AR Recycler $7 · cell phone casings and screens. But beyond growth in recovering materials,...

Transcript of AR Recycler $7 · cell phone casings and screens. But beyond growth in recovering materials,...

As smart phones get smarter andsmaller, they also get slimmer, more fragileand more prone to breaking. But most willbecome obsolete and be upgraded to newer,more powerful devices before they crack.The same can be said for regular cell phones,pagers, PDAs, e-readers, mobile MP3 play-ers and the new breed of wearable electronicsnow entering the marketplace. Whereverthere is a mobile device, and they are seem-ingly everywhere in ever growing quantitiesand configurations, they are destined to betrashed, refurbished or shredded to recovermaterials. It all adds up to a boom in businessfor e-recyclers.

According to the U.S. EnvironmentalProtection Agency (EPA), mobile phones areusually replaced every 18 months, yet nearly66 percent of men believe that their currentwallet will outlast their smartphone and 53percent of women believe their current pursewill last longer than their smartphone.Turnover times get shorter each year and techsavvy enthusiasts constantly upgrade to themost recently released devices.

Mobile devices are a prized recyclablecommodity because they can contain smallbut valuable amounts of various preciousmetals, including silver, gold, palladium,platinum, tin, copper and more. Plastics andglass are other valuable materials found incell phone casings and screens. But beyondgrowth in recovering materials, refurbishingand reselling small devices is a rapidly grow-ing business and highly profitable for manyrecyclers.

The Pew Research Center reported that91 percent of all adults in the U.S. owned acell phone in 2013. Although manufacturersproduce a massive variety from basic cellphones to fully-featured touch-screen smartphones to other mobile devices, environmen-tal organizations recommend reusing or recy-

cling phones rather than discarding themwhenever practical. This conserves materialsand lessens the environmental impact tolandfills and prevents a witch’s brew of toxicsubstances from leeching into water supplies.These can include lithium, cobalt, cadmium,mercury, beryllium, arsenic, bromides, tantalum and antimony.

The U.S. EPA’s latest estimate of themobile phones collected for recycling in2009, found that 38 percent were refurbishedor reused and the remaining 62 percent wererecycled.

Being small by nature, these wirelessdevices and accessories are too often thrownin the trash, but there are nationwide effortsto further educate the public to recycle, eitherto have devices refurbished for continueduse, or responsibly dismantled to recovervaluable feedstocks. Most major wirelesscarriers and many electronic retailers haveinstituted free, drop-off or mail-in programsto recycle handsets, tablets and netbooks aswell as chargers, batteries and accessories.Unfortunately, many national and Internetretailers that sell these devices are not provid-ing recycling services.

Before recycling, all users are urged toerase all stored information, remove SIMcards and restore the device to factory set-tings. If not cleared of personal information,an R2 or eSteward certified electronics recy-cler will automatically wipe all user content.

Tolena Thorburn, senior communica-tions manager at T-Mobile USA shared, “Ourhandset recycling and reuse program pro-vides the opportunity for our customers tobring their used handsets to any T-Mobilelocation in the United States and Puerto Rico.

In 2013, we took back more than 5.2 millionhandsets and refurbished, resold or invento-ried for future use about 90.2 percent ofthem. We then disassembled and processedresponsibly to recover precious metals fromthe remaining 9.8 percent of the returnedhandsets. In total, our recycling rate was 21.6percent in 2013.

“Our recycler is R2 certified. The R2Standard sets forth requirements relating toenvironmental, health, safety and securityaspects of electronics recycling. R2 alsorequires e-recyclers to assure that the moretoxic material streams are managed safelyand responsibly by downstream vendors, allthe way to final disposition. It also prohibitse-recyclers and their downstream vendorsfrom exporting these more toxic materials tocountries that have enacted laws making theirimport illegal.”

But perhaps the advent of new technol-ogy can help recycle older technology? TakeecoATM as an example. It’s the first com-pany to create an automated self-serve kiosksystem that uses patented, advanced machinevision, electronic diagnostics, and artificialintelligence to evaluate and pay cash for oldand unused electronics.

Founded in 2009, ecoATM became asubsidiary of Outerwall, Inc in 2013, a majorprovider of automated retail solutions. Thusfar, ecoATM kiosks have collected over twomillion mobile devices. And collection issnowballing according to Amy Rice, com-pany spokesperson. “It took from 2009 toApril, 2013 for us to collect our first millionunits, however we reached two million byJanuary of this year.”

AmericanRecycler.comNewsVoice of Salvage, Waste and Recycling

$7.00AR ecyclerR

Vol. 17 • Issue 8 August 2014

ecyclerR

08.2

014

900 W. South Boundary, Bldg. 6Perrysburg, OH 43551-5235

CH

AN

GE

SE

RV

ICE

RE

QU

ES

TE

DP

RS

RT

ST

DU

.S.

Po

sta

ge

PA

IDC

olu

mb

ia,

MO

Pe

rmit N

o.

35

3

FOCUS:Alternative Energy Recycling small mobile devices

emerges as big businessby MIKE [email protected]

See MOBILE DEVICES, Page 4

WHAT’S INSIDEFlorida passes legislation toprotect workers. Page A5Carton recycling access reaches50 percent milestone. Page A8Plant will recycle 100 millionpounds of bottles annually.Page A10Steel imports increase 7 percentin May. Page A14Wind power growth still surgingwhere supported. Page B3

Food processors offsetenergy costs with scraps

Events CalendarScrap Metals MarketWatchSalvaging MillionsBusiness BriefsNew Product ShowcaseAR ClassifiedsEquipment SpotlightA Closer Look

Located in high traffic areas, ecoATM machines offer a convenient way to recycle mobile devices andreceive cash for reusable products. PHOTO COURTESY OF ECOATM

41516182020B4B6

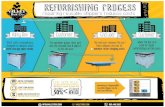

Before refurbishing, each phone is registered with aunique barcode, and scanned into inventory.

PHOTO COURTESY OF ELECTRONIC RECYCLERS INTERNATIONAL

Shaw Industries Group, Inc. willexpand its robust reclamation and recycling program to include a newEvergreen facility in Ringgold, Geor-gia. The Berkshire Hathaway companywill create at least 70 new full time jobsand invest over $17 million into thefacility.

Shaw has recycled more than 700million pounds of carpet since 2006 viathe company’s take-back program andan expansive reclamation network. As anaddition to Shaw’s portfolio of recyclingsolutions, Evergreen Ringgold will givethe company a flexible recycling solu-tion that is capable of recycling nylonand polyester carpet.

Complementing Shaw’s carpetrecycling portfolio, Evergreen Ringgoldwill create a high purity post-consumerrecycled material that can be used in abroad range of applications. The facilitywill be operational in 2015 and will belocated in what was previously ShawPlant 37 – a rug distribution center.

Shaw has committed to 100 percentof its products being designed to Cradleto Cradle protocols by 2030.

Carl Campbell, senior project man-ager for the existing industry andregional recruitment team, oversaw the

project for the state. In addition, GeorgiaQuick Start, the nation’s top-rankedworkforce training program, will workwith Shaw to ensure its employeesreceive the proper training to support thecompany’s recycling investments.

American RecyclerPage A2, August 2014

Shaw Industries Group expands withGeorgia facility to recycle more fiber types

A new, five year agreement withRumpke Waste and Recycling will supportthe University of Dayton’s sustainabilityeducation efforts and recover more than1.6 million pounds of recycling annually.

In addition to weekly trash and recy-cling collection, Rumpke will:

•Support the University’s sustainabil-ity curriculum with hands-on educationalexperiences and campus sustainabilityprogramming such as facility tours, guestlectures and special projects.

•Assist with the University’s sustain-ability education efforts in local schools.

•Assist with the University’s partici-pation in the nationwide Recyclemaniacompetition to encourage a campus-widerecycling culture.

•Sponsor messages at University ofDayton athletics events to help promoterecycling and sustainability initiativesbeyond campus.

Earlier this year, the Universityearned a silver rating in the Association

for the Advancement of Sustainability inHigher Education Sustainability Tracking,Assessment & Rating System for its sus-tainability achievements.

The University also made ThePrinceton Review’s Guide to 332 GreenColleges: 2014 Edition for demonstrat-ing a strong commitment to sustainabil-ity in the University’s academicofferings, campus infrastructure, activi-ties and career preparation.

University of Dayton and Rumpke form partnership

GlyEco, Inc. has increased its wasteglycol recycling capacity 400 percent atits Minnesota processing center.

During the first quarter, GlyEcorelocated its Minnesota facility from2,000 sq.ft. to a 10,000 sq.ft. stand-alonebuilding which provides improved logis-tics for large volume operations.

Additionally, GlyEco completed aseries of technology and equipmentupgrades, including new main circulationequipment, an advanced pumping sys-tem, and secondary containment system.

“Our recent upgrades at this facil-ity enable us to produce larger batchesof recycled glycol from multiple newwaste streams,” stated John Lorenz,chief executive officer of GlyEco. “Wecan now process ethylene and propy-lene waste glycols as well as ethyleneoxide waste in Minnesota. We intend toramp sales by expanding our servicesinto the heat transfer fluids and aircraftdeicing waste markets. We also intendto service a larger geographic territoryat this facility.”

