Arresting Operational Leakages using Energy Analytcis

-

Upload

umesh-bhutoria -

Category

Data & Analytics

-

view

263 -

download

0

Transcript of Arresting Operational Leakages using Energy Analytcis

0

1000

2000

3000

4000

5000

6000

7000

8000

22-12-2014 22-01-2015 22-02-2015 22-03-2015 22-04-2015 22-05-2015 22-06-2015 22-07-2015

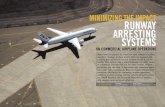

Graph shows compressed air energy consumption in a spinning unit for a specific period.

-

5

10

15

20

25

30

35

0

1000

2000

3000

4000

5000

6000

7000

8000

22-12-2014 22-01-2015 22-02-2015 22-03-2015 22-04-2015 22-05-2015 22-06-2015 22-07-2015

COMP Prod

Interestingly as soon as we start to look at the energy consumption in respect to production, we observe a rather disturbing trend in the last 30 days. Has the plant started to leak energy here? How to do a consistency check?

-

5

10

15

20

25

30

35

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

10000

22-12-2014 22-01-2015 22-02-2015 22-03-2015 22-04-2015 22-05-2015 22-06-2015 22-07-2015

COMP CompEx Prod

Expected energy consumption as per the forecasting model does not show up the “peak” in energy consumption as observed in the actual trend. This confirms that there is a leakage happening and is not linked to production/process.

0

200

400

600

800

1000

1200

0

1000

2000

3000

4000

5000

6000

7000

Deemed loss of Energy consumption is to the tune of 500 units/day i.e. almost Rs 3,500 per day!