AMSOIL Motor Oil Dealer | Best Oil Company - G-2047 89559 … · 2020-03-04 · HIGH QUALITY...

Transcript of AMSOIL Motor Oil Dealer | Best Oil Company - G-2047 89559 … · 2020-03-04 · HIGH QUALITY...

G-2047 89559 2/18/08 3:20 PM Page 2

Imagine being able to see exactly what’s happening inside an engine, a gearbox or hydraulic

system. OIL ANALYZERS Fluid Analysis is a preventive maintenance tool that provides a picture of

both the fluid condition and the internal condition of a component or system without disassembly.

OIL ANALYZERS Fluid Analysis will:

• Extend oil drain intervalsMonitoring the condition of the oil optimizes drain intervals so that you get the most out of the

fluid you’re paying for. Fewer oil changes minimize maintenance costs and maximize uptime.

• Extend equipment lifeMonitoring system cleanliness and filtration efficiency allows you to keep your equipment

longer and significantly reduce replacement costs.

• Identify minor problems before they become major failuresState-of-the-art fluid analysis identifies dirt, wear particles, fuel dilution, and coolant –

contaminants that can cause catastrophic failure or significantly shorten equipment life.

• Maximize asset reliabilityTesting and analysis ensures that units are up, running and making money.

• Increase resale valueAnalysis results provide valuable sampling history documentation that easily justifies higher

equipment resale values.

What Can the OIL ANALYZERS Fluid Analysis Program Do For You?

G-2047 89559 2/18/08 3:21 PM Page 3

HIGH QUALITY TESTINGThe OIL ANALYZERS Fluid Analysis Program utilizes independent ISO 17025 A2LA accredited

testing laboratories. This is the highest level of quality attainable by a testing laboratory backed

by the most stringent accrediting body in the industry. You can be confident that the results you

receive are accurate, repeatable, and traceable to a standard and that your fluid analysis

program is supported by a documented quality system you can depend on to deliver superior

testing and customer services.

INNOVATIVE INFORMATION TECHNOLOGY SOLUTIONSThe OIL ANALYZERS Fluid Analysis Program’s online reporting software shows you how to

get the most from your information. Using HORIZON online you receive results fast – almost

immediately after sample processing is complete. The software’s management reports can then

take your fluid analysis program to the next level by helping you manage your data and your

program efficiently and effectively.

Why OIL ANALYZERS?

Fluid Analysis Program

G-2047 89559 2/18/08 3:21 PM Page 4

Suggested Sampling Intervals & Methods

Taking SamplesOIL ANALYZERS Fluid Analysis will show you how

regular sampling and TREND ANALYSIS – monitoring

test data over an extended period of time – will

provide the information you need to continually

maximize asset reliability, and, ultimately, increase

company profits. Comparing a component’s most

recent samples to its historical data is instrumental

in identifying trends that can pinpoint potential

problems.

Although an equipment manufacturer’s

recommendations provide a good starting point

for developing preventative maintenance practices,

sampling intervals can easily vary. How critical a

piece of equipment is to production is a major

consideration for determining sampling frequency,

as are environmental factors such as hot, dirty

operating conditions, short trips with heavy loads

and excessive idle times.

Fluid analysis is most effective when samples are

representative of typical operating conditions. Dirt,

system debris, water and light fuels tend to separate

from the lubricants and coolants when system

temperatures cool. For optimum results, consider

the following best practices:

• Take samples while systems are operating under

normal conditions or immediately after shutdown

while they are still at operating temperature.

• Take samples at regularly scheduled intervals.

• Take samples from the same sampling point

each time.

Whether you’re a seasoned veteran or a first-time

sampler, a well-designed, quality fluid analysis

program puts you on track for well-managed,

cost-effective equipment maintenance

programming.

