Ask 21 Flight Sim

description

Transcript of Ask 21 Flight Sim

Aeroelastic Simulations of a Sailplane

David Eller and Ulf RingertzAeronautical and Vehicle Engineering

Royal Institute of TechnologySE - 100 44 Stockholm, Sweden

December 2005

Abstract

Using the ASK 21 training and aerobatics sailplane as a test case,different structural and aerodynamic modeling approaches are compared.For the structure, a simplified model consisting of a beam framework isassembled and compared with a more complex shell finite element model.Frequency-domain lifting-surface aerodynamics is employed for flutteranalysis and compared with results obtained from three-dimensional time-domain potential flow aerodynamics. Finally, a 4g pull-up maneuver isperformed in flight testing and numerical aeroelastic simulations of thesame maneuver are evaluated.

Introduction

The purpose of the present study is to compare and evaluate different levels

of modeling detail when trying to assess the aeroelastic behavior of a complete

aircraft configuration. Many different modeling approaches are possible depend-

ing on the application at hand. If the analysis is part of a preliminary design

process, a computational approach is the only option and standard procedures

involve a finite element model to assess the structural dynamics properties and

a linear potential flow model to obtain the unsteady aerodynamic forces.

Combining the structural model with the model of unsteady aerodynamics,it is possible to pose the aeroelastic stability problem as a nonlinear eigenvalue

problem for which there are efficient methods available [1]. Essentially the same

computational model can be used to analyze other aeroelastic phenomena such

as control surface efficiency and gust response [2].

Different levels of detail can be used for both the structural and aerody-

namic model. The simplest structural model is usually obtained in the form

1

E 2 D. Eller and U. Ringertz

of a beam model of the wings, fuselage and tail. Even though the topology ofthe beam model is simple, significant difficulties arise when trying to accurately

estimate the properties of the beams and their interaction at connections such

as the wing-fuselage interface. A more detailed structural model, using for ex-

ample shell elements, may make it easier to define structural properties. The

drawback is that one may have to model much more details in terms of local re-

inforcements in order to obtain accurate global stiffness properties and accurate

representations of resonance frequencies and the associated modal eigenvectors.

If the analysis is concerned with the certification process of an already exist-ing design for which a prototype has been manufactured, one may eliminate the

numerical structural analysis all together. In this case, a detailed ground vibra-

tion test is used to experimentally determine the structural dynamics in terms

of resonance frequencies and modal eigenvectors. This procedure is well de-

scribed in [3]. The measured structural dynamics properties are then combined

with a numerical model of the aerodynamic forces to perform the actual flutter

analysis. This approach is mainly used for smaller general aviation aircraft and

gliders. However, even though general design guides such as those provided

by the DLR [4] are used, costly design changes to the already existing aircraft

prototype may be needed to demonstrate the aeroelastic stability required by the

certification authority as defined in the airworthiness code (CS-22 [5]).

In case the needed engineering manpower and resources are available, a nu-

merical model is used for the structural dynamics even in the early design stages.

The numerical model is then refined during the design process and finally cor-

related to ground vibration test data as it becomes available. A structural op-

timization approach [6] may be used to improve the correlation between the

numerical and the experimental data. Such an approach helps to avoid surprises

late in the development process.

The model of the unsteady aerodynamics can also be of very different detail

even if it is restricted to unsteady potential flow. The least complex model

would be to use a strip model were the flow is assumed to be well represented

by a locally two-dimensional analysis as described by Rodden and Johnson [7].

A more detailed model involves the use of a panel method to approximate all

lifting bodies by their mean surfaces, but still neglecting the fuselage and the

thickness of the wing and tail surfaces, using the well known Doublet-Lattice

method [7] or the similar methods described in Refs. [8, 9]. An even more

detailed model would involve a model of the fuselage and also the actual wingprofile of the lifting surfaces.

In this study, different modeling approaches for the structural and aerody-

namic behavior of the ASK 21 sailplane will be investigated and compared with

respect to flight mechanics and aeroelastic properties. Numerical models are

Aeroelastic Simulations of a Sailplane E 3

compared with data from ground vibration and flight testing in order to assess

the accuracy which can be obtained with the different simulation methods. Fi-

nally, some remarks regarding the relative effort required to create and validate

the different models are provided.

The ASK 21 sailplane

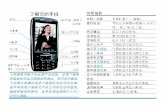

The reason for using the ASK 21 sailplane [10] in this study is the availability

of an instrumented aircraft of this type and also that detailed design data has

been kindly provided to the authors by the manufacturer. The ASK 21, whichis shown in Figure 1, is a two-seat sailplane for pilot training and aerobatics. It

Figure 1: The ASK 21 glider.

features a wing aspect ratio of 16.1, large wing thickness and robust glass fiber

composite construction. In comparison to modern high-performance sailplanes,

the ASK 21 is relatively stiff, and hence less susceptible to aeroelastic instability.It operates at flight speeds between 80 km/h and 280 km/h and, as it is certified

for aerobatics, may be subjected to load factors from −4g to +6.5g. Due to the

high allowed load factor, elastic deformations experienced in service may still be

fairly high and likely exceed those encountered in other general aviation aircraft

considerably.

Structural model

With a relatively large wing thickness of 19.6% at the root, a moderate wing

aspect ratio, and sandwich shell construction throughout, the ASK 21 is rela-

tively light for its size. Wings, fuselage and tail shells are built from glass-fiber

E 4 D. Eller and U. Ringertz

reinforced epoxy resin and polymer foam or tubus core. Most sandwich compo-

nents employ outer face sheets which are thicker than the corresponding inner

faces in order to improve the impact strength of the exposed external layers. In

lightly loaded regions such as the control surfaces, layer thickness is as low as0.09 mm/0.18 mm (inner/outer face) with 4 mm light foam core, while even

the outboard wing shell is not thicker than 0.18 mm/0.6 mm with 9 mm foam

core. In comparison to more recent sailplane designs featuring carbon fiber

sandwich construction and much higher aspect ratio, the ASK 21 is expected

to be relatively stiff in terms of global deformations, but comparatively flexible

with respect to localized loads.

Modal subspace formulation

When considering small elastic deformations, linear equations of motion ac-

cording to

Mx + Kx = fa(t,x, x, . . . ) (1)

are used. Here, M is the mass matrix relating accelerations in the structural

degrees of freedom x to inertial forces, K is the stiffness matrix and fa a vector

of aerodynamic forces. Note that the aerodynamic forces fa also depend on the

time history of motion and loads because these determine the shape and strength

of the wake. In order to drastically reduce the number of degrees of freedom,

the standard modal subspace technique is adopted. Let zj be eigenvectors and

ω2

j eigenvalues solving the generalized eigenvalue problem

(

K − ω2

j M)

zj = 0. (2)

Then, a reduced number of eigenvectors with low eigenfrequencies ωj are used

to define a subspace Z = [z1,z2, . . . ]. Low-frequency eigenvectors are utilizedbecause it is assumed that higher order modal deformations do not contribute

relevant aerodynamic loads. With mass-normalized eigenvectors, the equations

of motion in modal subspace become uncoupled according to

Iq + Ωq = fq(t,q, q, . . . ), (3)

with the modal displacements q such that Zq = x, modal loads are found by

projection of the aerodynamic forces into the subspace f q = ZT fa. For the

matrices holds

ZT MZ = I, and ZT KZ = Ω. (4)

Here, I is the identity matrix and Ω is a diagonal matrix of the squares of

the eigenfrequencies ωj . The modal equation of motion (3) only has a small

number of degrees of freedom, but retains the aeroelastically relevant dynamic

Aeroelastic Simulations of a Sailplane E 5

characteristics of the structure if sufficiently many eigenmodes are included in

the subspace Z.

