and tolerances; and a third to correlate and edit the technical information emanating from the other two groups. Also at this meeting, numerous suggested changes were reviewed and assigned to the respective subgroups for further development. Additional meetings of the Subcommittee were held on October 9, 1952, October 29, 1953, and April 1 and 2, 1954. Between each of these meetings the subgroups held numerous working sessions and carried on technical development in cooperation with the technical committees of the U.S. Machine Screw and Tapping Screw Service Bureaus.

' As of April I , 1966, subcommittee 3 was redesignated Subcommittee 6.

... I I I

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

At the April 1954 meeting, Subcommittee 3,' contemplating a partial revision of the ASA BI 8.6 document, recommended the publication of standards for wood screws, cap and set screws, machine screws, and tapping and drive screws in four separate documents, each of which would consist of a complete product specification. This approach was confirmed by the B I 8 Committee with the further stipulation that the coverage for hexagon head cap screws, square head set screws, and machine screw nuts from the ASA B 18.2 standard be transferred to the documents covering cap and set screws and machine screws, respectively. I t was understood that jurisdiction over the square head set screws and hexagon head cap screws would remain with Subcommittee 2 and that Subcommittee 3' would retain responsibility for machine screw nuts. Following this confirmation and additional direction, the preparation of proposals for the new documents was undertaken.

The proposed standard covering slotted and recessed head machine screws and machine screw nuts was approved by Subcommittee 3' at a meeting held on December 6, 1955. After being circulated to industry for comment, it was revised and subsequently approved by letter ballot of the B 18 Committee in March of 1958. The proposal was, however, redrafted to incorporate additional revisions and refinements adopted by Subcommittee 3' at meetings held on October 30, 1958 and September 17, 1959. The revised proposal was recirculated to the B I 8 Committee and was approved by the sponsor organizations and the American Standards Association and formally designated an American Standard, ASA B 18.6.3, on February 12, 1962.

Following issuance of the 1962 document, Subcommittee 3' and the working subgroups continued to develop revisions and refinements reflecting changes in industry practices and technical improvements. Work over the intervening years culminated in the Subcommittee 6 acceptance of a draft dated November 1969, incorporating revisions in the following areas: inclusion of Type IA cross recess data; addition of the No. o o 0 0 , 000, and O0 sizes to most slotted head styles; extensions of size coverage for 1 0 0 deg flat countersunk heads and binding heads in smaller sizes, and for pan heads in larger sizes; redimensioning of flat and oval countersunk heads; revision of thread lengths; inclusion of appendices for wobble gaging of recessed heads and wrench sizes for square and hex products; and a complete revamping of the format.

In 1997 Subcommittee 6 initiated work to revise the head diameters for flat head screws, the length measurement method for oval head screws, the height inspection for oval head screws, adding protrusion height inspection for oval head screws and quality assurance and designated inspection characteristics. Several drafts were prepared, which resulted in further refinements. These changes were balloted and approved by the ASME BI8 Committee.

This revision was approved as an American National Standard on July 16, 1998.

iv

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

CORRESPONDENCE WITH THE B18 COMMITTEE

General. ASME Standards are developed and maintained with the intent to represent the consensus of concerned interests. As such, users of this Standard may interact with the Committee by requesting interpretations, proposing revisions, and attending Committee meetings. Correspondence should be addressed to:

Secretary, B 18 Main Committee The American Society of Mechanical Engineers Three Park Avenue New York, NY 10016-5990

Proposing Revisions. Revisions are made periodically to the Standard to incorporate changes that appear necessary or desirable, as demonstrated by the experience gained from the application of the Standard. Approved revisions will be published periodically.

The Committee welcomes proposals for revisions to this Standard. Such proposals should be as specific as possible, citing the paragraph number(s), the proposed wording, and a detailed description of the reasons for the proposal, including any pertinent documentation.

Interpretations. Upon request, the B 18 Committee will render an interpretation of any requirement of the Standard. Interpretations can only be rendered in response to a written request sent to the Secretary of the B I 8 Main Committee.

The request for interpretation should be clear and unambiguous. It is further recommended that the inquirer submit hisher request in the following format:

Subject: Cite the applicable paragraph number(s) and the topic of the inquiry. Edition: Cite the applicable edition of the Standard for which the interpretation

is being requested. Question: Phrase the question as a request for an interpretation of a specific

requirement suitable for general understanding and use, not as a request for an approval of a proprietary design or situation. The inquirer may also include any plans or drawings, which are necessary to explain the question; however, they should not contain proprietary names or information.

Requests that are not in this format may be rewritten in the appropriate format by the Committce prior to being answered, which may inadvertently change the intent of the original request.

ASME procedures provide for reconsideration of any interpretation when or if additional information that might affect an interpretation is available. Further, persons aggrieved by an intcrpretation may appeal to the cognizant ASME Committee or Subcommittee. ASME does not “approve,” “certify,” “rate,” or “endorse” any item, construction, proprietary device, or activity.

Attending Committee Meetings. The B18 Main Committee regularly holds meetings, which are open to the public. Persons wishing to attend any meeting should contact the Secretary of the B 18 Main Committee.

V

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B18 STANDARDS COMMITTEE Standardization of Bolts, Nuts, Rivets, Screws,

Washers, and Similar Fasteners

(The following is the roster of the Committee at the time of approval of this Standard.)

OFFICERS

D. A. Clever, Chair R. D. Strong, Vice Chair S. W. Vas , Vice Chair R. L. Crane, Secretary

COMMITTEE PERSONNEL

J. C. Akins, Safety Socket Screw Corp. J. Altman, Rotor Clip Co. J. B. Belford, Lawson Products Inc. D. Broornfield, Illinois Tool Works Inc. J. A. Buda, SPS Technologies D. A. Clever, Deere and Co. A. P. Cockrnan, Ford Motor Co. T. Collier, Cam-Tech Industries Inc. R. L. Crane, The American Society of Mechanical Engineers A. C. DiCola, Wrought Washer Co. A. Dinh, Defense Industrial Supply Center W. D, Downing, Emhart Heli-Coil D. L. Drobnich, Alternate, Ford Motor Co. B. A. Dusina, Federal Screw Works D. S. George, Ford Motor Co. B. Hasiuk, Defense Industrial Supply Center A. Herskovitz, U. S. Army ARDEC A. C. Hood, ACH Technologies J. Hubbard, Rockford Fastener, Inc. F. W. Kern, Consultant W. H. Kopke, ITW Shakeproof Assembly Corp. J. G. Langenstein, Consultant M. Levinson, ITW Shakeproof L. L. Lord, Caterpillar Inc. A. D. McCrindle, Genfast Manufacturing Co. K. E. McCullough, Consultant R. F. Novotny, Camcar Decorah Operations M. D. Prasad, General Motors Corp. W. Schevey, EGM Fastener Co. Inc. J. H. Slass, Alternate, Rotor Clip R. D. Strong, General Motors Corp. J. F. Sullivan, National Fasteners Distribution Association R. L. Tennis, Caterpillar Inc. S. W. Vass, Industrial Fasteners Institute R. G. Weber, Fairfield University School of Engineering C. J. Wilson, Industrial Fasteners Institute

vii Previous page

is blank COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

SUBCOMMITTEE 6 - SLOTTED AND RECESSED HEAD SCREWS

R. D. Strong, Chair, General Motors Corp. R. L. Crane, Secretary, The American Society of Mechanical Engineers D. Broomfield, Illinois Tool Works Inc. D. A. Clever, Deere and Co. A. Dinh, Defense Industrial Supply Center J. Greenslade, Greenslade and Co. A. Herskovitz, U.S. Army ARDEC M. W. Holubecki, Electric Boat Corp. J. Hubbard, Rockford Fastener, Inc. R. W, Kerr, Kerr Lakeside Inc. R. F. Novotny, Camcar Decorah Operations J. A. Schlink, Caterpillar Inc. J. F. Sullivan, National Fasteners Distribution Association C. B. Wackrow, MNP Corp. C. J. Wilson, Industrial Fasteners Institute

V l l l ...