GlyEco boostsglycol recycling

ReCommunity has acquired the assetsof JFD Associates. The addition of JFD’sfacility in Farmingdale is ReCommunity’sfifth processing operation in New Jersey.ReCommunity provides service to dozensof haulers and more than 110 communitiesacross the Garden State.

JFD has operated this facility formore than 10 years.

ReCommunityacquires JFD

American Recycler August 2014, Page A3

A Buzz Lightyearaction figure wasused last month tocapture a thief out-side Atlanta, Geor-gia. The Buzz Lightyeardoll, with a hidden GPStransmitter, was placedinside a bag of used cloth-ing in a collection bin oper-ated by Mid-Atlantic ClothingRecycling (MAC Recycling) of OwingsMills, Maryland. The collection binbeing monitored was at the DouglasMarketplace in Douglasville, Georgiajust west of Atlanta.

“We have experienced a recent rashof thefts from our collection bins,” saidMax Glikman, operations manager ofMAC Recycling. “In some cases our col-lections were down as much as 40 per-cent at specific locations. The team atMAC Recycling came up with the ideaof using a GPS device to track materialsonce they were taken illegally from oneof the company’s collection bins.”

Tim Peck, Atlanta territory managerfor MAC Recycling recently hid one ofthe companies 90 GPS monitors in aBuzz Lightyear stuffed toy along withother items of used clothing. An onlinetracking system allows Peck, and otherMAC Recycling managers to remotelymonitor the “seed” materials. Yesterday,Peck was alerted that Buzz Lightyearwas on-the-move. Peck immediatelycontacted police to report a “theft inprogress.”

“We have found law enforcementofficials to be very appreciative of ourefforts with the GPS devices,” said Glik-man. “While we can’t identify the makeand model of the vehicle transporting thestolen items, we can direct the police towithin a few feet of the GPS tracker.”

Following the directions of Peck,Douglas County police located the stolenproperty and observed a suspect unloadingthe materials from the back of a pick-uptruck. The officers used a directionalfinder to sweep the property and foundBuzz Lightyear and the GPS device insidethe suspect’s house. The man confessed tostealing a total of six large bags of cloth-ing. He was arrested and taken to jail.

Glikman said the company has usedthe trackers in five other cases. Most casesinvolved individuals removing items fromMAC Recycling clothing collection bins,although in one case a competitor wascaught with the stolen goods.

Clothing binscontinue tobe targets

I was having trouble with my com-puter so I called Harold the computerguy, to come over. He clicked a couple ofbuttons and solved the problem.

He gave me a bill for a minimum serv-ice call. As he was walking away, Iasked him what was wrong.

He replied, “It was an ID ten T error.”I didn’t want to appear stupid, but

inquired, “What’s that?”“Write it down,” he said, “and I think

you’ll figure it out.”So I wrote down: I D 1 0 T... I used to

like Harold.

Recycling industry brings $13 billionboost to South Carolina’s economy

The recycling industry in SouthCarolina brings a $13 billion boost tothe state’s economy annually – doublethe estimated impact of recycling in2006 – according to a new report com-piled by Dr. Frank Hefner.

The economic impact report quan-tified the contributions of recyclingthrough a combination of direct surveydata from recycling companies as wellas economic modeling throughIMPLAN. The report was an update to a 2006 study with the same methodology.

Despite the recession, the total eco-nomic impact of recycling activities inthe state grew nearly 5 percent annuallyto double its impact in 8 years, whilerecycling’s benefit to jobs across SouthCarolina grew to 54,121 jobs impacted– a 44 percent increase since 2006.

The updated report was commis-sioned through a partnership betweenthe South Carolina Department ofCommerce, the South Carolina Depart-ment of Health and EnvironmentalControl (SCDHEC), New Carolina andRecyclonomicsSC, a non-profit organi-zation that promotes recycling as a wayto improve the economy.

The 2014 report’s key findingsreveal that recycling contributes:

•$13 billion in total economicimpact – double the impact of $6.5 bil-lion in 2006.

•54,121 jobs, up 44 percent from37,440 impacted jobs 8 years ago.

•$2.7 billion in labor income, up 80percent from the 2006 report.

•$329 million in state and localtaxes.

Moreover, the state’s recyclingindustry expects additional growth thiscalendar year. Nearly 64 percent of sur-vey respondents indicated they areplanning an expansion in 2014 with anaverage of 3.5 employees each, orapproximately 1,162 new employeesadded to payrolls this year. The averageannual growth rate predicted for theindustry is 19 percent.

“While many recognize the envi-ronmental benefit of recycling, theseresults show the strong connectionbetween recycling and business,” saidsecretary of commerce Bobby Hitt. “Asthe business agency for South Carolina,Commerce will continue to providesupport for the more than 500 compa-nies in the state that are engaged inrecycling activities and making sizeablecontributions to our state’s economy.”

Along with the growth of recy-cling’s impact to the economy, partici-pation in recycling also has grown. Thestate’s recycling rate increased to 31percent in 2013 from 22 percent in2009, with each South Carolinian onaverage recycling 1.59 pounds per day.

“Last year, South Carolina recycledalmost 600 pounds per person. It is anextraordinary number and is only grow-ing thanks to the grass roots dedicationof our local governments in partnershipwith DHEC,” said Catherine Temple-ton, director of SCDHEC. “As a result,local governments saved more than $53million in disposal costs last year alone

and have earned more than $67 millionin the last 4 years.”

A directory of businesses engagedin recycling activities maintained by theDepartment of Commerce identifies524 firms in 2014, up 54 percent from340 firms in 2006. These companiesinclude collectors, haulers, processors,end-users, exporters and others. Since2006, the state’s recycling industry hasannounced more than $4.63 billion innew investments.

Companies large and small com-prise South Carolina’s recycling indus-try. Of the more than 520 recyclingfirms in the state, the number of person-nel ranges from 1 to 577 employees.The average number of employees percompany is 63, while the median num-ber of employees is 14. Additionally,the average payroll per employee in theindustry is $40,203, above the averagewage in South Carolina of $38,700.

“With an annual economic impactof $13 billion and over 520 companiesacross the state, there’s no denying thatrecycling in South Carolina is makingtreasure out of trash,” remarked TinaHuskey, chair of RecyclonomicsSC.“RecyclonomicsSC set a robust goal to‘Arrive at 75’ by increasing our currentrecycling rate from 31 percent to 75percent before 2030. That successwould mean even more innovation, jobopportunity and cost savings – furtherproof that making one small changetoday can lead to a greener, more pros-perous South Carolina.”

Republic Services dedicated theConover Recycling Facility in CatawbaCounty, which will introduce or expandsingle-stream recycling capabilitiesthroughout Alamance, Catawba, Guild-ford, Montgomery, Richmond, and Stanlycounties. The expanded, highly-advancedfacility has the capacity to process morethan 25 tons of mixed recyclables perhour, or 400 tons per day.

The Conover Recycling Facilityaccepts and processes all plastics marked 1through 7, paper products, cardboard,glass, aluminum and other materials. Thefacility utilizes several advanced technolo-gies which include a touch-screen HumanMachine Interface control, SupervisoryControl and Data Acquisition monitoringand innovative sorting technologies thatmaximize sorting efficiencies. The facilityhas the capacity to sort and process incom-ing materials, and ship finished commodi-ties to domestic and international markets.

There are approximately 43 full-timeemployees working at the Conover Recy-cling Facility. In addition, the facilityoffers a unique Learning Center for thecommunity to visit and experience a rare,up-close view of the recycling process.

Republic opensrecycling facilityin North Carolina

American RecyclerPage A4, August 2014

American Recycler is published 12 times per year, postage paid at Columbia, Missouri.

SUBSCRIPTIONS: Call our offices at 877-777-0043 or visit w w w. A m e r i c a n R e c y c l e r. c o m . US 1 year $48; 2 years $72.

© COPYRIGHT 2014 by American Recycler News, Inc. All rights are strictly reserved and reproduction in whole or in part is prohibited without prior written permission from the publisher.

Submission of articles, artwork and all photography must be accompa-nied by a self-addressed stamped envelope if a return of materials is wanted. Byline contributors’ views should not be construed as repre-senting the opinion of the publisher.

American Recycler reserves the right to edit any and all material submitted for publication. All Letters to the Editor must be signed and include a telephone number for verification. The editor of this publi-cation does not accept responsibility for statements made by advertisers herein.

PRINTED ON RECYCLED PAPER

Publisher and Editor

ESTHER G. [email protected]

Production and Layout

MARY E. [email protected]

Editorial Focus Section Editor, Production and Layout

DAVID FOURNIER, [email protected]

Marketing Representatives

MARY M. [email protected] E. [email protected]

Circulation Manager

DONNA L. [email protected]

Writers and Contributors

MIKE [email protected] [email protected] [email protected] [email protected]

Production Offices

900 W South Boundary, Bldg 6Perrysburg, OH 43551-5235877-777-0043 fax 419-931-0740www.AmericanRecycler.com

877-777-0043 Fax 419-931-0740

Events CalendarAugust 26th-28th

WASTECON/SWANA. Gaylord Texan,Dallas, Texas. 800-467-9262 • www.swana.org

September 17thUpper Peninsula Recycling CoalitionMeeting. Bay College West Campus, IronMountain, Michigan. 906-786-9212 • www.uprecycles.com

September 23rd-25thWaste Conversion Tech Conference &

Tradeshow. The Westin Downtown Denver,

Denver, Colorado.