Finite element models

Two finite element models of different type were assembled for comparison

purposes. The first, much simpler model is based on a framework of beams,

the properties of which were chosen to match ground vibration test data, and

was initially developed by Keller [11] and co-workers [12, 13, 14]. It was later

modified in order to improve the accuracy of the control system modeling. The

final beam finite element model contains approximately 2900 structural degrees

of freedom.

The second model is based on triangular and quadrilateral shell finite ele-

ments, as shown in Figure 2, where different colors are used for different shell

properties. In contrast to the beam model, stiffness properties are not designed

to match test data, but derived from lamination plans which were kindly pro-vided by the manufacturer. The main load-carrying structure accounts for only

roughly 50% of the empty mass of the aircraft, and the distribution of the re-

maining mass is to a large extent unknown. Therefore, mass properties were

used to match the model to data obtained from vibration testing. The model

for which results are discussed below has about 23 000 elements and 70 000

structural degrees of freedom. Both finite element models were constructed for

NASTRAN [15].

Figure 2: Shell FE model including control surfaces.

Testing and validation

The main source of validation data for the structural model was the ground

vibration test (GVT), shown in Figure 3, of the full aircraft performed at KTH

[16], along with additional vibration testing of the fuselage performed as part of

E 6 D. Eller and U. Ringertz

the present investigation. These ground vibration tests were also compared to the

Figure 3: Ground vibration test of the ASK 21 glider.

tests by Niedbal [17] performed during the original certification process. Due

to friction in the control system, most control surfaces do not move when the

aircraft is excited to vibrate, at least not with moderate excitation amplitudes.

Therefore, all flaps were fixed rigidly to the adjacent wing or tail surface in orderto create a well-defined structural configuration.

In Table 1, eigenfrequencies obtained from modal analysis of the beam (fb)

and shell (fs) finite element models are compared with test data (fexp). For

a more compact notation, the abbreviations given in Table 2 are used in the

following presentation.

In general, it should be noted that due to the placement of acceleration

sensors and excitation devices employed in the GVT, some eigenmode shapes

present in the FE models could not be detected experimentally. The rather

distinct mode at 15 Hz involves mainly torsion of the vertical fin, which can

hardly be excited with a laterally acting shaker placed at the rear wheel, i.e. close

to the elastic axis of the fin. Even for the higher wing bending modes above20 Hz, accelerometer data sometimes leaves doubts about the bending mode

shape. Furthermore, very few eigenmodes can be unambiguously identified as

pure fundamental modeshapes. Instead, complex coupling patterns of fuselage,

wing and tail deformations are observed. Comparisons of eigenfrequencies alone

Aeroelastic Simulations of a Sailplane E 7

fexp [Hz] fb [Hz] fs [Hz] Description

2.95 2.90 2.96 sym. wing 1b.

4.09 4.00 4.11 asym. fuselage 1t.6.50 6.64 6.23 asym. wing 1b. + fuselage 1b.

- 7.28 7.07 sym. fuselage 1b. + wing 1ipb.

7.29 7.09 7.34 asym. fuselage 1b. + fin b.

8.25 - - asym. fuselage 1b. + stabilizer rotation

8.74 9.25 8.56 sym. wing 2b. + fuselage 1b. ip.

10.5 10.7 10.3 sym. wing 2b. + fuselage 1b. cp.

12.2 11.6 12.0 asym. fuselage 1b. + fin t.

- 15.5 14.2 asym. fin torsion + fuselage 1b.

16.9 18.8 16.5 asym. wing 2b. + stabilizer b. cp.

17.4 - - asym. wing 2b. + stabilizer b. ip.

20.4 19.8 19.7 sym. wing 2b. + fuselage 2b. + stab. b. cp.

- 27.9 20.9 asym. fuselage b. + stabilizer b22.3 - 22.7 sym. wing 2b. + fuselage 2b. + stab. b. ip.

22.5 20.6 24.3 asym. wing 1ipb.

- 26.2 - sym. wing t. + stabilizer b. ip.

- 27.0 - sym. wing t. + stabilizer b. cp.

- - 28.1 sym. wing 2ipb. + stabilizer b.

26.9 - 28.7 sym. stabilizer 1b.

- - 28.8 asym. wing t. + wing 3b.

29.3 - 29.5 sym. wing t.

- 26.1 30.0 asym. wing t.

32.7 36.2 32.4 asym. wing 3b.

Table 1: Comparison of measured and computed eigenfrequencies.

are hence not necessarily useful, as modes with the same description in Table 1

may combine different magnitudes of fuselage and wing deformations, although

the modeshape appears visually similar.

For the lowest-frequency eigenmode shapes up to about 15 Hz, both finite

element models compare reasonably well with GVT data. There is one low-

frequency modeshape at 8.25 Hz which remarkably is not present in either nu-

merical model. A possible interpretation of the accelerometer data for this modeis that the stabilizer which is attached to the vertical tail using two detachable

centerline connections, rotates about the line through the attachment points as

in a joint. The motion may even be combined with some degree of local fin

bending and rear fuselage torsion. Both finite element models fail to reproduce

E 8 D. Eller and U. Ringertz

b. modeshape dominated by bending

t. modeshape dominated by torsion

2b. second fundamental bending mode

ipb. in-plane bending (xy-plane)

sym. symmetrical

asym. antisymmetrical

ip. wing & stabilizer tips moving in phase

cp. wing & stabilizer tips moving counter-phase

Table 2: Abbreviations used in Table 1

this particular type of motion accurately, although elastic connections between

fin and stabilizer bodies are used. The modeled attachment stiffness has a strong

impact on the frequency of the mode at 7.3 Hz, but does not appear to allow a

motion such as that observed in the GVT at 8.25 Hz.

For higher frequencies above 20 Hz, differences become more pronounced.

Evidently, the shell finite element model produces a number of eigenmode

shapes not observed in vibration testing. As noted previously, this may partly

be due to the location of excitation devices and accelerometers. Moreover, com-

puted fuselage deformations for modes with frequencies exceeding 22 Hz and

wing deformations for all eigenmodes involving torsion show significant local

shell bending deformations. It is considered likely that the type of local fuselage

deformations observed in the shell finite element model would not occur in

reality since inertial loads are introduced by means of local reinforcements, not

all of which are included in the finite element model. Computed shell defor-

mations for the wings, however, are considered realistic as the stiffness of thewing shell is well defined and the mass fairly evenly distributed. In contrast to

the forward fuselage, no large inertial loads, except the mass forces of the wing

itself, act normal to the surface of the wing. Local shell deformations of this

kind would be hard to detect in vibration testing of the full aircraft unless a

very large number of accelerometers were used.

Five eigenmodes of the shell finite element model have eigenfrequencies be-

tween 28 Hz and 30 Hz, while only one symmetric wing torsion mode with

possibly some bending component was experimentally observed in this interval.

Not a single eigenmode of the beam model is located in the same frequency in-terval, which, instead, has four eigenmodes with frequencies between 26 Hz and

28 Hz, none of which appeared in vibration testing with a similarly coupled

deformation pattern. Considering the substantial differences between experi-

mentally identified and computed eigenmodes, results obtained with the above

Aeroelastic Simulations of a Sailplane E 9

structural models should be regarded as approximations. At this point, the

beam model appears to be globally somewhat less accurate than the shell finite

element model for moderate to high eigenfrequencies.