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

CONTENTS

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Correspondence With the B 18 Committee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introductory Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tables I A Dimensions of Slotted Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . IB Dimensions of Type I Cross Recessed Flat Countersunk Head Machine

IC Dimensions of Type IA Cross Recessed Flat Countersunk Head Machine

ID Dimensions of Type 11 Cross Recessed Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2A Dimensions of Slotted 100 deg Flat Countersunk Head Machine Screws . . . . . . . . . . 2B Dimensions of Type I Cross Recessed 100 deg Flat Countersunk Head Machine

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2C Dimensions of Type I A Cross Recessed 1 0 0 deg Flat Countersunk Head Machine

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2D Dimensions of Type II Cross Recessed 100 deg Flat Countersunk Head Machine

3A Dimensions of Slotted Close Tolerance 1 0 0 deg Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3B Dimensions of Type I Cross Recessed Close Tolerance 100 deg Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3C Dimensions of Type I A Cross Recessed Close Tolerance 100 deg Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3D Dimensions of Type II Cross Recessed Close Tolerance 100 deg Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4A Dimensions of Slotted Oval Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . 4B Dimensions of Type I Cross Recessed Oval Countersunk Head Machine

4C Dimensions of Type I A Cross Recessed Oval Countersunk Head Machine

4D Dimensions of Type II Cross Recessed Oval Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5A Dimensions of Slotted Undercut Flat Countersunk Head Machine Screws . . . . . . . . . 5B Dimensions of Type I Cross Recessed Undercut Flat Countersunk Head Machine

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C Dimensions of Type I A Cross Recessed Undercut Flat Countersunk Head Machine

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standards Committee Roster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Screws

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

... 111

V

v i i

I

3

7

8

10

I I 12

13

14

15

16

17

18

19 20

22

24

26 28

29

30

ix

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

SD

6A 6B

6C

6D

7A

7B

7 c

8A

SB

8C

9A 9B 9 c 9D I 0A I OB I oc 1 OD 1 1 12A 12B 12c I2D 13A 13B 13C 13D 14

15 16 17

Dimensions of Type II Cross Recessed Undercut Flat Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dimensions of Slotted Undercut Oval Countersunk Head Machine Screws . . . . . . . . 32

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 Dimensions of Type I Cross Recessed Undercut Oval Countersunk Head Machine

Dimensions of Type IA Cross Recessed Undercut Oval Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Dimensions of Type II Cross Recessed Undercut Oval Countersunk Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Dimensions of Type I Cross Recessed Flat Countersunk Trim Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dimensions of Type IA Cross Recessed Flat Countersunk Trim Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Dimensions of Type II Cross Recessed Flat Countersunk Trim Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Dimensions of Type I Cross Recessed Oval Countersunk Trim Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Dimensions of Type IA Cross Recessed Oval Countersunk Trim Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Dimensions of Type II Cross Recessed Oval Countersunk Trim Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Dimensions of Slotted Pan Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Dimensions of Type I Cross Recessed Pan Head Machine Screws . . . . . . . . . . . . . . . . 49 Dimensions of Type IA Cross Recessed Pan Head Machine Screws . . . . . . . . . . . . . . 50 Dimensions of Type II Cross Recessed Pan Head Machine Screws . . . . . . . . . . . . . . . 51

Dimensions of Type I Cross Recessed Fillister Head Machine Screws . . . . . . . . . . . . 53 Dimensions of Type IA Cross Recessed Fillister Head Machine Screws . . . . . . . . . . 54 Dimensions of Type 11 Cross Recessed Fillister Head Machine Screws . . . . . . . . . . . 56 Dimensions of Slotted Drilled Fillister Head Machine Screws .................... 57 Dimensions of Slotted Truss Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Dimensions of Type I Cross Recessed Truss Head Machine Screws . . . . . . . . . . . . . . 59 Dimensions of Type IA Cross Recessed Truss Head Machine Screws . . . . . . . . . . . . 60 Dimensions of Type II Cross Recessed Truss Head Machine Screws . . . . . . . . . . . . . 61

Dimensions of Type I Cross Recessed Binding Head Machine Screws . . . . . . . . . . . . 63 Dimensions of Type IA Cross Recessed Binding Head Machine Screws . . . . . . . . . . 64 Dimensions of Type II Cross Recessed Binding Head Machine Screws . . . . . . . . . . . 6.5 Dimensions of Plain and Slotted Regular and Large Hex Head Machine

Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Dimensions of Plain and Slotted Hex Washer Head Machine Screws . . . . . . . . . . . . . 68 Dimensions of Square and Hex Machine Screw Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 Dimensions of Header Points for Machine Screws Before Threading . . . . . . . . . . . . . 71

Dimensions of Slotted Fillister Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Dimensions of Slotted Binding Head Machine Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Mandatory Appendices

2 Across-Corners Gaging of' Hex Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

4 Wobble Gaging of Recessed Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SS 5 Dimensions for No . 0000, No . 000, and No . 00 Thread Sizes . . . . . . . . . . . . . . . . . . . 89

I Protrusion Gaging of Flat Countersunk Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3 Penetration Gaging of Recessed Heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

x

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

STDOASME BLB.b.3-ENGL 3798 0759b70 Ob34372 005 m

Nonmandatory Appendices A Formulas for Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91 B Wrench Openings for Hex Head Screws and Square and Hex Nuts . . . . . . . . . . . . . . 99 C Dimensions of Round Head Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

xi

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME 818.6.3-1998

MACHINE SCREWS AND MACHINE SCREW NUTS

1 INTRODUCTORY NOTES

1.1 Scope

This Standard is intended to cover the complete general and dimensional data for the various types of slotted and recessed head machine screws and machine screw nuts recognized as American National Standard. Also included are appendices that provide specifications and instructions for the protrusion gaging of flat count- ersunk head screws; across-comers gaging of hex head screws; penetration gaging and wobble gaging of re- cessed head screws; wrench openings for hex and square products; thread dimensions for the No. 0000, No. 000, and No. O0 sizes; and formulas on which dimensional data are based. It shall be understood, however, that where questions arise concerning acceptance of product, the dimensions in the tables shall govern over recalcula- tion by formula.

The inclusion of dimensional data in this Standard is not intended to imply that all of the products described are stock production sizes. Consumers should consult with manufacturers concerning the availability of products.

1.2 Machine Screw Head Types

The head types covered by this Standard include those commonly recognized as being applicable to machine screws and are enumerated and described in the following paragraphs.

