API675 US

-

Upload

aksheymehta -

Category

Documents

-

view

215 -

download

0

Transcript of API675 US

-

7/28/2019 API675 US

1/2

JOB NO. ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

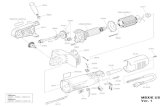

CONTROLLED VOLUME PUMP (API 675-2ND) REVISION NO. DATE

DATA SHEET PAGE 1 OF 2 BYU.S. CUSTOMARY UNITS

1 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

2 FOR UNIT

3 SITE NO. OF PUMPS REQUIRED

4 SERVICE MODEL SIZE AND TYPE

5 MANUFACTURER SERIAL NO.

6 NOTE: INDICATES INFORMATION TO BE COMPLETED BY PURCHASER BY MANUFACTURER

7 GENERAL

8 NO. MOTORS DRIVEN OTHER DRIVER TYPE

9 PUMP ITEM NO'S PUMP ITEM NO'S

10 MOTOR ITEM NO'S DRIVER ITEM NO'S GEAR ITEM NO'S

11 MOTOR PROVIDED BY DRIVER PROVIDED BY GEAR PROVIDED BY

12 MOTOR MOUNTED BY DRIVER MOUNTED BY GEAR MOUNTED BY

13 MOTOR DATA SHEET NO. DRIVER DATA SHEET NO. GEAR DATA SHEET NO.

14 OPERATING CONDITIONS LIQUID

15 CAPACITY @ PT (GPH/GPM): TYPE OR NAME OF LIQUID

16 MAXIMUM MINIMUM RATED PUMPING TEMPERATURE (F):

17 DISCHARGE PRESSURE (PSIG): NORMAL MAX MIN

18 MAXIMUM MINIMUM SPECIFIC GRAVITY MAXIMUM MINIMUM

19 SUCTION PRESSURE (PSIG): SPECIFIC HEAT Cp (BTU/lb F)

20 MAXIMUM MINIMUM VISCOSITY (Cp) MINIMUM MAXIMUM21 DIFFERENTIAL PRESSURE (PSI) CORROSIVE/EROSIVE AGENTS

22 MAXIMUM MINIMUM CHLORIDE CONCENTRATION (PPM)

23 NPSH AVAILABLE (FT.) H2S CONCENTRATION (PPM)

24 WITHOUT ACCELERATION HEAD ACTUAL LIQUID TOXIC FLAMMABLE OTHER

25 TURNDOWN RATIO

26 PERFORMANCE SITE AND UTILITY DATA

27 NUMBER OF FEEDS RATED CAPACITY (GPH/GPM) LOCATION INDOOR OUTDOOR

28 NPSH REQUIRED (FT.) HEATED UNHEATED UNDER ROOF

29 BHP RATED AT RELIEF SETTING ELECTRICAL AREA CLASS GROUP DIV

30 PLUNGER SPEED (strokes/min) DESIGN MAX WINTERIZATION REQD TROPICALIZATION REQD

31 DIAMETER (IN) LENGTH OF STROKE (IN) SITE DATA

32 PUMP HEAD: RANGE OF AMBIENT TEMPS:MIN/MAX / F

33 MAXIMUM PRESSURE (PSIG) UNUSUAL CONDITIONS

34 HYDRO TEST PRESSURE (PSIG) DUST FUMES SALT ATMOSPHERE

35 MAX DISCH PRESS. W/ JOB DRIVER (PSIG) OTHER

36 MAX BHP BASIS GEAR STRENGTH UTILITY CONDITIONS

37 CONSTRUCTION ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN

38 SIZE ANSI FACING POSITION VOLTAGE

39 CONNECTIONS RATING HERTZ

40 SUCTION PHASE

41 DISCHARGE COOLING WATER INLET RETURN DESIGN MAX D42 FLUSH TEMP F MAX

43 PRESS. (PSIG) MIN

44 LIQUID END JACKET REQ'D SOURCE

45 TYPE DIAPHRAGM PLUNGER INSTRUMENT AIR MAX MIN

46 DIAPHRAGM DIA (IN) NO REQ. PRESSURE (PSIG)

47 VALVES/FEED SUCTION DISCHARGE APPLICABLE SPECIFICATIONS:

48 TYPE API 675 POSITIVE DISPLACEMENT PUMPS - CONTROLLED VOLUME

49 NUMBER GOVERNING SPECIFICATION (IF DIFFERENT)

50 REMARKS

51

06/95 SHT 1 OF 2 API675.XLS REV 0

-

7/28/2019 API675 US

2/2

JOB NO. ITEM NO.