Fuselage vibration testing

The mass distribution in the fuselage is affected by appreciable uncertainties.

A number of heavy local reinforcements, composite landing gear frames and

cockpit installations were found difficult to model. Most of these items can

probably not be represented well by means of shell elements, and accurate mass

distributions were unknown. Therefore, the isolated fuselage was subjected to

vibration testing, as shown in Figure 4 in order to collect more detailed eigen-

mode shapes. Following the testing, the shell finite element model was updated

Figure 4: Ground vibration test of the fuselage.

with three concentrated masses which in total account for the difference between

measured weight and the structural mass of the finite element model.

Using a trial-and-error approach, the concentrated masses were placed in theforward and central fuselage and connected to the shell structure using inter-

polation elements (Nastran element type RBE3). These elements compute the

displacement of the connected concentrated point mass as a weighted average

of a supplied set of mesh nodes. In the current case, all three masses were

E 10 D. Eller and U. Ringertz

connected to all mesh nodes in the lower half of the forward fuselage. In this

manner, the resulting inertial forces were effectively distributed among a large

number of shell elements, thus avoiding locally concentrated forces. Neverthe-

less, it eventually turned out that even the load-carrying pilot seat shells andsome minor local reinforcements in the lower cockpit shell needed to be mod-

eled in order to avoid that local shell deformation modes (’breathing modes’)

appear at unrealistically low frequencies.

Figures 5 and 6 show the front view of the undeformed mesh and the same

view of the deformed surface for the 14th mode. The 14th mode is dominated

by antisymmetric in-plane bending of the wing but contains a significant com-

ponent of lateral fuselage bending. At the relatively high frequency of 24.3 Hz,

this fuselage bending combines with significant local shell deformations.

X

Z

X

Z

Figure 5: Undeformed mesh.

X

Z

X

Z

Figure 6: ’Breathing’ mode.

A comparison of the first two longitudinal (vertical) bending eigenmode

shapes of the fuselage is shown in Figure 7. Note that here, the classification

of modes refers to the isolated fuselage alone and that these modeshapes are

not directly related to the full aircraft eigenmodes discussed above. To make

measurements and numerical results directly comparable, the computed shellmodel modeshape was interpolated to the known locations of the accelerometers.

Then, both the measured and computed vector of displacement magnitudes were

normalized to unit length. The choice of normalization is admittedly rather

arbitrary.

Aeroelastic Simulations of a Sailplane E 11

0 1 2 3 4 5 6 7 8

−0.4

−0.2

0

0.2

0.4

Position [m]

Ver

tical

dis

plac

emen

t [−

]

1st longitudinal bending

0 1 2 3 4 5 6 7 8−0.6

−0.4

−0.2

0

0.2

Position [m]V

ertic

al d

ispl

acem

ent [

−]

2nd longitudinal bending

ExperimentShell FE model

Figure 7: Modeshape comparison for two longitudinal fuselage modes.

The normalized eigenmode shapes for the first two longitudinal modes

match fairly well. In both cases, there is a small parallel shift between ex-

perimental and computed modeshapes, which indicates that the longitudinal

mass distribution is not accurate, while the fuselage stiffness is matched well.

In the left part of Figure 7, the location of the forward and rear node of thefirst longitudinal bending mode is shown to lie slightly farther apart in the

experiment than the modal finite element solution predicts. When considering

that both the fuselage mass and the center of gravity match closely between the

experimental setup and the corresponding model, this indicates that the mass

in the real aircraft is less concentrated near the center than in the finite element

model.

Figure 8 shows the first lateral bending and torsion modes of the fuselage.

In this case, there is a small irregularity at the 3 m position, just behind the

cockpit, where the measured acceleration data shows a localized peak. For the

torsion mode, the irregularity may be related to measurement noise, since at

this position, there are only small displacements from which the torsion angle is

computed by finite differences. Even the inconsistency between two experiments

performed for the same excitation hints at this explanation.

The irregularity in the first lateral bending mode occurs at the same posi-

tion. In this case, a repetition of the experiment yields practically the same data.Since the fuselage shell in this region is locally reinforced with internal frames,

it is considered unlikely that the accelerometer senses local shell deformation.

It rather appears as if the effect of the said reinforcements is not represented

sufficiently accurately in the FE model. Similar to the longitudinal case, the

E 12 D. Eller and U. Ringertz

0 1 2 3 4 5 6 7

−0.4

−0.2

0

0.2

0.4

Position [m]

Late

ral d

ispl

acem

ent [

−]

1st lateral bending

0 1 2 3 4 5 6 7

−0.4

−0.2

0

0.2

0.4

Position [m]T

orsi

on [−

]

1st torsion

ExperimentShell FE model

Experiment 1Experiment 2Shell FE model

Figure 8: Modeshape comparison for lateral fuselage modes.

overall match of the lateral eigenmode shapes is fairly good.

Looking at the eigenfrequencies for the isolated fuselage shown in Table 3,

it appears that the shell model of the fuselage yields slightly higher frequencies

for all three bending modes. This difference could be related to the placement

of concentrated masses near the centerline. As a result, the inertia in bending is

too low for the same total mass. The torsion frequency, on the other hand, is

matched with better accuracy.

fexp [Hz] fs [Hz] Description

10.8 11.4 1st lateral bending

13.2 13.7 1st longitudinal bending

19.8 19.6 fuselage torsion

32.5 32.9 2nd longitudinal bending

Table 3: Measured and computed eigenfrequencies for the fuselage.

Control system model

For the beam finite element model, control surfaces are modeled as rigid el-ements connected to the beam by means of rigid bar elements, which allow

control surface rotation as the only degree of freedom. Aileron rotation is as-

sumed to occur about the y-axis instead of the actual aileron hinge axis, which

makes an angle of only 7.2 with the y-axis. The rotational degree of freedom

Aeroelastic Simulations of a Sailplane E 13

is connected to a concentrated mass and rotational inertia corresponding to val-

ues measured by the manufacturer. Since the internal kinematics of the control

system introduces a small stiffness, rotational springs are added to constrain the

control surface motion accordingly.

The shell finite element model shown in Figure 2 includes shell models

of the control surfaces. In this case, all surfaces are attached by means ofmultiple hinges positioned according to the drawings. Hinge nodes on the

wing, fin and stabilizer are locally reinforced with small beam elements in order

to better distribute inertial loads into the rather flexible sandwich shell.The

rather detailed modeling has the advantage of including the effect of elastic

control surface motion. For this particular aircraft, the first elastic eigenmodes

involving aileron torsion and bending appear around 25 Hz, close to the wing’s

fundamental torsion modes, and may hence be relevant from an aeroelastic

point of view.

Unfortunately, the detailed structural model caused difficulties when at-

tempting to interpolate eigenmode shapes to the aerodynamic surface mesh.

The elastic motion of the hinged control surfaces which is part of most relevant

modeshapes could not be represented as a smoothly varying deformation of the

closed aerodynamic surface. Even comparatively small deformations involvingcontrol surface rotation or twist lead to geometric inconsistencies such as locally

self-intersecting surface elements or much too large variation of the local surface

normal. Even when the elastic surfaces were constrained to the wing, stabilizer

and fin in order to approximate a fixed-stick configuration, the pronounced flex-

ibility of the very light control surface shells caused discontinuous deformations

e.g. at the outboard end of the aileron.