1.2.1 Flat Countersunk Head. The flat count- ersunk head shall have a flat top surface and a conical bearing surface with a head angle for one style of approximately 82 deg and for another style of approxi- mately 1 0 0 deg. Dimensions are given in Tables IA through ID, and 2A through 2D, respectively. Dimen- sions of close tolerance 100 deg flat countersunk heads are given in Tables 3A through 3D.

1.2.2 Oval Countersunk Head. The oval count- ersunk head shall have a rounded top surface and a conical bearing surface with a head angle of approxi- mately 82 deg. Dimensions are given in Tables 4A through 4D.

1

1.2.3 Undercut Flat and Oval Countersunk Heads. For short lengths, 82 deg flat and oval count- ersunk head machine screws shall have heads undercut to 70% of normal side height to afford greater length of thread on the screws. Dimensions are given in Tables 5A through 5D, and 6A through 6D, respectively.

1.2.4 Flat and Oval Countersunk Trim Heads. Flat and oval countersunk trim heads shall be similar to the 82 deg flat and oval countersunk heads except that the size of head for a given size screw is one or two sizes smaller than the regular flat and oval count- ersunk head size, and oval countersunk trim heads shall have a controlled radius where the curved top surface meets the conical bearing surface. Trim heads are furnished only in cross recessed head types. Dimensions are given in Tables 7A through 7C, and 8A through 8C, respectively.

1.2.5 Pan Head. The slotted pan head shall have a flat top surface rounded into cylindrical sides and a flat bearing surface. The recessed pan head shall have a rounded top surface blending into cylindrical sides and a flat bearing surface. Dimensions are given in Tables 9A through 9D.

1.2.6 Fillister Head. The fillister head shall have a rounded top surface, cylindrical sides, and a flat bearing surface. Dimensions are given in Tables 10A through IOD. Dimensions of drilled fillister head ma- chine screws are given in Table l l .

1.2.7 Truss Head. The truss head shall have a low rounded top surface with a flat bearing surface, the diameter of which for a given screw size shall be larger than the diameter of the corresponding round head. Dimensions are given in Tables 12A through 12D.

1.2.8 Binding Head. The binding head shall have a rounded top surface and slightly tapered sides. The bearing surface shall be flat and, where so specified by purchaser, slotted heads shall have an annular under- cut adjacent to the shank. Dimensions are given in Tables 13A through I3D.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

STD-ASME BLB-b-3-ENGL 1998

ASME 818.6.3-1998

D 0759b70 Ob14174

MACHINE SCREWS AND MACHINE SCREW NUTS

1.2.9 Hex Head. The hex head shall have a flat 1.7 Terminology or indented top surface, six flat sides, and a flat bearing surface. Dimensions for regular and large heads are given in Table 14.

For definitions of terms relating to fasteners or fea- tures thereof used in this Standard, refer to ASME B 18.12, Glossary of Terms for Mechanical Fasteners.

1.2.10 Hex Washer Head. The hex washer head shall have an indented top surface and six flat sides 1-8 Related Standards formed integrally with a flat washer that projects beyond It should be noted that standards for cap screws, set the sides and provides a flat bearing surface. Dimensions screws, tapping screws, wood screws, drive screws, are given in Table 15. sems, washers, and other related fasteners are published

under separate cover as listed at the end of this Standard. 1.2.11 Round Head. The round head shall have

a semielliptical top surface and a flat bearing surface. In recognition of superior slot driving characteristics 1.9 Comparison With IS0

of pan head screws over round head screws, and the This Standard has no IS0 counterpart. overlap in the dimensions of cross recessed pan heads and round heads, it is recommended that pan head screws be used in new designs and wherever possible l. 1 O References

substituted in existing designs. To expedite elimination The following is a list of publications referenced in of the necessity for perpetuating stocks of finished this Standard. products and tooling, it should be recognized that during the transition period manufacturers may, when it is ASME B 1.1, Unified Inch Screw Threads (UN and agreeable to users, substitute pan head where round head is specified. Dimensions are given for reference ASME B18.12, Of Tenns for purposes in Appendix C.

UNR Thread Form)

Fasteners

for General Purpose Fasteners

for High-Volume Machine Assembly Fasteners

ASME B 18.18. IM, Inspection and Quality Assurance

1.3 Machine Screw Nuts ASME B 18.18.2M, Inspection and Quality Assurance

The machine screw nuts covered by this Standard ASME B 18.24.1, Part Identifying Number (Pin) Code include the hexagon and square varieties. Dimensions System Standard for B 18 Externally Threaded are given in Table 16. Products

ASME B18.24.2, Part Identifying Number (Pin) Code System Standard for B18 Internally Threaded Products

All dimensions i n this Standard are given in inches, publisher: The ~~~~i~~~ Society of Mechanical Engi- unless stated otherwise. neers (ASME International), Three Park Avenue,

New York, NY 10016-5990; Order Department: 22 Law Drive, Box 2300, Fairfield, NJ 07007-2300.

Unless otherwise specified at the time the order is Options7 where 'Pecified7 be at the placed, the latest level of all reference standards shall

of the manufacturer unless otherwise agreed upon by be used. the manufacturer and the purchaser. ANSI and IS0 standards may be obtained from

ANSI, the American National Standards Institute, 1 I

1.4 Dimensions

1.5 Options

1.6 Responsibility for Modification West 42nd Street, New York, NY 10036-8002. ASTM standards may be obtained from the American

The manufacturer shall not be held responsible for Society for Testing and Materials, 100 Barr Harbor malfunctions of product determined to be due to plating Drive, West Conshohocken, PA 19428-2959. or other modifications when such plating or modification SAE standards may be obtained from the Society of is not accomplished under the manufacturer's control Automotive Engineers, Inc. 400 Commonwealth Drive, or direction. Warrendale, PA 15096-OO01.

2

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

MACHINE SCREWS ANO MACHINE SCREW NUTS

1.11 Inspection and Quality Assurance

Unless otherwise specified, acceptability to this Stan- dard shall be determined i n accordance with ASME B 18.18. I M, Inspection and Quality Assurance for Gen- eral Purpose Fasteners.

When applicable, the following designated character- istics shall be inspected to the inspection levels shown according to ASME B 18.1 8.2M, Inspection and Quality Assurance for High-Volume Machine Assembly Fasten- ers, and shall be within their specified limits.

Designated Characteristic Inspection Level

Recess penetration depth C Slot depth C Width across corncrs C Thread acceptance C Tensile strength test C Nut proof load test C

If verifiable in-process inspection is used, inspection sample sizes and reporting shall be in accordance with the applicable ASME, ASTM, or SAE quality system consensus standard.

For nondesignated dimensional characteristics, the provisions of ASME B 18.18. IM shall apply. Should a nondesignated dimension be determined to be outside its specified limits, it shall be deemed conforming to this Standard if the user who is the installer accepts the dimension, based upon form, fit, and function considerations.

2 GENERAL DATA

2.1 Heads

2.1.1 Head Height. All dimensions pertaining to head height specified in the dimensional tables shall be measured parallel to the axis of screw and those relating to the top of head shall represent a metal-to- metal measurement. In other words, any truncation of rounded head contours due to the slot or recess shall not be considered part of the head height.