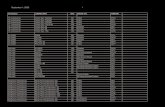

COMPONENT INTERVAL SUGGESTED METHOD & LOCATION

MOTOR VEHICLES

Engines 250 hours/15,000 miles By vacuum pump through dipstick retaining tube or sampling valve installed in filter return

Gears, By vacuum pump through oil level plugDifferentials & 250 hours or dip stick retaining tubeFinal Drives

Planetaries 250 hours By vacuum pump through oil fill port of system reservoir at mid-level

Cooling System 1,000 hours By vacuum pump through radiator cap or fill port of system reservoir at mid-level

INDUSTRIAL EQUIPMENT

Hydraulics 250-500 hours By vacuum pump through oil fill port of system reservoir at mid-level

Through sample valve installed upstream Gas Turbines Monthly or every 500 hours of the filter on the return line or out of

the system reservoir

Through sample valve installed upstream Steam Turbines Bi-monthly or monthly/quarterly of the filter on the return line or out of

the system reservoir

Gas/Air Monthly or at Through sample valve installed upstream

Compressors 500 hours/quarterly of the filter on the return line or out of the system reservoir

G-2047 89559 2/18/08 3:21 PM Page 5

Sampling with a Vacuum PumpA vacuum pump is used to take samples from a

dipstick or non-pressurized system. The pump is

attached to the sample jar, a tube is inserted into the

pump and then into the dipstick retaining tube or oil fill

port. Activating the pump handle, the sample jar should

be filled about 3/4 full or to its shoulder.

When sampling engines:

• Measure length or depth of fill port tube,

reservoir or dipstick.

• Add six (6) inches and mark the measurement

on the tubing.

• Cut the tubing 12 inches

beyond this mark.

• Insert tubing onto top

of vacuum pump and

tighten lock ring.

• Remove sample jar lid

and attach jar to bottom

of vacuum pump and

tighten securely.

• Insert tubing into fill port, reservoir or dipstick

retaining tube only to the mark on the tubing. To

avoid drawing settled debris into the sample,

do not allow contact between tubing and bottom

of reservoir.

• Push and pull vacuum pump plunger until sample

jar is 3/4 full.

• When sample reaches shoulder of jar, unscrew jar

from pump, replace jar lid and tighten securely.

• Unscrew pump locking ring, remove tubing and

drain excess oil back into reservoir.

• Discard tubing after each sample to avoid cross

contamination.

• Complete sample jar label and affix to

sample jar.

Fluid Analysis Program

G-2047 89559 2/18/08 3:21 PM Page 6

OIL ANALYZERS Fluid Analysis Test Packages

Oil KitTest Packages

Applications Engines Non-Engines

Purpose Monitors wear & contamination

24 Metals by ICP • •

% Fuel Dilution •

% Soot •

Water % by Crackle • •

Viscosity @ 40°C • •(if ISO grade fluid)

Viscosity @ 100°C • •(if SAE grade fluid)

Oxidation/NitrationBy FTIR • •

Total Base Number •

Total Acid Number •

OIL ANALYZERS Fluid Analysis provides diagnostic testing designed to evaluate

lubricant condition, component wear and contamination in mobile and industrial

applications with a test report provided by an independent laboratory for each

sample submitted. Refer to the chart below to determine which combination of tests

each component will receive.

To order OIL ANALYZERS Fluid Analysis kits, please call OIL ANALYZERS at 800-777-7094. For product

information, if you have questions regarding the OIL ANALYZERS fluid analysis program, or for help in

understanding your test reports, call 877-458-3315.

G-2047 89559 2/18/08 3:21 PM Page 7

Coolant Kit17 Metals by ICP

pH

Glycol % (Ethylene or Propylene Glycol)

Freeze Point

Boil Point

Nitrite

SCA Number

Total Dissolved Solids

Specific Conductance

Total Hardness

Visuals (color, oil, fuel, magnetic precipitate, non-magneticprecipitate, odor & foam)

Basic Fuel Kit24 Metals by ICP

Viscosity @ 40°C

Calculated Cetane Index

Distillation

API Gravity

Basic Fuel KitFuel Contamination

Water & Sediment

Aerobic Bacteria

Basic Winter Fuel KitCloud Point

Pour Point

Premium Winter Fuel Kit

Cloud Point

Pour Point

Cold Filter Plug Point

Sampling Equipment and Supplies

Vacuum Pump

Plastic Tubing (100 ft. roll)

Plastic Tubing (56”)

Fluid Analysis Program

* Cold Filter Plug Point can be added to any fuel test package.

To order OIL ANALYZERS Fluid Analysis kits,please call 800-777-7094.

