APOLLO GRANITE PRODUCT MODULE -...

Transcript of APOLLO GRANITE PRODUCT MODULE -...

Contents..

Raw Material – What is Granite?

Manufacturing

Fabrication

Technical Points and tables

Key points & USP’s

Certification

Planning & options

Handling & Size

Damage Prevention

Care & Maintenance

Contents

Granite is an igneous rock formed as a result of the slow crystallisation of molten magma at depth in the earths crust.

Darker colours formed deeper in the earth than the lighter more crystalline colours and were thus cooled more slowly and are subsequently more stable (stronger) e.g.. Nero Absoluto. Colours such as Baltic Brown formed closer to the surface and cooled quicker and exhibit bigger crystals which are weak points.

Uplift and erosion has over millions of years resulted in this material outcropping at the surface (i.e. mountain ranges).

The minerals that make up Granite are generally quartz, feldspar and various mafic minerals (amphiboles - a group of common rock-forming silicate minerals., pyroxenes a group of important rock-forming inosilicate minerals , micas – reflectors in blue pearl and secondary materials .

It is the size, distribution and precise chemistry of these minerals which give granite its colour.

What is Granite ?

No two pieces of Granite are alike, each is totally unique.

Granite is one of the hardest substances on earth with a rating of 7 on Moh’s hardness scale (Diamond having a rating of 10 !)

What is Granite ?

Composition :

Mica Feldspar Quartz

The material is rubbed , not cut, into scants (slabs) of

uniform thickness by using a series of steel blades and steel shot (aggregate) . This process can take between one and five

days depending on the material density.

The slabs are then highly polished on one side using a line polishing machine. A series of polishing heads holding in excess of 100

polishing pads create this finish. This is very difficult to replicate using hand held machinery or a

CNC. Hence why recess drainers are duller in appearance

How is it manufactured? ..

Granite is quarried in large blocks, typically measuring 3m by 2m.

These huge rough cut blocks often do not give any indication of the

beautiful Granite colour until polished.

The worktops are then taken for hand finishing,

QA checking and packaged ready for dispatch.

Once cut, the edge detail is applied using an edge

polisher, then any cut outs or drainer grooves are

added by the CNC machine.

How is it manufactured? ..

The worktops are then cut from the raw sheet material

using one of our stone saws or the Combi Cut machine,

currently the only in the UK.

The molecular structure renders Granite very stable and rigid, it will not bend or

flex.

Granite is not suitable in long span applications.

Pitting and veining will occur in a random distribution of swirls, in addition,

variations in shade or areas of contrast are all common within Granite.

Occasionally this can be quite dramatic.

Some level of what could be referred to as spots or blotches are inherent in the

material. Small fissures are a common feature in any Granite and these natural

flaws were present at rock formation.

Baltic Brown, Giallo Veneziano and certain other lighter colours are resin

treated at source to fill natural flaws and larger pit marks.

Small scratches of less than 25mm in length are within tolerance and are

considered acceptable.

Technical – Points to note

Due to the nature of Granite, the thickness of the worktops can vary slightly.

Sheridan endeavor to keep this variation within a tolerance of +2mm.

Granite is sometimes susceptible to ‘blowing out’. This occurs when contact is

made with the material whilst cutting or grinding. This is very common in large

particled Granite, Sheridan will fill and seal affected areas with epoxy resin,

(color may vary) to ensure the material is not left with any sharp edges or chips.

Please note, drainer grooves are designed to create a vacuum release for items

that are placed over the drainer area. Excess water that is retained over the

drainer area and in the grooves themselves, needs to be wiped away as is the

case with all sink drainers.