Total or overall head heights shall be measured from the top of the head to the plane of the bearing surface for flat bearing surface type heads, to the plane of the undercut for undercut countersunk heads, and to the junction of the conical bearing surface with the basic screw diameter for countersunk heads.

Head side heights shall be measured from the theoreti- cal intersection of the top surface of head with the head diameter to the plane of the bearing surface for flat bearing surface type heads, to the plane of the

ASME 818.6.3-1998

undercut for undercut countersunk heads, and to the junction of the conical bearing surface with the basic screw diameter for countersunk heads.

On countersunk heads, the junction of the conical bearing surface with the basic screw diameter may not necessarily be the same as the actual junction of head with shank and the head height delineating the conical bearing surface is a reference dimension.

2.1.2 Bearing Surface. The bearing surface of flat bearing surface type machine screw heads shall be perpendicular to the axis of the screw shanks within 2 deg.

2.1.3 Depth of Recess. The depth of recess in recessed head screws shall be measured, parallel to the axis of screw, from the intersection of the maximum diameter of the recess with the head surface to the bottom of the recess.

Recess penetration gaging depth values are included in the respective dimensional tables, and the method of gaging and specifications for gages are contained in Appendix III .

Recess wobble gages, gaging procedures, and permis- sible limits are given in Appendix IV.

2.1.4 Depth of Slot. The depth of slot in slotted head screws shall be measured, parallel to the axis of screw, from the top of the head to the intersection of the bottom of the slot with the head surface or bearing surface.

2.1.5 Feature Positional Tolerances. The posi- tional relationship of the heads and driving provisions of screws with respect to the shanks of screws (formerly defined as eccentricity) shall be as follows.

(a) True Position of Head. The axis of the head shall be located at true position relative to the axis of the screw shank within a tolerance zone having a diameter equivalent to 6% of the specified maximum head diameter, or maximum width across flats of hex and hex washer heads, regardless of feature size.

(b) True Position of Recess. The recess in cross recessed head screws shall be located at true position relative to the axis of the screw shank within a tolerance zone having a diameter equivalent to 12% of the basic screw diameter or 0.030 in., whichever is greater, regardless of feature size.

3

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

STDOASME BLB.b.3-ENGL

ASME B18.6.3-1998

(c) True Position of Slot. The slot in slotted head screws shall be located at true position relative to the axis of the screw shank within a tolerance zone having a diameter equivalent to 12% of the basic screw diameter or 0.020 in. , whichever is greater.

2.1.6 Underhead Fillets. Machine screws shall have a definite underhead fillet large enough to ensure that full fastener strength is achieved. The radius of the fillct under countersunk head screws shall be no greater than 40% of the basic screw diameter. The radius of the fillet under truss heads and number 6 sized pan heads shall be no greater than 25% of the basic screw diameter. The radius of the fillet under all other head styles shall be no greater than 15% of the basic screw diameter.

2.2 Length

2.2.1 Measurement. The nominal length of screw L shall be measured, parallel to the axis of screw, from the extreme point to the plane of the bearing surface for screws having perpendicular bearing surface type heads, and to the theoretical intersection of the top surface of head with the head diameter for screws having countersunk type heads. For all oval heads, the overall length L, shall be measured, parallel to the axis of the screw, from the extreme point to the top of the head, where

L , = L + c

L998

MACHINE SCREWS AND MACHINE SCREW NUTS

sizes, which are covered in Appendix V, shall be Unified Standard, Class 2A, UNC and UNF series, or UNRC and UNRF series, at option of manufacturer, in accordance with ASME B I . l . For threads with additive finish, the maximum diameters of Class 2A may be exceeded by the amount of the allowance: that is, the Class 2A maximum diameters shall apply to an unplated or uncoated part, or to a part before plating or coating, whereas the basic diameters (Class 3A GO) shall apply to a part after plating or coating. The minimum major diameter of plated or coated screws may approach but shall not be less than the Class 2A minimum limit.

2.3.2 Machine Screw Nuts. Threads shall be Unified Standard, Class 2B, UNC or UNF series for hexagon machine screw nuts, and UNC series for square machine screw nuts, in accordance with ASME B 1 . l .

2.4 Length of Thread

2.4.1 Machine Screws. Machine screws shall have thread lengths conforming to the following (on screws threaded full length, the distance to first full form thread shall be measured, parallel to the axis of screw, from the bearing surface of the head to the face of a nonchamfered or noncounterbored standard 3A GO thread ring gage assembled by hand as far as the thread will permit).

2.2.2 Tolerance on Length. The length tolerance shall apply to L , for all oval heads and to L for all other head styles. The tolerance on the length of machine screws shall conform to the following for the respective screw types:

( a ) Sizes No. 5 and Smaller. Screws of nominal lengths equal to three diameters and shorter shall have full form threads extending to within one pitch (thread) of the bearing surface of the head, or closer, if practica- ble. Nominal lengths greater than three diameters, up to and including IV8 in., shall have fu l l form threads

Tolerance on Length extending to within two pitches (threads) of the bearing for Nominal Screw Size

Nominal m 0 94

Screw Through Through Through Lengrh O0 12 v4

up to '/z in., incl. -0.0 I -0.02 -0.03 Over '12 IO I in., inci. -0.02 -0.03 -0.03 Over I to 2 in.. incl. . . . -0.06 -0.06 Over 2 in. . . . -0.09 -0.09

2.3 Threads

2.3.1 Machine Screws. The threads on machine screws, except for the No. 0000, No. 000, and No. 00

surface of the head, or closer, if practicable. Screws of longer nominal lengths shall, unless otherwise specified, have a minimum length of full form thread of I in.

(b) Sizes No. 6 and Larger. Screws of nominal lengths equal to three diameters and shorter shall have full form threads extending to within one pitch (thread) of the bearing surface of the head, or closer, if practica- ble. Nominal lengths greater than three diameters, up to and including 2 in., shall have ful l form threads extending to within two pitches (threads) of the bearing surface of the head, or closer, if practicable. Screws of longer nominal lengths shall, unless otherwise specified, have a minimum length of ful l form thread of 1.50 in.

4

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

MACHINE SCREWS AND MACHINE SCREW NUTS

2.5 Points

Unless otherwise specified, machine screws shall have plain sheared ends. Where so specified, header points shall be as shown in Table 17. Other points or pointing of longer lengths to header point dimensions may require machining.

2.6 Diameter of Body

2.6.1 Machine Screws. The diameter of body on machine screws having other than trim heads shall not be less than the Class 2A thread minimum pitch diameter nor greater than the basic major diameter of the thread.

2.6.2 Trim Head Machine Screws. The diameter of body on trim head machine screws shall not be less than the Class 2A thread minimum pitch diameter nor greater than the basic major diameter of the thread. Screws not threaded to the head shall have a 0.062 in. minimum length shoulder under the head with diameter limits as specified in the dimensional tables.

2.7 Material

2.7.1 Machine Screws. Unless otherwise speci- fied, machine screws shall be fabricated From carbon steel and shall have a minimum tensile strength of 60,000 psi.

Machine screws. where so specified, may also be made from higher strength steels, corrosion resistant steel, brass, monel, aluminum alloys, or other materials, as agreed upon between the manufacturer and the purchaser.