G-2047 89559 2/18/08 3:21 PM Page 8

Component Registration FormsA CCoommppoonneenntt RReeggiissttrraattiioonn FFoorrmm is included with

every sample kit. Fill it out only when sampling a

component for the first time or to notify the laboratory

of a change in component and/or fluid information

already registered with the laboratory. CCoommpplleettee,,

uupp--ttoo--ddaattee iinnffoorrmmaattiioonn eennssuurreess tthhaatt yyoouu rreecceeiivvee

tthhee pprrooppeerr tteessttiinngg aanndd aann aaccccuurraattee aannaallyyssiiss ooff

tthhee rreessuullttss..

• Fill out the CCoommppoonneenntt RReeggiissttrraattiioonn FFoorrmm

completely and accurately.

• Use this form oonnllyy for first-time samples or changes

in unit oorr oil information previously submitted.

• Include it in the black mailer with the sample jar.

Sample LabelsComplete a ssaammppllee jjaarr llaabbeell for eevveerryy sample

submitted to the laboratory. BBee ssuurree ttoo ffiillll oouutt aallll llaabbeell

iinnffoorrmmaattiioonn ccoommpplleetteellyy aanndd aaccccuurraatteellyy ttoo eennssuurree

pprrooppeerr tteessttiinngg aanndd aaccccuurraattee,, iinn--ddeepptthh aannaallyyssiiss..

Once complete, attach the label to the sample bottle. Fill

in the unit’s ID on the removable tracking number sticker

located to the right of the sample label and retain for your

records.

• Fill out the ssaammppllee jjaarr llaabbeell completely and

accurately.

• Include aallll unit and fluid information requested

including unite ID, type of component and position,

time on both the fluid and the unit and whether or

not fluid has been added or changed.

• Track sample processing at www.trackmysample.com.

NNOOTTEE:: WWhheenn yyoouu pprroovviiddee tthhee mmoosstt aaccccuurraattee aanndd ccoommpplleettee

uunniitt aanndd ooiill iinnffoorrmmaattiioonn,, yyoouurr llaabboorraattoorryy ccaann ddeelliivveerr tthhee

mmoosstt aaccccuurraattee aanndd ccoommpplleettee rreessuullttss aanndd rreeccoommmmeennddaattiioonnss..

SSTTEEPP 11 SSTTEEPP 22

G-2047 89559 2/18/08 3:21 PM Page 9

Shipping Information

Complete the mailer return address label for the

laboratory nearest you and attach it to the shipping

container, affix the appropriate postage and mail.

Use a trackable shipping service for sending samples

to the laboratory.

• Complete and attach the return mailer address label

to the black shipping container.

• Ship by trackable mail service such as FedEx or UPS.

Test Reports and DataManagementYour FREE, online reporting option – HORIZON – is fast,

bringing you test results almost immediately after

processing is complete.

HORIZON Management Reports allow you to affect

positive changes in your daily maintenance practices by:

• Keeping sampling schedules on track

• Identifying bottlenecks in turnaround time that are

costing you money

• Summarizing unit problems that could influence

future purchasing decisions.

Control over an extensive host of personal application

settings and preferences also gives you the power to put

the information you need most in front of you first.

Go to www.horizonsignup.com

SSTTEEPP 33 SSTTEEPP 44

Fluid Analysis Program

NOTE: When you providethe most accurate andcomplete unit and fluidinformation, your laboratory can deliver the most accurate andcomplete results and recommendations.

SSaalltt LLaakkee CCiittyy

IInnddiiaannaappoolliiss

HHoouussttoonn

G-2047 89559 2/18/08 3:21 PM Page 10

Diesel & Gasoline Engine Oil Guidelines(for physical properties, contaminants & degradation)

Normal Abnormal Excessive

Glycol 0 Trace Trace

Water <0.05% 0.05% >1.0%

Fuel Dilution <1.0% 2.0% 3.0%

Viscosity in grade + or – one SAE/ISO + or – two SAE/ISO

viscosity grade change viscosity grade change

Solids <1.5% 2.0% >4.0%

Soot (diesel only) <2.0% 3.0% >4.0%

Oxidation* Expressed as absorption units per cm 50.0 synthetic

30.0 petroleum

Nitration* Expressed as absorption units per cm 50.0 synthetic

30.0 petroleum

Total Base Number Change oil when TBN strength diminishes to <2

Total Acid Number 1-3 3-4 >4

(industrial)

SAE Engine & Gear OilViscosity Grade @ 100°C (Automotive Fluids)

SAE Engine Oil Min MaxGrade @ 100° cSt. cSt.

