Appendix C Job Performance Measure Form ES-C-i Worksheet

Transcript of Appendix C Job Performance Measure Form ES-C-i Worksheet

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPM Aib RO

2014 Admin—JPM Aib RO (REV_071414) NUREG 1021, Revision 9

Facility:

Task Title:

McG u ire

Determine License Status

Task No.:

JPM No.: 2014 Admin — NRCJPM Aib RO

K/A Reference:

Examinee:

2.1.4 (3.8)

NRC Examiner:

Facility Evaluator:

Method of testing:

Date:

Simulated Performance:

Classroom X Simulator

Actual Performance:

Plant

x

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page of this JPM).

• You are a Licensed Reactor Operator who is currently assigned tothe day shift staff for a special project, and not routinely standingwatch in the Control Room.

• Your supervisor has directed you to stand watch as needed tomaintain your license active.

• Your work history this quarter is as follows:

o 7/02/1 4, Unit 2 BOP (0600-1 800)

o 7/1 2/1 4, Unit 2 OATC (1800-2400)

o 7/20/1 4, Unit 1 BOP (0600 1800)

o 8/04/1 4, Unit 2 BOP (0700-1 300)

o 8/11/14, Unit I OATC (1800-0600)

Initiating Cue: • Complete NSD Form 512-1 to track the maintenance of your licensefor this quarter.

• Identify additional requirements, (if any), that must be met thisquarter to maintain your license active. (Include number of watches,required watch positions, and any time restraints).

Appendix C Page 2 of 6 Form ES-C-i

Job Performance Measure Worksheet

Initial Conditions:

2014 Admin Audit JPM Al b SRO NUREG 1021, Revision 9

Appendix C Page 3 of 6 Form ES-C-i

Job Performance Measure Worksheet

Task Standard: The operator will record the completion of the following watches, (U2BOP on 7/2/1 4, Ui BOP on 7/20/14 and Ui OATC on 8/11/14) on Form512-1 in accordance with the attached KEY, the operator will identifythat 2 additional 12-hour shifts must be stood as either the Ui RO, UiBOP, U2 RO or U2 BOP by 9/30/14 to maintain the license active.

Required Materials: Calculator

General References: AD-OP-ALL-i 000 (Conduct of Operations), Rev 0

NSD-200 (Work Hour Guidelines and Limits), Rev i6

NSD-5i2 (Maintenance of RO/SRO NRC Licenses), Rev 6

Handouts: Blank Form NSD 512-i

Time Critical Task: NO

Validation Time: 10 minutes

2014 Admin —Audit JPM Aib SRO NUREG 1021, Revision 9

Appendix C Page 4 of 6 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk*)

Provide Candidate with Initial ConditionslCue (Last Page of this JPM).

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*i Complete any paperwork The operator completesnecessary to track the Form 512-i of NSD 512 inmaintenance of your accordance with thelicense, attached KEY.

*2 Identify additional The operator identifies thatrequirements that must be a minimum of 2 additionalmet this quarter to maintain 12-hour shifts must beyour license active (Include stood as either the Ui RO,number of watches, Ui BOP, U2 RO or U2 BOPrequired watch positions, by 9130/i4 to maintain theand any time restraints), license active.

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2014 Admin — Audit JPM Al b SRO NUREG 1021, Revision 9

Appendix C Page 5 of 6 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No.: 2014 Admin — Audit JPM Al b SRO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2Ol4Admin—AuditJPM Alb SRO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

Initial Conditions: • You are a Licensed Reactor Operator who is currentlyassigned to the day shift staff for a special project, and notroutinely standing watch in the Control Room.

• Your supervisor has directed you to stand watch as needed tomaintain your license active.

• Your work history this quarter is as follows:

o 7/02/1 4, Unit 2 BOP (0600-i 800)

o 7/i 2/i 4, Unit 2 OATC (1800-2400)

o 7/20/i 4, Unit 1 BOP (0600-i 800)

o 8/04/i 4, Unit 2 BOP (0700-i 300)

o 8/11/14, Unit 1 OATC (1800-0600)

INITIATING CUE: • Complete NSD Form 512-i to track the maintenance of yourlicense for this quarter.

• Identify additional requirements, (if any), that must be met thisquarter to maintain your license active. (Include number ofwatches, required watch positions, and any time restraints).

NUREG 1021, Revision 9

VERIFY HARD COPY AGAINST WEB SITE IMMEDIATELY PRIOR TO EACH USE

Nuclear Policy Manual- Volume 2 NSD 512

FORMS

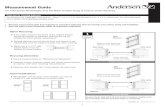

Form 512-1 Documentation of Operating Experience Maintenance for Active Licensed Operators

1. Licensed Operators Name Employee Number

Name

______________________

NOTE: Time as the extra RO/SRO on an Outage Unit or as a ROSRO in the Outage Control Center cannot becounted as an ACTIVE LICENSED OPERATOR position.

2. ACTIVE LICENSED OPERATOR POSITION

a. Operations Shift Manager (SRO)

b. Control Room Supervisor (SRO)

c. Operator at the Controls (RO)

d. Balance of Plant Operator (RO)

3. A minimum of five 12-hour shifts per calendar quarter performing one or more of the functions listed in item 2shall be worked and documented below to maintain active status. The position must be filled for the entire shiftperiod including both turnovers to obtain credit.

Licensed Duty Letter Shift Start Date Shift(A- D) (Month/Day/Year) (day I night)

D 07/02/2014 Day

D 07/20/2014 Day

C 08/11/2014 Night

4. 1 hereby certify that the information set forth above is accurate and complete.

Licensed Operator Signature

5. When complete, send a copy of this form to Operations Administrative Support and keep a copy for yourpersonal records.

6. Updateverify LOQR Initial Date

7. Send completed form to Operations Training Group for filing with the individuals training record.

REVISION 6 11

VERIFY HARD COPY AGAINST WEB SITE IMMEDIATELY PRIOR TO EACH USE

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPMA2RO

2014 Admin - JPM A2 RO (REV_073114) NUREG 1021, Revision 9

Appendix C Page 2 of 9 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Perform NC Loop Operability JPM No.: 2014 Admin - JPM A2Verification in Mode 4 RO

K/A Reference: 2.2.12 (3.7)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handout 1.

Initial Conditions: • The Plant is in Mode 5 with NCS Temperature at 188°F and stable.

• S/G Narrow Range Levels are as follows:

• iA=10%

• 1B=35%

• 1C=15%

• 1D=25%

• The following plant conditions exist:

• Power is available to both 1 ETA and 1 ETB.

• ND Pump 1A is running maintaining NCS Temperature < 200°F.

• ND Pump lB is OFF.

• The WCCSRO has reported lB ND Pump Air Handling Unit hasfailed to meet acceptance criteria during surveillance testing.

• Both ND Pump Breakers are in the CONNECT position withcontrol power ON (all breaker indications are normal)

• All NC Pumps are OFF.

• Except where noted below, all NC Pump Normal FeederBreakers and Safety Breakers are Racked In (all breakerindications are normal)

• The I B NCP is tagged out for motor maintenance.

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

Appendix C Page 3 of 9 Form ES-C-i

Job Performance Measure Worksheet

The I D NCP Safety Breaker is Racked Out for breakermaintenance.

• ITA, 1TB and lTD are energized via their Normal FeederBreaker (all breaker indications are normal).

• ITC is energized via its Standby Feeder Breaker (Normal FeederBreaker is OPEN and RACKED OUT).

Initiating Cue: The CRS has directed you to perform Enclosure 13.5 (NC LoopOperability Verification in Mode 4) of PT111A146001003 C (WeeklySurveillance Items), in preparation to transition to Mode 4.

Task Standard: The operator will complete Enclosure 13.5 in accordance with theprovided KEY.

Required Materials: All General References should be available to the operator.

General References: PT/i 1A146001003 C (Weekly Surveillance Items), Rev 72

PT/i IA/4204/01 1 (1 B ND Pump Air Handling Unit Performance Test),Rev 19

OP/i/A16100/SU-9 (Mode 4 Checklist) Rev 64

McGuire Technical Specifications (LCO 3.4.6/Amendment 216/1 97 and261/241)

AD-HU-ALL-0004 (Procedure and Work Instruction Use and Adherence)Rev i

Handouts: Handout 1: PT/1/A/4600/003 C (Weekly Surveillance Items) Procedurebody and Enclosure 13.5 (NC Loop Operability in Mode 4))

Time Critical Task: NO

Validation Time: 15 minutes

NOTE: An Answer KEY is provided as a separate document.

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

(Step 1.2) IF performing thisprocedure in preparation fora Mode change, record thefollowing:

Mode to be entered:

Date:

The operator enters 4 in theMode to be entered andToday’s Date in the DateBlock, and initials thesignoff space.

Appendix C Page 4 of 9 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk*)

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handout 1.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

i (Step 1.1) IF performing The operator places an N/Aroutine weekly in the signoff space andsurveillances, record the proceeds.following:

Mode of Operation:

Date:

2

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

Appendix C Page 5 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*3 (Step 1.3) Check two of the The operator recognizesfollowing Loops operable that NC Loop A is NOTand one (of the operable) in OPERABLE because theoperation: SG NR Level is too low.