800-441-7949 • www.waste-to-fuels.org

September 24th-26th19th International Congress for BatteryRecycling ICBR 2014. Hamburg, Germany.41 62 785 10 00 • www.icm.ch

October 19th-21stWV Educational Conference on LitterControl & Solid Waste Management.Huntington, West Virginia.304-573-5194 • www.awvswa.com

October 22nd-25th71st Annual ARA Convention & Expo.Gaylord Opryland Resort & ConventionCenter. Nashville, Tennessee.888-385-1005 • www.araexpo.org

Today ecoATM has over 900 kioskslocated in 42 states, mostly in metro areas inhigh traffic locations like malls. The com-pany is currently expanding into retail storesand now has kiosks in Wal Mart and Kroger.The machines accept e-readers, MP3s,tablet computers, cell and smart phones.

“We’ve found that our machines areconvenient and easy for people to get cashfor recycling old devices when cleaning outdrawers and getting rid of old phones, orwhen upgrading their phones,” said Rice.

To use the machine, and prevent theacceptance of stolen goods, the user has tobe 18 years or older and show a valid, statepicture ID such as a driver’s license, plus athumbprint. “While the phone is being eval-uated we have three high resolution camerasthat take photos of the person standing infront of the machine. Then back at our head-quarters in San Diego we have live humansverifying that the person in front of themachine is the person on the ID. Allmachines are live-monitored for verificationin this way,” Rice explained.

Users put their device in the ecoATM’s10” x 5” inspection station for automaticevaluation. Many devices presented have asecondary resale value. Sellers have beenpaid upwards of $250 dollars for newermodels. It depends on the make, model andcondition of the device. The machine dis-penses $1, $5 and $10 bills. If there is nomarket for refurbishing the device for resale,the ecoATM offers $1 in exchange for thedevice to ensure it gets properly recycled, orinstead of taking the $1 the user has theoption of donating it to a selection of charitypartners.

“We are simply an aggregator and ourpartners either refurbish or recycle what wecollect. We have really strong standards and

are R2 certified. That means that the compa-nies that buy phones from us have to adhereto R2 compliance standards,” said Rice.

“We also have an excellent relation-ship with law enforcement. On staff, wehave two directors of law enforcement whoare retired police officers. A key part of ourbusiness is making sure we work closelywith law enforcement to stop cell phonetheft and catch thieves,” Rice concluded.

Jamie Hastings, vice president, exter-nal and state affairs for CTIA, also knownas The Wireless Association, said, “CTIAand its member companies offer a numberof programs to encourage consumers toresponsibly retire their wireless products,including accessories. According to theEPA, recycling one million cellphonessaves enough energy to power more than185 U.S. households with electricity for ayear.

“CTIA and our participating compa-nies developed the CTIA Green WorkingGroup, which has developed some initia-tives and benchmarks. We encourage con-sumers to visit our website for step-by-stepdirections to remove their personal infor-mation before they recycle their devicesand accessories,” said Hastings.

John Shegerian, president and chiefexecutive officer of Electronic RecyclersInternational (ERI) provided insight intowhat’s happening in the business of recy-cling and refurbishing small, wirelessdevices. His company is the world’s largestprivately-held recycler of electronic waste.ERI is dual certified by R2 and e-Stewardsto de-manufacture and recycle every typeof electronic waste. With 8 U.S. locations,ERI is processing nearly 300 millionpounds of electronic waste annually.

“Currently we receive approximately50,000 cell phones per month which arerepaired and sold or responsibly recycled.In seven of our eight locations we have

separated, highly secured areas built-out tohandle the asset management part of ourbusiness. We refurbish everything fromGoogle glasses and watches to other wear-ables to cell phones and tablets. There aremassive secondary and tertiary markets inthe U.S. for these products.

“What we’re seeing in small wirelessdevices is smaller and smaller, lighter, thin-ner and also wearable. Wearables are thenext big thing. In the weeks and monthsahead it’s going to be clothing wearables.Clothing wearables with electronic sensorsare going to be huge for our industry,huge,” said Shegerian.

Wearable devices, also called techtogs, or fashion electronics are clothingand accessories incorporating computersand advanced electronics. WearableDevices Magazine estimated that 90 mil-lion wearable devices are expected to shipin 2014. And, that’s only the beginning,industry experts predict.

“And we also see growth in the partssector as well,” Shegerian continued. “Atend of life, we can remove parts fromdevices before shredding the remainder.There’s going to be a parts replacementbusiness that will be booming in the yearsahead. One of the greatest things thatcomes in to us is shattered glass. Changingout glass for a tablet or phone is part ofwhat we do.

“At the Consumer Electronics Showapproximately 20,000 new products areintroduced every year. The interestingthing about our industry, besides our shred-ding to recover plastics, metal and glass, isthe human element, which is so important.More and more skilled workers are neededto test, disassemble, data-wipe, repair,retest, recertify and resell these devices.You move from just strict automation inshredding the end-of-life stuff, to needingmore and more skilled workers in assetmanagement to handle it. While our end-of-life business has grown 30 percent peryear, which is our core business of shred-ding and making things into commodities,our asset management which covers smalldevices has grown 50 percent. That’s howbusy that sector is, and it’s growing,”Shegerian ended.

Mobile devices■Continued from Page 1

Copper Wire Stripper

Model CWS-1

American Recycler August 2014, Page A5

Florida Governor Rick Scott signedinto law legislation aimed at preventingroad accidents and fatalities involvingwaste and recycling workers and vehi-cles caused by careless drivers.

House Bill 7005, an omnibus trans-portation bill sponsored by Rep. FrankArtiles (R-Miami) and signed by Gover-nor Scott, includes a section that addedsanitation and utility vehicles to the“Move Over Act.”

Currently in Florida, when anyvehicle approaches an emergency vehi-cle or tow truck, it must move over onelane. In instances where changing lanesis unsafe or the driver is traveling on atwo-lane road, the driver must slow to aspeed 20 miles per hour (mph) less thanthe posted speed limit, unless the postedlimit is 20 mph or less. In that case, thedriver is required to slow to a speed of 5mph. This law adds sanitation and utilityvehicles to those covered under the act.

“On behalf of the Florida Chapterof the National Waste & RecyclingAssociation, I want to thank the FloridaLegislature for adding sanitation vehi-cles to the Move Over Act,” said ChuckDees, Florida chapter chair and vicepresident of public affairs for WasteManagement of Florida. “We especiallywant to recognize Rep. Holly Raschein(R- Key Largo), whose original lan-guage was incorporated into the finalversion of H.B. 7005. It was Rep.Raschein’s commitment to include sani-tation and utility workers in the MoveOver Act and the leadership of Rep.Daniel Davis (R-Jacksonville), chair ofthe House Transportation & HighwaySafety Subcommittee, which allowedthis legislation to pass this session.”

Being struck by motorists is a lead-ing cause of death for waste and recy-cling collection employees nationwideand, with proper awareness, is com-pletely preventable.

NW&RA has worked to pass simi-lar “Slow Down to Get Around” legisla-tion in other states. In addition toFlorida, NW&RA chapters have suc-cessfully championed such legislation inAlabama, West Virginia, and Wisconsin.Michigan has passed a similar law.“Slow Down to Get Around” is theindustry’s safety campaign remindingmotorists to drive more carefully whennear waste and recycling collectionvehicles.

Florida passeslegislation toprotect workers

AmericanRecycler.com

NewsVoice of Salvage, Waste and Recycling

$7.00

AR ecyclerR

Vol. 17 • Issue 7

July 2014

FOCUS: Rubber Once maligned methane gas nowan asset for energy production

WHAT’S INSIDEEPA provides job training forpollution reduction. Page A7Honeywell UOP technologypowers largest biofuel facility.Page A8

AF&PA releases paper reports.Page A11Metal theft claims see three yeardecrease. Page A15Colorado Governor signs wastetire legislation. Page B3

Stable rubber marketattracts new plant

No. 1Preferred

Publication

American RecyclerPage A6, August 2014

Engineered Solutions for Moving Your Materials in the Right Direction

SCRAP MANAGEMENT AND MATERIAL HANDLING SOLUTIONS

YOUR JOB IS TO KEEP THE SCRAP COMING. OUR JOB IS TO TAKE IT AWAY.

• Shuttle Conveyors • Diverter Chutes • Rotating Chutes• Sensor-driven performance to ensure level loading• Laser sensors detect trailer scrap levels to move shuttle as necessary for even loading. Increases scrap value and reduces cost • Allows for installation of weigh scales for improved accuracy of scrap loading

Put the experience of an industry leader to work in your facility with engineered solutions for scrap management. Choose the leader of multiple container load-out systems. Numerous design options available:

www.Mayfran.com • [email protected]

Covanta and Indianapolis Mayor Greg Ballard disclosed aplan to bring recycling to all single family homes in the city.The Covanta Advanced Recycling Center, to be built adjacent tothe Covanta Indianapolis Energy-from-Waste facility, will beone of the most modern recycling facilities in the world,designed to recover recyclables from mixed municipal solidwaste. Covanta will invest approximately $45 million to buildthe facility, which will increase the amount of material recycledin Indianapolis by up to 500 percent at no cost to the city or itsresidents.