2.7.2 Machine Screw Nuts. Machine screw nuts are normally supplied in steel, corrosion resistant steel, or brass as specified by the purchaser. Unless otherwise specified, no physical requirements shall apply.

2.8 Finish

Unless otherwise specified, machine screws and ma- chine screw nuts shall be supplied with a natural (as processed) finish, unplated or uncoated.

ASME 618.6.3-1998

2.9 Workmanship

Machine screws and machine screw nuts shall not contain an excess of surface imperfections that might affect their serviceability, such as, burrs, seams, laps, loose scale, and other irregularities.

2.10 Designation

2.10.1 Machine Screws. Machine screws shall be designated by the following data in the sequence shown: nominal size (number, fraction, or decimal equivalent); threads per inch; nominal length (fraction or decimal equivalent); product name, including head type and driving provision; header point, if desired; material; protective finish, i f required; or, optionally, ASME B1 8.24. I PIN code. For example:

EXAMPLE I : 1/4 - 20 x 1-1/4 Slotted Pan Head Machine Scrcw. Steel, Zinc Plated

" i'

I

530N A99 C A ""

.D19 155NN CE + 4 + "-

1~" Plating, coating, and passiv- ation: electrodeposited coat- ings of zinc on irnn and steel, type I I , SC 1

L Material and treatment: equiva- lent to PIN 001 through 15.3

-Diameter and length: 0.250 and 1.250

L T h r e a d series: thread forming. thread cut- ting, and metallic drive

1 1 ._ Head and drive: screws, machine, pan head,

i B I8 standard designation: B 18.6.3 slvtted

- Fastener family: screw

EXAMPLE 2: 16 - 32 x 3/1 Type IA Cross Recessed Filli\kr Head Machine Screw, Brasa

S 630N A60 C A614 603NN AA

Unplated, uncoated IL UNS 46200

__ 0.138 and 0.750

Screws, machine, fillister head, type I A cross recess

818.6.3 - Screw

5

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME 818.6.3-1998

EXAMPLE 3: 3 7 5 - 16 x 1.50 Hexagon Washer Head Machine Screw. Header Poinled, Steel

S 630N AX1 C AK21 l55NN AA 4 A A 4 r 4

~

Unplated, uncoated i ~~ Equivalent to PIN 001 through 153

0.375 and 1.500

L UNC ~ ~ Screws, machine, hex washer head, unslotted

818.6.3 ~ Screw

EXAMPLE 1: . I O 0 - 24 x 1 S O Type II Cross Recessed Flat Count- ersunk Head Machine Screw. Steel. Nickel Plated

"" S 630N A65 C AA21 302NN RA I

I Special feature: none Nickel plating, class I, grade E

to PIN 217, 224, 274, or 275

I , L Screws, machine, Rat head, type II cross recess I L ßlX.6.3 L- Screw

I !

2.10.2 Machine Screw Nuts. Machine screw nuts shall be designated by the following data i n the sequence shown: nominal size (number, fraction, or decimal

MACHINE SCREWS AND MACHINE SCREW NUTS

equivalent); threads per inch; product name; material; protective finish, if required; or, optionally, ASME B18.24.2 PIN code. For example:

EXAMPLE I : 10 - 2 1 Hexagon Machine Screw Nut, Steel, Zinc Plated

N 630N I5 C AAN __ . N 155NNN CE 1 ""

Special feature: none Plating, coating, and passiv- ation: electrodeposited coat- ings of zinc on iron and steel, type II, SC 1

Material and treatment: equiva- lent to PIN O01 through 153

- Diameter (for nuts or inserts) and length (for inserts): 0.190, size 10

-Thread series: UNC -Fastner type: machine screw nuts, hex (inch)

- BIS Standard Designation: BlS.6.3 - Fastener Family: Nut

EXAMPLE 2: ,138 - 3 2 Square Machine Screw Nut, Brass

630N -

i I4 C A6NN 603NNN AA 1 A 1 L Special feature: none

i Machine screw nuts, square (inch) B18.6.3

- Nut

6

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

MACHINE SCREWS AND MACHINE SCREW NUTS ASME B18.6.3-1998

Edge of head may be A min. rounded or flat

L G - 4 L Protrusion gage

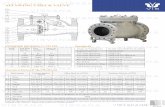

TABLE 1A DIMENSIONS OF SLOTTED FLAT COUNTERSUNK HEAD MACHINE SCREWS

Nominal Size Head

L H. Ref. Diameter G

Protrusion Above Slot Depth Gaging Diameter or Basic Screw Length Head Diameter Height 'lot Width

Gaging Diameter

A J T F [Note 1411

[Note (111 [Note (211 Max. Min. [Note (311 Max. Min. Max. Min. Max. Min. [Note (411

O000 0.0210 O00 0.0340 O0 0.0470

O 0.0600 1 0.0730 2 0.0860 3 0.0990

4 0.1120 5 0.1250 6 0.1380

8 0.1640 10 0.1900 12 0.2160

1/4 0.2500 0.3125 0.3750

'/16 0.4375

v2 0.5000 0.5625

"/B 0.6250 3/, 0.7500

. . . 0.040

. . . 0.060

. . . 0.087

l/8 0.112 '/a 0.137 '/a 0.162 'h 0.187

3/16 0.212 3/16 0.237 % 6 0.262

l/4 0.312 5/,6 0.362 '18 0.412

'h 0.597 '4 0.717 "8 0.760

9 4 0.815

'/16 0.477

. . . 0.932

. . . 1 .O50

. . . 1.285

0.035 0.055 0.080

0.096 0.120 0.144 0.167

0.191 0.215 0.238

0.285 0.333 0.380

0.442 0.556 0.670 0.715

0.765 0.878 0.990 1.215

0.01 1 0.008 0.016 0.011 0.028 0.017

0.035 0.023 0.043 0.026 0.051 0.031 0.059 0.035

0.067 0.039 0.075 0.043 0.083 0.048

0.100 0.054 0.116 0.060 0.132 0.067

0.153 0.075 0.191 0.084 0.230 0.094 0.223 0.094

0.223 0.106 0.260 0.118 0.298 0.133 0.372 0.149

0.004 0.007 0.010

0.016 0.019 0.023 0.027

0.031 0.035 0.039

0.045 0.050 0.056

0.064 0.072 0.081 0.081

0.091 0.102 0.116 0.131

0.007 0.009 0.014

0.015 0.019 0.023 0.027

0.030 0.034 0.038

0.045 0.053 0.060

0.070 0.088 0.106 O. 103

0.103 0.120 O. 137 0.171

0.003 0.005 0.009

0.010 0.012 0.015 0.017

0.020 0.022 0.024

0.029 0.034 0.039

0.046 0.058 0.070 0.066

0.065 0.077 0.088 0.111

Note (5) Note (51 Note (51

0.026 0.028 0.029 0.031

0.032 0.034 0.036

0.039 0.042 0.045

0.050 0.057 0.065 0.073

0.081 0.089 0.097 0.112

Note (5) Note (5) Note (51

0.016 0.016 0.077 0.018

0.019 0.020 0.021

0.023 0.025 0.027

0.029 0.034 0.039 0.044

0.049 0.053 0.058 0.067

Note (51 Note (5) Note (5)

0.078 0.101 0.124 0.148

0.172 0.196 0.220

0.267 0.313 0.362

0.424 0.539 0.653 0.690

0.739 0.851 0.962 1.186

GENERAL NOTE: For additional requirements refer to para. 2.