The operator recognizesthat NC Loop B is NOTOPERABLE because the1 B NCP is tagged out formotor maintenance.

The operator recognizesthat NC Loop C isOPERABLE, and places acheck in the Checkbox inColumn I (OPERABLE).

The operator recognizesthat NC Loop D is NOTOPERABLE because the1 D NCP Safety Breaker isRacked Out for breakermaintenance.

The operator recognizesthat ND Loop A isOPERABLE and inoperation, and places acheck in the Checkbox inColumn I (OPERABLE)and 2 (In Operation).

The operator recognizesthat ND Loop B is NOTOPERABLE because thelB ND PUMP AHU has justfailed its surveillance.

The operator initials thesignoff space.

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

(Step 1.4) IF2 of theoperable Loops in Step 1.3are NOT in operation,complete the following forthe operable pump NOT inoperation.

The operator recognizesthat the 1 C NC Pump mustbe assessed in Step 2.

The operator recognizesthat except where noted, allNC Pump Normal FeederBreakers and SafetyBreakers are Racked In (allbreaker indications arenormal). There are nonoted exceptions for the 1 CNC Pump Breakers.Consequently, the operatorplaces a check in the fourYES Checkboxes for theNC Pump IC.

The operator recognizesthat 1TA, 1TB and lTD areenergized via their NormalFeeder Breaker (all breakerindications are normal); andthat 1TC is energized via itsStandby Feeder Breaker (allbreaker indications arenormal); and that accordingto Note 2 this is acceptableto meet the iNC Pumprequirements. The operatorplaces a check in the NOCheckbox for the NormalFdr Bkr Racked In, andcalls attention (i.e. circles

Appendix C Page 6 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*4

or equivalent) to Note 2;and checks YES in thesecond Checkbox forITC.

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

Appendix C Page 7 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

(Step 1.5) Initial one of the The operator initials thefollowing: “No Discrepancy” signoff

. space.No Discrepancy

Discrepancy SheetAttached (IF anyAcceptance Criteria NOTmet, it is identified as adiscrepancy, evaluated perTech Spec/SLC andappropriate correctiveaction taken.)

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

Appendix C Page 8 of 9 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No.: 2014 Admin - JPM A2 RO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2014 Admin - JPM A2 RO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

Initial Conditions: • The Plant is in Mode 5 with NCS Temperature at 188°F andstable.

• SIG Narrow Range Levels are as follows:

• 1A=10%

• 1B=35%

• 1C=15%

• 1D=25%

• The following plant conditions exist:

• Power is available to both 1 ETA and 1 ETB.

• ND Pump 1A is running maintaining NCS Temperature <

200°F.• NDPump1BisOFF.

• The WCCSRO has reported lB ND Pump Air HandlingUnit has failed to meet acceptance criteria duringsurveillance testing.

• Both ND Pump Breakers are in the CONNECT positionwith control power ON (all breaker indications are normal)

• All NC Pumps are OFF.

• Except where noted below, all NC Pump Normal FeederBreakers and Safety Breakers are Racked In (all breakerindications are normal)

• The 1 B NCP is tagged out for motor maintenance.

• The 1 D NCP Safety Breaker is Racked Out forbreaker maintenance.

• 1TA, 1TB and lTD are energized via their Normal FeederBreaker (all breaker indications are normal).

• 1TC is energized via its Standby Feeder Breaker (NormalFeeder Breaker is OPEN and RACKED OUT).

INITIATING CUE: The CRS has directed you to perform Enclosure 13.5 (NC LoopOperability Verification in Mode 4) of PT/1/A’4600!003 C (WeeklySurveillance Items), in preparation to transition to Mode 4.

NUREG 1021, Revision 9

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPMA3RO

2014 Admin - JPM A3 RO (REV_071414) NUREG 1021, Revision 9

Appendix C Page 2 of 10 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Perform a Unit Vent Flow JPM No.: 2014 Admin - JPM A3Calculation of a Containment Air RORelease

K/A Reference: 2.3.11 (3.8)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handouts 1-3.

Initial Conditions • GWR Package #2014013 for Unit 1 Containment Air Release iscurrently in use to conduct a series of Containment air releases.

• Three releases have been made.

• During the first release, conducted using Enclosure 4.2 (Air ReleaseMode With VQ Flow Monitor Operable) of OP/1/A16450/01 7(Containment Air Addition and Release), the Unit 1 VQ Monitorbecame inoperable

• The crew stopped the release and continued the air release usingEnclosure 4.3 (Air Release Mode with VQ Flow Monitor Inoperable)of OP/1/A16450/017 (Containment Air Addition and Release), andrecorded the release volume on the GWR paperwork.

• At 1743 on 8/4/14, containment pressure was 0.18 PSIG andanother (41h) VQ release was initiated to reduce pressure to 0.12PSIG per Step 3 9 of Enclosure 4.3.

• This release was secured at 1839 on 8/4/14 and the procedure wascompleted through step 3 8.1 for this 4th release.

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 3 of 10 Form ES-C-i

Job Performance Measure Worksheet

Initiating Cue: • You have been directed to calculate the volume released for the 4th

release and complete all required paperwork starting with Step 3.8.2,AND, since this is the last release for GWR package 2014013,perform Steps 3.10.4 through 3.10.9 of Enclosure 4.3 to determinethe total volume released from the Containment.

• The CRS notified RP (Mike Cline) at 1840 on 8/4/14 that the releasehas been terminated.

Task Standard: The operator will calculate the volume of air released from theContainment during the final release, and determine the total volume ofair released in the series of four releases in accordance with theprovided KEY.

Required Materials: Calculator

General References: OP/1/A16450/017 (Containment Air Release and Addition System), Rev41

Handouts: Handout 1: Enclosure 4.2 (Air Release Mode With VQ Flow MonitorOperable) of OP/1!A/6450/01 7 (Containment Air Addition and Release)marked up as follows:Step 2.1 — Initialed.

Step 2.2— IniSaled.

Step 2.3— Initialed.

Step 2.4— Initialed, GWR# 2014013 recorded.

Step 3.1 — Checkbox is checked.

Step 3.2— Initialed.

Step 3.2.1 — Initialed and CV initialed.

Step 3.2.2 — Initialed and CV initialed.

Step 3.2.3— Checkbox is checked

Step 3.2.4 — Initialed and Mike Cline/Date/Time Recorded consistent with first release Date/Time (8/4/14 0903).

Step 3.3— N/A and Initialed.

Step 3.4 —Initialed.

Step 3.5—Initialed and CV initialed.

Step 3.6 — Initialed.

Step 3.7 — Initialed.

Step 3.8— Initialed.

Step 3.8.1 — Checkbox is checked.

Step 3.8.2 — Checkbox is checked.

Step 3.8.3 — Initialed and CV initialed, VQ Monitor flow is recorded as 1236, and Actual Volume Released is recorded as 12,360.

Step 3.8.4 — All three Checkbox’ are checked.

Step 3.8.5 — Initialed.

Step 3.8.6 — Checkbox is checked.

Step 3.9.1 — Checkbox is checked.

Step 3.9.2 — Checkbox is checked.

Step 3.9.3 — Checkbos is checked.

Step 3.9.4 — Checkbox is checked.

Step 3.9.5 — Both Checkbox’ are checked.

Step 3.9.6 — Checkbox is checked.

Step 3.9.7— Initialed.

Step 3.10— Initialed.

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 4 of 10 Form ES-C-i

Job Performance Measure Worksheet

Page 5 of 5 (Attachment 1) is marked up as follows: Sheet I of I

IVQ-2B Open IVQ-2B ClosedDoer CV VQ Flow VQ Flow DatelTime Doer CV DatelTime

Monitor LessCounting Than 300

(J) cfm_(‘1)Initial Initial 814114 0903 Initial Initial 814114 1016

Handout 2: Enclosure 4.3 (Air Release Mode With VQ Flow MonitorInoperable) of 0P111A164501017 (Containment Air Addition and Release)marked up as follows:Step 2.1 — Initialed.

Step 2.2 — Initialed.

Step 2.3 — Initialed.

Step 2.4— Initialed, GWR# 2014013 recorded.

Step 3.1 — Checkbox is checked.

Step 3.2— Initialed.

Step 3.2.1 — Initialed and CV initialed.

Step 3.2.2 — Initialed and CV initialed.

Step 3.2.3 — Checkbox is checked.

Step 3.2.4 — Initialed and Person Notified/Date/Time Recorded consistent with first release Date/Time on Page 6 of 6.

Step 3.3— NA and Initialed.

Step 3.4—Initialed.

Step 3.5—Initialed and CV initialed.

Step 3.6.1 — Checkbox is checked.

Step 3.6.2 — Checkbox is checked.

Step 3.6.3 — Checkbos is checked.

Step 3.6.4 — Both Checkbox are checked.

Step 3.6.5 — Checkbox is checked.

Step 3.6.6 — Initialed.

Step 3.7— NA and Initialed.

Step 3.8— Initialed.