As an alternative, the control surface motion was modeled separately. The

aerodynamic surface mesh was deformed according to the flap deflection using a

previously developed procedure which guarantees smooth surface deformations

up to moderate deflection angles of at least ±15. The structural model, on the

other hand, was simplified by removing the explicit control surface components

and replacing them with a continuation of the wing, stabilizer and fin shell.

In this manner, fully continuous modeshapes could be obtained for which suf-ficiently smooth interpolated deformations of the aerodynamic mesh could be

computed.

In order to account for the mass coupling effect between modal displace-

ments and control surface deflections, a point-mass model was used. The equa-

tions of motion in modal form (3) are augmented with the control surface

deflections δi according to

E 14 D. Eller and U. Ringertz

[

I CT

C diag(Jδ,i)

] [

q

δ

]

+

[

Ω 00 diag(kδ,i)

] [

q

δ

]

=

[

f q

Mh

]

. (5)

Here, Jδ,i are the inertia terms associated with control surface rotation, in-

cluding the rotational inertia of the control surface itself and components of

the control system mechanics which are coupled to the flap deflection. The cor-

responding stiffness terms kδ,i constitute the lower diagonal of the new stiffness

matrix. On the right hand side, the excitation force vector is augmented with

the aerodynamic hinge moments Mh.

Since there are significant coupling effects between the structural motion

as described by the modal coordinates q and the control surface rotation, off-

diagonal terms C are added to the mass matrix. The coupling term Ci,j is the

hinge moment experienced by the control surface i due to an acceleration inmode j. It is computed by considering a point mass mi located at the center of

mass of the control surface. Taking ~ri as the vector from the center of mass to its

projection on the hinge axis and ~aj as the translational acceleration experienced

by the center of mass due to an acceleration qj in mode j, the coupling term is

found to be

Ci,j = ~hi · (mi~aj × ~ri), (6)

where ~hi is the normalized direction vector of the hinge axis.

In practice, there are also kinematic coupling effects, i.e. a steady modal

deformation would lead to certain flap deflections. Such effects are caused by

the kinematics of the complex internal actuation mechanism, which is not only

difficult to include in a structural model but also nonlinear, at least for some

control surface positions. Kinematic couplings are therefore not present in the

current structural models.

Remarks on structural modeling effort

Creating the structural models required a significant amount of time. The beam

model is a strongly reduced representation of the structure, so that the deriva-

tion of beam properties involves a certain degree of heuristic approximations

and fairly many iterations until a reasonable match with experimental data can

be obtained. Without GVT data, creating such a model would be even more

difficult. Furthermore, the credibility of simulations performed with a beam

model not validated with experimental data would be poor due to the largeamount of approximations involved.

The process of creating a much more complex shell model revealed that,

with drawings and lamination plans available, a finite element model with rea-

sonably accurate global stiffness properties can be created comparatively easily.

Aeroelastic Simulations of a Sailplane E 15

The by far most demanding problem in this context is the realistic modeling

of component connections such as the interface of the fuselage with the detach-

able wing. These points are usually designed with complex local reinforcements

which are not easily included in a shell model and must hence be approximated.A finite element model with accurate stiffness behavior is obviously not suffi-

cient for dynamic analyses, and mass properties are most likely less well defined

than laminate properties. Unless the mass distribution can be established from

accurate weight and balance calculations, it is unlikely that a credible shell model

can be created without access to vibration testing data.

Aerodynamic model

Two different aerodynamic models based on subsonic potential flow theory are

used in this study. The first model is based on the ZONA6 method implemented

in the commercial code ZAERO [18], which is a frequency domain formulation

similar to the Doublet-Lattice Method (DLM). In Figure 9, the discretization of

the lifting surfaces used with this method is shown.

X Y

Z

X Y

Z

Figure 9: Panel mesh used with ZAERO.

The second model uses a time-domain formulation based on linear potentialflow. In contrast to lifting-surface methods, the actual aircraft geometry is

discretized, as illustrated in Figure 10. The mesh is shown in the deformed state

for a positive loadfactor of 4. The computational method is described in detail

in [19].

Comparison of aerodynamic coefficients for rigid-body motion

The aerodynamic response of the aircraft to prescribed rigid-body motion is

computed in order to investigate if the numerical methods yield similar results

E 16 D. Eller and U. Ringertz

Figure 10: Surface mesh for time-domain aerodynamic method.

despite the considerably different discrete surface representations. Since ZONA6

is formulated in the frequency domain, the results are complex pressure coeffi-

cient differences ∆Cp between upper and lower side of the lifting surfaces as a

function of frequency. In this context, it is common to use the reduced formof the angular frequency ω according to

k =ωc

2u∞

, (7)

which is made nondimensional with the reference chord c and the airspeed

u∞. Integration of the pressure coefficient over the aerodynamic surface yieldsintegral aerodynamic coefficients, which depend on type and frequency of the

unsteady rigid-body motion. Harmonic heave and pitch motion about the center

of gravity of the aircraft were used as prescribed motion.

Frequency-domain coefficients cannot be computed directly with a time-

domain method, so that an indirect approach must be taken. Here, time-

marching simulations were performed for a prescribed harmonic rigid-body

motion with reduced frequency k. The coefficients are then evaluated by di-

viding the discrete Fourier transform of the output lift coefficient time series

by the (known) Fourier transform of the prescribed motion. In this manner,

coefficients can be determined at discrete frequencies, which is a quite costly

procedure since a new simulation is necessary for each desired frequency. Fig-

ure 11 shows the results of a number of harmonic excitation simulations next

to ZONA6 results for the same four coefficients, namely lift and moment coef-ficient as a function of heave and pitch motion frequency. These time-domain

simulations were performed using timesteps of 2.5 ms, and repeated with a

timestep of 1 ms with the same mesh for comparison. Despite the considerably

higher computational cost, no significant differences could be found.

Aeroelastic Simulations of a Sailplane E 17

0 0.5 1 1.5−20

−15

−10

−5

0

5

10

15

Reduced frequency

CLh

(k)

DLM, real partDLM, imag. parttime−domain, realtime−domain, imag.

0 0.5 1 1.5−5

0

5

10

15

20

Reduced frequency

CL

α(k)

0 0.5 1 1.5−8

−6

−4

−2

0

2

4

6

Reduced frequency

CM

h(k)

0 0.5 1 1.5−40

−30

−20

−10

0

10

20

Reduced frequency

CM

α(k

)

Figure 11: Dependence of integral aerodynamic coefficients on reduced fre-

quency.

At low to moderate reduced frequencies, both methods yield similar results.

Even the characteristic ’wavy’ behavior for the moment coefficient response to

harmonic heave motion, CMh(k) is represented well. For k in excess of about

0.8, more differences appear. A possible reason may be the added mass effect

of the displacement bodies, i.e. wing thickness and fuselage, which is neglected

completely in the ZONA6 model. This effect would normally be assumed to

be very small for low reduced frequencies, it increases however linearly with

frequency and may play a certain role at high reduced frequencies.

Additionally, it should be noted that the time-domain method requires the

explicit enforcement of the Kutta condition due to the location of collocation

points exactly at the trailing edge, which is not the case in the same way forZONA6. It is not clear to what extent the kinematic (velocity) formulation

chosen here for the Kutta condition yields accurate results for high reduced

frequencies [20, 21].