CONTROLLED VOLUME PUMP (API 675-2ND) REVISION NO. DATE

DATA SHEET PAGE 2 OF 2 BY

U.S. CUSTOMARY UNITS

1 MATERIALS CONTROLS

2 LIQUID END TYPE: SIGNAL:

3 CONTOUR PLATE MANUAL REMOTE PNEUMATIC

4 HYDRAULIC DIAPHRAGM AUTOMATIC LOCAL ELECTRONIC

5 PROCESS DIAPHRAGM STROKE CONTROL:

6 PLUNGER PNEUMATIC (PSIG):

7 LANTERN RING MINIMUM MAXIMUM

8 PACKING GLAND ELECTRONIC (mA):

9 PACKING MINIMUM MAXIMUM

10 VALVE OTHER PURCHASE REQUIREMENTS

11 VALVE SEAT NAMEPLATE UNITS U.S. CUSTOMARY SI

12 VALVE GUIDE VENDOR FURNISHED PROCESS PIPING

13 VALVE BODY

14 VALVE GASKET VENDOR REVIEW PIPING DRAWINGS

15 FRAME VENDOR FURNISHED PULSATION SUPRESSION DEVICES

16 SPECIAL MATERIAL TESTS (2.13.1.3) VENDOR FURNISHED RELIEF VALVE

17 INTERNAL EXTERNAL

18 LOW AMBIENT TEMPERATURE MATERIALS TESTS (2.13.5) RELIEF VALVE SETTING (PSIG)

19 VENDOR FURNISHED BACK-PRESSURE VALVE

20 QA INSPECTION AND TEST DOUBLE CHECK VALVES REQUIRED

21 COMPLIANCE WITH INSPECTORS CHECK LIST OIL-FILLED PRESSURE GAUGES REQUIRED

22 CERTIFICATION OF MATERIALS VENDOR FURNISHED CONTROL PANEL

23 FINAL ASSEMBLY CLEARANCES BASEPLATE PREPARED FOR EPOXY GROUT

24 SURFACE AND SUBSURFACE EXAMINATIONS PROVIDE TECHNICAL DATA MANUAL

25 RADIOGRAPHY

26 ULTRASONIC

27 MAGNETIC PARTICLE PREPARATION FOR SHIPMENT

28 LIQUID PENETRANT DOMESTIC EXPORT EXPORT BOXING

29 CLEANLINESS PRIOR TO FINAL ASSEMBLY OUTDOOR STORAGE MORE THAN 6 MONTHS

30 HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONES WEIGHTS (LBS)

31 FURNISH PROCEDURES FOR OPTIONAL TESTS PUMP BASE GEAR DRIVER

32 TESTS REQ'D WIT OBS DRIVERS

33 HYDROSTATIC X MOTOR:

34 STEADY STATE ACCURACY X MANUFACTURER

35 REPEATABILITY TYPE

36 LINEARITY FRAME NO.

37 CONSTANT SPEED

38 VARIABLE SPEED

39 LUBRICATION FLUID HP RPM

40 CRANKCASE INTERMEDIATE VOLTS PHASE

41 HYDRAULIC FLUID HERTZ SERVICE FACTOR

42 ACCESSORIES ENCLOSURE

43 SPEED REDUCER MANUFACTURER OTHER (SEE SEPARATE DATA SHEETS)

44 INTEGRAL SEPARATE GAS DRIVEN

45 MODEL STEAM TURBINE

46 RATIO OTHER

47 BASEPLATE UNDER

48 COUPLING MANUFACTURER

49 TYPE

50 REMARKS

51

06/95 SHT 2 OF 2 API675.XLS REV 0