20 5.6 >9.3

30 9.3 >12.5

40 12.5 >16.3

50 16.3 >21.9

60 21.9 >26.0

SAE Gear Oil Min MaxcSt. cSt.

90 13.5 >24.0

140 24.0 >41.0

250 41.0 No Req.

G-2047 89559 2/18/08 3:21 PM Page 11

ISO Viscosity Grade @ 40°C(Industrial Fluids)

ISO Viscosity Grade Min Max@ 40°C cSt. cSt.

2 1.98 2.42

3 2.88 3.52

5 4.14 5.06

7 6.12 7.48

10 9.00 11.0

15 13.5 16.5

22 19.8 24.2

32 28.8 35.2

46 (AGMA 1)* 41.4 50.6

68 (AGMA 2) 61.2 74.8

100 (AGMA 3) 90.0 110

150 (AGMA 4) 135 165

220 (AGMA 5) 198 242

320 (AGMA 6) 288 352

460 (AGMA 7) 414 506

680 (AGMA 8) 612 748

1000 (AGMA 8A) 900 1100

1500 1350 1650

Fluid Analysis Program

G-2047 89559 2/18/08 3:21 PM Page 12

Accurate, thorough, and completefluid and equipment informationallows for more in-depth analysis andcan eliminate confusion when inter-preting results.

How to Read theOIL ANALYZERSFluid Analysis Report

EEqquuiippmmeenntt IIDD is eachccuussttoommeerr’’ss opportunityto uniquely identifyunits being tested andtheir location.

UUnniitt TTyyppee should give as muchdetail as possible. WWhhaatt kkiinndd ofcompressor, gearbox, engine,etc..., influences flagging parameters and depth of analysis. Different metallurgiesrequire different lubrication and have great impact on how results are interpreted.

AApppplliiccaattiioonn identifies inwhat type of environmentthe equipment operatesand is useful in determining exposure topossible contaminants.

FFiilltteerr TTyyppeess and theirMMiiccrroonn RRaattiinnggss areimportant in analyzingparticle count-the higherthe micron rating, thehigher the particle countresults.

LLuubbee MMaannuuffaaccttuurreerr,, TTyyppee aannddGGrraaddee identify a lube’s propertiesand its viscosity and is critical indetermining if the right lube isbeing used.

G-2047 89559 2/18/08 3:21 PM Page 13

The information submitted with a sample is as important to who is reading the report as

it is to the analyst interpreting the test results and making recommendations. Properly document your equipment and share this knowledge with your laboratory. Implement a

sampling process for every piece of equipment in your oil analysis program that can be

followed consistently each time the unit is sampled. Accurate, thorough and complete

lube and equipment information not only allows for in-depth analysis, but can eliminate

confusion and the difficulties that can occur when interpreting results.

SSuummpp CCaappaacciittyy identifiesthe total volume of oil (in gallons) in which wear metals are suspended and is criticalto trending wear metalconcentrations.

LLuubbee TTiimmee is howlong the oil has beenused. UUnniitt TTiimmee is theage of the equipmentand LLuubbee AAddddeedd ishow much oil hasbeen added since thelast sample was taken.

DDaattaa AAnnaallyyssttss IInniittiiaallss

SSeevveerriittyy SSttaattuuss LLeevveellss::00- Normal.11- At least one or more items have

violated initial flagging points yet are still considered minor.

22- A trend is developing.33- Simple maintenance and/or

diagnostics are recommended.44- Failure is eminent if

maintenance is not performed.

Customer Equipment and Sample Information

Make note of the differencebetween the DDaattee SSaammpplleedd andthe DDaattee RReecceeiivveedd by the lab.Turnaround issues may point tostoring samples too long beforeshipping or shipping serviceproblems. Also noted is testingDDaattee CCoommpplleetteedd..