For better computational efficiency, time-domain simulations can be per-

formed with a non-harmonic input signal, which contains more than a single

frequency. Good results were obtained with a frequency ramp (’chirp’) signal,

E 18 D. Eller and U. Ringertz

for which the frequency increases linearly with time. Using the output of a simu-

lation with a ramped frequency input, the complex coefficients can be computed

at a number of frequencies from the ratio of the Fourier transform of the coef-

ficient time series to the Fourier transform of the input signal. Figure 12 showslift and moment coefficient response to a chirp excitation in heave.

0 0.5 1 1.5−20

−15

−10

−5

0

5

10

15

Reduced frequency

CLh

(k)

0 0.5 1 1.5−8

−6

−4

−2

0

2

4

6

Reduced frequency

CM

h(k)

harmonic motion, realharmonic motion, imag.identification, realidentification, imag.

Figure 12: Identification from harmonic input and chirp response.

Coefficients obtained from the identification procedure are overall fairly

close to those found from single harmonic motion simulations, although small-

scale variations occur between adjacent frequencies. Such a wiggling behavior in

frequency is not realistic and must hence be regarded as computational noise.

The thin solid lines in Figure 12 are approximating 5th order polynomialsfitted to the discrete frequency response data. Alternatively, cubic spline fits

with multiple segments can be used to approximate the frequency dependency.

Frequency-domain stability analysis

Substituting the damped harmonic ansatz x = xept into the aeroelastic equa-

tion of motion (1) yields(

Mp2 + K)

xept = fa(t, p, x, . . . ) (8)

for p = σ + iω, where σ is the damping constant and ω the angular frequency.

Using a modal subspace approach according to (3), the above becomes(

Ip2 + Ω)

qept = ZT fa, (9)

where the deformations are now expressed in terms of the structural eigenmode

shapes Z obtained from the solution of the free vibration eigenproblem (2).

Aeroelastic Simulations of a Sailplane E 19

Hence, q is a vector of complex modal (or generalized) displacements. For

small displacements, the modal aerodynamic loads (or generalized aerodynamic

forces) ZT fa are assumed to depend linearly upon the magnitude of the modal

displacements q, so that (9) can be written as a nonlinear eigenvalue problemaccording to

(

(

c

2u∞

)2

Ip2 + Ω − q∞A(p)

)

q = 0, (10)

where p =σc

2u∞

+ ik. (11)

Here, q∞ is the dynamic pressure and A(p) relates the modal aerodynamic

forces to modal displacements. The real part of the nonlinear eigenvalue p is

the nondimensional damping value and its imaginary part corresponds to the

reduced frequency. In terms of actual deformations x, the solution can be

expressed as

x(t) = Z Re(

qept)

, (12)

where Re(·) extracts the real part. In order to simplify the computation of

frequency-domain aerodynamic loads, it is often assumed that A depends on

the reduced frequency k alone, and not on the damping. This approximation is

exactly fulfilled for a purely imaginary solution pcrit = ik of (10), corresponding

to neutral stability.

Results for the shell finite element model

The nonlinear eigenvalue problem (10) is solved using the robust pk−algorithm

by Back and Ringertz [22], which yields eigenvalues and eigenvectors solving

(10) for a particular dynamic pressure. Figures 13 to 14 show the damping g

and frequency of solutions for airspeeds up to 160 m/s, where the damping isdefined as

g = 2Re(p)

Im(p). (13)

This type of diagram is usually called vg-plot. As the nonlinear eigenvalue

solver does not track modes but instead employs a more robust scheme based

on sorting eigenvalues by reduced frequency, the line colors in the graphs below

identify the position of a solution in the frequency order.

In Figure 13, solutions to the eigenvalue problem are shown for the shellFE model in combination with aerodynamic loads A(k) computed using the

ZONA6 method implemented in ZAERO 6.2 [18]. Although the load matrices

are computed using this software, the pk−solution is performed externally us-

ing a Matlab implementation of the algorithm by Back and Ringertz [22]. The

E 20 D. Eller and U. Ringertz

50 100 150−0.2

−0.15

−0.1

−0.05

0

0.05

0.1

Airspeed [m/s]

Dam

ping

[−]

50 100 1500

5

10

15

20

25

30

Airspeed [m/s]

Fre

quen

cy [H

z]Figure 13: Damping and frequency for shell model and ZONA6 aerodynamics.

shell finite element model used is the simplified version which does not con-

tain structurally modelled control surface mechanisms. Aerodynamic effects of

control surface motions are not modelled either.

Figure 14 shows results computed using aerodynamic loads obtained fromthe identification process described previously, applied to modal displacements

instead of rigid body motion. Time-domain simulations are performed for

50 100 150−0.2

−0.15

−0.1

−0.05

0

0.05

0.1

Airspeed [m/s]

Dam

ping

[−]

50 100 1500

5

10

15

20

25

30

Airspeed [m/s]

Fre

quen

cy [H

z]

Figure 14: Damping and frequency for identified aerodynamics matrices.

prescribed motions in one or two modal coordinates, and the time history of themodal aerodynamic forces is recorded. The input signal is a sine which linearly

increases in frequency up to 40 Hz, corresponding to a reduced frequency of

1.47. One symmetric and one antisymmetric mode are excited simultaneously

in each simulation, and the resulting modal forces are partitioned according

Aeroelastic Simulations of a Sailplane E 21

to symmetry, relying on the assumption that symmetric deformations do not

cause antisymmetric loads and vice versa. After the simulations are completed,

complex frequency-domain loads are computed from the ratio of the Fourier

transforms of output (modal force) and input (modal displacement) signals.

Figures 13 and 14 indicate that both approaches to compute frequency-

domain aerodynamic loads give similar flutter results. In Table 4, the airspeeds

for the first two critical modes are listed with their (absolute and reduced) fre-

quencies at the flutter boundary (g = 0). Note that the computed instabilities

occur far beyond the flight envelope of the ASK 21, which is certified for amaximum permitted flight speed of 78 m/s.

Mode ZONA6 Identification Difference

1 airspeed 126 m/s 126 m/s <1%

frequency 9.65 Hz 9.52 Hz -1.3%k 0.254 0.251

2 airspeed 150 m/s 150 m/s <1%

frequency 16.1 Hz 15.8 Hz -1.9%k 0.356 0.340

Table 4: Critical aeroelastic modes

While there are small differences in the frequencies of the critical modes,

the overall behavior is quite similar. Some of the aeroelastic modes show slightly

more significant differences. As an example, consider the mode which becomes

unstable at 150 m/s. While the aeroelastic system using identified aerody-

namic frequency-domain loads predicts that this particular mode will achieve

its strongest damping of g = −0.18 at about 130 m/s, the model employing

ZONA6 aerodynamics predicts only g = −0.13 at the same airspeed. For air-

speeds slightly larger than 130 m/s, the same mode quickly becomes less strongly

damped.

Figure 15 to 18 show the first critical flutter modeshape for each of the two

aerodynamic methods. Since aeroelastic modes q are complex-valued, real and

imaginary part of the mode are plotted separately. The real part can be under-

stood as the deformation shape at the beginning of the neutrally stable flutter

oscillation, while the imaginary part would be the shape after one quarter of a

period, according to (12). Comparing the modeshapes obtained using differentaerodynamic methods, considerable similarities in the deformation pattern can

be found. Symmetric wing bending is visible in both flutter modes. The bending

pattern is a combination of first and second fundamental wing bending in such

a way that mainly the outboard third of the wing appears to move. Vertical

E 22 D. Eller and U. Ringertz

Figure 15: Real part of the first critical

flutter mode (ZONA6).Figure 16: Imaginary part of the first

critical flutter mode (ZONA6).