Step 3.8.1 - Checkbox is triple-checked.

Step 3.8.2 - Checkbox is double-checked.

Step 3.8.3 - Double Initialed, and double CV initialed.

Step 3.9—Initialed.

Page 6 of 6 (Attachment 1) is marked as follows: Sheet I of I

IVQ-2B Open IVQ-2B ClosedDoer CV DatelTime Start Doer CV DatelTime Stop Ft Total Ft

Pressure Pressure Released Released(psig) (psig)

Initial Initial 8I4!14 1117 0.22 Initial Initial 8I4I14 1258 0.12 21,740.17 21,740.17Initial Initial 8I4I14 1432 0.20 Initial Initial 8/4114 1547 0.12 15,747.32 37,487.49Initial Initial 8I4I14 1743 0.18 Initial Initial 0.12

Handout 3: GWR Paperwork with 12360ft3 release volume fromEnclosure 4.2 recorded.

Time Critical Task: NO

Validation Time: 15 minutes

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 5 of 10 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk*)

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handouts 1-3.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

(Enclosure 4.3, Step The operator records

3.8.2) Record stop 8/4/14 1839 in the 1VQ-

date/time on Attachment 2B Closed Date/Time

1 Block of Attachment 1.

2 (Step 3.8.3) Calculate The operator uses Table 1volume released using the of Enclosure 4.3 andfollowing and record on determines X to be 17.31

Attachment 1. (Start Pressure of 0.18).

(Documentation of The operator uses Table 1calculation NOT required) of Enclosure 4.3 and

Cu. Ft. Released = x + determines Y to be 203.99

(YxZ)(Start Pressure of 0. 18).

Where:The operator usesAttachment 1 of Enclosure

X and Y are from Table 1 4.3 and determines Z to be56 (Stop Time of 1839 -

Z is actual release duration Start Time of 1743).in minutes fromAttachment 1. The operator calculates

volume released as follows:

17.31 + (203.99 x 56)=11,440.75±0.5% (SeeKEY), and records thisvalue in the 1VQ-2BClosed Cubic Ft ReleasedBlock of Attachment 1.

3 (Step 3.10.4) Ensure The operator ensures

release stop date/time 8/4/14 1839 recorded in

recorded on Attachment the 1VQ-2B Closed

1. Date/Time Block ofAttachment 1.

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 6 of 10 Form ES-C-i

PERFORMANCE INFORMATION

STEPS

4

5

ELEMENTS

(Step 3.10.5) Notify RPthat release has beenterminated

(Step 3.10.6) DetermineTotal Cu. Ft Released onAttachment 1.

STANDARD

The operator recognizesfrom the initial conditionsthat RP has been notified.

The operator adds thevolume of this most recentrelease (11,440.75) to thetotal previously released onAttachment 1 (37,487.49)and determines that thetotal volume released is48.928.24 ft3 (See KEY.

S/U COMMENTSREQUIRED

FOR UNSAT

6 (Step 3.10.7) Record Total The operator recordsCu. Ft Released from 48,928.24 (See KEY) in theAttachment 1: ft3 1 VQ-2B Closed Cubic Ft

Released Block ofAttachment 1.

The operator records thisvalue in the 1VQ-2BClosed Total Cubic FtReleased Block ofAttachment 1.

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 7 of 10 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

*7 (Step 3.10.8) IF any VQ The operator observesTotalizer readings recorded GWR paperwork andon GWR paperwork, determines that 12,360 ft3perform the following: had been released when

the VQ Monitor was(Step 3.10.8.1) Determine operable and records thisTotal Volume Released as value on Enclosure 4.3recorded on GWR Step 3.10.8.2.paperwork.

(Step 3.10.8.2) RecordTotal Volume Releasedfrom GWR:ft3.

*8 (Step 3.1 0.9) Calculate The operator adds the totalTotal Volume Released for volume released recordedGWR as follows: in Step 3.10.7 (48,928.24)

and the total volumereleased recorded in Step

ft3 + ft3 = 3.9.8.1 (12,360), anddetermines the TotalVolume Released for this

Step 3.10.7 Step 3.10.8.2 Total Vol series of Containment AirReleases is 61,288.24 W(See KEY).

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 8 of 10 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No.: 2014 Admin - JPM A3 RO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Page 9 of 10 Form ES-C-i

VERIFICATION OF COMPLETION

KEY:

Enclosure 4.3, Attachment 1:

RED = filled in at start of JPM.GREEN = filled in during JPM performance

IVQ-2B Open IVQ-2B ClosedDoer CV Date/Time Start Doer CV Date/Time Stop Ft3 Total Ft4

Pressure Pressure Released Released(psig) (psig)

Initial Initial 8/4114 1117 0.22 Initial Initial 8I4114 1258 0.12 21,740.17 21,740.17Initial Initial 8/4114 1432 0.20 Initial Initial 8/4114 1547 0.12 15,747.32 37,487.49Initial Initial 8/4114 1743 0.18 Initial Initial 8/4/14 1839 0.12 11,440.75 48,928.24

Enclosure 4.3, Step 3.8.3 (JPM Step 2): Volume released, current release:17.31 ft3 + (203.99 ft3/min x 56 mm ) = 11,440.75 ft3 (11,383.55 - 11,497.95)

Enclosure 4.3, Step 3.10.6 (JPM Step 5): Total Volume released, during performance ofEnclosure 4.3:11,440.75 ft3 + 37,487,49 ft3 = 48,928.24 ft3 (48,871.04 — 48985.44)

Enclosure 4.3, Step 3.10.9 (JPM Step 8): Total Volume released, during performance of GWPermit:48,928.24 ft3 + 12360 ft3 = 61,288.24 ft3 (61,231.04 — 61,345.44)

2014 Admin - JPM A3 RO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

Initial Conditions: • GWR Package #2014013 for Unit 1 Containment Air Releaseis currently in use to conduct a series of Containment airreleases.

• Three releases have been made.

• During the first release, conducted using Enclosure 4.2 (AirRelease Mode With VQ Flow Monitor Operable) ofOP/1/A16450/017 (Containment Air Addition and Release), theUnit 1 VQ Monitor became inoperable.

• The crew stopped the release and continued the air releaseusing Enclosure 4.3 (Air Release Mode with VQ Flow MonitorInoperable) of OP/1/A16450/017 (Containment Air Addition andRelease), and recorded the release volume on the GWRpaperwork.

• At 1743 on 8/4/1 4, containment pressure was 0.18 PSIG andanother (4th) VQ release was initiated to reduce pressure to0.12 PSIG per Step 3.9 of Enclosure 4.3.

• This release was secured at 1839 on 8/4/14 and the procedurewas completed through step 3.8.1 for this 4th release.

INITIATING CUE: • You have been directed to calculate the volume released forthe release and complete all required paperwork startingwith Step 3.8.2, AND, since this is the last release for GWRpackage 2014013, perform Steps 3.10.4 through 3.10.9 ofEnclosure 4.3 to determine the total volume released from theContainment.

• The CRS notified RP (Mike Cline) at 1840 on 8/4/14 that therelease has been terminated.

NUREG 1021, Revision 9

ES-301 Administrative Topics Outline Form ES-301-1(Rev_0731 14)

Facility: McGuire Date of Examination: 8/2014

Examination Level: SRO Operating Test Number: N14-1

Administrative Topic Type Code* Describe activity to be performed(see Note)

2.1.18 (3.8) Ability to make accurate, clear, conciseConduct of Operations

N Rlogs, records, status boards, and reports.

JPM: Determine Reportability Requirements

2.1 .20 (4.6) Ability to interpret and execute procedureConduct of Operations steps

N, R

JPM: Review a Completed Procedure

2.2.12 (4.1) Knowledge of Surveillance Procedures.Equipment Control

D, RJPM: Perform NC Loop Operability Verification in

Mode 4

2.3.1 1 (4.3) Ability to control radiation releasesRadiation Control

M,RJPM: Perform a Unit Vent Flow Calculation of a

Containment Air Release

2.4.41 (4.6) Knowledge of emergency action levelEmergency thresholds and classifications.Procedures/Plan M, R

JPM: Classify an Emergency Event

NOTE: All items (5 total) are required for SROs. RD applicants require only 4 items unless they are retakingonly the administrative topics, when 5 are required.

*Type Codes & Criteria: (C)ontrol room, (0) (S)imulator, (0) or Class(R)oom (5)

(D)irect from bank ( 3 for ROs; 4 for SROs & RD retakes) (1)

(N)ew or (M)odified from bank (> 1) (4)

(P)revious 2 exams ( 1; randomly selected) (0)

NUREG-1 021, Revision 9

ES-301 Administrative Topics Outline Form ES-301-1(Rev_0731 14)

SRO Admin JPM Summary

Ala This is a New JPM. The operator will be provided with a set of plant conditions thatultimately led to the injection of the ECCS Accumulators into the NCS during a plantshutdown. The operator will be directed to determine reportability requirements,including completion of any necessary paperwork. The operator will be expected toidentify that this condition requires a 4 hour notification to the NRC in accordance withRP/O/A15700/0l0 (NRC Immediate Notification Requirements), and to completeEnclosure 4.2 (NRC Event Notification Worksheet) in accordance with the attached Key.