Tables should be referred to when planning for granite worktops:

1- aesthetics,

2- weight, maximum lengths with cut outs and upstands

Technical – Points to note

1- aesthetics & weight, maximum lengths with cut outs and upstands

Technical – Points to note

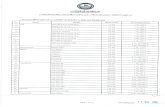

COLOUR

Weight/area ratio Max20mm length 30mm length with cutout Max length

kg/sq mtr Upstand

Crystal

Porosity Strength Dyes/Fillers or Colour Enhancers

Veining

Unpolished Polished Unpolished Polished

Size 20mm 30mm 40mm Cutout Cutout Cutout Cutout 60mm 100mm

Deep Deep Deep 20mm 20mm 30mm 30mm Upstand Upstand

Group 1

Spice Black Small Good Good Resin Filled None 62 93 124 2.3 2.5 2.3 2.5 2.3 2.5

Steel Grey Medium Good Good None None 62 93 124 2.3 2.5 2.3 2.5 2.3 2.5

Bianco Sardo Medium Poor Good None Moderate 62 93 124 2.3 2.5 2.3 2.5 2.3 2.5

River Valley White Large Poor Poor Resin Filled Prominent 62 93 124 2.0 2.3 2.0 2.3 2.0 2.3

Baltic Brown Large Good Good Resin Filled None 62 93 124 2.3 2.5 2.3 2.5 2.3 2.5

Group 2

Uba Tuba Medium Poor Good Resin Filled Moderate 62 93 124 2.0 2.3 2.0 2.3 2.0 2.3

Group 3

Nero Impala Medium Poor Poor None Prominent 62 93 124 2 2.3 2 2.3 2 2.3

Group 3A

Viscon White Large Poor Good None Prominent 62 93 124 2.3 2.5 2.3 2.5 2.3 2.5

Group 4

Venetian Gold Large Poor Moderate Resin Filled Moderate 62 93 124 2.1 2.1 2.5 2.1 2.5 2.5

Group 5

Jet Black Small Good Excellent None Moderate 67 99.5 134 2.4 2.8 2.4 2.8 2.4 2.8

Group 6 B

Star Galaxy Small Good Excellent None Occasional 67 99.5 134 2.4 2.8 2.4 2.8 2.4 2.8

Group 6 B

Blue Pearl large Good Good Resin Filled None 62 93 134 2.3 2.6 2.3 2.6 2.3 2.6

Key points & USP’s

Beautiful timeless appearance

No two pieces of Granite are ever exactly the same

Extremely hardwearing, Granite is one of the hardest materials on earth

A Granite worktop can last a lifetime if looked after well

Granite will not scratch under normal use

Easy to clean and maintain

All Sheridan products are offered with a 10 year manufacturer’s limited

warranty.

Apollo Granite Colours

Spice Black

Steel Grey

Baltic Brown

Viscon White Star Galaxy

Blue Pearl

Verde UbaTuba Bon Accord

Ivory Fantasy Jet Black River Valley White

New Venetian Gold

Granite Naturally

What’s Granite ? - Granite is a natural substance, formed from slowly cooling magma

subjected to Extreme pressures deep beneath the earths surface. Pitting and veining is

natural and will occur in a random distribution of swirls, in addition, variations in shade or

areas of contrast are all common within Granite. Occasionally this can be quite dramatic in

both veining and base colour.

Features

Pro’s Considerations

Timeless Beauty, ageless yet always

contemporary

Can vary in thickness, colour, grain, vein

and may contain pitmarks

One of the hardest substances on earth Recess drainers and drainer grooves are

duller in appearance compared to the

surface

Extremely hardwearing – wont scratch

under normal use

Stain resistant not stain proof, requires

sealant

Easy to clean and maintain Joints are not seamless and are visible

with a small arris

Solid 30mm thickness Scratches cannot be polished out

Joint positions..

Plan the worktop layout to ensure joints don’t fall on or within 50mm of

cutouts and cutouts are at least 50mm from the worktop edge.

Wherever possible, joints in worktops should fall on a carcass end panel not

in the middle, this gives additional support to a joint.

Location of joints are determined at template stage. The number of joints will

always be kept to a minimum where possible (please refer to table 2 above) .

Joints/notches are finished with a small arris to the top edge to remove sharp

edges. Silicon sealant is applied to the joint below the arris to avoid water

ingression.

Arris Joint

100mm min

100mm min

Joints must be at least 100mm from sink or 120mm from

hob cutout.

Where Sheridan are templating, all aspects below will be taken into

consideration by the Sheridan templater

Butt Joint – required for double bevel and double

pencil edge.

Scribed Joint - required for Bullnose and Sharks Nose

edge.

Joint positions

Joints above appliances are acceptable provided front and back support rails are fitted.

Joints should never fall on sink or hob cut-

outs

Joint positions..

