Aquaculture Design Project

-

Upload

brendan-luther -

Category

Documents

-

view

106 -

download

0

Transcript of Aquaculture Design Project

Aquaculture Design Project: Black Sea Bass

Brendan Luther WFB 4500

Introduction

The bulk of fin-‐fish aquaculture in the United States consists of trout, tilapia and catfish. These fish, while great table fair, command a low price requiring large operations to make significant financial gains. In addition, their relative ease of cultivation allows almost unlimited entry into the market where economical.

In this paper, a recirculating system is designed to produce Black Sea Bass, Centropristis striata. A popular seafood fish comparable in value to grouper and snapper, this fish is native to the east coast of the United States. The complicated nature of mariculture (marine aquaculture) and recirculating systems is inherently prohibitive to entry into the market. Also, as wild stocks are depleted and established markets wanting, Black Sea Bass have the possibility of being a very profitable species for aquaculture.

Research on Black Sea Bass as a candidate for commercial aquaculture is still in its infancy, but early signs are promising. The Southern Regional Aquaculture Center has compiled data from a range of research projects to outline the diet needs, stocking densities and economics of culturing the species. It is from this document that most of the numerical values in this paper are based.

Black Sea Bass, courtesy of www.chefs-‐resources.com

Goal and Scope

The goal of this research project is to design a recirculating aquaculture system for Black Sea Bass in a 50’ x 30’ greenhouse. There are many calculations and consideration that need to be made before constructing a system of this nature for commercial use. Energy consumption, filtration design, feed economics, and bottom line profits are just a few of the very critical analyses that are crucial to the success

of a business raising fish in recirculating systems; these however are outside the scope of this project. The focus is instead on mathematically analyzing feed schedules, stocking densities, and yearly production. Greenhouse Design and Grow out Dynamics

For a small operation of this kind, it is likely uneconomical to hatch the sea bass within the greenhouse. Luckily, there are small-‐scale dealers that sell fingerling Black Sea Bass, such as University of North Carolina at Wilmington. Therefore the start of the growout process will begin with a nursery to grow the fingerling fish. As fish inevitably die throughout the growout process, the number of fingerlings purchased must be larger than the final harvest number desired. Therefore a starting number of fingerlings are back calculated from the max number of fish possible at harvest for the 12 foot diameter tanks based on biomass densities (N= 813 fish).

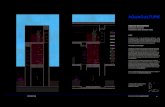

Figure 1: The Greenhouse recirculating system design

Nursery Raceway System:

The fingerlings begin in the nursery immediately after being received from the dealer. A 25% mortality of fish post nursery (SRAC), and a similar mortality rate of 25% (somewhat arbitrary) of fingerlings in the nursery due to stress and the cannabilistic nature of their early life are assumed. Therefore the number of fingerlings purchased per batch must be roughly 1450 fish. Based on research, cannibalism can be reduced by increasing stocking density between 1-‐5 fish per L (Watanabe and Truesdale, 2008) and fast flow-‐rates of between .04-‐.09 m/sec in rectangular raceway systems. The fish will be moved to the first of the grow-‐out tanks at a mean weight of 30 grams. Subsequently, to keep a biomass density below 53 kg/ cubic meter (SRAC, Watanabe) a stocking density of 2 fish/L can be used; within the desired range Watanabe and Treusdale found. Therefore the volume needed for the nursery is simply the final weight of the fish before transfer to the next tank, divided by the max biomass density. A raceway tank with dimension of 1.3’ x 2.3’ x 5.4’ (h, w, l) satisfies the volumetric requirement. The flowrate for this tank will be .09 m/sec to minimize cannibalism (SRAC).

Black Sea Bass fingerlings can be raised on commercial pellet feed. Below is the feed schedule for the nursery (dph= days post harvest). Feed pellets require a protein composition of 50%. (SRAC) 60-‐74dph: 1mm feed @ 4% body weight per day 75-‐95 dph: 3mm feed @ 3% body weight per day 95-‐124 dph: 5mm feed, feed until satiation 125 dph: transfer to grow out tank Grow Out Tanks:

Stocking small fish in a large tank and growing them to a large size within the same tank is an inefficient way to grow fish in a recirculating aquaculture system. This method uses an unnecessary amount of energy to heat and pump water. Also, as stated previously, higher stocking at a smaller size reduces cannibalism. Therefore three different tank sizes were designed for the grow out process (post nursery) as can be seen in Figure 1. This allows for a more efficient use of energy, reducing running costs, and keeps biomass densities high. Black Sea Bass are also resilient when it comes to being handled (SRAC), therefore little mortality is expected when tank transfers take place.

Just as was done with the nursery system, numbers of fish in each tank are back calculated from the final harvest number and the tank volume needed to satisfy the max biomass density. Based on the numbers found in the SRAC document, fish at UNCW took 20 months post hatch to grow to an average weight of over 500 g on commercial feed. The 20 months (600 days) minus the time spent in the nursery