The Covanta Advanced Recycling Center is an automatedmaterials recovery facility (MRF) modeled after successfullyoperating recycling facilities in Europe. Using the latestmechanical and sensor-based technologies, and supported byskilled operators, the facility will efficiently recover recyclablesfrom mixed waste.

The recycling plan will also give an important boost to thelocal economy, providing green jobs and additional revenue forthe city. Approximately 70 jobs will be created during construc-tion of the facility and 60 permanent, full-time workers will behired to operate the facility.

The Covanta Advanced Recycling Center will accomplishthe following:

•Recover up to 80 to 90 percent of recyclable materials,increasing recycling by approximately 500 percent.

•Reduce greenhouse gas emissions equivalent to removing40,000 cars from the road every year and save the energy equiv-alent of the annual energy use of more than 20,000 homes.

•Complement the existing energy-from-waste facility bysharing trucks and maintaining current traffic flow and avoidingadditional vehicle emissions and burdens on road infrastructure.

•Help the State of Indiana take a major step forward inrecycling, supporting the new statewide recycling goal of 50percent.

The recycling plan is subject to approval from the city’sBoard of Public Works. Covanta expects the facility to be upand running in 2016, following the receipt of necessary permits.

Covanta bringsrecycling to homesin Indianapolis

Industrial Emissions Directiveforces European glass factoriesto invest in modernizations

By 2020, around 14 billion EUR will beinvested in European glass factories. The plants haveto be modernized to comply with the new limit val-ues of the Industrial Emission Directive, which willresult in annual investment increases by up to 50 per-cent. These are the results of a study by the Germanconsultancy ecoprog.

The European Industrial Emissions Directivecame into force in 2013. For the first time ever, itdefines obligating limit values for air and wateremissions in different industrial sectors. These limitvalues are effective throughout the EU and theaffected industries have to implement them by 2016.Their respective limit values are defined in the so-called BAT reference documents and their legallybinding summaries, the BAT conclusions.

The glass industry was one of the first sectorsthese BAT conclusions have been published for.Such specifications are a completely new issue forthe companies and therefore result in considerableuncertainties. Their implementation will thus alsogive a signal to other industrial sectors.

More than 420 of the largest European glass fac-tories have to comply with the new emission limitvalues (ELVs). The ELVs for nitrogen oxides andsulphur oxides will be particularly challenging formany glass factory operators.

This means that most glass manufacturers haveto invest in modernizing their glass factories. Fundswill go to optimizing individual productionprocesses or to new technical components for fluegas cleaning, furnace technology or sealing themelter. According to a survey for this study, manyoperators in Eastern Europe are also considering toconstruct a new glass furnace.

The Industrial Emission Directive does not onlyforce the manufacturers into unscheduled invest-ments. They also have to prepone routine invest-ments as they have to comply with the ELVs at aspecific date. Up to 2.7 billion EUR will be investedin European glass factories in 2016 and 2017. Thisinvestment sum will then decrease to around 1.5 bil-lion EUR in the subsequent years.

Investments will increase the most in regionswith so far less strict legal frameworks, as is the casein many Eastern European states. However, there arealso many glass factories lacking state-of-the-arttechnology in countries such as France and Spain.

By 2020, about 2.3 billion EUR will be investedin glass factories in Eastern Europe and 4.1 billionEUR in Southern European plants. This is anincrease of up to 50 percent compared to the averageinvestments of the past years.

Wise Recycling merges with Source RecyclingWise Metals Group disclosed the merger of

Wise Recycling with Source Recycling. The mergerwill combine Wise’s five yards in Colorado, NorthCarolina, Florida and Virginia along with Wise’s net-work of feeder locations in six states with SourceRecycling’s three yards in Maryland and North Car-olina and one feeder yard in Maryland.

The new company will be named Wise Recy-cling and all of the yards will operate under the WiseRecycling name and logo. Wise will own a majorityof the equity in the new company which will consistof a new class of preferred interest and a portion ofthe common equity.

Remote Control Remote Control •• Automatic CycleAutomatic Cycle

The Enviro-Rack is the most superior auto fluid removal and dismantling

system on the market today.

All shears feature 360° continuous rotation.

ALL ENVIRO-RACKS ARE MADE IN AMERICA WITH AMERICAN STEEL FOR AMERICAN-SIZED CARS.

RECYCLINGE Q U I P M E N T S A L E S , I N CE Q U I P M E N T S A L E S , I N C

Toll-free 877-247-6629Fax 478-252-9030Wadley, Georgia

Website: www.ironax.comE-mail: [email protected]

Equipment Ready For Shipment Today

We have a NEW Doosan DX225 with a NEW Iron Ax IA25R Shear mounted

and ready to cut iron.

We have a new Iron Pack Baler in stock and ready to begin work.

Contact us for full details!

View the Iron Ax YouTube Channelto see the Iron Pack Baler

In Action Today!

• 2 Piece Cutting Tip• 8 Cutting Edges per Blade!• Low Operating Cost• Flip the Tip without Rebuilding!

According to The Carton Council of NorthAmerica, 50 percent of U.S. households can recyclecartons through curbside and other local recyclingprograms. This milestone represents the tremen-dous industry-led effort made possible by the sup-port of countless recycling, packaging, municipaland sustainability stakeholders.

Carton recycling access has grown 177 percentover the last 5 years, starting at just 18 percent in2009 when the Carton Council was first formed.Since then, impressive progress has been made inbuilding infrastructure and improving access to car-ton recycling nationwide. The Carton Council is agroup of carton manufacturers united to deliversolutions in order to divert valuable cartons fromthe landfill.

With access growing every day, cartons arequickly becoming a standard recyclable material.Since 2009, carton recycling access has been addedto more than 36 million homes and is now in 77 ofthe top 100 U.S. cities. Today, more than 58 millionhomes in 46 states have access to carton recycling.

Made primarily from a renewable resource,lightweight and compact in design and with a lowcarbon footprint, cartons have proven to be a sus-tainable packaging solution that is growing in usefor a variety of liquid and food products. Recyclingfacility managers and community program officialsare finding it necessary to integrate cartons into therecycling supply chain, where they are a provenvaluable material thanks to their high-quality, virginlong fiber. In addition to the fiber, cartons have thinlayers of polyethylene (plastic). Shelf-stable cartonsalso have a thin layer of aluminum to enable theproduct to be stored safely without refrigeration.These materials can also be recovered and recycled.

American RecyclerPage A8, August 2014

PAPER

Carton recycling access reaches 50 percent milestone

American Recycler August 2014, Page A9

• 96" Big Grapple• Approximate Weight 2,500 Lbs.

• Lifting Capacity 25,000• Tines 5/8"

• 2 Yd. and Up Loader

• 72" Skid Steer• Small Loader Grapple

36" 36" Custom Custom GrappleGrapple

Designed for 1½ to 3½ Yard LoadersLarger and Smaller Sizes Available!

Skid Steer Skid Steer Buckets and Buckets and

GrapplesGrapples

Excavator GrapplesExcavator Grapples

SCRAP SCRAP GRAPPLESGRAPPLES

Extreme Duty

ACS QCACS QC

Replacement Replacement L-tines 42"–14'L-tines 42"–14'

CustomCustomAssemblyAssembly

Shredder Shredder ForksForks

Custom AssemblyCustom Assembly

Replacement Flat TineReplacement Flat Tine

3-Pt.3-Pt.Hook-upHook-up

4-Pt. 4-Pt. Hook-upHook-up

QuickQuickCoupler -Coupler -

JRB/ITL5GLGRLGRLGR

PNEUMATIC AND SOLID

We Also Have:

• Wheels • Tubes

and Flaps • Retread

Tires • Used

Tires • New Tires

DT – Wide footprint for maximum contact and longer life. Deeper lugs for a better bite. Ideal for softer soil conditions and dirt areas.

SM – Wide footprint for maximum contact and longer life. Ideal for use on dry asphalt and concrete surfaces.

Ideal for Scrap and Auto Salvage Operations!

SKID STEER, SKID STEER, FORKLIFT, AIRCRAFT, FORKLIFT, AIRCRAFT,

LOADER TIRES

Dcclllssaa

DTDT

Loader Buckets Loader Buckets and and

GrapplesGrapples

P

SSScccuuus

SM

and cd conconcnn rretretrretretretand cd cccccconconconconcoonconconc etretretretretretretretretee eee

LGLG

LG – Wide footprint for maximum contact and longer life. Best for use in areas with sharp debris. Ideal for use on dry and wet asphalt or concrete surfaces.

ooo ::: s s s d

XHXH BLLL SLSL LDLD HRLHRL

100’s of in-stock items Heavy ply tires Reduced fl ats

Most Items

Shipped Same Day!

Deals On

New And Used

Equipment!