Aib This is a New JPM. The operator will be told that Unit 1 is in Mode 4 during a plantstartup, provided with the current EFPD and NC System pressure, told thatPTI1IAI4600IOO3D, Monthly Surveillance Items, Enclosure 13.4, NC BoronConcentration Checklist, has been performed prior to entry into Mode 3, and that thecompleted Enclosure 13.4 is now ready for review. The operator will be directed toreview the completed procedure and identify (1) whether Mode 1 can be entered, and (2)all administrative procedural/paperwork requirements. The operator will reviewcompleted Enclosure 13.4 of PT/1/A/4600/003D and identify that the Surveillanceperformer has entered an incorrect value for the minimum value of the Cold LegAccumulator Boron Concentration; and correct this entry. Then when the correction ismade, the operator will determine that the 1A through 1C CLA are within the allowableBoron concentration range, but that the 1 D CLA is outside of the allowable range. Theoperator will identify that Mode 3 cannot be entered until 1 D CLA boron concentration israised, and that Attachment 6 of AD-HU-ALL-0004 (Procedure and Work Instruction Useand Adherence) must be completed in accordance with a provided KEY.

A2 This is a Bank JPM. The operator will be told that the Plant is in Mode 5 with NCSTemperature at 188°F and stable, and will be provided with current plant data regardingthe decay heat removal systems. The operator will be directed to perform Enclosure13.5 (NC Loop Operability Verification in Mode 4) of PT/1/A/4600/003 C (WeeklySurveillance Items), in preparation to transition to Mode 4. The operator will beexpected to complete Enclosure 13.5 in accordance with the Attached KEY. This is thesame JPM as the RO Exam.

A3 This is a modified Bank JPM. The operator will be told that GWR Package # 2014013for Unit 1 Containment Air Release is currently in use to conduct a series of Containmentair releases, and that during the first release, conducted using Enclosure 4.2 (AirRelease Mode With VQ Flow Monitor Operable) of OP/1/A/6450/017 (Containment AirAddition and Release), the Unit 1 VQ Monitor became inoperable. The operator will betold that the crew stopped the release and continued the air release using Enclosure 4.3(Air Release Mode with VQ Flow Monitor Inoperable) of OP/1/AJ6450/017 (ContainmentAir Addition and Release), and that three previous releases have been made; includingthe one which was made with the Unit 1 VQ Flow Monitor in operation. Finally, theoperator will be provided with the pertinent data for the current (4tl) release, and then bedirected to calculate the volume released for the current release and to determine thetotal volume released from the Containment during all releases. The operator will beexpected to calculate the volume of air released from the Containment during the finalrelease, and determine the total volume of air released in the series of four releases.This is the same JPM as the RO Exam.

NUREG-1 021, Revision 9

ES-301 Administrative Topics Outline Form ES-301-1(Rev_0731 14)

A4 This is a modified Bank JPM. The operator will be told that Unit 1 and Unit 2 are inMode 1 at 100% power; and then given a timeline of events that result in theimplementation of the Abnormal/Emergency Operating Procedures at Unit 1. Theoperator will be directed to classify the event in accordance with RPIOIAI5700I000(Classification of Emergency). The operator will be expected to declare an ALERTbased on 4.4.A.1, Failure of Reactor Protection System Instrumentation to Complete orInitiate an Automatic Reactor Trip Once a Reactor Protection System Setpoint Has BeenExceeded and Manual Trip WAS Successful. This action is Time Critical and must becompleted within 15 minutes. Then, the operator must prepare an EmergencyNotification Form for this event in accordance with RP/0/B/5700/029 (Notifications toOffsite Agencies From the Control Room), and present this form to the EmergencyCoordinator for approval, also within 15 minutes of the event classification.

NUREG-1 021, Revision 9

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPM Ala SRO

2014 Admin — JPM Ala SRO (REV_07141 4) NUREG 1021, Revision 9

Appendix C Page 2 of 9 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Determine Reportability JPM No.: 2014 Admin — JPM AlaRequirements SRO

K/A Reference: 2.1.18 (3.8)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handouts 1-2.

Initial Conditions: • With Unit 1 in Mode 3, the following event occurred at 0400 today:

• Valve 1 NC-27C (Pzr Spray Valve) stuck OPEN resulting in arapid decrease of NCS pressure.

• The crew entered the appropriate Abnormal Operating Procedureand manually closed the valve.

• Prior to stabilizing the plant, approximately 1200 gallons of waterfrom the Cold Leg Accumulators was injected into the NCS.

• The OSM has verified that this event has NOT exceeded anEmergency Action Level (Level).

• The OSM believes that this event is reportable to the NRC.

• No external persons and/or agencies have been notified of thisevent, nor have any actions other than those identified been taken.

Initiating Cue: The OSM directs you to determine reportability requirements, includingcompletion of any necessary paperwork.

2014 Admin — JPM Al a SRO NUREG 1021, Revision 9

Appendix C Page 3 of 9 Form ES-C-i

Job Performance Measure Worksheet

Task Standard: The operator will identify that this condition requires a 4 hour notificationto the NRC in accordance with RPIOIAI5700/0i0 (NRC ImmediateNotification Requirements), and to complete Enclosure 4.2 (NRC EventNotification Worksheet) in accordance with the affached Key.

Required Materials: None

General References: RP/0/A15700/OiO (NRC Immediate Notification Requirements), Rev. 21

RPIO/A1570010i 4 (Emergency Telephone Directory), Rev. 28

NSD 202 (Reportability), Rev. 25

Handouts: Handout 1: RPIOIAI5700IO1O (NRC Immediate NotificationRequirements).

Handout 2: NSD 202 (Reportability)

Time Critical Task: NO

Validation Time: 20 minutes

2014 Admin — JPM Al a SRO NUREG i 021, Revision 9

Appendix C Page 4 of 9 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk*)

Provide Candidate with Initial Conditions/Cue (Last Page of this JPM), and Handouts 1-2.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

(Step 3.2) The Operations The operator reads the Step. and proceeds.Shift Manager shall assure

the Notificationrequirements of thisprocedure are met for thereportable events providedin Enclosure 4.1.

*2 (Step 3.3) Determine the The operator addresses

appropriate notification Enclosure 4.1.

requirement and thereporting time requirement The operator recognizesusing Enclosure 4. 1, that Event ConditionEvents Requiring NRC 4.1.3.2 is applicable andNotification. that this event must be

reported as soon aspractical and within 4hours of the occurrence.

The operator may alsodetermine that in additionto the 4 hour notification,and 8 hour notificationmay also be required inaccordance with EventCondition 4.1.4.4. (NotCritical)

Examiner Note:

IF operator only identifiesthe 8 hour requirement,then the JPM is FAILED.

2014 Admin —JPM Ala SRO NUREG 1021, Revision 9

Appendix C Page 5 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

(Notes prior to Step 3.4) The operator reads theSecurity Reports should be Notes and proceeds.reported using ProcedureE)(AC 15, Reporting ofSafeguards Events. TheSecurity Shift Supervisorwill provide all informationto the Operations ShiftManager for the NRCNotification.

NSD 202 containsadditional informationpertaining to reportabilityrequirements of selectedevents.

MNS Regulatory AffairsGroup, the Fleet RegulatoryAffairs Organization OR theCommunity RelationsOrganization can providesupport for completingEnclosure 4.2 (NRC EventNotification Work Sheet).

Sections of Enclosure 4.2that are not applicableshould be marked (N/A)

2014 Admin — JPM Al a SRO NUREG 1021, Revision 9

Appendix C Page 6 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

(Step 3.4) Complete the The operator completes. applicable portions of Enclosure 4.2 in

Enclosure 4.2 as identified accordance with the(As shown onKEY) by Enclosure 4.1. If Attached Key.

being completed for a drillwrite: “This is a Drill” on thefirst line of the eventdescription. Then transmit Cue:to the NRC OperationsCenter using After the Enclosure 4.2 isRPIOIAI5700IO1 4, Tab 2. presented for transmittal,

indicate that anotheroperator will complete therequired actions.

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2014 Admin — JPM Ala SRO NUREG 1021, Revision 9

Appendix C Page 7 of 9 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No.: 2014 Admin — JPM Ala SRO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2014 Admin —JPM Ala SRO NUREG 1021, Revision 9

Appendix C Page 8 of 9 Form ES-C-i

VERIFICATION OF COMPLETION

KEY:

Enclosure 4.2 NRC Event Notification Worksheet Page i of 2

All blocks left blank except as follows:

Notification Time/Date: (Left Blank)Unit ICaller’s Name Operator’s NameEvent Time and Zone 0400 (time)Event Date Present DatePower/Mode Before 3Power/Mode After 34-Hr Non-Emergency Check Mark in (50.72 b2(IV)(A) ECCS

Discharge to RCS BlockEvent Description The ECCS Cold Leg Accumulators

discharged 1200 gallons into the RCSduring a valve failure transient (orequivalent).

