AR Standing Seam - Agway Metals Inc.

Transcript of AR Standing Seam - Agway Metals Inc.

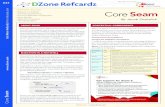

0.5VARIABLE

1.0PAINTED SURFACE

VARIABLE 0.51

1.5PAINTEDSURFACE

VARIABLE 0.71

2.0PAINTEDSURFACE

4 (102)

2 (51)

1 3/4(45)

3/8 (10)

60°

1 1/2(38)

1/4 (6)

Clip attaches with fasteners here

Batten

Open 1/16”

tight

tight

Tool End View:

Material: 18 ga. galvanized

6”1.25”

1”1.5”

22”

Cut 1” out of both vertical ribs.

Apply Hand Folder to panel edge as shown and bend down.

After installation, the edge may be closed over Starter with wide-jaw pliers.Protect inside of pliers to avoid damage to pre-painted steel.

OPERATING SEQUENCE:

This tool is available from Agway Metals Inc.

1

2

3

4

5

6

AR Standing Seam

Dimensions & SpecificationsOptional Batten Cap & Assembly

AR-25/38/50 Hemming Tool

Mar. 2021

FEATURES: • No exposed fasteners • Ease of installation • Full range of stock colours • Variable width • Optional stiffening flutes • Concealed hold-down clips • Knee Caps available • Optional two-piece expansion clip to accommodate roof movement • 24 gauge can be seamed 90° and 180°; 22 gauge can be seamed 90° only • Butyl Tape is recommended in 90° seams • Able to be curved - minimum sheet length 5’-0”

AR-25 AR-38 AR-50

24/22 ga. 21” 20” 18.5”

AR-25

AR-38

AR-50STIFFENING FLUTES OPTIONAL

Panel Specifications

Standard Panel Widths

Min./Max. Min./Max. Min./Max. Min./Max. Slope Material Sheet Panel Thickness Length* Width

AR-25: 3/12 - 12/12 0.024 - 0.030 in. 2’-6” – 45’ 10” – 28” AR-38: 1.5/12 - 12/12 0.024 - 0.030 in. 2’-6” – 45’ 10” – 28”

AR-50: 0.5/12 - 12/12 0.024 - 0.030 in. 2’-6” – 45’ 10” – 28”

*NOTES: Longer sheets are available on request. Additional charges may apply. Side lap caulking is recommended when the slope is less than 2/12

OIL CANNING: • Oil canning may be present due to various factors. Oil canning is not a valid reason for rejection of this product.

AR-38 Break Formed Batten Cap, 26 ga. Finish to match roofing panels. Available in lengths up to 20’-2”. Batten Cap must be secured at Ridge and Hip areas.

AR-38 Batten Clip 18 ga. Galvanized. Maximum 48” on centre. Install using (2) fasteners w/washers per clip.

ROOF ASSEMBLYAR Roof Panel

Membraneon Solid Substrate AR Clip

AR-25, 38 & 50 Metal Roof Panel

Section AA

Breathable Water Barrier

Rigid Insulation & Sub-Girt

Air/Vapour Barrier (Peel & Stick)Densdek 1/2”Steel Deck or Solid Substrate

AR Roof Clip

AR Roof Clip

Double Fold Single Fold

Plain Fluted

A

A

AR-25, 38 & 50 Metal Roof Panel

Breathable Water Barrier

Rigid Insulation & Sub-Girt

Air/Vapour BarrierDensdek 1/2”Steel Deck or Solid Substrate

Installation

Hold-down Clip Detail

AR-38 Mist Green

AR Standing Seam

Typical Installation on Solid Substrate

Typical Installation on Insulated Roof

FIXED CLIP EXPANSION CLIP

90° Seaming Stages T-Style 22 & 24 Gauge 180° Seaming Stages I-Style 24 Gauge only

Overlap Seaming Options

Overlap prior to seaming.

• Single skin application • Recommended that this always be applied over solid substrate • Recommended that this be applied over waterproof membrane • Clips at maximum 2’ centres - 2 fasteners per clip • Mechanical and Hand Seamer required

CRC Barrel 400 mm SSR Panels 24 ga. Mist Green

AR-38 Galvalume Plus

0.5VARIABLE

1.0PAINTED SURFACE

VARIABLE 0.51

1.5PAINTEDSURFACE

VARIABLE 0.71

2.0PAINTEDSURFACE

4 (102)

2 (51)

1 3/4(45)

3/8 (10)

60°

1 1/2(38)

1/4 (6)

Clip attaches with fasteners here

Batten

Open 1/16”

tight

tight

Tool End View:

Material: 18 ga. galvanized

6”1.25”

1”1.5”

22”

Cut 1” out of both vertical ribs.

Apply Hand Folder to panel edge as shown and bend down.

After installation, the edge may be closed over Starter with wide-jaw pliers.Protect inside of pliers to avoid damage to pre-painted steel.

OPERATING SEQUENCE:

This tool is available from Agway Metals Inc.

1

2

3

4

5

6

AR Standing Seam

Dimensions & SpecificationsOptional Batten Cap & Assembly

AR-25/38/50 Hemming Tool

Mar. 2021

FEATURES: • No exposed fasteners • Ease of installation • Full range of stock colours • Variable width • Optional stiffening flutes • Concealed hold-down clips • Knee Caps available • Optional two-piece expansion clip to accommodate roof movement • 24 gauge can be seamed 90° and 180°; 22 gauge can be seamed 90° only • Butyl Tape is recommended in 90° seams • Able to be curved - minimum sheet length 5’-0”

AR-25 AR-38 AR-50

24/22 ga. 21” 20” 18.5”

AR-25

AR-38

AR-50STIFFENING FLUTES OPTIONAL

Panel Specifications

Standard Panel Widths

Min./Max. Min./Max. Min./Max. Min./Max. Slope Material Sheet Panel Thickness Length* Width

AR-25: 3/12 - 12/12 0.024 - 0.030 in. 2’-6” – 45’ 10” – 28” AR-38: 1.5/12 - 12/12 0.024 - 0.030 in. 2’-6” – 45’ 10” – 28”

AR-50: 0.5/12 - 12/12 0.024 - 0.030 in. 2’-6” – 45’ 10” – 28”

*NOTES: Longer sheets are available on request. Additional charges may apply. Side lap caulking is recommended when the slope is less than 2/12

OIL CANNING: • Oil canning may be present due to various factors. Oil canning is not a valid reason for rejection of this product.

AR-38 Break Formed Batten Cap, 26 ga. Finish to match roofing panels. Available in lengths up to 20’-2”. Batten Cap must be secured at Ridge and Hip areas.

AR-38 Batten Clip 18 ga. Galvanized. Maximum 48” on centre. Install using (2) fasteners w/washers per clip.