Arai parts brochure

-

Upload

premierassociates -

Category

Business

-

view

343 -

download

1

Transcript of Arai parts brochure

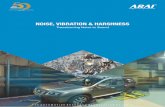

COMPANY PROFILE

www.arai-parts.com

Made of recycled paper

We open up a new field of cold heading

Arai Parts Co., LtdArai Parts Co., Ltd

Name:

Arai Parts Co., Ltd. Founded

June 1, 1972

Sales USD $30 Million - 2008

CEOMitsuaki Arai

Employees83 in Japan

Main productSpecial Cold Headed Parts, Unique Secondary Operations, Assembly parts

HQ

Headquarters, 1st Factory734 Kizone Yashio Saitama 340-0813

TEL +81-48(995)1223 FAX +81-48(995)5331

ISO 9001 Certified 2000

ISO 14001 Certified 2004

Second Factory

1079-1 Oaza 2 Yashio Saitama 340-0811

TEL +81-48(994)1933 FAX +81-48(994)1932

ISO 9001 Certified 2000

ISO 14001 Certified 2004

Tsukuba Factory381-1 Baba Josho Ibaraki 300-2748

TEL +81297(30)5035 FAX +81297(30)5036

ISO 9001 Certified 2000

ISO 14001 Certified 2004

Company Motto: Originality, Ingenuity, Think and Take Action

Tsukuba Factory

Second Factory

Company Introduction

83 in Japan

Main suppliersO and K , Sugita Wire, Yashima, Almine

Main bank Main Customers

Aishin Seiki, Fuji KokiMitsubishi Heavy Industries Tokyo Mitsubishi UFJ Bank

Musashino BankKameari Credit Union

Name: ARAI PARTS (TAICANG) Co., LtdFounded: Aug. 9, 2002

Address: A4 TONGJI TECHNOLOGY GARDEN, 288 SHANGHAI ROAD TAICANG ECONOMY

DEVELOPMENT AREA, TAICANG CITY, JIANGSU PROVINCE 215400, CHINA

Tel: 0512-5356-7360 From Overseas: +86-512-5356-7360

Fax: 0512-5356-7365 From Overseas: +86-512-5356-7365

Sales: USD $5 Million - 2008 Employees: 110

Contact: Masahiro Hoshino- General Manager

Hui Lin Guo – Assistant General Manager

Wang Feng- Sales Manager

Terms: USD, Chinese Yuan or Japanese Yen

Main Bank: Tokyo Mitsubishi UFJ Shanghai

Bank of China Taicang

Factory Area: 8,330 Square Meters

Products:

Specialized Cold Headed Parts, Secondary Processing

Size: 3 to 20mm (Length = 100mm max)

Material: Fe, SUS, Aluminum

We can produce your specialized order.

ISO 9001:2000Certified FactoryISO 14001:2004Certified Factory

China Taicang Factory Overview

China Taicang Factory

CAM Style Shaver

Heading

We have increased infrastructure to deal with difficult and precise parts.We have increased infrastructure to deal with difficult and precise parts.

Induction Heat Treat

Machining Center

Header CapacityФ #WH Ф3 – 6mm 2

2D2B Ф3 – 7mm 22D3B Ф3 – 6mm 32D3B Ф7 – 16mm 4

Cutting Machines # CAM Style Shaver 8 Precision Automated Lathe 23 CNC Precision Automated Lathe 2 Desktop Lathe 19 Tapping Machine 7 End Mill Machining Center 1

Heat treatment # Induction Heat Treat 1

Thread Rolling Capacity #

DR375 M8 – M10 1

DR250 M5 – M7 1

DR200 M3 – M5 1

Cold heading & Secondary Processing

We are capable of manufacturing complicated and difficult products that other companies decline to quote.

Please do not hesitate to contact us.

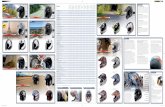

Product Summary

Terminal / Sensor Products

Brake / Oil Pump Products

Door / Seat Products

We have equipped our machines with various sensors and indexing parts containers so that these machines can operate unattended for increased labor savings.