Notifications: NRC Resident NO or Will Be is checkedNotifications: State NO or Will Be is checkedNotifications: Local NO or Will Be is checkedNotifications: Other Gov NO or Will Be is checkedAgenciesNotifications: Media/Press NO or Will Be is checkedReleaseAnything Unusual or NOT NO is checkedunderstood?Did all Systems Function as YES is checked, or NO is checked and anrequired explanatory note is included in Event

Description indicating that the Pzr Spray Valve(1 NC-27) failed open (or equivalent).

Approved By: Operator’s NameTime/Date: Present Time and Date

Enclosure 4.2 NRC Event Notification Worksheet Page 2 of 2

All blocks left blank except as follows:

Event Description Continued from Page 1 ONLY IF NEEDED:The ECCS Cold Leg Accumulatorsdischarged 1200 gallons into the RCSduring a valve failure transient (orequivalent).

CRITICAL Information is in BOLD

2014 Admin — JPM Ala SRO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

Initial Conditions: • With Unit 1 in Mode 3, the following event occurred at 0400today:

• Valve 1 NC-27C (Pzr Spray Valve) stuck OPEN resulting ina rapid decrease of NCS pressure.

• The crew entered the appropriate Abnormal OperatingProcedure and manually closed the valve.

• Prior to stabilizing the plant, approximately 1200 gallons ofwater from the Cold Leg Accumulators was injected intothe NCS.

• The O5M has verified that this event has NOT exceeded anEmergency Action Level (Level).

• The OSM believes that this event is reportable to the NRC.

• No external persons and/or agencies have been notified of thisevent, nor have any actions other than those identified beentaken.

INITIATING CUE: The OSM directs you to determine reportability requirements,including completion of any necessary paperwork.

NUREG 1021, Revision 9

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPM Aib SRO

2014 Admin - JPM Aib SRO (REV_071414) NUREG 1021, Revision 9

Appendix C Page 2 of 9 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Review a Completed Procedure JPM No.: 2014 Admin - JPM AibSRO

K/A Reference: 2.1.20 (4.6)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page ofthis JPM), and Handout 1.

. The completed Enclosure 1 3.4 is now ready for review.

201 4 Admin - JPM Al b SRO NUREG 1 021 , Revision 9

Appendix C Page 3 of 9 Form ES-C-i

Job Performance Measure Worksheet

Task Standard: The operator will review completed Enclosure 13.4 of PTI1IAI4600IOO3Dand identify that the Surveillance performer has entered an incorrectvalue for the minimum value of the Cold Leg Accumulator BoronConcentration; and correct this entry. Then when the correction ismade, the operator will determine that the 1A through 1 C CLA are withinthe allowable Boron concentration range, but that the 1 D CLA is outsideof the allowable range. The operator will identify that Mode 3 cannot beentered until 1 D CLA boron concentration is raised, and that Attachment6 of AD-HU-ALL-0004 (Procedure and Work Instruction Use andAdherence) must be completed in accordance with a provided KEY.

Required Materials: Unit 1 COLR and Technical Specifications must be available to theoperator for reference during the JPM.

General References: PT/1/A/4600/003D (Monthly Surveillance Items), Rev 87

AD-HU-ALL-0004 (Procedure and Work Instruction Use and Adherence)Rev 1

MCEI-0400-280 (McGuire Unit 1 Cycle 23 Core Operating LimitsReport), Rev 0

McGuire Technical Specification LCO 3.5.1 (Accumulators), Amendment218/200

Handouts: Handout 1: PT/i/A14600/003D (Monthly Surveillance Items) marked upas follows:

• Procedure Cover Comments Block: This procedure used forEnclosure 13.4 ONLY.

• Checkmarks adjacent to Limits and Precautions 6.1 through 6.4.

• Step 7.1 initialed (with Kevin Cole printed aside).

• Note prior to Step 12.3 checked.

• Step 12.3 initialed.

Enclosure 13.4, “Boron Concentration Checklist,” marked up as follows:

• Step 1 Bullet 1 is NA and initialed.

• Note prior to Step 1 Bullet 2 is checked.

• Step 1 Bullet 2 is initialed, MODE 3 is recorded and TODAY isentered as the date.

• Step 2.1 — ALL four checkboxes are checked. Boron concentrationfor each CLA is recorded as follows:

• CLA1A-2385

• CLA1B-2372

• CLA1C-2291

• CLA 1 D — 2270 (Does NOT Meet Acceptance Criteria)

• Step 2.2 Checkbox is checked. COLR values are recorded asfollows:

2014 Admin - JPM Aib SRO NUREG 1021, Revision 9

Appendix C Page 4 of 9 Form ES-C-i

Job Performance Measure Worksheet

• (MIN) — 2347 (Recorded in ERROR from UI COLR for 250 - 300EFPD, should be 2272)

• (MAX)—2875

• Step 3 Bullet 1 - Left Blank

• Step 3 Bullet 2 - Left Blank (This will be signed off by SROperforming JPM)

Handout 2: Blank copy of Attachment 6, “Equipment Problem EvaluationForm” of AD-H U-ALL-0004, “Procedure and Work Instruction Use andAdherence.” (Handed out during JPM Step 3)

Time Critical Task: NO

Validation Time: 15 minutes

Note: A Key is provided as a separate document to this JPM.

2014 Admin - JPM Al b SRO NUREG 1021, Revision 9

Appendix C Page 5 of 9 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk*)

Provide Candidate with Initial Conditions/Cue (Last Page of this JPM), and Handout 1.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

(AD-H U-ALL-0004, The operator reviews theAttachment 4, Step 6) procedure and SectionProcedure completion 2.11.1 of the Unit 1 COLRapproval and discovers the following

errors:*

(Step 6.c) A supervisor shall • The Minimum Cold Legperform a timely review of Accumulator limit hasthe procedure and verify been incorrectly recordedcompleteness. as 2347, when it should

be 2272.

• The operator will draw aline through 2347, record2272, initial and date theentry.

Cue:

If the operator wantsChemistry to checkindividual CLA BoronConcentration values,report that the valueslisted on Enclosure 13.4are correct.

2014 Admin - JPM Alb SRO NUREG 1021, Revision 9

Appendix C Page 6 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*2 (PT/l/A146001003D, The operator refers to StepEnclosure 13.4, Step 3) 11.3 of PTI1/A146001003DInitial one of the following: and determines that each

Cold Leg Accumulator shallNo Discrepancy contain a boron

concentration within theLCO limits specified in theCOLR.

The operator compares the1 A CLA Cb of 2385 to thecorrected minimum Cb, anddetermines that theAcceptance Criteria is MET.

The operator compares the1 B CLA Cb of 2372 to thecorrected minimum Cb, anddetermines that theAcceptance Criteria is MET.

The operator compares the1 C CLA Cb of 2291 to thecorrected minimum Cb, anddetermines that theAcceptance Criteria is MET.

The operator compares the1 D CLA Cb of 2270 to thecorrected minimum Cb, anddetermines that theAcceptance Criteria is NOTMET.

The operator indicates thatthe procedure would bereturned to the RO tocorrect.

2014 Admin - JPM Al b SRO NUREG 1021, Revision 9

Appendix C Page 7 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*3 (PTI1IAJ4600IOO3D,Enclosure 13.4, Step 3)Initial one of the following: Cue:

. Discrepancy Sheet When the operatorAttached (IF any indicates that the RO willAcceptance Criteria complete a DiscrepancyNOT met, it is identified Sheet, provide Handout 2,as a discrepancy, and ask the operator toevaluated per Tech complete the sheet asSpec/SLC and they would expect the ROappropriate corrective to do.action taken.)

The operator completesAD-H U-ALL-0004Attachment 6 per theprovided KEY.

The operator reviewsTechnical SpecificationLCO 3.5.1 and determinesthat the Specification isNOT applicable in Mode 4,but that entry into Mode 3cannot be made under thecurrent conditions.

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2Oi4Admin-JPMA1bSRO NUREG 1021, Revision 9

Appendix C Page 8 of 9 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No.: 2014 Admin - JPM Aib SRO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2014 Admin - JPM Aib SRO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

Initial Conditions: • Unit 1 is in Mode 4 during a plant startup.

• Current EFPD is 334.

• NC System pressure has stabilized at 1600 psig.

• PTI1IAI4600IOO3D, Monthly Surveillance Items, Enclosure13.4, NC Boron Concentration Checklist, has been performed.

• The completed Enclosure 13.4 is now ready for review.

INITIATING CUE: Review the completed procedure to identify:

• Whether the startup may continue to Mode 1.

• ALL administrative procedural/paperwork requirements.

NUREG 1021, Revision 9

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPMA2SRO

2014 Admin - JPM A2 SRO (REV_071414) NUREG 1021, Revision 9

Appendix C Page 2 of 9 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Perform NC Loop Operability JPM No.: 2014 Admin - JPM A2Verification in Mode 4 SRO

K/A Reference: 2.2.12 (4.1)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handout 1.

Initial Conditions: • The Plant is in Mode 5 with NCS Temperature at 188°F and stable.