Figure 17: Real part of the first critical

flutter mode (identified loads).

Figure 18: Imaginary part of the first

critical flutter mode (identified loads).

fuselage bending and a minor component of symmetric stabilizer bending are

also present in both modeshapes. Even the ratio of fuselage to wing bending

appears to be similar for the two methods. However, the phase between fuselage

bending and wing tip motion is slightly different, as the comparison of the

imaginary part of the modes shows. Since, in this case, the same structural

model is used, the differences must either be caused by different interpolation

of structural eigenmode shapes to the aerodynamic mesh, or by differences in

the computation of modal aerodynamic forces.

The interpolation procedure employed by ZAERO is based on the fitting

of a plate spline to a subset of structural mesh nodes. Visualization of the

ZONA6 mesh, deformed according to structural eigenmodes reveals that the

quality of the spline interpolation procedure depends on the chosen node subset.

Subsets with too many structural nodes lead to ’wavy’ interpolated deformation

shapes, while too small node sets do not define the structural deformationwith sufficient accuracy. For the results shown above, only a small number of

structural, i.e. only 60 of 3800 finite element nodes per half-wing were used, in

order to suppress waviness in the interpolated modeshapes. The selected nodes

cover most of the structural surface, but are not regularly spaced in any way,

which may decrease interpolation accuracy.

For the time-domain aerodynamics used in the identification process, the

deformation of the surface mesh is computed from the shell FE model by as-

Aeroelastic Simulations of a Sailplane E 23

suming that surface mesh points are connected rigidly to the nearest structural

element. Since the distance is very small (typically below 3 mm), the surface

mesh follows the shell model surface very closely except where the structural

model is not defined. Such small ’gaps’ in the FE model exist e.g. between wingroot rib and fuselage. Due to the different interpolation method, the deformed

shape can differ significantly from the deformation of the ZONA6 mesh for the

same modeshape. Such differences are more likely to occur for higher frequency

modes, where local shell deformations become important.

The first and fourth structural eigenmode contain deformations which ap-

pear prominently in both flutter modeshapes, namely first wing bending and

first vertical fuselage bending. In Figure 19, frequency-domain modal aerody-

namic loads computed using the two methods are compared for reduced fre-

quencies up to 1.5.

0 0.5 1 1.5−2

−1.5

−1

−0.5

0

0.5

1

Reduced frequency

A1,

1

DLM, real partDLM, imag. partResponse, realResponse, imag.

0 0.5 1 1.5−0.04

−0.02

0

0.02

0.04

0.06

0.08

Reduced frequency

A1,

4

0 0.5 1 1.5−0.04

−0.03

−0.02

−0.01

0

0.01

0.02

Reduced frequency

A4,

1

0 0.5 1 1.5−0.15

−0.1

−0.05

0

0.05

0.1

Reduced frequency

A4,

4

Figure 19: Four elements of A(k) compared.

Both methods generate similar results for the elements A1,1(k) and A4,4(k),i.e. the aerodynamic loads in modes one and four due to harmonic excitation

of the mode itself, for reduced frequencies up to 1.2. Much less similarity can

be found in the off-diagonal terms A1,4(k) and A4,1(k). The imaginary part

E 24 D. Eller and U. Ringertz

of the former shows quite significant deviations, which appear to be systematic

differences in the aerodynamic model, as the values obtained from the discrete

Fourier transform are not too far from some smooth function of frequency. In

the latter case, however, the identification process using the FFT failed. Realand imaginary part of the response are found to vary wildly with frequency

and deviate strongly from values computed with the ZONA6. Such an erratic

behavior indicates that the modal force response to chirp excitation for the

corresponding time-domain simulation is either noisy or does not resemble the

input signal sufficiently.

Figure 20 shows the time history of aerodynamic forces in mode 1 and 4

due to a chirp excitation of the first structural eigenmode. While the response

0 0.2 0.4 0.6 0.8 1−3000

−2000

−1000

0

1000

2000

3000

Time [s]

Fq,

1

0 0.2 0.4 0.6 0.8 1220

240

260

280

300

320

340

Time [s]

Fq,

4

Figure 20: Time-domain response to excitation of the first mode.

of the first mode itself is smooth and directly correlated to the modal veloc-

ity of the excitation signal, the force in the fourth mode is of much smaller

amplitude and more noisy. Furthermore, the time history looks more like a

response to two superimposed excitation signals. Since such a signal clearly is

not properly correlated to a single input, the simple identification procedure

fails to yield reasonable results. In this particular case, the level of noise may

be related to the extreme difference in magnitude between modal force compo-

nents. The large values of modal force in the first mode indicate that the surface

pressure distribution must differ substantially from the equilibrium state. Sincethe modal force amplitude in the fourth mode is about 40 times smaller, the

apparent superposition in this mode can be related to a numerical integration

error. This problem is also encountered when computing small integrated force

coefficients such as induced drag in the presence of large pressure differences.

Aeroelastic Simulations of a Sailplane E 25

Results for the beam finite element model

Finally, the same flutter analysis as above has been performed with the shell

finite element model replaced by the beam model and ZONA6 aerodynamics.

Damping and frequency over velocity are shown in Figure 21. Interestingly,there is no instability in the speed range of interest, and even the development

of the eigenfrequencies of the aeroelastic modes is quite different. In contrast

to the flutter solution based on the shell model, almost all eigenfrequencies

below 30 Hz rise with airspeed. With the shell FE model, several of the higher

frequency eigenmodes show a distinct drop in frequency above 100 m/s, with

possible divergence in the vicinity of 160 m/s.

50 100 150−0.2

−0.15

−0.1

−0.05

0

0.05

0.1

Airspeed [m/s]

Dam

ping

[−]

50 100 1500

5

10

15

20

25

30

Airspeed [m/s]

Fre

quen

cy [H

z]

Figure 21: Damping and frequency for beam FE model.

The very significant differences between flutter solutions using the beamand the shell models emphasize the utmost importance of an accurate finite

element model for aeroelastic analysis. That does not necessarily mean that a

high-fidelity shell model must be used in every case. As seen in Table 1, the

differences in modal properties of beam and shell model cannot be regarded as

drastic, but still the flutter solutions show very few similarities. This indicates

that an aeroelastic analysis may not be meaningful unless the structural model

reproduces the actual flying structure very accurately.

Maneuver simulation

Due to the difficulties and risks associated with flutter flight testing, a more

benign maneuver flight test serves to compare aeroelastic simulation results with

experimental data. The flight maneuver is a pull-up with a maximum load

factor of about 4, close to the saturation limit of the installed attitude and

E 26 D. Eller and U. Ringertz

heading reference system (AHRS). The test aircraft is the ASK 21 shown in

Figure 1 which is equipped with position sensors at the control surfaces, solid-

state AHRS and fitted with an air data boom with vanes to measure angle of

attack and sideslip. All of these sensors are currently sampled with 10 Hz usinga digital on-board data acquisition computer. Furthermore, 16 piezoelectric

accelerometers are installed in the aircraft, which are sampled with 1 kHz.

The recorded elevator deflection is used as input for the numerical sim-

ulations, where its value is shifted by a constant in order to achieve initial

equilibrium conditions. The first simulation is performed with a flexible air-

craft model using the shell finite element model with eigenmodes up to 40 Hz.