Bucket ForksBucket Forks

10–15 ft. 10–15 ft. Vertical Vertical

TinesTines

Skid Steer Skid Steer Universal QCUniversal QC

OUR

MANY PRODUCTS!

1-800-955-8288678-564-8691Local

3027 Summer Oak PlaceBuford, Georgia 30518

[email protected] ROBERTS COMPANY, INC.

PAPER

AF&PA releases paper reportsThe American Forest & Paper Asso-

ciation released its May U.S. paperreports.

ContainerboardContainerboard production increased

7.7 percent from April and was essen-tially flat compared to the same monthlast year. The month-over-month averagedaily production increased 4.2 percent.Shipments for May were 2,957.6 thou-sand tons, representing 167.6 billions ofsquare feet. The containerboard operatingrate for May increased 2.2 points com-pared to April.

Kraft PaperTotal Kraft paper shipments were

128.9 thousand tons, 3.4 percent lowercompared to the prior month. BleachedKraft paper shipments dropped from 11.8thousand tons in April to 9.4 in May,while unbleached Kraft paper shipmentsdecreased from 121.7 thousand tons to119.5. Overall, shipments for the first 5months of 2014 were 1.4 percent lowerthan the same period last year. Totalmonth-end inventories increased 6.4 per-cent compared to April.

Printing-Writing Paper ReportAccording to the report, total print-

ing-writing paper shipments decreasedseven percent in May compared to May2013, with total paper inventories increas-ing two percent from April levels.

•Uncoated free sheet (UFS) papershipments in May decreased 10 percentcompared to May 2013. YTD shipmentsare down 8 percent in 2014. Year-to-dateUFS imports through April are up 19 per-cent compared to the same period in2013.

•May coated free sheet (CFS) papershipments decreased six percent com-pared to the first five months of 2013.YTD shipments of coated freesheetgrades are essentially down one percentand imports through April are down fourpercent.

•Uncoated mechanical (UM) papershipments increased eight percent in May,the fourth consecutive month of year-over-year increases. Year-to-date ship-ments of UM are up three percentcompared to 2013.

The Newark Group to be acquiredCaraustar Industries, Inc., a portfo-

lio company of H.I.G. Middle Market,has entered into an agreement to acquireThe Newark Group, Inc. The acquisitionis subject to customary closing condi-tions and required regulatory approvals.

Newark is a manufacturer of recy-cled paperboard, linerboard, industrial

tubes, cores and other converted productincluding book covers and packagingsolutions. Headquartered in Cranford,New Jersey, The Newark Group hasapproximately 1,500 employees andoperates over 20 manufacturing facilitiesin the U.S. and Canada.

International Paper gainson sustainability goals

International Paper released its 2013Sustainability Report titled Connectionsthat Matter, revealing progress againstits voluntary sustainability goals andhighlighting collaborations that advancesustainability throughout the life cycleof its products. By working closely withemployees, customers, suppliers andcommunities, International Paper hasmade strong progress in a number ofareas, including:

•A 14 percent reduction in criteriaemissions from 2010 levels, exceedingthe company’s reduction goal of 10 per-cent by 2020;

•The announcement of a new goalto reduce manufacturing waste to land-fills 30 percent by 2020 and ultimatelyaim to achieve zero waste;

•A 20 percent reduction in year-over-year life-changing injuries, reflect-ing International Paper’s commitment toan accident-free workplace; and,

•The announcement of a new,higher target for third-party-certifiedfiber purchases of 35 percent globally by2020.

The report also highlights Interna-tional Paper’s collaborations with promi-nent non-governmental organizationsincluding the World Wildlife Fund,Global Forest & Trade Network and the

National Fish and Wildlife Foundation.In 2013, International Paper continuedits collaborative model to help sustainthe economic and environmental bene-fits of working forests. Efforts included:

•Granting more than $725,000 inthree U.S. regions, resulting in on-the-ground work on the Forestland StewardsInitiative, an International Paper partner-ship with the National Fish and WildlifeFoundation;

•Working with 43 landowners tocertify an additional 67,000 acres offorestland through the Forest Steward-ship Council™ group certification pro-gram; and,

•Introducing a Supplier Code ofConduct to more than 40,000 U.S. sup-pliers, furthering International Paper’ssustainable forestry goals and other sus-tainability objectives.

The report details progress againstInternational Paper’s 2020 sustainabilitygoals which were initially set in 2010and span eight impact areas: energy effi-ciency, air emissions, safety, waste,water, fiber, supply chain and philanthropy.

To see the complete report,view this article on

www.AmericanRecycler.com.

My friend recently got crushed by a pile of books, but he’s only got his shelf toblame.

American RecyclerPage A10, August 2014

800-548-6469605-352-6469

2009 E-Z Log Baler | $105,000 John Deere engine w/1,200 hours. Heat/AC, 23’ crane, joystick operation. 2001 Big Mac Crusher | $65,000 Portable Automation, New John Deere Engine - Less than 100 hours.1996 MAC Crusher Portable Remote | $42,500 Rebuilt diesel engine, remote control. Located in Central FL.1994 E-Z Crusher Elec. Stationary | $35,000 No automation. Located in Northern IA.

More trades coming in weekly, check them out on our website!

BALERS CRUSHERS BALERS CRUSHERS BALERS

2007 OverBuilt CrusherRemote control - Hyd. landing gear. Located

in Huron, SD. $85,000.

2010 E-Z Crusher Elec. Stationary248 hours. Fully automated. Like new.

Located in Northern Iowa. $90,000.

2011 Sierra 5000 Baler 150 HP with 2,445 hours, orange peel

grapple, air compressor. $275,000.

2012 OverBuilt Logger/BalerLoaded - full rotation, air compressor,

hydraulic landing gear. $345,000.

PLASTICS

Consolidated Container buystwo plastic recycling firms

Consolidated Container Co. (CCC)has acquired sister companies EnvisionPlastics Industries LLC and Ecoplast Corp.

Atlanta-based CCC, a rigid plasticpackaging company already with morethan 50 container manufacturing sites,added 2 locations in Reidsville, North Car-olina and Chino, California, for EnvisionPlastics, a polyethylene recycler.

Ecoplast, which calls itself Califor-nia’s oldest thermoplastics recycler andcustomer compounder, is located inFontana. That company handles a varietyof resins including polystyrene, ABS,polypropylene, and low, linear low andhigh density PE.

Both Ecoplast and Envision Plasticshad common ownership, Massoud Radand Parham Yedidsion, prior to their saleto CCC, which is itself owned by privateequity firm Bain Capital.

In purchasing both Ecoplast andEnvision Plastics, CCC gained 2 of thelarger plastics recyclers in the country rep-resenting nearly 200 million lbs. ofreprocessed material annually.

The companies will operate as astand-alone business, the new owners said.Scott Booth, who has been chief operatingofficer at Envision Plastics since 2008,will lead the firms along with the existingmanagement team.

Recycling program beginsThe American Chemistry Council’s

(ACC) Flexible Film Recycling Group(FFRG) is partnering with Dunn CountyWisconsin, the Wisconsin Department ofNatural Resources, Indianhead Enter-prises, Inc. and Trex Company, Inc. to helppromote a new film recycling initiative ofthe Wrap Recycling Action Program(WRAP). This WRAP pilot is designed toincrease the recycling of wraps made frompolyethylene film.

The pilot is designed to expand thecollection infrastructure for businesses andto increase public awareness and involve-ment in the recycling of postconsumerplastic film packaging. The pilot involvesrural drop-off locations, a consolidationpoint within an industrial park and a col-

lection program run by a vocational center.At present, county residents are recyclingapproximately 400 lbs. of plastic bags andwraps every 2 weeks at 7 rural collectiondepots.

There are currently more than 18,000locations across the U.S. where consumerscan bring their used polyethylene bags andwraps to be recycled, primarily at largegrocery and retail chains.

Recycling of plastic bags and wrapsexceeds one billion pounds annually in theU.S., according to a national report pre-pared by Moore Recycling Associates, Inc.The report also noted that the recycling ofplastic film has grown 56 percent sincejust 2005.

Get the 411

FREEADDESIGN

OVER34,000

READERS877-777-0043

www.AmericanRecycler.com

• The hot topics chosen for the editorial calendar

• Which equipment made it onto our Equipment Spotlight list

• Details about our incredible package deals and discounts

• A price list that hasn’t increased in years!

Call us today to receive the new 2015 Media Kit.Call us today to receive the new 2015 Media Kit.

Inside, you’ll find:

Advertising in American Recycler = 10, A-1, A-OK, aces, astonishing, astounding, awesome, best, breathtaking, cool, doozie, excellent, fab, fantastic, fictitious, first-class, good deals, greatest, groovy, immense, inconceivable, incredible, legendary, marvelous, mind-blowing, out-of-sight, out-of-this-world, outrageous, peachy, phenomenal, primo, prodigious, rad, remarkable, smart business, spectacular, striking, stupendous, super, superb, terrific, top drawer, tops, turn-on, unbelievable class, unreal value, wicked good.

Advertise in American Recycler!