NOTES: (11 Where specifying nominal size in decimals, zeros preceding decimal and in the fourth decimal place shall b e omitted. (2) Screws of these lengths and shorter shall have undercut heads as shown in Table 5A. (31 Tabulated values determined from formula for maximum H in Appendix A. (41 No tolerance for gaging diameter is given. If the gaging diameter of the gage used differs from tabulated value, the protrusion will be affected

(5) Not practical to gage. accordingly and the proper protrusion values must be recalculated using the formulas shown in Appendix I.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ciw

This

typ

e of

re

cess

ha

s a

larg

e ce

nter

op

enin

g,

wide

st

raig

ht

wing

s,

and

blun

t

botto

m,

woth

al

l ed

ges

relie

ved

or

roun

ded.

TABL

E 1B

IL

LUST

RAT

ION

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

TABL

E 1B

D

IMEN

SIO

NS

OF

TYPE

I

CR

OSS

R

ECES

SED

FL

AT

CO

UN

TER

SUN

K H

EAD

M

ACH

INE

SCR

EWS

!i 2 No

mina

l Siz

e

or

Basic

Sc

rew

Diam

eter

Leng

th 1

Head

Diam

eter A

Head

He

ight

Ii,

Ref.

Rece

ss

Protr

usion

Ab

ove

Pene

tratio

n Ga

ging

Diam

eter

Gagin

g F

Rece

ss

Rece

ss

Rece

ss

Diam

eter

6 Di

amete

r De

pth

Widt

h Dr

iver

Gagin

g De

pth

F [N

ote

14)J

G

7

[Not

e (1

11

[Not

e C

iH

Max

. M

in.

[Not

e (3

11

M.

Ref.

T, R

ef.

N,

Ref.

Size

Max

. M

in.

Max

. M

in.

[Not

e (4

11

g

0 0.

0600

1

0.07

30

2 0.

0860

3

0.09

90

4 0.

1120

5

0.12

50

6 0.

1380

8 0.

1640

10

0.19

00

12

0.21

60

v3

‘/4

0.25

00

‘&

0.31

25

“/s

0.37

50

?&

0.43

75

‘I*

0.50

00

?‘,5

0.

5625

“/8

0.

6250

“/a

0.

7500

‘43

0.112

'A

0.13

7 ‘/s

0.

162

‘/8

0.18

7

%a

0.21

2 %

6 0.

237

%I3

0.

262

‘4

0.31

2 5/

6 0.

362

%I

0.41

2

‘/16

0.47

7 ‘4

0.

597

%a

0.71

7 %

0.

760

3/,

0.81

5 .

. 0.

932

. 1.

050

. 1.

285

0.096

0.

035

0.06

2 0.

035

0.01

4 0

0.03

6 0.

020

0.02

6 0.

016

0.12

0 0.

043

0.07

0 0.

043

0.01

5 0

0.04

4 0.

028

0.02

8 0.

016

0.14

4 0.

051

0.09

6 0.

055

0.01

7 1

0.05

6 0.

040

0.02

9 0.

017

0.16

7 0.

059

0.10

0 0.

060

0.01

8 1

0.06

1 0.

045

0.03

1 0.

018

0.191

0.

067

0.12

2 0.

081

0.01

8 1

0.08

2 0.

066

0.03

2 0.

019

0.21

5 0.

075

0.14

8 0.

074

0.02

7 2

0.07

5 0.

052

0.03

4 0.

020

0.23

8 0.

083

0.16

8 0.

094

0.02

9 2

0.09

5 0.

072

0.03

6 0.

021

0.28

5 0.

100

0.18

2 0.

110

0.03

0 2

0.11

0 0.

087

0.039

0.

023

0.26

7

0.33

3 0.

116

0.19

8 0.

124

0.03

2 2

0.12

5 0.

102

0.04

2 0.

025

0.31

3

0.38

0 0.

132

0.26

2 0.

144

0.03

5 3

0.13

9 0.

116

0.04

5 0.

027

0.36

2

0.44

2 0.

153

0.27

6 0.

160

0.03

6 3

0.15

4 0.

131

0.05

0 0.

029

0.42

4 0.

556

0.19

1 0.

358

0.20

5 0.

061

4 0.

196

0.17

4 0.

057

0.03

4 0.

539

0.67

0 0.

230

0.38

6 0.

234

0.06

5 4

0.22

5 0.

203

0.06

5 0.

039

0.65

3

0.71

5 0.

223

0.40

2 0.

250

0.06

8 4

0.24

1 0.

219

0.07

3 0.

044

0.69

0

0.76

5 0.

223

0.41

8 0.

265

0.06

9 4

0.25

6 0.

234

0.08

1 0.

049

0.739

0.87

8 0.

260

0.44

3 0.

289

0.07

3 4

0.28

0 0.

258

0.08

9 0.

053

0.85

1

0.99

0 0.

298

0.56

5 0.

329

0.07

9 5

0.30

9 0.

283

0.09

7 0.

058

0.96

2

1.21

5 0.

372

0.62

8 0.

393

0.08

7 5

0.37

3 0.

347

0.11

2 0.

067

1.18

6

0.07

8 z z

0.10

1 m

0.12

4 0.

148

8 z

0.17

2 0.

196

c=

0.22

0 o,

GEN

ERAL

NO

TES:

(a

) Fo

r ad

ditio

nal

requ

irem

ents

refe

r to

pa

ra.

2.

(b)

For

refe

renc

e,

see

Tabl

e IB

Illu

stra

tion

on

prev

ious

page

.

NOTE

S:

(1)

Whe

re

spec

ifyin

g no

min

al

size

in

decim

als,

ze

ros

prec

edin

g de

cimal

an

d in

th

e fo

urth

de

cimal

pl

ace

shal

l be

om

itted

. (2

) Sc

rews

of

th

ese

leng

ths

and

shor

ter

shal

l ha

ve

unde

rcut

he

ads

as

show

n in

Ta

ble

58.

(3)

Tabu

late

d va

lues

de

term

ined

from

fo

rmula

fo

r m

axim

um

H in

Ap

pend

ix A.

(4

) No

to

lera

nce

for

gagi

ng

diam

eter

is

give

n.

If th

e ga

ging

dia

met

er

of

the

gage

us

ed

diffe

rs

from

ta

bula

ted

value

, th

e pr

otru

sion

will

be

affe

cted

ac

cord

ingl

y an

d th

e R

prop

er

prot

rusio

n va

lues

m

ust

be

reca

lcula

ted

usin

g th

e fo

rmul

as

show

n in

Ap

pend

ix I.

2 a ZiJ

b ;

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

,-Edg

e of

he

ad

may

be

This

ty

pe

of r

wcs9

hn

s il

Iarg

c cc

n1cr

op

ening

. wi

de

stra

ighr

w

mgs

. an

d blu

nt

botto

m.

vrilh

all

ed

ges

relie

ved

or

roun

ded.

