Amit mahto

-

Upload

jitendra-rajput -

Category

Engineering

-

view

119 -

download

0

Transcript of Amit mahto

THE UNIVERSAL CURRENT SENSORS

AMIT KUMAR MAHTO13EE06

GUIDE : A R ANSARI SIR

CONTENTS1.INTRODUCTION2.EARLY SOLUTION3.TYPE OF SENSOR4.HOW IT WORKS5.ADVANTAGES6.APPLICATION7.SUMMARY8.CONCLUSION

INTRODUCTION

1. The measurement of electric current strength is not always easy, especially when the measured signal requires further electronic conditioning.

2. Simply connecting an ammeter to an electrical circuit and reading out the value is no longer enough. 3. The current signal must be fed into a computer in which sensors convert current into a proportional voltage with minimal influence on the measured circuit.

EARLY SOLUTIONS1.The oldest technique is to measure the voltage drop across a resistor placed in the current path.

2. To minimize energy losses the resistor is kept very small, so the measured voltage must be highly amplified.

3.Another widespread principle is the transformer. Its construction is much simpler, but it doesn’t allow the measurement of DC signals.

TYPE OF SENSOR

HALL CURRENT SENSORS

MAGNETO RESISTIVE FIELD SENSORS

HALL CURRENT SENSORS

1.Hall sensors measure the magnetic field surrounding the conductor but, unlike current transformers, they also sense DC currents.

2. A circular core of soft magnetic material is placed around the conductor to concentrate the field.

3. The Hall element, which is placed in a small air gap, delivers a voltage that is proportional to the measured current.

TWO TYPES OF HALL SENSOR

Open Loop Sensor

Closed Loop Sensor

1.In open loop, the amplified output signal of the Hall element is directly used as the measurement value.

2. The linearity depends on that of the magnetic core. The price of these sensors is low, but so is their sensitivity.

3.Closed-loop Hall sensors are much more precise.

4.The Hall voltage is first highly amplified, and the amplifier’s output current then flows through a compensation coil on the magnetic core (Figure 1)

5. Closed-loop current sensors work up to frequencies of ~150 kHz.

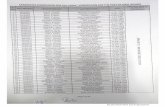

Figure 1 – Closed loop hall sensor

MAGNETO RESISTIVE FIELD SENSORS

1.Magnetic field sensors based on the magneto resistive effect are easily fabricated by means of thin film technologies. 2.They have been in production for years in many different executions.

3.To reduce the temperature dependence, they are usually configured as a half or a full bridge.

4 In one arm of the bridge, the barber poles are placed in opposite directions above the two magneto resistors, so that in the presence of a magnetic field the value of the first resistor increases and the value of the second decreases (Figure 2).

Figure 2 – Magneto resistive sensors

1.A very clever and cost-effective solution for the measurement of high currents, especially in series applications, was presented at PCIM’99 in Nuremberg, Germany.

2.In this execution, the current is directly measured in the primary conductor and the sensor module is then simply clipped into a slot made in the conductor.

3.The sensor is mounted on an appropriate substrate and encapsulated in a plastic package (Figure 3). With this sensor, a broad range of currents can be measured simply by adapting the geometry of the conductor.

HOW IT WORKS

Figure 3 Working Principle

THE ADVANTAGES OF THESE SENSORS ARE:1. Significantly smaller volume and weight compared to conventional current sensors, permitting greater flexibility in application-specific design

2. No remanence in the event of overload

3. Measurement of DC and AC currents without additional loss

4. Wide frequency range due to low inductive design

5. No auxiliary supply necessary on the level of current to be measured

6. Low system costs

APPLICATION> CURRENT SENSORS IN TOMORROW’S CARS

1.Fuel efficiency first—this is the present motto of automotive development worldwide.

2. Many components that are at present powered by the car’s engine will in the near future operate on electricity—air conditioning compressors, water pumps, oil pumps, and the like.

3. Due to continuously changing engine speed, these components have rather poor efficiency ratings. Electric motors have the capability of optimizing their operation, independent of engine speed.

SUMMARY A new generation of current

sensorsBased on the magneto resistive effectIs extremely compact and offers tightMeasurement tolerances and a high Band-width at a low price.

CONCLUSION1.We can conclude that the universal current sensor provide greater flexibility in application-specific design.

2. The universal current sensor is immune to perturbations in the lead fibers.

3.There is no remanence in event of overload.

4.Measurement OF AC & DC current is possible without additional loss.

References

1. H. Lemme. 1998. “Magnetfeld-Sen soren-vielseitige Helfer,” Elektronik, H.3, S.40.2. A. Petersen. 1985. “Magnetoresistive Sen soren im Kfz,” Elektronik, H.10, S.99–102.3. G. Reiniger. 1986. “Drehwinkel mes sung mit Magnetfeldsensoren,” Elektronik, H.23, S.129.4. projectsreport.org/tag/file-type-semina-report-on-universal-current-sensor5.https://www.maximintegrated.com/en/glossary/definitions.mvp/.../Current-Sensor/.../6...