Main Plant

Cold Heading

Tsukuba Plant

Header Type Capacity(ΦDxL) #

1 Die 2 Blow H-20 Φ2.5 × 100 2AT-675 Φ7.0 × 75 2TH2-4A Φ7.0 × 75 1PF-210 Φ2.5 × 12 1PF-420 Φ4.8 × 30 3NP-40 Φ4.8 × 30 2PF-630 Φ7.0 × 30 4NP-60 Φ7.0 × 50 8PF-860 Φ10.0 × 80 8NP-81 Φ10.0 × 80 3NP-120 Φ16.0 × 120 2PF-1280 Φ16.0 × 120 1

3 Die 5 Blow TH3-6 Φ7.0 × 75 1MST-508 Φ10.0 × 100 2YMP-580 Φ9.0 × 40 3

6 Die 6 Blow MST-612 Φ16.0 × 120 1SF-170 Φ20.0 × 120 1YMP-780 Φ9.0 × 40 6YMP-7120 Φ12.0 × 60 2

8 Die 8 Blow YMP-880 Φ9.0 × 40 5

2 Die 2 Blow

2 Die 3 Blow

5 Die 5 Blow

7 Die 7 Blow

Oval & D Shapes achieved by the cold heading process can offer price reductions.

Headed products that eliminatedSinter and Mechanical Processing

Extrusion Process Upset Process Backward Extrusion Process

Cold Heading Basic Process

Cold Heading Application Process

Cold Heading

Specialty Products

All machines are equipped with lift sensors and continuously variable transmissions.

We strive to save labor with unmanned automation and inspection. Each machine line is equipped with an automatic auxiliary hopper & conveyer.

Lift Sensor

Threads and Knurl

Screw, Knurling

Shave

Form Rolling

Pointing & Drilling

Examples of Thread Rolling Process

Thread Rolling Machine Type Number

DR-200

DR-250

DR-375

Kyoei SR-1, SR-15

Others Specialty Machine

Dainittetsu

Total 30

Secondary Processing

We have a wide range of secondary operations to meet your needs.

Driller

Tapper

Mechanical Processing

Automated tapping machinePress Shaving Machine

Flanging Bending Shaving, Tier grinding, Pointing

Examples of Secondary Processing

Assembled Products

Second processing machine #

Machine tool #Head part cutting machine 35 Lathe 3End part cutting machine 44 Drill press 4Automated pit tap machine 3 Flat-surface grinding machine 3Automated pit drilling machine 6 Shaver 1Automated tap process machine 5 Blade grinding machine 2Procon cutting machine 5 Shot Blast 2NC precision lathe 7

Desktop lathe 11Press 35 - 50 ton 15Others Multiple Others Multiple

Drill / TappingPress / Flattening

Collect Chuck Over Chuck

Header Blank

Header Blank

Head ProcessShavingTier GrindingSpherical process

Tail ProcessShavingTier GrindingTip cut

We have approx. 100 CAM style automatic shavers that deal with cutting process. These machines perform secondary operations after the cold heading process and can produce complex parts.

Head part processing Tail part processing

CAM Part

Cold Heading and Second Processing

Automatic feed

Axis straightness inspection

Thread presence & depth inspection

Axis damage, nick inspection

Dimensional measurement

TIR accuracy and dimensional inspection

Missed or incomplete operations

We can detect non-conforming products by applying strobe lighting with high-speed digital camera inspection.

Inspection speeds 70-200 pieces per minute

We can detect dimensional non-conformances by matching the digital image of the product with preset screen overlay measurements.

Inspection speeds 70-200 pieces per minute.

Digital Image Processing Inspection System

Quality Principle / Environmental Principle

Environmental Principle

1. We aim for continuous improvement in all aspects.2. Accomplish (Report/ Advise/ Communicate) to become a reliable company.May 7, 1998 internally enacted

Quality Principle

Thoroughly check procedure manual, specification and product appearance to eliminate incompatibility.

Sep.29, 2001 internally enacted

Internal Slogan

Arai Parts aim is for the entire enterprise to deal with energy saving and environmental conservation activities by all employees . We acknowledge that we will reduce the global environmental effect as one of our social responsibilities that will arise from our related manufacturing and supply activities.

1. To strive to realize our environmental influence and aim to continuously conserve through environmental activities.

2. We strive to prevent environmental pollution in all work sites. We strive to reduce amount of resources used and waste discharged. We strive to reduce the amount of energy used.

3. We abide by all environmental related decrees, bylaws and other demands postulated.

4. We will strive to inform employees of this environmental policy through instruction and education. We have set environmental goals specifically to manage the project. We request that our vendors understand and incorporate our environmental policy.

5. We will work with the local community to contribute to preserve the local environment.

6. We publish our environmental policy in the company introduction so that we can disclose our environmental policy to the general public.

May 12, 2008

Arai Parts CO., LTD. CEO, President Mitsuaki Arai