TABL

E IC

D

IMEN

SIO

NS

OF

TYPE

IA

CR

OSS

R

ECES

SED

FL

AT

CO

UN

TER

SUN

K H

EAD

M

ACH

INE

SCR

EWS

Nom

inal

Si

ze

or

Basi

c Sc

rew

Diam

eter

[Not

e (V

I

Leng

th

[Not

: (2

)I

Head

Di

amet

er

A

Max

. M

in.

Head

He

ight

If,

Re

f.

[Not

e W

I

Rece

ss

Rece

ss

Diam

eter

De

pth

M.

Ref.

T,

Ref.

Rece

ss

Wid

th

N,

Ref.

Drive

r Si

ze

Rece

ss

Pene

tratio

n G

aging

De

pth

Max

. M

in.

Prot

rusio

n Ab

ove

Gag

ing

Gag

ing

Diam

eter

Di

amet

er

F [N

ote

(411

G

Max

. M

in.

[Not

e (4

11

0 0.

0600

1

0.07

30

2 0.

0860

3

0.09

90

0.11

2 0.

096

0.03

5 0.

062

0.03

6 0.

018

0.13

7 0.

120

0.04

3 0.

070

0.04

4 0.

018

0.16

2 0.

144

0.05

1 0.

096

0.05

5 0.

029

0.18

7 0.

167

0.05

9 0.

100

0.06

0 0.

029

0.03

7 0.

021

0.02

6 0.

016

0.07

8 0.

045

0.02

9 0.

028

0.01

6 0.

101

0.05

3 0.

037

0.02

9 0.

017

0.12

4 0.

058

0.04

2 0.

031

0.01

8 0.

148

4 0.

1120

5 0.

1250

6

0.13

80

0.21

2 0.

191

0.06

7 0.

122

0.08

1 0.

030

1 0.

079

0.06

3 0.

032

0.01

9 0.

172

0.23

7 0.

215

0.07

5 0.

148

0.07

7 0.

041

2 0.

071

0.05

3 0.

034

0.02

0 0.

196

0.26

2 0.

238

0.08

3 0.

168

0.09

8 0.

041

2 0.

091

0.07

3 0.

036

0.02

1 0.

220

8 0.

1640

IO

0.

1900

12

0.

2160

0.31

2 0.

285

0.100

0.

182

0.11

2 0.

041

2 0.

107

0.08

9 0.

039

0.02

3 0.

362

0.33

3 0.

116

0.19

8 0.

127

0.04

1 2

0.12

2 0.

104

0.04

2 0.

025

0.41

2 0.

380

0.13

2 0.

262

0.14

9 0.

056

3 0.

136

0.11

8 0.

045

0.02

7

0.26

7 0.

313

0.36

2 5 1

0.42

4 F

0.53

9 Ill

1/

, 0.

2500

5/

6 0.

3125

"18

0.37

50

)/16

0.43

75

0.47

7 0.

442

0.15

3 0.

276

0.16

4 0.

057

0.59

7 0.

556

0.19

1 0.

358

0.21

1 0.

086

0.71

7 0.

670

0.23

0 0.

386

0.23

9 0.

086

0.76

0 0.

715

0.22

3 0.

402

0.25

6 0.

086

0.15

1 0.

133

0.05

0 0.

029

0.19

3 0.

175

0.05

7 0.

034

0.22

2 0.

204

0.06

5 0.

039

0.23

8 0.

220

0.07

3 0.

044

0.65

3 8

0.69

0 g

0.73

9 5

0.85

1 0.

962

2

1.18

6 $

72

0.50

00

%6

0.56

25

5/8

0.62

50

"/4

0.75

00

0.81

5 0.

765

0.22

3 0.

418

0.27

1 0.

086

0.93

2 0.

878

0.26

0 0.

440

0.29

4 0.

087

1.05

0 0.

990

0.29

8 0.

566

0.33

4 0.

098

1.28

5 1.

215

0.37

2 0.

630

0.40

0 0.

099

0.25

3 0.

235

0.08

1 0.

049

0.27

6 0.

258

0.08

9 0.

053

0.30

7 0.

286

0.09

7 0.

058

0.37

2 0.

351

0.11

2 0.

067

GEN

ERAL

NO

TE:

For

addi

tiona

l re

quire

men

ts re

fer

to

para

. 2.

NOTE

S:

El

(I)

Whe

re

spec

ifyin

g no

min

al

size

in

decim

als,

ze

ros

prec

edin

g de

cimal

an

d in

th

e fo

urth

de

cimal

pl

ace

shal

l be

om

itted

. (2

) Sc

rews

of

th

ese

leng

ths

and

shor

ter

shal

l ha

ve

unde

rcut

he

ads

as

show

n in

Ta

ble

5C.

w

(3)

Tabu

late

d va

lues

de

term

ined

from

fo

rmula

fo

r m

axim

um

H in

Ap

pend

ix A.

?i

(4)

No

tole

ranc

e fo

r ga

ging

dia

met

er

is

given

. If

the

gagi

ng

diam

eter

of

th

e ga

ge

used

di

ffers

fro

m

tabu

late

d va

lue,

the

prot

rusio

n w

ill be

af

fect

ed

acco

rdin

gly

and

the

z

prop

er

prot

rusio

n va

lues

m

ust

be

reca

lcula

ted

usin

g th

e fo

rmul

as

show

n in

Ap

pend

ix I.

z d

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

TABL

E ID

D

IMEN

SIO

NS

OF

TYPE

II

CR

OSS

R

ECES

SED

FL

AT

CO

UN

TER

SUN

K H

EAD

M

ACH

INE

SCR

EWS

5 Pr

otrus

ion

Abov

e 2

Nom

inal

Size

Head

He

ad

Gagin

g 2

or

Basic

Sc

rew

Leng

th Di

amete

r He

ight

Rece

ss

Rece

ss

Rece

ss

Drive

r Re

cess

Pe

netra

tion

Gagin

g Di

amete

r Di

amete

r m

Diam

eter

1 A

H,

Ref.

Diam

eter

Depth

W

idth

Size

Gagin

g De

pth

F [N

ote

(511

G

t?

[Note

(Il

l [N

ote

WI

Max

. M

in.

[Note

(3

11

M,

Ref.

T, R

ef.

N,

Ref.

[Note

(4

11

Max

. M

in.

Max

. M

in.

[Note

(5

11

$

0 0.0

600

1 0.0

730

2 0.0

860

3 0.0

990

4 0.1

120

5 0.1

250

6 0.1

380

8 0.1

640

10

0.190

0

12

0.216

0

‘/4

0.250

0

5/16

0.312

5

“/8

0.375

0

‘/,c

0.437

5

5;

0.500

0

9/6

0.562

5

5/8

0.625

0

“/a

0.750

0

‘1s

0.112

0.0

96

0.035

0.0

78

0.036

‘h

0.137

0.1

20

0.043

0.0

92

0.048

‘1.