• S/G Narrow Range Levels are as follows:

• 1A=10%

• 1B=35%

• iC=15%

• 1D=25%

• The following plant conditions exist:

• Power is available to both 1 ETA and 1 ETB.

• ND Pump 1A is running maintaining NCS Temperature <200°F.

• NDPump1BisOFF.

• The WCCSRO has reported 1 B ND Pump Air Handling Unit hasfailed to meet acceptance criteria during surveillance testing.

• Both ND Pump Breakers are in the CONNECT position withcontrol power ON (all breaker indications are normal)

• All NC Pumps are OFF.

• Except where noted below, all NC Pump Normal FeederBreakers and Safety Breakers are Racked In (all breakerindications are normal)

• The 1 B NCP is tagged out for motor maintenance

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

Appendix C Page 3 of 9 Form ES-C-i

Job Performance Measure Worksheet

• The I D NCP Safety Breaker is Racked Out for breakermaintenance.

• ITA, ITB and lTD are energized via their Normal FeederBreaker (all breaker indications are normal).

• 1TC is energized via its Standby Feeder Breaker (Normal FeederBreaker is OPEN and RACKED OUT).

Initiating Cue: The CRS has directed you to perform Enclosure 13.5 (NC LoopOperability Verification in Mode 4) of PTIIIAI4600/003 C (WeeklySurveillance Items), in preparation to transition to Mode 4.

Task Standard: The operator will complete Enclosure 13.5 in accordance with theprovided KEY.

Required Materials: All General References should be available to the operator.

General References: PT111A146001003 C (Weekly Surveillance Items), Rev 72

PTI1IA/4204101 1 (1 B ND Pump Air Handling Unit Performance Test),Rev 19

OPI1/A/6100/SU-9 (Mode 4 Checklist) Rev 64

McGuire Technical Specifications (LCO 3.4.6/Amendment 216/1 97 and261/241)

AD-HU-ALL-0004 (Procedure and Work Instruction Use and Adherence)Rev 1

Handouts: Handout 1: PT/1/A/4600/003 C (Weekly Surveillance Items) Procedurebody and Enclosure 13.5 (NC Loop Operability in Mode 4))

Time Critical Task: NO

Validation Time: 15 minutes

NOTE: An Answer KEY is provided as a separate document.

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

Appendix C Page 4 of 9 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk*)

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handout 1.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

i (Step 1.1) IF performing The operator places an NIAroutine weekly in the signoff space andsurveillances, record the proceeds.following:

Mode of Operation:

Date:

2 (Step i .2) IF performing this The operator enters 4 in theprocedure in preparation for Mode to be entered anda Mode change, record the Today’s Date in the Datefollowing: Block, and initials the

signoff space.Mode to be entered:

Date:

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

Appendix C Page 5 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*3 (Step 1.3) Check two of the The operator recognizesfollowing Loops operable that NC Loop A is NOTand one (of the operable) in OPERABLE because theoperation: SG NR Level is too low.

The operator recognizesthat NC Loop B is NOTOPERABLE because the1 B NCP is tagged out formotor maintenance.

The operator recognizesthat NC Loop C isOPERABLE, and places acheck in the Checkbox inColumn I (OPERABLE).

The operator recognizesthat NC Loop D is NOTOPERABLE because the1 D NCP Safety Breaker isRacked Out for breakermaintenance.

The operator recognizesthat ND Loop A isOPERABLE and inoperation, and places acheck in the Checkbox inColumn I (OPERABLE)and 2 (In Operation).

The operator recognizesthat ND Loop B is NOTOPERABLE because thelB ND PUMP AHU has justfailed its surveillance.

The operator initials thesignoff space.

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

(Step 1.4) IF 2 of theoperable Loops in Step 1.3are NOT in operation,complete the following forthe operable pump NOT inoperation.

The operator recognizesthat the 1C NC Pump mustbe assessed in Step 2.

The operator recognizesthat except where noted, allNC Pump Normal FeederBreakers and SafetyBreakers are Racked In (allbreaker indications arenormal). There are nonoted exceptions for the 10NC Pump Breakers.Consequently, the operatorplaces a check in the fourYES Checkboxes for theNC Pump IC.

The operator recognizesthat 1TA, 1TB and lTD areenergized via their NormalFeeder Breaker (all breakerindications are normal); andthat iTO is energized via itsStandby Feeder Breaker (allbreaker indications arenormal); and that accordingto Note 2 this is acceptableto meet the 1 NC Pumprequirements. The operatorplaces a check in the NOCheckbox for the Normal

Appendix C Page 6 of 9 Form ES-C-i

PERFORMANCE INFORMATION

*4

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

Fdr Bkr Racked In, andcalls attention (i.e. circlesor equivalent) to Note 2;and checks YES in thesecond Checkbox forITC.

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

Appendix C Page 7 of 9 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

(Step 1.5) Initial one of the The operator initials thefollowing:

“ No Discrepancy” signoff. space.

No Discrepancy

Discrepancy SheetAttached (IF anyAcceptance Criteria NOTmet, it is identified as adiscrepancy, evaluated perTech Spec/SLC andappropriate correctiveaction taken.)

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

Appendix C Page 8 of 9 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No.: 2014 Admin - JPM A2 SRO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2014 Admin - JPM A2 SRO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

Initial Conditions: • The Plant is in Mode 5 with NCS Temperature at 188°F andstable.

• SIG Narrow Range Levels are as follows:

• iA=iO%

• iB=35%

• iC=i5%

• iD=25%

• The following plant conditions exist:

• Power is available to both 1 ETA and 1 ETB.

• ND Pump 1A is running maintaining NCS Temperature <

200°F.• ND Pump lB is OFF.

• The WCCSRO has reported lB ND Pump Air HandlingUnit has failed to meet acceptance criteria duringsurveillance testing.

• Both ND Pump Breakers are in the CONNECT positionwith control power ON (all breaker indications are normal)

• All NC Pumps are OFF.

• Except where noted below, all NC Pump Normal FeederBreakers and Safety Breakers are Racked In (all breakerindications are normal)

• The 1 B NCP is tagged out for motor maintenance.

• The 1 D NCP Safety Breaker is Racked Out forbreaker maintenance.

• 1TA, 1TB and lTD are energized via their Normal FeederBreaker (all breaker indications are normal).

• 1TC is energized via its Standby Feeder Breaker (NormalFeeder Breaker is OPEN and RACKED OUT).

INITIATING CUE: The CRS has directed you to perform Enclosure 13.5 (NC LoopOperability Verification in Mode 4) of PT/i/A14600/003 C (WeeklySurveillance Items), in preparation to transition to Mode 4.

NUREG 1021, Revision 9

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPMA3SRO

2014 Admin - JPM A3 SRO (REV_071414) NUREG 1021, Revision 9

Appendix C Page 2 of 10 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Perform a Unit Vent Flow JPM No.: 2014 Admin - JPM A3Calculation of a Containment Air SRORelease

K/A Reference: 2.3.11 (4.3)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last Page of this JPM), and Handouts 1-3.

Initial Conditions • GWR Package #2014013 for Unit 1 Containment Air Release iscurrently in use to conduct a series of Containment air releases.

• Three releases have been made

• During the first release, conducted using Enclosure 4.2 (Air ReleaseMode With VQ Flow Monitor Operable) of OP/1/A16450/01 7(Containment Air Addition and Release), the Unit 1 VQ Monitorbecame inoperable.

• The crew stopped the release and continued the air release usingEnclosure 4.3 (Air Release Mode with VQ Flow Monitor Inoperable)of OP/1/A16450/01 7 (Containment Air Addition and Release), andrecorded the release volume on the GWR paperwork.

• At 1743 on 8/4/14, containment pressure was 0.18 PSIG andanother (4th) VQ release was initiated to reduce pressure to 0.12PSIG per Step 3.9 of Enclosure 4.3.

• This release was secured at 1839 on 8/4/14 and the procedure wascompleted through step 3.8.1 for this 4t release.

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Page 3 of 10 Form ES-C-i

Job Performance Measure Worksheet

Initiating Cue: • You have been directed to calculate the volume released for therelease and complete all required paperwork starting with Step 3.8.2,AND, since this is the last release for GWR package 2014013,perform Steps 3.10.4 through 3.10.9 of Enclosure 4.3 to determinethe total volume released from the Containment.

• The CRS notified RP (Mike Cline) at 1840 on 8/4/14 that the releasehas been terminated.

Task Standard: The operator will calculate the volume of air released from theContainment during the final release, and determine the total volume ofair released in the series of four releases in accordance with theprovided KEY.

Required Materials: Calculator

General References: OPI1/A16450/017 (Containment Air Release and Addition System), Rev41

Handouts: Handout 1: Enclosure 4.2 (Air Release Mode With VQ Flow MonitorOperable) of OP/1/A16450/0i7 (Containment Air Addition and Release)marked up as follows:Step 2.1 — Initialed.

Step 2.2— Initialed.

Step 2.3— Initialed.

Step 2.4— Initialed, GWR# 2014013 recorded.

Step 3.1 — Checkbox is checked.

Step 3.2— Initialed.

Step 3.2.1 — Initialed and CV initialed.

Step 3.2.2 — Initialed and CV initialed.