Where Sheridan are templating, all aspects below will be taken into

consideration by the Sheridan templater

Double Notch

Triple Notch

Full/Part Return

Single Radius

Internal Splay

External Splay

Return Ends/Options ..

Double Radius/Curved End Breakfront Curved Breakfront

Sink / Hob Cut outs ...

Unpolished cut out (overmount/inset sink or hob cutout )

Undermounted polished sink cut out

Undermounted square polished sink cut out (less than 15mm radius corners)

Tap hole

Polished Belfast cut out (Includes drip groove

on underside)

Drainer Grooves ...

5 Groove (1-5mm Slope) Leaf (1-5mm Slope) 5 Groove Angled (1-5mm Slope)

Flat with a 3mm recess)

Note : Drainer grooves do not drain

Oblique – Dogs Leg(1-

5mm Slope)

Drainer Grooves ...

5 Groove (1-5mm Slope)

Recessed Drainer (flat with a 3mm recess)

There are two drainer options available in Granite, a five grooved drainer and the recessed drainer.

Drainer grooves and recessed drainers will be slightly duller than the surrounding worksurface, as they are machined after the slab has been polished.

Drainer grooves are designed to create a vacuum release for items that are placed over the drainer area. Excess water that is retained over the drainer area and in the grooves themselves, needs to be wiped away as is the case with all sink drainers.

Pan Rests ...

Pan rests are aesthetically pleasing and provide a solution to

the problem of hot pans on worktops.

Hot pans can cause thermal shock and / or scorching when placed on a

quartz worktop and the consequences can be both dangerous and

damage worktops.

Pan rest are stainless steel

Cut outs – further notes ..

Granite can expand by up to 1mm per metre. A gap of at least 3mm should be

left at each end of the worktop when fitted, and filled with decorators caulk.

Granite sink / hob cut outs are barred front & back (fitting of steel support bars

to give additional support to cutouts), without steel support bars the length of a

cut out is reduced considerably.

Allow a minimum 50mm from the hob cut out or unpolished sink cut out to the

front edge

Allow a minimum of 120mm between heated cut outs

Allow a minimum of 80mm from the polished sink cut out to the front edge

Cut outs – further notes ..

Allow a minimum of 70mm between sink cut outs

Splash backs and upstands over 100mm must have a minimum gap from the

face to the rear of the hob of:

Electric 50mm, Gas 100mm

If a waste disposal system is fitted to an undermounted sink additional support

will be required. This must be addressed by the kitchen fitter/plumber NOT by

Sheridan. Failure to add the additional support will invalidate the warranty.

Additional support is required for ceramic sinks. This too, must be addressed by

the kitchen fitter NOT by Sheridan.

Cut outs – further notes ..

Stainless Steel Sink Installation -

All sink cut outs will be as the sink manufactures specification (Unless otherwise

requested in writing)

Silicone sealant may be rendered ineffective when connecting taps and

plumbing in the sink.

It is important that the sink is resealed immediately after connection to avoid

moisture ingression. This is done by the consumers plumber. Failure to do so

with invalidate the warranty

Edge Detail..

Double Bevel

Double Pencil Full Bullnose

Single Pencil

Single Ovolo Imperial

Sharks Nose*

The edge detail can completely change the appearance of a worktop to suit the

kitchen design. Edge detail may also be slightly duller than the worksurface.

* Please note: this edge detail requires a minimum worktop width of 615mm (as opposed to 600mm).

Ogee Birds Beak

Half bull

Single Bevel

Edge Detail..

An edge detail may be slightly duller than the worksurface.

Bevel edges are hand finished and in some instances the material may chip

when cut, this will result in a larger bevel being applied, which will be matched

throughout the installation.

Bull nose and Sharks nose edge details will require a scribed (Masons mitre)

joint.

Apollo Granite joints are finished with a small arris to the top edge to remove

sharp edges. Silicone sealant is applied between the two pieces to prevent water

ingression, it’s not used to fill the joint.

Overhangs ..

Please note if walls are not straight, you may need to order 700mm wide

worktops rather than 600mm

Unsupported worktop overhang must not exceed 300mm.

Maximum unsupported span between units is 600mm. For the rear edge,

anything over 600mm requires a support baton fitted to the back wall.

Standard overhang is 35mm from the carcass front, not the door.

