Application manual of 3 d sublimation vacuum machine

-

Upload

bestsub -

Category

Technology

-

view

1.428 -

download

1

description

Transcript of Application manual of 3 d sublimation vacuum machine

Application Manual

of

3D Sublimation Vacuum Machine

Preface Thanks for choosing products from BestSub Technologies. Please read the Application Manual carefully before application. This Manual consists of application instruction and notes, frequently asked questions and solutions etc. WARNING: incorrect operation could cause unexpected incidents. For your security as well as good protection of the machine under proper operation and the maximum returns of investment, we strongly recommend you to read though this Application Manual when you handle the machine for the first time, regardless how you are familiar with products alike.

Contents Application Manual ........................................................................................................................... 1

of.......................................................................................................................................................... 1

3D Sublimation Vacuum Machine.................................................................................................. 1

Preface ............................................................................................................................................... 1

Contents ............................................................................................................................................. 2

1 Safety Issues ............................................................................................................................. 3

1.1 Electric Shock (!) .......................................................................................................... 3

1.2 Fire Prevention (!) ........................................................................................................ 3

1.3 Injury Prevention (!) ..................................................................................................... 4

1.4 Other Issue .................................................................................................................... 4

1.4.1 Delivery and Installation .................................................................................. 4

1.4.2 Wiring and Installation ..................................................................................... 4

1.4.3 Commissioning ................................................................................................. 5

1.4.4 Decommissioning and Dispose ..................................................................... 5

2 General Introduction ................................................................................................................ 5

3 Application Scope and Characteristics ................................................................................. 6

3.1 Application ..................................................................................................................... 6

3.2 Suitable Materials ......................................................................................................... 6

3.3 Characteristics .............................................................................................................. 6

4 Specification .............................................................................................................................. 7

5 Technical Parameters .............................................................................................................. 7

6 Application Description ............................................................................................................ 8

6.1 Installation and Commissioning ................................................................................. 8

6.2 Power On & Pre-heating ............................................................................................. 9

6.3 Printing Manipulation ................................................................................................... 9

6.4 Power Off ..................................................................................................................... 10

7 FAQ and Solutions ................................................................................................................. 10

7.1 Maintenance and Components Replacement (after the machine cools) ......... 10

7.2 FAQ and Solutions ..................................................................................................... 11

8 Reference ................................................................................................................................ 11

9 Electric Diagram ..................................................................................................................... 13

1 Safety Issues

1.1 Electric Shock (!)

In order to prevent electric shock, please keep the case of the vacuum machine closed when connecting it with power. In order to prevent electric shock caused by the contact of high voltage interface and charged components, please shut down the machine when open the case. To prevent electric shock, even when the power is off, please keep the case of driver and controller closed except for overhaul. Please wiring and check- up of the machine shall be done 10 minutes after the power is cut off and the remaining voltage is vanished when confirmed by multimeters. Please make sure that the machine is grounded. All wiring and check shall be carried out by professionals. Wet handed operation is prohibited. Please check cables connected to the machine and make sure the cables are not damaged and not pressed by heavy objects in case of electric shock. Please avoid exchanging component when the machine is connected to power, or danger would occur.

1.2 Fire Prevention (!)

In order to avoid fire, please keep explosives away from the machine when the internal temperature of the machine >150℃. To avoid fire caused by powerful current, please cut the power at the power side in case of accident. To avoid fire, please make sure the machine is under surveillance during running. To avoid fire caused by high temperature, the power shall be cut off only when the internal temperature of machine is under 100℃ after the machine is stop from running. To avoid fire, please pull the platform out of the box for cooling down and cut power off when the machine is unexpectedly stopped or in case of power outage.

1.3 Injury Prevention (!)

Please work with protective gloves, bare hand operation is prohibited, which would cause burning by the edge of the platform or the objects. Make sure the machine is connected to the rated voltage as regulated in the Application Manual, or explosion and damage would occur. Keep wires dry and make sure cables are firmly connected with right interfaces. In order to prevent burning, do not touch the platform directly without any protective gloves when the machine is running or immediately after stop. The height of the printing targets shall be lower than the maximum height of the box entrance, or the platform and the machine would be damaged. Do not put hand into the entrance of the platform in case of injury.