AR

Plant will recycle 100 millionpounds of bottles annually

CarbonLITE Recycling LLC hassigned contracts for the supply of primaryprocess equipment to be installed in itsnew plastic recycling facility in Abilene,Texas.

The 200,000 sq.ft. plant will annuallyrecycle roughly 100 million pounds ofbeverage bottles into PET pellets that canbe used to make new bottles. It willemploy more than 100 personnel. The Car-bonLITE group currently operates a simi-lar facility in Riverside, California. Thisplant also has an annual capacity ofroughly 100 million pounds. In keepingwith its philosophy of carbon reduction,CarbonLITE intends to power the Abileneplant with 100 percent green energy.

The new plant’s front-end, bale-open-ing and bottle-sorting will be built by Bulk

Handling Systems of Eugene, Oregonusing sorting modules from its subsidiary,NRT of Nashville, Tennessee. The label-removal, bottle-washing, grinding andflake-washing modules will be sourcedfrom AMUT S.p.A of Novara, Italy, andfood grade purification and pelletizing willuse the Prime technology from EREMANorth America Inc. Total investment inequipment and infrastructure will exceed$60 million.

CarbonLITE has a strategic alliancewith Nestlé Waters North America and itsAbilene plant will be supplying Nestlé’sbottling facilities near Dallas.

Installation of the equipment in Abi-lene will begin in Q4 2014 with first pro-duction expected in Q2 2015.

Vega earns certification for bottles Plant-based nutrition company, Vega,

has received 100 percent post-consumerrecycled content certification from leadingthird-party certification firm, SCS GlobalServices, for its recycled post-consumer(PCR) plastic bottles. Vega’s new packag-ing, used for its nutritional supplements, ismade with Envision Plastics’ EcoPrime™

resin, the first food grade recycled HDPE(#2) plastic available in the marketplace.

Vega launched its sustainable pack-aging initiative after an internal sustain-ability audit revealed that over 70percent of its carbon footprint wasrelated to its packaging materials,

specifically petroleum-derived virginHDPE plastic. As part of its “Journey toZero” initiative to reduce greenhouse gasemissions, Vega partnered with EnvisionPlastics to develop a system for recy-cling plastic jugs, milk bottles and other#2 plastics into a food grade vessel.

According to Vega’s research, in 2014its switch from virgin plastic to 100 per-cent certified PCR bottles will result in278 fewer tons of CO2 emissions (63 per-cent less), divert 233 tons of plastic fromthe waste stream, and use 86 percent lessenergy than virgin plastic.

American Recycler August 2014, Page A11

View products in action on our YouTube channel!

3010P TUB GRINDER

BAD BOY BLUE“BEATS STUMPS INTO SPLINTERS”

Call today or visit us online to learn more.

888-210-0902w w w.duratech.info

BAD BOY BLUEBAD BOY BLUEBAD BOY BLUEBAD BOY BLUEBAAD BBOY BBLUE

gotcasters.com

Quality products at great prices!Best service in the industry.

CASTERS ∙ WHEELS ∙ MATERIAL HANDLING COMPONENTS

got casters??®

877-496-5300

WASTE

A Missouri Department of NaturalResources on-site inspector detected ele-vated levels of benzene at the Bridgetonlandfill’s perimeter substantially in excessof site-specific standards established bythe Missouri Department of Health.

The Bridgeton landfill, a subsidiaryof Republic Services, has drawn the ire ofneighboring businesses and residents eversince an underground fire was detectedthere over three years ago.

Bridgeton is a suburb of St. Louis,Missouri.

The U.S. Environmental ProtectionAgency, which is overseeing the cleanupof the radioactive waste in the nearbyWestlake landfill, has stated that the land-fill does not pose a health risk.

“The release of benzene by Republicinto the environment at the BridgetonLandfill is unacceptable,” Attorney Gen-eral Chris Koster said in a statement.“Despite the order Republic agreed tomore than a year ago, the company stilldoes not appear to have the situation undercontrol. My office is asking the court tocompel Republic to take additional stepsto prevent any such future release of haz-ardous material into the air.”

Attorney General Koster demandsadditional remedial measures by RepublicServices to protect public health and theenvironment.

In a filing in St. Louis County Cir-cuit Court, Koster is seeking a prelimi-nary injunction for more aggressivelandfill management by Republic, aswell as additional reimbursement to thestate of Missouri for its monitoring ofthe site. Specifically, Koster asked thecourt to order:

•Installation of additional controlsystems to prevent hazardous sub-stances, such as benzene, from enteringthe air around the site;

•Additional comprehensive air sam-pling for hazardous substances, includ-ing benzene and other volatile organiccompounds;

•Additional odor-control measures;•Enhanced monitoring of the slope andstability of the landfill itself.

Koster also asked the court to orderRepublic to reimburse the state an additional $315,000 for site monitoringexpenses. Previously, Republic agreedto reimburse the state for costs associated with oversight of the landfill,up to $900,000. However, the state’scosts associated with monitoring thelandfill have thus far exceeded $1.2 million.

The state’s demand for additionalcost recovery under the Agreed Orderdoes not affect future demands for dam-ages and penalties expected to be a part

of the underlying pending lawsuitagainst Republic.

Recognizing that potential threatsto public safety may extend beyond theboundaries of the Westlake site, Kosteralso submitted a Freedom of Informa-tion Act (FOIA) request with the EPAand the U.S. Army Corps of Engineers(Army Corps) demanding raw samplingdata and results from previous radio-logical testing along roadways leadingto the Westlake Landfill.

Koster called upon the EPA to testfor radiological contamination alongcertain roadways leading to the West-lake Landfill, focusing specifically onroutes used during the 1970s to haulradiological material from the LattyAvenue storage facility to Westlake.The EPA has declined to conduct newtesting, stating as its rationale that sim-ilar sampling was conducted prior to2005.

In response, Koster demanded thatEPA and the Army Corps share the rawdata with the State of Missouri; how-ever, both agencies have indicated theyare now having difficulty locating thedata. Koster’s FOIA request is a formaldemand that such data be immediatelyfound and produced.

Benzene gas detected at Missouri landfills

New Jersey’s Department of Environ-mental Protection’s (DEP) new initiativeto crack down on illegal dumping in stateparks and natural lands has resulted incharges of a Seaside Heights man who hasbeen court ordered to pay more than$21,000 in penalties.

The DEP’s “Don’t Waste Our OpenSpace” campaign was launched in lateMarch. Since the launch, investigations ofillegal dump sites on state properties byState Park Police, Division of Fish &Wildlife’s Conservation Officers andDEP’s Compliance & Enforcement per-sonnel has resulted in 10 arrests orenforcement actions.

On April 26, Conservation OfficerSean McManus located eight garbagebags with siding shingles containingasbestos and other debris along DoverRoad in the Greenwood Forest WildlifeManagement Area in Lacey Township,Ocean County. An investigation of thecontents in the garbage led McManus toAdam Wardell of Seaside Heights.

Wardell acknowledged dumping thegarbage bags after being paid to removethem from a residence in Brick Township,according to Division of Fish & WildlifeConservation Officers. Wardell wascharged with illegally dumping solidwaste in a State Wildlife ManagementArea. On June 17, under a plea agreementat Lacey Township Municipal Court,Wardell pled guilty and was ordered topay $21,533 in penalties.

The “Don’t Waste Our Open Space”program is a coordinated effort of a host ofDEP agencies, including Parks, Fish &Wildlife, Solid Waste, Water Resources,State Forestry Services and the NaturalLands Trust. All activities of this new effort are posted on www.stopdumping.nj.gov.

Strategically deployed motion-sensorcameras have been set up in select stateparks and wildlife management areas tohelp nab violators.

Seaside Heightsman charged inillegal dumping

DADE Capital Corp.

800-823-9688Perrysburg, OH

GREAT RATES!

Visit www.DADECapital.comfor more photos

and other available equipment.

DEALER FINANCINGNEW EQUIPMENT FINANCINGUSED EQUIPMENT FINANCING

PRIVATE SALE FINANCINGExcellent condition with only 2,500 hours. $425,000

2010 SIERRA 500SL SHEAR LOGGER BALER

2011 Hitachi 225LC with 2012 Genesis GXP300R shear. $196,0002011 HITACHI 225LC W/SHEAR

Being completely rebuilt. $68,0002006 LABOUNTY MSD3000 SHEAR

16,665 hours. Engine replaced 11,766 hours. $168,0002007 SENNEBOGEN 850M W/ GENSET

In great operating condition. $99,0002003 CATERPILLAR 330C

Completely rebuilt by dealer. Very nice shear at a very good price. $68,000

2000 GENESIS GMS 400 SHEAR

4,200 hours. Good condition, great price! $265,0002010 AL-JON 580CL CAR LOGGER

GOOD condition. $98,500 1996 AL-JON 400 METAL BALER

Nice condition, ready to work. $205,0002006 LOLLINI AUTO LOGGER AL6000

Good condition. Fresh motor and main pump. $155,0002002 FUCHS MHL 360

This Harris 1335-ton shear was completely rebuilt only months

before it was professionally decommissioned and dismantled.

It is immediately available for sale and ready to be loaded on trucks,

railcars or sea vessels.$595,000. USD

Harris BSH1335-Ton Shear

This shear comes with THOUSANDS

OF DOLLARS in new spare parts!