35mm

Upstands ..

100mm

20mm Granite upstands are 20mm thick.

Upstands are not normally cut from the same slab as the worksurfaces, therefore an exact colour match is not possible.

Granite upstands are straight and rigid, gaps will be visible where there are variations in the wall profile. Plastering or tiling should ideally be completed after the worksurface installation.

NEVER plaster between template and installation as this would ensure that the worktops don’t fit.

Wall Cladding & End Panels

Offset Butt Joint Standard Flush Butt Joint

Wall cladding will be manufactured in 20mm thickness material.

The Standard Flush butt Joint for Granite End Panels will be a flush butt joint with no overhang.

Also available as an Offset Butt Joint with 5mm overhang. Unless requested otherwise we will supply a Standard Flush Butt Joint

All end panels will be manufactured to the correct specified height, with no scribing allowance as the material is not easily scribed to the floor.

Handling & Size

Limiting factors like access, stairs and service lift size should be taken into

consideration with fragile nature of the tops. This will increase the number of

joints required.

For installations you will need to supply additional labour on orders which have

worktops larger than 1.8m2 or weighing above 150kg. Every additional 75kg

requires an extra person to assist with lifting. Sheridan can supply additional

labour due to H&S at an extra cost. This may include lifting equipment.

The size of ‘scant’ or ‘slab’ is a major factor in selecting the maximum usable

length of a worksurface. Approximately 2.80m x 1.3m is the largest worksurface

we are able to manufacture. This may be drastically reduced if you require a cut-

out, especially in Granite with larger crystals.

Due to the weight of Granite, please ensure that units are level and securely

fixed before installation.

Damage Prevention

Never place hot pans or cooking equipment directly onto the worksurface (or into

an empty sink). Always use a heat protection pad or a trivet with rubber feet for

hot cook wear or leave pans etc to cool on the hob first.

Always use a chopping board. Apart from the effect that cutting on Granite has on

blunting your knives, the surface is not scratch proof but is highly scratch resistant.

Care should always be taken to protect your worksurface from sharp or heavy

items. Care should be taken with exposed edges as if caught accidentally chipping

can occur.

In the event of this happening however, contact Sheridan as it is possible to

repair small chips on edges or on the surface.

Care & Maintenance..

The Care & Maintenance instructions that are included in the kit should be read

and followed to ensure the worktops continue to look as good as the day they

were installed. Please ensure your keep these instructions for future reference.

Your Care & Maintenance Kit contains all of the items required to help keep

your new Worksurfaces in pristine condition.

Please ensure you fully read and follow the safety instructions carefully before

using the products in the care kit.

Always wear rubber gloves when using chemicals to prevent any cracking,

drying or other reaction to your skin.

How often should you re seal ?? - The water test !! Simply spill a drop of water

onto the worksurface. If it disappears and soaks in you need to seal.

Care & Maintenance..

What's in the Care Kit ?

Care & Maintenance instructions

Stone Guard

Disposable gloves

Micro Fibre Cloth

Stone Seal

Stone Guard - is an anti-bactericidal surface cleaner specially formulated to

tackle grease and grime leaving surfaces sparkling clean with a residual

antibacterial effect.

Stone Seal – formulated for protection of Granite worktops. Protects against

stains caused by food and drinks such as coffee and tea. One application will

guarantee protection for long period of time (subject to proper maintenance).

Care & Maintenance..

Every day cleaning -

Any spillage must be removed immediately, delay could case permanent

damage.

Granite must not be rubbed with abrasive materials.

For normal day to day cleaning, wipe the worksurface with a damp cloth and the

Stone Guard, rinse with warm clean water and dry with a lint free cloth.

Wipe the worksurface, with a damp cloth and the Stone Guard cleaner to remove

any oils and fat. Buff dry with a soft white cloth.

Persistent stains -

If any stains need further attention, allow the Stone Guard 30 seconds contact

time before wiping and rinsing.

Care & Maintenance..

Sealing Granite –

Granite worktops are sealed during manufacture and

upon installation, they should then be sealed every 6

months using Stone Seal supplied in the Care &

Maintenance kit.

To test if a worktop requires resealing, apply a drop of

water to the surface, if the water runs away, the seal is

ok, if the water forms a pool, it requires sealing.