1.4 Other Issue

Please be careful with the following issues in case of accidents, injury, electric shock and damage.

1.4.1 Delivery and Installation

Please handle and move the machine with proper lifting apparatus to avoid damage. Packing boxes of the machine shall avoid stacking, inclining or inverting. Please be careful in moving without shocking. Do not turn on the machine when elements are found missing or damaged. The cooling fan vent at the top of the machine shall not be covered. Operational Environment: Temperature: -15℃~60℃ Humidity: ≤90% Keep the machine away from corrosive gas, inflammable gas or fog, etc.

1.4.2 Wiring and Installation

Please install the machine in noise filtered environment if the voltage is instable, or to connect the machine with matchable voltage stabilizer with the help of proper cables.

1.4.3 Commissioning

Check all the parameters and make sure the start would be safe. Do not remould the machine, and inspection and commissioning are demanded after being put unused for a long time.

1.4.4 Decommissioning and Dispose

The machine shall be disposed as industrial waste.

2 General Introduction

This 3D vacuum sublimation machine is featured with a sealed thermal circulating system with outstanding thermal insulation, vacuum transfer system and an accurate driving controlling system. In addition, the machine is perfect in thermal insulation and energy conservation, capable of image transfer on surfaces or sides of 3 dimensional subjects.

3 Application Scope and Characteristics

3.1 Application

This 3D sublimation vacuum machine is designed with the capacity of transferring print onto any proceeded 3D objects, without carving and chromatography printing. Besides, the one-stop printing with the machine is limitless either in quantity or color. The printing appears clear, vivid and color fading resistant, making it perfect for various printing, such as customized products, digital products, advertising materials and building materials.

3.2 Suitable Materials

Applicable materials include coated pearl sheet, crystal, wood, chemical fabric, cloth leather, metal board, photo slate, coated slate, ceramic tile, glass tile, glass board, glass clock, photo crystal, coating crystal, T-shirts and mouse pads etc.

3.3 Characteristics

High efficiency and energy conservative With the equipment of heating system and the effective thermal circulating system, the machine can reach 180℃ within 10-20 minutes, thus shortening the heating time and improving efficiency. Also, the box inside is conditioned with even temperature. The heating balance for the new material to the box is fast, which saves energy consumption and enhancing transferring quality.

Cost effective Air-compressors and hydraulic systems are avoided, reducing costs. The design of efficient thermal preservation in the box further saves thermal loss which decreases the producing costs.

Eco-friendly With the sealed electric heating system, air pollution is avoided during printing. Due to the application of a vacuum pump and soundless ball bearing tracks, vibrating noise is largely reduced.

Durable The machine is equipped with advanced highly elastic screen, two-side coated thermal proof silicon and fluoro-rubber coated layers, make it elastic, durable and suitable for continuous processing under high temperature.

Widely applicable and competitive The machine is suitable for transfer printing on various special 3D subjects, resulting in sound printing effect with the vacuum pressing and tight wrapping technology.

4 Specification

5 Technical Parameters

Type Item

3D Sublimation Vacuum Machine SZK3D

Working voltage (V/Hz) 220/50 Rated voltage (Kw) 4 Temperature (℃) 0~300 Maximum vacuum (kpa) 0.1 Working size (mm) 500×500

Dimension (mm) L*W* H 1600*1100*1400

Preheating (M) 10 Weight (kg) 350 Height of Input Entrance(mm) 80

6 Application Description

6.1 Installation and Commissioning

1. Unpack the package and check if any components missing or damaged; 2. Mounting the machine in line with the provided Manual; 3. Connect the machine with the right power source. Note: Make sure the power

matches the rated voltage in case of danger. 4. Check the power source; make sure the level of vacuum pump oil is higher than the

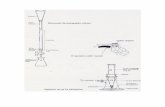

normal level; check the voltage at the wiring point, normally between -0.04~0.08Mpa; check the set temperature 170~200℃ and timer at 30 seconds to 10 minutes. Upon confirmation, proceed with the following step as in figure 1 to 4; Figure one: controlling board and instruments

Figure two: Voltage at wiring points Figure three: time relay

Figure four: Auto temperature controller

6.2 Power On & Pre-heating

1. Turn on the power switch clockwise and the instruments start working; 2. Turn the vacuum pump switch to “on”, then the pump starts working till reaching the

rated pressure (normally at 0.1 mpa); 3. Turn on the circulating fan to “warm-up”, set the time relay at around 20 minutes

which can avoid repeated alarm, and set the time according to different subjects; 4. Turn on heating switch A and B, set the temperature controller to 180℃. Then the

actual temperature will display accordingly. As the machine is heating, the temperature will keep rising continuously. When the time relay reads 10 to 20 minutes, the machine stars working.

