Anilox 160 l/cm (400 lpi) leaning olution · 2016-09-06 · regulation of frequency and ultrasonic...

Transcript of Anilox 160 l/cm (400 lpi) leaning olution · 2016-09-06 · regulation of frequency and ultrasonic...

Cle

anin

g s

olu

tions

17, rue de Montréal • 74100 Ville-la-Grand • France • Tél. +33 (0)450 92 48 68 • Fax +33 (0)450 95 54 72www.recyl.com • [email protected]

www.recyl.com

NextWave

• non-contractual photos

100% safe and effective cleaning for your Anilox!

Anilox 160 l/cm (400 lpi)

Cell Volume Analysis and Inspection

Take control of your cleaning...

Ultrasound Operating Principle:

The increase in pressure / pressure release of the gas dissolved in the cleaning bath creates a cavitation micro-bubble phenomenon; these microbubbles act like thousands of micro-jets on the surfaces of the parts. These bubbles release a high level of thermal and kinetic energy and remove any fine dirt particles.

The ultrasonic cavitation micro-jets have a mechanical effect to remove dirt. Using a tank and the Recyl W200 chemical at 35°C favours the ultrasonic phenomenon and amplifies efficacy of cleaning. The phenomenon of cavitation generated by traditional ultrasonic cleaning systems is relatively unstable and is dependent on the conditions in the cleaning tank:

• Power and Distribution of the ultrasonic field in relation to the parts & their layout• Frequency of the ultrasonic transducers• Temperature within the tank• Chemicals, to assist in cleaning• Duration of the cleaning cycle

The new generation of Recyl NextWave Ultrasonic Cleaning machines enable everyone these to be controlled and guarantees reliable Anilox cleaning in the long term with consistent cleaning results, thanks to the double-closed loop regulation system (Ultrasounic Power & Frequency Controls, Cleaning Tank Temperature Management etc.)

0.00.81.62.43.24.85.66.47.28.08.89.610.411.212.012.813.714.515.316.116.917.718.519.320.120.921.722.523.324.124.925.726.527.328.1

um

ANILOX ULTRASOUND CLEANING

Cle

anin

g s

olu

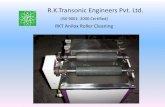

tions NW2 Model | Narrow-web Anilox Cleaner Up to 700 mmNextWave Ultrasonic Cleaning

In partnership with SINAPTEC, the French leader in solutions using Ultrasonic technology for over 30 years, RECYL has developed a new Anilox Cleaning Machine.

Recyl NextWave revolutionises the flexography ultrasound cleaning domain by enabling users to check the effectiveness of their cleaning tanks.

This patented technology guarantees reliable and consistent long-term cleaning through ultrasound to industrial printers. Sinaptec’s NexTgen range of ultrasonic generators enable optimal cavitation thanks to the consistent regulation of frequency and ultrasonic power.

Simultaneous Cleaning of 2 Anilox rollers in our NW2 Model.

RECYL reserves the right to modify the characteristics of its machines without notice. Images and text are non-contractual.A 1-year warranty applies to the machine’s parts and a 2-year warranty to the ultrasonic generator and transducers.

Delivery time: Approx. 6 to 8 weeks upon order confirmation.

Technical SpecificationsBench-top Model

Technical specifications NW2Overall Dimensions 855 x 580 x 519 mmWorking Dimensions 700 x 450 x 145 mmMax. Anilox Diameter 180 mmTank Capacity 45 litresTotal Weight Approx 60 kgUltrasound P : 1200 W / f : 40 kHzHeating 2 kWElectricity Supply L + N + E 230 VNominal Intensity 15 A

Optional lid

Usage principle:

• Fill the ultrasonic tank with the Recyl W200 product (recommended dilution 1:3)

• Switch on the machine; the temperature is preset to 35° C.

• Select the DEG function to degas the liquid.

• Launch the cleaning cycle according to the required programme (15, 30, 45 minutes)

• After cleaning, remove the cylinder(s), rinse well in clean water.

• Switch-off the machine.

The NextWave machine is used with our Recyl W200 product, which is

suitable for all types of ink.

Cylinder Supports (Adjustable)

Level SensorImplosion of Microbubbles on contact with the Anilox surface

Ultrasonic waves

Ultrasonic transducers

Heating Resistance

Overflow

Control Panel includingan Ethernet Port

Integrated functions:• Ultrasound Power and Frequency Management & Control: Whatever the drift over time for the different parameters, the ultrasonic

power delivered into the cleaning tank is constant (W/litre), and the utilisation frequency of each piezo (transducer) is optimal. This certifies consistent cleaning results in the long-term.

• Cleaning Tank Temperature Management & Control, via a temperature sensor: High enough to facilitate cleaning, low enough to avoid excess evaporation which may result in crystallisation; the cleaning temperature is constant over time.

• Tank Level Check, via a Level Sensor: Safety is assured, the heating and the ultrasounds may only operate if the vector of the ultrasonic waves – i.e., the cleaning tank with the precise level of the liquid is present.

• Frequency Sweep: Restricted Sweep (+/- 2 kHz) around the optimal frequency of the piezoelectric material.

• Diagnostics: NexTgen integrates a function of diagnostics and control on the efficacy of the ultrasonic generator and transducers, facilitating the maintenance & the long-term use of the machine.

The NexTgen Advanced software enables the visualisation of data on diagnostics and control as delivered by the ultrasonic generators.

NextWave

Traditional Ultrasonic Cleaning Systems

Power and Frequency Control

Temperature Control

Cleaning Tank Level Check

2-directional Rotation

Connected Ultrasound Generator

Diagnostics on the efficacy of the Cleaning Tank

Frequency Sweep

SinaptecTransducers

Ultrasonic Technology