0.1

62

0.144

0.0

51

0.114

0.0

60

‘h 0.1

87

0.167

0.0

59

0.133

0.0

72

346

0.212

0.1

91

0.067

0.1

51

0.082

3A

6 0.2

37

0.215

0.0

75

0.169

0.0

94

3/16

0.262

0.2

38

0.083

0.1

88

0.106

‘h 0.3

12

0.285

0.1

00

0.224

0.1

24

5/16

0.362

0.3

33

0.116

0.2

60

0.148

“6

0.4

12

0.380

0.1

32

0.297

0.1

72

‘46

0.477

0.4

42

0.153

0.3

44

0.195

%

0.597

0.5

56

0.191

0.4

32

0.252

g/6

0.717

0.6

70

0.230

0.5

09

0.302

%

0.7

60

0.715

0.2

23

0.554

0.3

32

“4

0.815

0.7

65

0.223

0.5

93

0.358

. 0.9

32

0.878

0.2

60

0.640

0.3

87

1.050

0.9

90

0.298

0.6

40

0.387

1.285

1.2

15

0.372

0.6

40

0.387

0.021

No

te (6

) No

te (6

)

0.024

No

te (6

) No

te (6

)

0.027

0.0

40

0.029

0.030

0.0

53

0.041

0.032

0.0

64

0.052

0.0

32

0.019

0.1

72

0.035

0.0

77

0.064

0.0

34

0.020

0.1

96

0.038

0.0

89

0.075

0.0

36

0.021

0.2

20

0.043

0.1

13

0.099

0.0

39

0.023

0.2

67

0.048

0.1

37

0.122

0.0

42

0.025

0.3

13

0.054

.

0.162

0.1

45

0.045

0.0

27

0.362

0.061

0.1

93

0.176

0.0

50

0.029

0.4

24

0.074

0.2

51

0.232

0.0

57

0.034

0.5

39

0.086

0.3

03

0.281

0.0

65

0.039

0.6

53

0.092

0.3

32

0.310

0.0

73

0.044

0.6

90

0.098

0.3

59

0.335

0.0

81

0.049

0.7

39

0.104

0.3

89

0.364

0.0

89

0.053

0.8

51

0.104

0.3

89

0.364

0.0

97

0.058

0.9

62

0.104

0.3

89

0.364

0.1

12

0.067

1.1

86

- 0.0

26

0.016

0.0

78

0.028

0.0

16

0.101

-5

0.029

0.0

17

0.124

2

0.031

0.0

18

0.148

GENE

RAL

NOTE

: Fo

r ad

dition

al re

quire

men

ts re

fer

to

para

. 2

NOTE

S:

(1)

Whe

re sp

ecify

ing

nom

inal

size

in de

cimals

, ze

ros

prece

ding

decim

al an

d in

the

fourth

de

cimal

place

sh

all

be

omitte

d.

iz

(2)

Scre

ws

of

these

len

gths

and

shor

ter

shall

ha

ve

unde

rcut

head

s as

sh

own

in Ta

ble

50.

5

(3)

Tabu

lated

va

lues

deter

mine

d fro

m

form

ula

for

max

imum

H

in Ap

pend

ix A.

03

(4)

Point

sa

me

on

all

drive

rs.

G

(5)

No

tolera

nce

for

gagin

g dia

mete

r is

given

. If

the

gagin

g dia

mete

r of

the

ga

ge

used

dif

fers

from

tab

ulated

va

lue,

the

protru

sion

will

be

affec

ted

acco

rding

ly an

d the

b,

L,

prope

r pro

trusio

n va

lues

mus

t be

rec

alcula

ted

using

the

for

mula

s sh

own

in Ap

pend

ix I.

(6)

Not

prac

tical

to

gage

. i

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

STD-ASME 818.b.3-ENGL 3998 m 0759670 0634384 827

ASME B18.6.3-1998 MACHINE SCREWS AND MACHINE SCREW NUTS

Edge of head may be

A min. rounded or flat

Al

TABLE 2A DIMENSIONS OF SLOTTED 100 deg FLAT COUNTERSUNK HEAD MACHINE SCREWS Nominal Size or

Depth Gaging Diameter F Diameter

Diameter [Note (I)] Max. Min. [Note (211 Max. Min. Max. Min. Max. Min. [Note (311

Head

A

Head Diameter Width Basic Screw Height

H. Ref.

Slot Slot Protrusion Above Gaging

J T [Note (311 G

O000 0.0210 O00 0.0340 O0 0.0470

O 0.0600 1 0.0730 2 0.0860 3 0.0990

4 0.1120 6 0.1380 8 0.1640 10 0.1900

0.2500 0.3125

3/8 0.3750

O. 040 0.060 0.087

0.112 0.137 O. 162 0.187

0.212 0.262 0.312 0.362

0.477 0.597 0.717

0.035 0.009 0.008 0.055 0.014 0.012 0.080 0.020 0.017

0.095 0.026 0.023 0.118 0.031 0.026 0.142 0.037 0.031 0.165 0.043 0.035

0.188 0.049 0.039 0.235 0.060 0.048 0.282 0.072 0.054 0.329 0.083 0.060

0.437 0.110 0.075 0.550 0.138 0.084 0.662 0.165 0.094

0.005 0.008 0.010

0.016 0.019 0.023 0.027

0.031 0.039 0.045 0.050

0.064 0.072 0.081

0.008 0.004 0.01 1 0.007 0.013 0.008

0.013 0.008 0.016 0.010 0.019 0.012 0.022 0.014

0.024 0.017 0.030 0.022 0.036 0.027 0.042 0.031

0.055 0.042 0.069 0.053 0.083 0.065

Note (4) Note (4) Note (4)

0.020 0.021 0.022 0.024

0.025 0.028 0.031 0.034

0.040 0.047 0.053

Note (4) Note (4) Note (4)

0.012 0.013 0.014 0.01 5

0.016 0.017 0.019 0.021

0.025 0.030 0.034

Note (4) Note (4) Note (4)

0.074 0.098 0.121 0.144

O. 167 0.214 0.261 0.307

0.415 0.526 0.638

GENERAL NOTE: For additional requirements refer to para. 2. NOTES: (1) Where specifying nominal size in decimals, zeros preceding decimal and in the fourth decimal place shall be omitted. (2) Tabulated values determined from formula for maximum H in Appendix A. (3) No tolerance for gaging diameter is given. If the gaging diameter of the gage used differs from tabulated value, the protrusion

will be affected accordingly and the proper protrusion values must be recalculated using the formulas shown in Appendix I. (4) Not practical to gage.

12

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

MACHINE SCREWS AND MACHINE SCREW NUTS ASME 818.6.3-1998

This type of recess has a large center opening, tapered wings, and blunt bottom, with all edges relieved or rounded.

Edge of head may be

A min. rounded or flat

LG-4 L Protrusion gage

6 F i n .

Not to exceed maximum major diameter of thread

Optional Shoulder for Long Screws with

Reduced Body

TABLE 2B DIMENSIONS OF TYPE I CROSS RECESSED 100 deg FLAT COUNTERSUNK HEAD MACHINE SCREWS

~~ ~ ~ ~~~~ ~~

Nominal Size or Basic Recess Gaging Gaging

Screw Diameter Height Recess Recess , Recess Penetration Diameter F Diameter

Diameter [Note (111 Max. Min. [Note (211 M, Ref. T, Ref. N, Ref. Size Max. Min. Max. Min. [Note (311

Protrusion Above

Head Head

H, Ref. Diameter Depth Width Driver Gaging Depth [Note (3)1 G A