6.3 Printing Manipulation

1. Turn on the circulating fan to “circulating”, and set the time relay at the needed time according to the target.

2. Pull out the board and turn the loading pallet to the middle or “loading”. Open the upper part of the board, put the target in with the paper facing upward; buckle the upper part, turn the loading pallet to “vacuum”, and the platform extracts air which making the thermal elastic film fixing the target firmly.

3. Push in the platform to trigger the limit switch and the timer starts working. When the time is up, it buzzes. Pull the platform out of the box, turn the loading pallet to “Loading” and take out the printed subtract after opening the upper part. For continuous printing, repeat step 3;

4. Tear off the transfer paper and check the printing, and then pack after cooling.

6.4 Power Off

1. Press the stop button, switch the circulating fan to “warm-up”, vacuum pump switch to “off”, pull the platform out of the box and open the upper cover of the platform. Then turn the vacuum switch to “vent” and wait the air pressure back to 0. Finally, set the delayed time to over 20 minutes for cooling.

2. The temperature will decreases on the controller. When the temperature is lower than 80℃, push the platform into the box and turn the power switch off.

7 FAQ and Solutions

7.1 Maintenance and Components Replacement (after the machine

cools)

Figure Eight Cross-section of the Machine

1. Replacing the heat-proof elastic silicon: open the upper layer of the platform till it against the case; dismount the buckle of the upper layer (6), and the heat-proof elastic silicon screen (3). Then put the trimmed new screen onto the layer, and press it with the buckle. Note: the screen shall not be too tight.

2. Replacing the lower layer: open the upper layer of the platform and take base

plate (8) out, and dismount the sealing strip (5) alone the edge of the platform (4), press the buckle of the sealing strip into the edge of the platform (4) and press tight downward.

3. Replacing the carbon heating component: turn off the power and take down the plug at the back of the machine, dismount the cooling fan on the top of the case and open the lock of side of the machine, and take down the cover of the case and reverse cautiously. Disconnect the heating component which shall be replaced, and connect a new heating component with the same method and press tight the interface.

4. Refill the vacuum pump oil: when the oil level is lower than the middle line on the oil window, you need refill the pump oil as the follows. Turn off the power and open the oil plug carefully and refill the oil until it rises above the middle line. Note: the oil shall not be too full to prevent spilling out. Besides, When the oil becomes dark or heavily polluted, the oil shall be refilled.

7.2 FAQ and Solutions

N.O. Malfunction Reasons Solutions

1 unclear image and incomplete

transfer

Time is too short Prolong the time

Temperature is too low Increase the temperature

2 clear image but over-transferred Time is too long shorten the time

Temperature is too high Decrease the temperature

3 Unclear image with vague edge Fixing between the transfer

paper and the subject is loose,

low pressure or air remain

Adjust the pressure or press

the surface manually

4 Vacuum pump unstoppable Short circuit or air leakage Check the pipe and the

platform

5 Slow in air extracting Low vacuum pump oil level Refill the oil

6 uneven transfer in large area

printing or the heat time longer

than 30 minutes

Malfunctioned heat elements or

heat fan damaged

Check and replace heat

elements and heat fan.

8 Reference

N.O Printing Material Time and Temp

(for reference)

1 Textile, apparel, mouse pads and pillows 30~50s, 150~180℃

2 pre-coated metals: sheet, aluminum and

stainless steel and etc.

1-mm plate: 1~2 mins, 180℃; heavier plate with

longer printing time

3 Ceramic plate, tiles and glass etc. 4 mins, 180℃

4 Aluminum alloy 2~4 mins, 180℃

5 Irregular shaped crystal, such as ashtray, trophy

or decoration stuffs.

6~8 mins, 180℃

6 Stone, bamboo, and wood etc. 8~10 mins, 180℃

9 Electric Diagram