A further numerical simulation is performed with exactly the same simulation

code, but without accounting for flexibility. The only difference in the input

signal between the two simulations is in the definition of the initial state, as

both computations must be started from an equilibrium state. This requires a

different initial elevator deflection (shifted by +2.3) for the rigid model, and

a slightly smaller angle of attack (reduced by 0.8). Moreover, both numeri-

cal simulations employ a simple model for the parasite drag which is addedto the induced drag obtained from surface pressure integration. Drag data was

extracted from the measured speed polar diagram in the aircraft datasheet [10]

and extrapolated for airspeeds in excess of 200 km/h. Since the maneuver is

performed in the vertical plane only, the numerical simulation of the flight me-

chanics was limited to longitudinal states, and lateral velocities and angles were

held fixed.

The time history of the pull-up in terms of altitude, calibrated airspeed and

load factor is shown in Figures 22 – 24. Measured airspeed and altitude are de-

0 2 4 6−8

−6

−4

−2

0

2

Time [s]

Ele

vato

r de

flect

ion

[deg

]

0 2 4 6

−20

−10

0

10

20

30

40

50

Time [s]

Flig

ht p

ath

angl

e [d

eg]

Flight testSimulation, flexibleSimulation, rigid

Figure 22: Measured elevator deflection and processed flightpath angle.

Aeroelastic Simulations of a Sailplane E 27

rived from pressure measurements using standard atmosphere conditions, while

the flight path angle in Figure 22 is computed from low-pass filtered altitude

and velocity data. The latter should therefore be understood as approximate be-

cause the angle is not measured directly. However, the initial short drop by 5 aswell as the steep change at t = 5.5 s hint at the presence of thermal drafts, since

comparison with the elevator position in the same figure indicate that these

rapid changes are not related to the commanded maneuver. Figure 23 shows

pressure altitude and airspeed, which are both reasonably well reproduced by

the numerical simulations. After six seconds simulated flight, the accumulated

0 2 4 6140

160

180

200

220

240

Time [s]

Airs

peed

[km

/h]

Flight testSimulation, flexibleSimulation, rigid

0 2 4 6

420

440

460

480

500

520

540

Time [s]

Alti

tude

[m]

Figure 23: Time history for pressure altitude and calibrated airspeed.

error reaches about 10 km/h and 15 m in altitude. The measured altitude data

contains a sudden jump of about 5 m at t ≈ 0.8 s, which may be caused by pres-

sure measurement noise. Accounting for the use of an approximate drag model,

the accuracy of the numerical simulation in terms of velocity and altitude is

considered reasonable.

Figure 24 shows load factor and pitch rate as obtained from flight test, along

with values computed by numerical simulation with rigid and flexible aircraft.

The global development of load factor and pitch rate is matched quite accurately

by the numerical time-domain simulation. In particular, the accumulated error

after completion of the maneuver is surprisingly small. It was expected that

differences between computed and actual control surface effectiveness would

lead to more significant error accumulation over the simulated 3000 timesteps.

The magnitude of vertical accelerations caused by thermal drafts can be esti-

mated by considering the measured load factor at t ≈ 5.5 s, just before the end

of the time window. Here, the load factor drops by about 0.2 for less than 0.5 s,

while the recorded elevator deflection is essentially flat. Consequently, neither

E 28 D. Eller and U. Ringertz

of the simulations contains this load excursion. Contrary to expectations, the

0 2 4 60

0.5

1

1.5

2

2.5

3

3.5

4

4.5

Time [s]

Load

fact

or [−

]

0 2 4 6−10

−5

0

5

10

15

20

25

30

Time [s]P

itch

rate

[deg

/s]

Flight testSimulation, flexibleSimulation, rigid

Figure 24: Load factor and pitch rate.

simulation of the elastic aircraft did not show large differences from the rigid

aircraft flight simulation. Only during the second half of the maneuver, an

error in pitch rate appears to accumulate for the rigid case. At the end, the flexi-

ble aircraft simulation still matches the experimentally obtained pitch rate fairly

well, while the rigid aircraft simulation is off by -3/s. Similarly, the flight path

angles of the two simulations diverge in the second half of the maneuver, to

reach a significant difference of about 10 at the end of the time window. How-

ever, since direct measurements for this angle are not available, it is difficult to

conclude if the elastic aircraft simulation improved accuracy.

The test aircraft is fitted with piezoelectric acceleration sensors which are

primarily intended for vibration testing. Each sensor contains a capacitance-

resistance circuit acting as a high-pass filter with a time constant of one second.

In order to enable interpretation of the measured data over the relatively long

time range considered, the raw accelerometer data was processed by filtering

with the inverted high-pass filter. This process introduces a linear drift sincethe raw electrical accelerometer data also contains a constant feed voltage signal.

Therefore, the corresponding linear term was subtracted from the acceleration

signal.

Figure 25 shows a comparison of the time history of measured wing tip

acceleration, when the cockpit acceleration signal as provided by the AHRS issubtracted. This difference can be regarded as an approximation of the tip mo-

tion due to elastic deflection. Furthermore, acceleration data for the simulation

is shown. It is obtained by finite-differencing the velocity of a mesh node at the

accelerometer position.

Aeroelastic Simulations of a Sailplane E 29

0 2 4 6−10

−5

0

5

10

Time [s]

Acc

eler

atio

n [m

/s2 ]

Flight testSimulation

0 10 20 30 40−40

−35

−30

−25

−20

−15

−10

−5

0

5

Frequency [Hz]

Pow

er s

pect

ral d

ensi

ty [d

B/H

z]Figure 25: Time history and PSD estimate for wing tip acceleration.

The measured time history contains considerably larger acceleration ampli-

tudes than simulation data. Moreover, the strong peaks do not correlate to the

known flight mechanic motion in an obvious manner. The acceleration data

from the simulated maneuver shows a considerably smaller variation and even

allows to recognize two points with particularly strong signals, i.e. pronounced

wing bending and torsion motion, at t = 1.5 s and t = 3.5 s. These points

correspond to the beginning and the end of the pull-up maneuver as seen in

Figure 24, where the load factor varies rapidly. There may be a similar patternin the measured data, but that is somewhat masked by the much stronger and

apparently noise-related peaks.

The right part of Figure 25 shows the Yule-Walker power spectral density

(PSD) estimate of the time series shown to the left. This estimate is the PSD of

a discrete autoregressive time-domain model fitted to the time series data and

yields spectrum information which contains much less variation in frequency

than the raw FFT. It is thus easier to identify the frequency content of thecorresponding signals, although the absolute value of the PSD would not be

directly useful, as it depends somewhat on the parameters used in the method.

Here, the autoregressive model was chosen to span 320 milliseconds, that is

order 320 for the measured data and order 160 for the accelerations obtained

from simulation.

First of all, the measured data comprises significantly higher magnitudesthroughout most of the frequency range considered, which is expected from the

time history. In addition, its PSD is considerably less varying, which indicates

that random processes (such as atmospheric turbulence) could be responsible

for some of the large magnitudes. The PSD estimate of the simulated accelera-

E 30 D. Eller and U. Ringertz

tions, on the other hand, contains several articulated peaks at 10 Hz, 20.5 Hz,

23.5 Hz, 28 Hz and 30 Hz. Most of these frequencies can be identified with

structural eigenfrequencies associated with symmetric modes (see Table 1), which

is expected since the representation of the structural behavior underlying the nu-merical simulation is based on the same modal data.