Step 3.2.3— Checkbox is checked

Step 3.2.4 — Initialed and Mike Cline/Date/Time Recorded consistent with first release Date/Time (8/4/14 0903).

Step 3.3— N/A and Initialed.

Step 3.4 —Initialed.

Step 3.5—Initialed and CV initialed.

Step 3.6— Initialed.

Step 3.7 — Initialed.

Step 3.8— Initialed.

Step 3.8.1 — Checkbox is checked.

Step 3.8.2 — Checkbox is checked.

Step 3.8.3 — Initialed and CV initialed, VQ Monitor flow is recorded as 1236, and Actual Volume Released is recorded as 1 2360.

Step 3.8.4 — All three Checkbox are checked.

Step 3.8.5 — Initialed.

Step 3.8.6 — Checkbox is checked.

Step 3.9.1 — Checkbox is checked.

Step 3.9.2 — Checkbox is checked.

Step 3.9.3 — Checkbox is checked.

Step 3.9.4 — Checkbox is checked.

Step 3.9.5 — Both Checkbox’ are checked.

Step 3.9.6 — Checkbox is checked.

Step 3.9.7—Initialed.

Step 3.10 — Initialed.

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Page 4 of 10 Form ES-C-i

Job Performance Measure Worksheet

Page 5 of 5 (Attachment 1) is marked up as follows: Sheet I of I

IVQ-28 Open IVQ-2B ClosedDoer CV VQ Flow VQ Flow DatelTime Doer CV Date/Time

Monitor LessCounting Than 300

(“I) cfm (‘i)Initial Initial 814114 0903 Initial Initial 8/4114 1016

Handout 2: Enclosure 4.3 (Air Release Mode With VQ Flow MonitorInoperable) of OPI1IAI6450/0i7 (Containment Air Addition and Release)marked up as follows:Step 2.1 — Initialed.

Step 2.2 — Initialed.

Step 2.3— Initialed.

Step 2.4— Initialed, GWR# 2014013 recorded,

Step 3.1 — Checkbox is checked.

Step 3.2—Initialed.

Step 3.2.1 — Initialed and CV initialed.

Step 3.2.2 — Initialed and CV initialed.

Step 3.2.3 — Checkbox is checked.

Step 3.2.4 — Initialed and Person Noti8ed/DatelTime Recorded consistent with first release Date/Time on Page 6 of 6.

Step 3.3— NA and Initialed.

Step 3.4— Initialed.

Step 3.5—Initialed and CV initialed.

Step 3.6.1 — Checkbox is checked.

Step 3.6.2 — Checkbox is checked.

Step 3.6.3 — Checkbox is checked.

Step 3.6.4 — Both Checkbox are checked.

Step 3.6.5 — Checkbox is checked.

Step 3.6.6 — Initialed.

Step 3.7— NA and Initialed.

Step 3.8 — Initialed.

Step 3.8.1 - Checkbox is triple-checked.

Step 3.8.2 - Checkbox is double-checked.

Step 3.8.3 - Double Initialed, and double CV initialed.

Step 3.9—Initialed.

Page 6 of 6 (Attachment 1) is marked as follows: Sheet I of I

IVQ-2B Open IVQ-2B ClosedDoer CV Date/Time Start Doer CV DatelTime Stop Ft Total Ft

Pressure Pressure Released Released(psig) (psig)

Initial Initial 8I4I14 1117 0.22 Initial Initial 814/14 1258 0.12 21,740.17 21,740.17Initial Initial 8!4I14 1432 0.20 Initial Initial 814114 1547 0.12 15,747.32 37,487.49Initial Initial 8/4/14 1743 0.18 Initial Initial 0.12

Handout 3: GWR Paperwork with 12360ft3 release volume fromEnclosure 4.2 recorded.

Time Critical Task: NO

Validation Time: 15 minutes

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Page 5 of 10 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk

Provide Candidate with Initial Conditions/Cue (Last Page of this JPM), and Handouts 1-3.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

(Enclosure 4.3, Step The operator records

3.8.2) Record stop 8/4/14 1839 in the 1VQ-

date/time on Attachment 28 Closed Date/Time

1 Block of Attachment 1.

2 (Step 3.7.3) Calculate The operator uses Table 1volume released using the of Enclosure 4.3 andfollowing and record on determines X to be 17.31Attachment 1. (Start Pressure of 0.18).

(Documentation of The operator uses Table 1calculation NOT required) of Enclosure 4.3 and

Cu. Ft. Released = x + determines Y to be 203.99

(YxZ)(Start Pressure of 0.18).

Where:The operator usesAttachment 1 of Enclosure

X and Y are from Table 1 4.3 and determines Z to be56 (Stop Time of 1839-

Z is actual release duration StartTimeof 1743).in minutes fromAttachment 1. The operator calculates

volume released as follows:

17.31 + (203.99 x 56) =

11,440.75±0.5% (SeeKEY), and records thisvalue in the 1VQ-2BClosed Cubic Ft ReleasedBlock of Attachment 1.

3 (Step 3.10.4) Ensure The operator ensures

release stop date/time 8/4/14 1839 recorded in

recorded on Attachment the 1VQ-2B Closed

1. Date/Time Block ofAttachment 1.

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Page 6 of 10 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

4 (Step 3.10.5) Notify RP The operator recognizesthat release has been from the initial conditionsterminated that RP has been notified.

5 (Step 3.10.6) Determine The operator adds theTotal Cu. Ft Released on volume of this most recentAttachment 1. release (11,440.75) to the

total previously released onAttachment 1 (37,487.49)and determines that the

* total volume released is48,928.24 ft3 (See KEY).

The operator records thisvalue in the 1VQ-28Closed Total Cubic FtReleased Block ofAttachment 1.

6 (Step 3.10.7) Record Total The operator recordsCu. Ft Released from 48,928.24 (See KEY) in theAttachment 1: ft3 1 VQ-2B Closed Cubic Ft

Released Block ofAttachment 1.

2Ol4Admin-JPMA3 SRO NUREG 1021, Revision 9

Appendix C Page 7 of 10 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

*7 (Step 3.10.8) IF any VQ The operator observesTotalizer readings recorded GWR paperwork andon GWR paperwork, determines that 12,360 ft3perform the following: had been released when

the VQ Monitor was(Step 3.10.8.1) Determine operable and records thisTotal Volume Released as value on Enclosure 4.3recorded on GWR Step 3.10.8.2.paperwork.

(Step 3.10.8.2) RecordTotal Volume Releasedfrom GWR:ft3.

*8 (Step 3.10.9) Calculate The operator adds the totalTotal Volume Released for volume released recordedGWR as follows: in Step 3.10.7 (48,928.24)

and the total volumereleased recorded in Step

ft3 + ft3 = 3.9.8.1 (12,360), anddetermines the TotalVolume Released for this

Step 3.10.7 Step 3.10.8.2 Total Vol series of Containment AirReleases is 61,288.24 ft3(See KEY).

Terminating Cue: Evaluation on this JPM is complete.

STOP TIME:

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Page 8 of 10 Form ES-C-i

VERIFICATION OF COMPLETION

Job Performance Measure No: 2014 Admin - JPM A3 SRO

Examinee’s Name:

Date Performed:

Facility Evaluator:

Number of Attempts:

Time to Complete:

Question Documentation:

Result: SAT UNSAT

Examiner’s Signature: Date:

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Page 9 of 10 Form ES-C-i

VERIFICATION OF COMPLETION

KEY:

Enclosure 4.3, Attachment 1:

RED = filled in at start of JPM.GREEN = filled in during JPM performance

IVQ-2B Open IVQ-2B ClosedDoer CV Date/Time Start Doer CV Date/Time Stop Ft4 Total Ft3

Pressure Pressure Released Released(psig) (psig)

Initial Initial 8/4/141117 0.22 Initial Initial 8/4/141258 0.12 21,740.17 21,740.17Initial Initial 814114 1432 0.20 Initial Initial 8/4/14 1547 0.12 15,747.32 37,487.49Initial Initial 8/4/14 1743 0.18 Initial Initial 8/4/14 1839 0.12 11,440.75 48,928.24

Enclosure 4.3, Step 3.7.3 (JPM Step 2): Volume released, current release:17.31 ft3 + (203.99 ft3!min x 56 mm ) = 11,440.75 ft3 (11,383.55 - 11,497.95)

Enclosure 4.3, Step 3.10.6 (JPM Step 5): Total Volume released, during performance ofEnclosure 4.3:11,440.75 ft3 + 37,487.49 ft3 = 48,928.24 ft3 (48,871.04 — 48985.44)

Enclosure 4.3, Step 3.10.9 (JPM Step 8): Total Volume released, during performance of GWPermit:48,928.24 ft3 + 12360 ft3 = 61,288.24 ft3 (61,231 .04 — 61,345.44)

2014 Admin - JPM A3 SRO NUREG 1021, Revision 9

Appendix C Form ES-C-i

JPM CUE SHEET

initial Conditions: • GWR Package #2014013 for Unit 1 Containment Air Releaseis currently in use to conduct a series of Containment airreleases.