The laboratory at which testingwas completed is denoted by an II for IInnddiiaannaappoolliiss, an HH forHHoouussttoonn and an SS for SSaalltt LLaakkeeCCiittyy. The following LLaabb ## isassigned to the sample uponentry for processing and shouldbe the reference number usedwhen contacting the lab withquestions, concerns or feedback.

MMaannuuffaaccttuurreerr aanndd MMooddeellcan also identify metallurgiesinvolved as well as the OEM’sstandard maintenance guidelines and possible wear patterns to expect.

Fluid Analysis Program

G-2047 89559 2/18/08 3:21 PM Page 14

A data analyst’s job is to explain and, if necessary, recommend actions for rectifying significant changes in the

lubricant or the unit’s condition. Reviewing comments before looking at the actual test results will provide a

road map to the report’s most important information. Any actions that need to be taken are listed first in order

of severity. Justifications for recommending those actions immediately follow.

Recommendations

Laboratory will request additional unit and lube information if incomplete on sample label

G-2047 89559 2/18/08 3:21 PM Page 15

Test results are listed according to age of the sample–oldest to most recent, top to bottom–so that

trends are apparent. Significant changes are flagged and printed in the gray areas of the report.

Test Data

Samples are listed by DDaattee RReecceeiivveedd in the lab-oldest first. They are also assigned a LLaabb NNuummbbeerrfor easy internal tracking. Important to also note iswhether or not the LLuubbee has been CChhaannggeedd sincethe last sample was taken.

FFuueell and SSoooott are reportedin % of volume. High fueldilution decreases unit loadcapacity. Excessive soot is asign of reduced combustionefficiency.

(only on engine oil samples)

WWaatteerr in oil decreases lubricity, preventsadditives from working and furthers oxidation. Its presence can be determinedby crackle or FTIR and is reported in % ofvolume. Water by Karl Fischer ASTMD1744 determines the aammoouunntt of waterpresent. These results appear in theSpecial Testing section of your report.

The IISSOO CCooddee is an index number that representsa range of particles within a specific micronrange, i.e., 4, 6, 14. Each class designates a rangeof measured particles per one ml of sample.The particle count is a cumulative range between 4 and 6 microns. This test is valuable in determining large particle wear in filtered systems.

VViissccoossiittyy measures a lubricant’s resistance toflow at temperature and is considered it’s mostimportant physical property. Depending on lubegrade, it is tested at 40 and/or 100 degreesCentigrade and reported in Centistokes.

Elemental Analysis, or Spectroscopy, identifies the type and amount of wear particles, contamination and oil

additives. Determining metal content can alert you to the type and severity of wear occurring in the unit.

Measurements are expressed in parts per million (ppm).

Elemental Analysis

Combinations of these WWeeaarr MMeettaallss canidentify components within the machine thatare wearing. Knowing what metal a unit ismade of can greatly influence an analyst’srecommendations and determine the valueof elemental analysis.

Knowledge of the environmentalconditions under which a unit operates can explain varying levelsof CCoonnttaammiinnaanntt MMeettaallss.Excessive levels of dust and dirt canbe abrasive and accelerate wear.

AAddddiittiivvee and Multi-Source Metals may turn up in test results for avariety of reasons. Molybdenum, antimony and boron are additivesin some oils. Magnesium, calcium and barium are often used indetergent/dispersant additives. Phosphorous is used as an extremepressure additive in gear oils. Phosphorous, along with zinc, areused in anti-wear additives (ZDDP).

Fluid Analysis Program

G-2047 89559 2/18/08 3:21 PM Page 16

OAI LABORATORIESINDIANAPOLIS

7898 Zionsville Road

Indianapolis, IN 46268

Phone: 877-458-3315

OAI LABORATORIESHOUSTON

10910 W. Sam Houston Pkwy. N.

Suite 700

Houston, TX 77064-6314

Phone: 877-458-3315

OAI LABORATORIESSALT LAKE CITY

3060 W. California Avenue

Suite B

Salt Lake City, UT 84104

Phone: 877-458-3315

Send your samples to the laboratory location

nearest you.

To order OIL ANALYZERS Fluid Analysis kits,

please call 800-777-7094.

G2047

G-2047 89559 2/18/08 3:20 PM Page 1