1,200 hours. Very good condition. $121,0002009 E-Z METAL BALER

Equipped with a 5-tine grapple and 48” magnet. Almost NEW with only 200 hours and grapple never used. $310,000

2011 FUCHS MHL335

6 cylinder John Deere engine. Well maintained. $80,0002007 OVERBUILT MODEL 10 CAR CRUSHER

2,750 hours. Includes Lincoln Quik Lube. $275,0002008 ELECTRIC AL-JON 400XL BALER

Koehring 6630 SK material handler with 15kW hydraulically driven genset. 8.3 Cummins power. $47,500

KOEHRING 6630 SK MATERIAL HANDLER

Rebuilt like new. $110,0002005 LABOUNTY MSD4500R ROTATING SHEAR

1999 Sierra 500 ton shear/logger/baler. $127,5001999 SIERRA 500T SHEAR/LOGGER/BALER

1,500 hp EMD Diesel power complete shredding system and spare parts. Great price! Call for all the details, see it running. $750,000

WILLIAMS 60 X 60 METAL SHREDDER

Great price! Recently painted and reworked. $70,0001988 AL-JON 400 METAL BALER

7,600 hours. Good condition and immediately available. $195,0002006 AL-JON 400 XL METAL BALER

READY TO SHIP!

Girls Scouts of Kansas HeartlandCouncil received the National RecyclingChampion award in the third annualGreat American Can RoundUp (GACR)Scout Council Challenge by recycling32,199 lbs. of aluminum cans and gener-ating more than $16,000 for scoutingactivities. The top recycling troop of the

2014 GACR Scout Council Challenge,Troop 50244 from Hutchinson, Kansas,won $500, plus the value of the cans col-lected for recycling nearly 1,500 lbs. ofaluminum per scout.

The GACR Scout Council Chal-lenge, sponsored by the Can Manufac-turers Institute, is designed to create

awareness of the environmental benefitsof recycling cans. The challenge beganon January 15, 2014, and ended on April30, 2014. A total of 27 councils com-peted for top honors with more than 800scouts from 56 troops participating inthis year’s recycling challenge.

Second and third place troop recy-cling honors went to Girl Scout Troop50028 from Kansas Heartland Counciland Girl Scout Troop 9869 from GirlScouts of Greater South Texas Council.These top ranking troops recycled 976and 363 lbs. per capita, respectively.

The Girl Scouts of Greater SouthTexas Council distinguished itself asGACR Reserve National RecyclingCouncil Champions by recycling morethan 3,460 lbs. of aluminum beveragecans and won $300.

Scouts recycle more than 57,000 pounds of cans

Based on preliminary CensusBureau data, the American Iron andSteel Institute (AISI) reported that theU.S. imported a total of 4,016,000 nettons (NT) of steel in May, including2,925,000 NT of finished steel (up 7.4percent and 6.4 percent, respectively, vs.April final data). Year-to-date (YTD)total and finished steel imports are17,480,000 and 12,829,000 NT, respec-tively, up 32 percent and 23 percentrespectively, vs. 2013.

Key finished steel products with asignificant import increase in May com-pared to April are oil country goods (up55 percent), heavy structural shapes (up44 percent), tin plate (up 39 percent),standard pipe (up 22 percent), line pipe(up 22 percent), hot rolled sheets (up 21percent) and sheets and strip galvanizedhot dipped (up 21 percent). Major prod-ucts with significant YTD importincreases vs. the same period last yearinclude wire rods (up 96 percent), platesin coils (up 76 percent), cold rolledsheets (up 56 percent), sheets and stripall other metallic coatings (up 47 per-cent), sheets and strip galvanized hot

dipped (up 40 percent), hot rolled sheets(39 percent), mechanical tubing (35 per-cent), oil country goods (up 26 percent),reinforcing bars (up 24 percent), cutlengths plates (up 24 percent) and heavystructural shapes up 20 percent).

In May, the largest volumes of fin-ished steel imports from offshore werefrom South Korea (584,000 NT, up 45percent vs. April final), China (303,000

NT, down 27 percent), Turkey (149,000NT, up 5 percent), Japan (145,000 NT,down 31 percent) and Taiwan (106,000NT, up 19 percent). For 5 months of2014, the largest offshore suppliers wereSouth Korea (2,152,000 NT, up 42 per-cent), China (1,286,000 NT, up 73 per-cent), Japan (852,000 NT, up 3 percent),Turkey (760,000 NT, up 19 percent) andRussia (501,000 NT, up 324 percent).

American RecyclerPage A14, August 2014

STANDARD FEATURES

Thelightweight

alternativefor

hauling scrap!

www.maurermfg.com888-274-6010

GondolaTrailers

Trailersavailable withHARDOX®450

• Trailer lengths: 40’, 44’ and 48’• Choice of 4’, 5’, 6’ or 8’ side walls• 22.5k tandem axles with one axle ABS brake• Three-leaf, heavy duty, spring suspension, closed tandem• Two-speed landing gear• Sealed wiring system designed for Maurer by Trucklite• Phosphate washed for superior adhesion• All exterior mating surfaces are caulked prior to paint • Diamond Vogel polyurethane primer and paint • D.O.T. approved conspicuity tape and rubber mounted lights• Anti-sail mud flaps

SSI Shredding Systems, Inc. www.ssiworld.com | [email protected] | Tel: (503) 682-3633Shredding everything including the kitchen sink at www.WatchItShred.com

PAPER FOILPOLY FOILBARE FOIL

~ We also buy surplus rolls ~

CONNECTICUTMETAL INDUSTRIES

www.CTMetal.com

WE BUY FOILLAMINATES

U.S. IMPORTS OF FINISHED STEEL MILL PRODUCTS BY COUNTRY OF ORIGIN (Thousands of Net Tons)

SOUTH KOREACHINAJAPANTURKEYRUSSIAGERMANYTAIWANAll OthersTOTAL

MAY2014584303145149103105106

1,4302,925

APR20144024162101421109990

1,2802,748

2014Annual (est)

5,1653,0882,0451,8251,2021,1581,077

15,23130,790

2013Annual3,6511,6521,9311,347

5951,279

83313,54324,829

% Change 2014Annual vs. 2013

41.5%86.9%

5.9%35.5%

101.9%-9.4%29.3%12.5%24.0%

METALS

Steel imports increase 7 percent in MayAll four Metal Recycling Services

(MRS) locations won the North CarolinaDepartment of Labor’s “Certificate ofSafety Achievement” for 2013. This placesMRS in a select group of businesses andpublic agencies in North Carolina. This isthe second year in a row that Monroe,Marion, and Whiteville were recognizedfor their safety record; it is the first yearfor Gastonia. Each facility was awardedthe North Carolina Department of Labor(NCDOL)’s Gold level Certificate ofSafety Achievement, the state’s highestsafety award.

This annual awards program, run bythe NCDOL, recognizes companies thatstrive to excel in safety. In order to qualifyfor the gold award, each company musthave ten or more full time employees,must have had no lost time accidents andalso must have achieved incident rates 50percent below their NAICS code.

Metal Recycling Services operatesfour scrap recycling facilities in NorthCarolina: Gastonia, Marion, Monroe andWhiteville.

MRS facilitiesreceive award

Based on the Commerce Depart-ment’s most recent Steel Import Moni-toring and Analysis (SIMA) data, theAmerican Iron and Steel Institute (AISI)reported that steel import permit appli-cations for the month of May total3,950,000 net tons (NT). This was a 7percent increase from the 3,706,000 per-mit tons recorded in April and a 6 per-cent increase from the April Preliminaryimports total of 3,726,000 NT. Importpermit tonnage for finished steel in Maywas 2,823,000, up 3 percent from thepreliminary imports total of 2,738,000in April. For the first 5 months of 2014(including May SIMA and April Prelim-inary), total and finished steel importswere 17,401,000 NT and 12,717,000NT, respectively, up 31 percent and 22percent from the same period in 2013.The estimated finished steel import mar-ket share in May was 27 percent and is26 percent year-to-date (YTD).

Finished steel imports with largeincreases in May permits vs. the AprilPreliminary included oil country goods(up 58 percent), tin plate (up 38 per-cent), heavy structural shapes (up 38percent), structural pipe and tubing (up29 percent), line pipe (up 21 percent),hot rolled sheets (up 18 percent), stan-dard pipe (up 15 percent) and sheets andstrip hot dipped galvanized (up 13 per-cent). Products with significant year-to-date (YTD) increases vs. the sameperiod in 2013 include wire rods (up 94percent), plates in coils (up 72 percent),cold rolled sheets (up 53 percent),sheetsand strip all other metallic coatings (up46 percent), hot rolled sheets (39 per-cent), sheets and strip hot dipped galva-nized (up 38 percent), mechanicaltubing (34 percent), oil country goods(up 27 percent), reinforcing bars (up 22percent) and cut lengths plates (up 20percent).

American Recycler August 2014, Page A15

INCREASE PROFITS

518-424-1168www.RecyclingFurnaces.com

RRECYCLING ECYCLING SERVICESERVICES

INTERNATIONALNTERNATIONAL • Built for years of continued service.