• Three releases have been made.

• During the first release, conducted using Enclosure 4.2 (AirRelease Mode With VQ Flow Monitor Operable) ofOP/11A16450101 7 (Containment Air Addition and Release), theUnit 1 VQ Monitor became inoperable.

• The crew stopped the release and continued the air releaseusing Enclosure 4.3 (Air Release Mode with VQ Flow MonitorInoperable) of OP/i /A1645010i 7 (Containment Air Addition andRelease), and recorded the release volume on the GWRpaperwork.

• At 1743 on 8/4/i 4, containment pressure was 0.18 PSIG andanother (4th) VQ release was initiated to reduce pressure to0.12 PSIG per Step 3.9 of Enclosure 4.3.

• This release was secured at 1839 on 8/4/14 and the procedurewas completed through step 3.8.1 for this 4th release.

INITIATING CUE: • You have been directed to calculate the volume released forthe 4th release and complete all required paperwork startingwith Step 3.8.2, AND, since this is the last release for GWRpackage 2014013, perform Steps 3.10.4 through 3.10.9 ofEnclosure 4.3 to determine the total volume released from theContainment.

• The CRS notified RP (Mike Cline) at 1840 on 8/4/14 that therelease has been terminated.

NUREG 1021, Revision 9

Appendix C Job Performance Measure Form ES-C-i

Worksheet

JPMA4SRO

2014 Admin - JPM A4 SRO (REV_071414) NUREG 1021, Revision 9

Appendix C Page 2 of 13 Form ES-C-i

Job Performance Measure Worksheet

Facility: McGuire Task No.:

Task Title: Classify an Emergency Event JPM No.: 2014 Admin - JPM A4SRO

K/A Reference: 2.4.41 (4.6)

Examinee: NRC Examiner:

Facility Evaluator: Date:

Method of testing:

Simulated Performance: Actual Performance: X

Classroom X Simulator Plant

READ TO THE EXAMINEE

I will explain the initial conditions, which steps to simulate or discuss, and provide initiatingcues. When you complete the task successfully, the objective for this Job PerformanceMeasure will be satisfied.

Provide Candidate with Initial ConditionslCue (Last two Pages of this JPM), andHandouts 1-2.

Initial Conditions: A plant event is in progress on Unit 1 (See Timeline).

IrlIIIaFIr-H--1 L •ue a I :Ia’ITI tn I—went in 1AII?ri 1..’I—’IlIiL1I’-, Il II Ifl Ii II I

f

approval

Task Standard: The operator will declare an ALERT based on 4.4.A.1, Failure ofReactor Protection System Instrumentation to Complete or Initiate anAutomatic Reactor Trip Once a Reactor Protection System Setpoint HasBeen Exceeded and Manual Trip WAS Successful; and complete thepre-printed ENF 4.4.A.1 in accordance with the attached KEY.

Required Materials: None

2014 Admin - JPM A4 SRO NUREG 1021, Revision 9

Appendix C Page 3 of 13 Form ES-C-i

Job Performance Measure Worksheet

General References: RPIOIAJ5700/000 (Classification of Emergency), Rev 21

RP/0/A/57001001 (Notification of Unusual Event), Rev 28

RP/0/A/5700/002 (Alert), Rev 28

RP/0/A’5700/003 (Site Area Emergency), Rev 29

RP/0!A157001004 (General Emergency), Rev 28

RP/0/B/57001029 (Notifications to Offsite Agencies From the ControlRoom), Rev ii

OP/lIAI6iOOIOiO Q (Annunciator Response for Panel 1RAD-i), Rev 65

AP/i/A/5500/10 (NC System Leakage Within the Capacity of Both NVPumps), Rev 23

AP111A1550014 (Rapid Downpower), Rev 25

EPI1IAI5000/E-0 (Reactor Trip or Safety Injection), Rev 33

EPI1/A15000/ECA-0.0 (Loss of All AC Power), Rev 34

OMP 4-3 (Use of Abnormal and Emergency Procedures), Rev 38

McGuire Technical Specifications

Handouts: Handout 1: RP/O/A/5700/000 (Classification of Emergency)

Handout 2: RP101B157001029 (Notifications to Offsite Agencies From theControl Room)

Handout 3: Blank copies of preprinted Nuclear Power Plant EmergencyNotification Forms

Time Critical Task: YES — 15 minute to make classification, and THEN 15 minutes tocomplete ENF.

Validation Time: 30 minutes

2014 Admin - JPM A4 SRO NUREG 1021, Revision 9

Appendix C Page 4 of 13 Form ES-C-i

PERFORMANCE INFORMATION

(Denote Critical Steps with an asterisk

Provide Candidate with Initial Conditions/Cue (Last two Pages of this JPM), andHandouts 1-2.

START TIME:

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

(OMP 4-3, Steps The operator enters7.20.1/7.20. 1.1) OSM RP/0/A15700/000, Step 2.1.Responsibilities

Assume role of EmergencyCoordinator upon activationof the Emergency Plan untilproperly relieved by theStation Manager.

2 (RPIO/A15700/000, Step The operator reads the step2.1) Assessment, and proceeds.classification anddeclaration of any The operator refers toapplicable emergency Enclosure 4.9 as needed.condition should becompleted within 15minutes after the availabilityto indications or informationto cognizant facility staffthat an EAL threshold hasbeen exceeded. (Refer toenclosure 4.9, EmergencyDeclaration Guidelines, asneeded.)

3 (RP/0/A/5700/000, Step The operator enters2.2) Determine operating determines that the plantmode that existed at the was in Mode 1 at the starttime the event occurred of the event.prior to any protectionsystem or operator actioninitiated in response of theevent.

2014 Admin - JPM A4 SRO NUREG 1021, Revision 9

Appendix C Page 5 of 13 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

4 (RP/0/A15700/000, Step The operator reviews2.3) IF the plant was in Enclosure 4.1, andMode 1-4 and a valid determines that no Loss orcondition affects fission Potential Loss of a Fissionproduct barriers, THEN Product Barrier exists perproceed to Enclosure 4.1 Enclosure i.(Fission Product BarrierMatrix).

2014 Admin - JPM A4 SRO NUREG 1021, Revision 9

(RPIOIAI5700I000, Step2.4) IF a GeneralEmergency is NOTdeclared in Step 2.3, ORthe condition does not affectfission product barriers,THEN review the listing ofenclosures to determine ifthe event is applicable toone of the categoriesshown.

The operator reviewsEnclosure 4.2 through 4.7,and determines thefollowing:

The operator reviewsEnclosure 4.2 anddetermines that a UE exists,based on 4.2.U.4. ReactorCoolant System (NCS)Leakage. [4.2.U.4-2Unidentified Leakage 10gpm].

The operator reviewsEnclosure 4.4 anddetermines that an ALERTexists, based on 4.4.A.1,Failure of ReactorProtection SystemInstrumentation toComplete or Initiate anAutomatic Reactor TripOnce a Reactor ProtectionSystem Setpoint Has BeenExceeded and Manual TripWAS Successful. [4.4.A.1-1The following conditionsexist: Valid reactor tripsignal received or requiredand automatic reactor tripwas not successful ANDManual reactor trip from thecontrol room is successfuland reactor power is lessthan 5% and decreasing.].

The operator reviewsEnclosure 4.5 anddetermines that no EALshave been exceeded(Although if 1 ETA is not reenergized by 0705, 4.5.U.1-1 NOUE would apply).

Appendix C Page 6 of 13 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIRED

FOR UNSAT

5

2014 Admin - JPM A4 SRO NUREG 1021, Revision 9

Appendix C Page 7 of 13 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT

*6 (RP/OIA/5700/000, Step The operator determines2.5) Compare actual plant that an ALERT exists,conditions to the based on based on 4.4.A.1,Emergency Action Levels Failure of Reactorevaluated in 2.3 and/or 2.4, Protection Systemthen declare the appropriate Instrumentation toEmergency Class as Complete or Initiate anindicated. Automatic Reactor Trip

Once a Reactor ProtectionSystem Setpoint Has BeenExceeded and Manual TripWAS Successful.

The operator records theevent declaration time inStep 2.5.1.

Examiner Note: Record Time Critical Stop Time

NOTE that this time is also the Start Time for the 2nd Time Critical action of completing thepre-printed ENF 4.4.A.1.

Provide the operator with Handout 3 (Pre-printed ENF for EAL). NOTE: that a pre-printedform for a different EAL must be provided if requested.

7 (RP/01A157001000, Step The operator proceeds to2.6) Implement the RP/O/A157001002,applicable Emergency Immediate Actions.Response Procedure (RP)for that classification andcontinue with subsequentsteps of this procedure.• Notification of Unusual

Event RP/0/A/5700/0O 1• Alert RPIO/A157001002• Site Area Emergency

RP/01A157001003• General Emergency

RPIO/A15700/004.

2014 Admin - JPM A4 SRO NUREG 1021, Revision 9

Appendix C Page 8 of 13 Form ES-C-i

PERFORMANCE INFORMATION

STEPS ELEMENTS STANDARD S/U COMMENTSREQUIREDFOR UNSAT