Computational effort

Structural modal analysis of the NASTRAN shell model shown in Figure 2 con-

tributed only a very minor amount of computational work; the extraction of the

first 30 eigenmodes was usually computed within 5 minutes. Evaluation of the

aerodynamic influence coefficient matrices required for the flutter analysis usingZAERO took approximately 2 hours on the same machine. This computation

need only be performed when the geometry or discretization of the panel mesh

has changed.

Time-domain simulations for the evaluation of frequency-domain load ma-

trices using the chirp response approach were far more computationally inten-

sive. The results presented here required approximately 11 hours computation

time on a dual-processor 2.4 GHz Opteron computer. On the same machine,

the maneuver simulation of the flexible aircraft with 3000 timesteps ran for 26hours. The current mesh-deformation procedure is adapted for arbitrary struc-

tural deformations and therefore performs a number of computations which

may not be necessary if deflections remain small. For that particular case, fur-

ther improvements of computational efficiency are possible.

Conclusions

When comparing aeroelastic stability analysis performed with a beam and ashell finite element model of the same aircraft, considerable differences in aeroe-

lastic stability are found although the structural models match fairly well in

the eigenfrequencies up to 15 Hz. Even though the first flutter mode detected

in the analyses involving the shell models is close to 10 Hz, the aeroelastic

system based on the beam model is stable throughout the whole speed range

investigated. This behavior leads to the conclusion that aeroelastic stability is

highly sensitive to differences in the structural model, even if these differences

are limited to eigenmode shapes with moderate and high frequencies.

A time-domain boundary element method was used to identify frequency-

domain aerodynamic loads from ramped frequency response simulations. In

most cases, the aerodynamic behavior thus obtained was found to differ lit-

tle from the aerodynamic loads computed by the frequency domain method

Aeroelastic Simulations of a Sailplane E 31

ZONA6. Flutter computations performed using the pk−method and with both

types of aerodynamic loads showed closely matching flutter speeds and similar

flutter modeshapes. However, the accuracy of the identification method degrades

significantly for modal aerodynamic loads of small relative magnitude and thecomputational cost of the identification process is comparatively high.

Finally, a 4g pull-up maneuver was performed with an instrumented flight

test aircraft. Numerical simulations which used the measured time history of

the elevator deflection as input demonstrated that the flight mechanic behav-

ior of the sailplane was represented fairly well by the simulation. Comparingsimulations including elastic deformations with those for the rigid aircraft, dif-

ferences were found to be present, but smaller than anticipated from the large

load factor.

Since control system modeling is known to have a strong effect on aeroelas-tic stability, in particular if the control surfaces are not mass balanced, future

efforts in this project will be concerned with the accuracy of control surface

aerodynamics and the mechanical properties of the control system. It is not

unusual that mild instabilities are tolerated in the certification analysis if the

damping required to stabilize is very small. A positive (unstable) value of the

damping parameter g less than 0.03 is sometimes accepted to account for un-

modeled damping in the structure and friction in the mechanical control system.

However, the damping defined by (13) is physically very different in comparison

to the stick-slip type of Coulomb friction that typical control surfaces experi-

ence. Accurate modeling of Coulomb friction requires a nonlinear time-domain

analysis for which the developed aerodynamic model is very suitable.

Acknowledgments

The authors would like to thank Michael Greiner and Gerhard Waibel of Alexan-der Schleicher Flugzeugbau for their valuable support in providing design draw-

ings, lamination plans and even rotational inertia data for control system com-

ponents. Sebastian Heinze implemented and tested the interpolation spline data

required to use the shell finite element model with ZAERO.

References

[1] E. H. Dowell, H. C. Curtiss, R. H. Scanlan, and F. Sisto. A modern course

in aeroelasticity. Kluwer, Dordrecht, 1989.

[2] R. L. Bisplinghoff, H. Ashley, and R. L. Halfman. Aeroelasticity. Dover

Publications, 1955.

E 32 D. Eller and U. Ringertz

[3] W. Stender and F. Kiessling. Aeroelastic flutter prevention in gliders and

small aircraft. Technical report, DFVLR e.V., Gottingen, 1990.

[4] W. Stender. Praxisnahe Abschatzungs- und Vorbeugungsmoglichkeiten

gegen die Flattergefahrdung von Segelflugzeugen und kleinen Motor-

flugzeugen. Technical Report IB 151-74/6, 151-74/20 and 151-74/22,

DFVLR e.V., Braunschweig, October 1974. Part I-III.

[5] European Aviation Safety Agency. CS-22, Certification specifications

for sailplanes and powered sailplanes, November 2003. Available at

www.easa.eu.int.

[6] T. Brama. The structural optimization system OPTSYS. International Series

of Numerical Mathematics, 110:187–206, 1993.

[7] W. P. Rodden and E. H. Johnson. Msc.Nastran Aeroelastic Analysis User’s

Guide. MacNeal-Schwendler Corp., Los Angeles, 1994.

[8] V. J. Stark. The AEREL flutter prediction system. In ICAS-90-1.2.3, 1990.

[9] ZONA Technology. ZAERO Version 6.2 Theoretical Manual, 17th edition,

October 2002. Available at www.zonatech.com.

[10] Alexander Schleicher Flugzeugbau, Poppenhausen. Datasheet for the ASK 21,

July 2003. Available at www.alexander-schleicher.de.

[11] A. Keller. Aeroelastic model development for the ASK 21 glider aircraft.

Master’s thesis, AVE, Kungliga Tekniska Hogskolan, Stockholm, October

2004.

[12] A. Westergren. Structural dynamics of the ASK 21 glider wing. Master’s

thesis, AVE, Kungliga Tekniska Hogskolan, Stockholm, June 2003.

[13] O. Bergogne. A simulation model of the ASK 21. Technical report, AVE,

Kungliga Tekniska Hogskolan, Stockholm, August 2003.

[14] R. Lardet. Flight dynamics model of the ASK 21 sailplane. Master’s thesis,

AVE, Kungliga Tekniska Hogskolan, Stockholm, May 2003.

[15] MacNeal-Schwendler Corp. Nastran Reference Manual, 2004. Msc.Nastran

2004.

[16] U. Nilsson, M. Norsell, and U. Carlsson. Ground vibration testing of

the ASK 21 glider aircraft. Technical Report TRITA/AVE 2003:32, AVE,

Kungliga Tekniska Hogskolan, Stockholm, May 2003.

Aeroelastic Simulations of a Sailplane E 33

[17] N. Niedbal and A. Bertram. Flatteruntersuchung ASK 21. Technical report,

DFVLR e.V., Gottingen, 1979.

[18] P. C. Chen, H. W. Lee, and D. D. Liu. Unsteady subsonic aerodynamics

for bodies and wings with external stores including wake effort. Journal of

Aircraft, 30(5):618–628, September 1993.

[19] D. Eller. An efficient boundary element method for unsteady low-speed

aerodynamics in the time domain. Technical Report TRITA/AVE 2005:40,

AVE, Kungliga Tekniska Hogskolan, Stockholm, December 2005.

[20] J. Katz and D. Weihs. Wake rollup and the Kutta condition for airfoils

oscillating at high frequency. AIAA Journal, 19(12):1604–1606, December

1981.

[21] J. Katz and A. Plotkin. Low Speed Aerodynamics. Cambridge University

Press, second edition, 2001.

[22] P. Back and U. T. Ringertz. Convergence for methods for nonlinear eigen-

value problems. AIAA Journal, 35(6):1084–1087, June 1997.