• New technology burner and control systems.

• Permit assistance available.

• Large hearth opening for automotive scrap.

INCREASE PROFITS with the

With a US Furnace’s MAX-4000 Hi Efficiency

Sweat Furnace, get the lowest fuel cost per lb

to process than any other furnace manufacturer —

GUARANTEED! The lowest melt loss rate than

any other manufacturer — GUARANTEED! On-site

installation, training & service.

most efficient sweat furnace!

FULL EPAcompliance

GUARANTEED.

DISCLAIMER: American Recycler (AR) collects pricing and other information from experienced buyers, sellers and facilitators of scrap metal transactionsthroughout the industry. All figures are believed to be reliable and represent approximate pricing based on information obtained by AR (if applicable) prior topublication. Factors such as grades, quality, volumes and other considerations will invariably affect actual transaction prices. Figures shown may not be con-sistent with pricing for commodities associated with a futures market. While the objective is to provide credible information, there is always a chance for humanerror or unforeseen circumstances leading to error or omission. As such, AR is not responsible for the accuracy or completeness of the information provided,or for outcomes arising from use of this information. American Recycler disclaims any liability to any person or entity for loss or damage resulting from errorsor omissions, including those resulting from negligence of AR, its employees, agents or other representatives.

Commodity Zone 1 Zone 2 Zone 3 Zone 4 Zone 5#1 Bushelings per gross ton $276.00 $282.00 $296.00 $375.00 $385.00#1 Bundles per gross ton 271.00 280.00 289.00 370.00 365.00Plate and Structural per gross ton 271.00 280.00 295.00 370.00 372.00#1 & 2 Mixed Steel per gross ton 268.00 285.00 295.00 335.00 345.00Shredder Bundles (t in) per gross ton 228.00 259.00 225.00 285.00 278.00Crushed Auto Bodies per gross ton 228.00 259.00 225.00 285.00 278.00Steel Turnings per gross ton 175.00 170.00 139.00 225.00 248.00#1 Copper per pound 2.90 2.89 3.00 2.90 3.11#2 Copper per pound 2.81 2.73 2.82 2.80 3.02Aluminum Cans per pound .65 .70 .77 .70 .73Auto Radiators per pound 1.95 1.91 1.95 1.94 1.98Aluminum Core Radiators per pound .61 .65 .73 .70 .65Heater Cores per pound 1.60 1.42 1.37 1.60 1.75Stainless Steel per pound .70 .72 .79 .83 .82All prices are expressed in USD. Printed as a reader service only.

May SIMA imports datareflect import marketshare at 27 percent in May

METALS

April steel shipments down1.2 percent from March

The American Iron and Steel Insti-tute (AISI) reported that for the monthof April 2014, U.S. steel mills shipped8,235,096 net tons, a 1.2 percentdecrease from the 8,337,578 net tonsshipped in the previous month, March2014, and a 3.2 percent increase fromthe 7,978,531 net tons shipped in April2013. Shipments year-to-date in 2014

are 32,086,347 net tons, a 1.7 percentincrease versus 2013 shipments of31,547,910 net tons for four months.

A comparison of April shipments tothe previous month of March shows thefollowing changes: hot rolled sheet, up2.0 percent; hot dipped galvanizedsheets and strip, no change; and coldrolled sheet, down 0.1 percent.

RUBBERRubber established asplayground safety surface

The Institute of Scrap RecyclingIndustries (ISRI) disclosed that it played asignificant role in the establishment ofstandard specifications for loose-fill rubberused in playground surfacing. ISRI mem-bers actively participated as part of a task-force within ASTM’s F08.63 committeeon Playground Surfacing Systems to cre-ate the Standard Specification for Loose-Fill Rubber for Use as a PlaygroundSafety Surface under and around Play-ground Equipment (standard designationASTM F3012).

“The work of ISRI members and thetaskforce in creating this standard specifi-cation will lead to safer, more uniform

loose-fill rubber playground surfacingproducts,” said Robin Wiener, president ofISRI. “By selecting a surface material thatmeets the standard, playground operatorswill have the confidence of knowingexactly what the material is children willbe playing on, and that it is safe.”

As part of the drafting process, thetaskforce considered points of view frommany stakeholders, including the recyclingindustry, playground equipment manufac-turers, playground operators, concernedparents, government and many others.

For a direct link to the summary and fullversion of F3012, view this article on

www.AmericanRecycler.com.

OSHA cites Liberty Tire for violationsLiberty Tire Recycling LLC has been

cited by the U.S. Department of Labor’sOccupational Safety and Health Adminis-tration for repeat safety violations forexposing workers to falls, fire/explosionand dangerous, unguarded equipment.OSHA cited the Port St. Lucie recyclerfollowing a Site-Specific Targeting inspec-tion in January 2014. Proposed penaltiestotal $45,000.

Two repeat citations, carrying penal-ties of $30,000, were issued for exposingworkers to fall hazards while working onplatforms that lacked guardrails or hadincomplete guardrails, and for exposingworkers to caught-in hazards while theyworked near unguarded shaft and con-

veyor belts. In November 2013, the com-pany was cited for these same violations atits facility in Saltillo, Mississippi.

Three serious violations, with$15,000 in penalties, were cited for expos-ing workers to safety hazards while a pow-ered industrial truck was operating with nofunctioning backup alarm or front lights.Additionally, employees were exposed tofire/explosion hazards from the accumula-tion of rubber dust and hazards fromunguarded dangerous machinery on con-veyors. A serious violation occurs whenthere is substantial probability that deathor serious physical harm could result froma hazard about which the employer knewor should have known.

The U.S. Environmental ProtectionAgency (EPA) has reached a legal settle-ment with W.R. Recycling of Cabo Rojo,Puerto Rico, resolving alleged violationsof federal hazardous waste law. W.R.Recycling is the owner and operator of anauto crushing and scrap recycling busi-ness. As part of the settlement, W.R. Recy-cling will make a range of siteimprovements to control runoff and invest$133,000 in a project to purchase andinstall equipment that will ensure the clean

extraction, removal and storage of harmfulliquids from all the vehicles it handles.These upgrades will benefit the environ-ment and the community and are notlegally required to bring the company intocompliance. In addition, W.R. Recyclingwill come into compliance with all federallaws and pay a $29,000 penalty.

“Recycling old cars has many bene-fits, but the process must be done in a waythat does not cause pollution,” said EPAregional administrator Judith A. Enck.

“This agreement will modernize the carrecycling operation in Cabo Rojo, ensur-ing that the facility is complying with allenvironmental laws.

Under the settlement’s terms, W.R.Recycling will construct a sealed concretepad, with a drainage collection system andan oil water separator, on which all vehi-cles it handles will be processed, crushed,and stored prior to shipping of the crushedcars for metal recovery. A roof will bebuilt over the vehicle crushing area toshield the fluids collection and crushingprocesses from rainwater. The companywill also purchase and use specializedrecovery equipment to ensure the cleanextraction, removal and storage of trans-mission and engine oil, gasoline and dieselfuel, coolant and refrigerants. This recov-ery equipment will ensure that all vehiclefluids are collected and segregated forreuse or recycling. The facility improve-ments and new equipment will help pre-vent the release of hazardous wastes intothe environment during W.R. Recycling’soperations.

Among the equipment purchased byW.R. Recycling is a mobile automotive

fluid recovery unit that will enable thecompany to process scrap vehicles notonly at its Cabo Rojo base but also at otherlocations in Puerto Rico where there areno other scrap operators. In areas that lackscrap processors, cars are often abandonedand the fluids and hazardous componentsare left, resulting in the potential for leaksand releases into the environment. Vehiclefluids and potentially hazardous car partssuch as mercury switches, lead wheelweights, batteries and airbag cartridgesshould be reused or recycled.

On three occasions from 2009 to2012, the EPA inspected W.R. Recycling’sfacility to determine its compliance withfederal hazardous waste regulations. As aresult of these inspections, the EPA issueda legal complaint to the company. Amongthe violations cited in the complaint werethe company’s failure to make hazardouswaste determinations for the fluids anddiscarded materials it generates, its failureto minimize the releases of hazardousmaterials, the disposal of hazardous wastewithout a permit, the improper disposal ofused oil and the failure to label used oilstorage containers.

EPA settles with Puerto Rico auto crushing company

American RecyclerPage A16, August 2014

866-804-3829www.arpiusa.com

Patented cam design gives two models to choose from!

RES14awg,

up to 600mcm

COMC16awg,

up to 250mcm

Pat

Strip single or multiple plastic-coated electrical wireSAFELY, ECONOMICALLY and EASILY

ttwoo mmoodddeells tto cchhoooossee fffrroomm!!teenntteeddd ccaamm dddeessiiggnn ggiivees tt

SAFELY, ECONOMICALLY and EASILYWITHOUR

PROCESSES up to 4,200 FEET PER HOUR!

by Ron SturgeonAutosalvageconsultant.com

Salvaging Millions

A continuing series of articles onincreasing profits and cash flows.

Increasing sales often takes monthsand requires the capital to buy more carsand absorb more marketing expenses. Wanta quicker path to increased profitability?