gives the grow out time for the fish. Each batch of fish will spend 1/3 of the grow out time in each tank (approximately 160 days). Assuming a linear growth rate between an initial weight of 27g and a final weight 900g (based on fish fed tilapia in unpublished data from Richard Lee, Skidaway institute of Oceanography), the mean weight at transfer for tanks 5 &6 , and tanks 3&4 are .332 kg and .662 kg respectively. The growth estimates are conservatively based on the grow out time of commercial pellet fed fish with no culling. If slow growing fish are culled, the growth rate will likely be faster (SRAC). Justification for the tank sizes, based on biomass density at transfer, is given below for each of the 4ft deep tanks. Each tank’s pump systems would be set to make a 10% water exchange per day. Fish will be fed pellet commercial feed until they reach a mean weight of 100 grams. A study performed by Richard Lee at the Skidaway Institute of Oceanography compared growth rates of fish fed commercial feed versus live tilapia beginning at 100 grams. The difference was drastic. With the commercial feed, the fish grew to 500 grams while the tilapia fed fish grew to 900 grams in the same length of time (270 days). Therefore in this designed system, the fish will be fed live fingerling tilapia once they reach a mean weight of 100 grams. The fish will be fed 0.75% of their body weight in tilapia each day. This feeding rate is based on calculations using the feed conversion ratio of 1.12 (SRAC) over the grow-‐out period. Justifications are listed in the Calculations section.

Photo of tilapia fingerlings, courtesy of www.alohaecowas.com

While neither the economics of using live tilapia, or the size of the tilapia hatchery production system needed is calculated in this design project, it is likely feasible. Tilapia reproduce rapidly and grow fast. Therefore with a large enough broodstock, and they right sized system, a huge number of small tilapia could be

grown to feed the sea bass. This is attractive for many reasons. On environmental front, tilapia can be raised on pellets that contain no fishmeal. Therefore the net use of wild caught fishmeal after the sea bass reach 100 g is 0. Secondly the sea bass grow much more rapidly to a large, highly marketable size allowing for more production per year. Thirdly, the process can be considered organic, an important factor potentially for sushi niche markets (Skidaway institute of Oceanography website). Production per year, with 8 separate batches at different life stages grown at a time, could reasonably produce 4 batches of market size fish. This should roughly be 3252 Black Sea Bass per year. At a market gate price of $11.20 per kg (SRAC), total yearly revenue before operation and feed costs is $32,780, using the mean harvest weight of .9 kg.

Photo courtesy of www.hungrynative.com

Additional Design Considerations:

While calculating the scale and flow rate numbers for the filtration system was outside the scope of this project, a sketch of the ones that would likely be used were included. There would be two large microbial mat solid filtration beds; one for each side of the greenhouse. There would also be a fluidized sand filter column for each of the two solid filtration beds. This design is based off the one used at the Skidaway Institute for Oceanography research center raising Black Sea Bass. A smaller version of this filtration system would be used for each of the nursery raceways as can be seen in the diagram.

Calculations: Nursery Tank Calculations

€

Nn = NT1,2/.75 =1084

N0 = Nn /.75 =1445

Vn= Volume of nursery N(T 1,2)=Number of fish at harvest Nn= Number of fish transferred from nursery raceway N0= Number of fish places in nursery

Tank 5,6 Calculations:

€

NT5,6=NT1.2

.75− (1/3)(Nn − NT1,2

) = 994 N(T 5,6)= Number of fish at transfer from tanks 5 and 6

€

VT5,6 = NT5,6(ρb

−1)(mfish ) = (994)(53kgm−3)−1(.332kg) = 6.22m3 V(T 5,6)= volume of tanks 5 and 6 ρb=max biomass density mfish= mass per fish at transfer (based on interpolating linear growth per time) Tank 5,6 Dimensions: D=8ft, h = 4ft

Tank 3,4 Calculations:

€

NT3,4=NT1.2

.75− (2 /3)(Nn − NT1,2

) = 904

€

VT3,4 = NT3,4(ρb

−1)(mfish ) = (994)(53kgm−3)−1(.662kg) =10.5m3

Tank 3,4 Dimensions: D=10ft, h=4 ft Number of fish at harvest:

€

NT1,2=VT1,2 (ρb

−1)(mfish ) = (13.8m3)(53kgm−3)−1(.9kg) = 813 fish

€

Vn = (1084 fish)(.027kgfish

)( m3

53kg) = .55m3

Grow Out Feed Schedule Determination *This calculation shows how a single number for feed required as a function on body mass per fish per day was determined. A function, f(t), was created to show the fishes body mass as a function of time. This function was then integrated over 270 days with a coefficient β to represent the growth per day as a percentage of body weight. Once β was found, it was simply multiplied by the FCR to find the feed needed per fish, per day, as a function of total body weight.

€

f (t) = xt +100900g = x(270d) +100x = 2.96g /day

F(t) = β f (t)dt0

270

∫

F(t) = β (2.96t +100)dt0

270

∫

900 = β[2.962

t 2 +100t]0270

900 = β[1.48(270)2 +100(270)]900 = β(134892)β = .00667βf = FCR × β =1.12 × .00667 = .00747βf = .75%

Where: f(t): Body mass as a function of time F(t): Body mass as a function of time t: time β: Growth per day as a function of body mass βf: Feed required per day as a function of body mass FCR: Feed Conversion Ratio

References Watanabe, W.O. and S.G. Truesdale. 2008. Optimizing hatchery and nursery technologies for production of black sea bass fingerlings for pilot commercial grow out projects. Final Report, FRG Project 04-‐AM-‐03,North Carolina Fishery Resource Grant Program, North Carolina Sea Grant, Raleigh, NC. Watanabe, W.O.. Species Profile: Black Sea Bass. Southern Regional Aquaculture Center. October 2011. Skidaway Institute of Oceanography, University of. Georgia. <www.skio.org>. Accessed November 21, 2014.