Alterra Brings Dokie Across The Finish Line

Transcript of Alterra Brings Dokie Across The Finish Line

Copyright © 2011 Zackin Publications Inc. All Rights Reserved.Subscription information is available online at www.nawindpower.com.

Mortenson Construction has built over 100 wind proj-ects in North America, so it

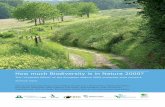

is certainly no newcomer to the wind industry. The company has worked through a variety of conditions, but those involved with the development of Canada’s Dokie wind project agree that it was one of the most challenging projects they have been involved with. For starters, the project is located in a remote area of British Columbia. The closest town, Chetwynd, is located in the foothills of the Canadian Rockies and is about an hour’s drive away from the project site. The 48 Vestas V90 3 MW turbines were delivered via a busy forest service road used by large logging trucks. A lot of coordination between Mortenson and Alterra Power Corp. – the project developer – and the logging companies was required prior to beginning con-struction so as to avoid accidents. “That presented all sorts of logis-tical challenges during construction, because it’s an active logging road,” says Paul Rapp, vice president of wind power at Alterra. “So, we would have to coordinate construction traffic for a couple of hundred workers plus tur-bine transport with between 30 and 60 … logging trucks coming down the road every day.” Mortenson was responsible for de-livering the turbines to the project site.

Reprinted with permission from the October 2011 issue

Alterra Brings Dokie Across The Finish LineThe wind project’s location in a remote area of British Columbia

and winter construction made this project challenging.

BY ANGELA BENIWAL

Copyright © 2011 Zackin Publications Inc. All Rights Reserved.Subscription information is available online at www.nawindpower.com.

economic development is good for them, and their concerns are quite logi-cal. They have a deep concern for the environment and the land – that it’s be-ing developed in a responsible way.”

Extreme weather Another challenge was the extremely cold and windy weather conditions. “Weather is probably one of the big issues at Dokie because it is quite northern and it has very severe win-ters,” says Rapp. “It’s a Class I site, so there are very high winds and a lot of gustiness, so it’s a tough site.” Mortenson was on-site in January 2010 to begin foundation and road work. Virgo agrees that the cold tem-peratures, high winds, lots of snow and low visibility made the work quite challenging. “Once you start to work with the el-ements, that’s where it tends to become more challenging,” he says. “All things considered, one of the large senses of accomplishment for us is that … we’ve done it successfully and safely in this very tough area. We see that as a very big accomplishment.” The extreme temperatures require special turbines. “We have very tough winters, so we have a special cold weather package on the Vestas V90s for that,” says Rapp. “We are aware of potential for things like blade icing, so we’ve had to put in op-erating procedures around approaching

project. GE Energy Financial Services owns the remaining 49%. Before EarthFirst went into credi-tors’ protection, it was able to take de-livery of eight turbines and partially construct five. After work stopped, lo-cal contractors did receive some com-pensation from EarthFirst but wound up losing a lot of work in the interim. “As much as we could, we tried to re-engage contractors that had previ-ously been involved,” says Rapp. “We wanted to try and give them the op-portunity to make some money on the job because a significant number of businesses and local contractors were left holding the bag.” He says that many of the original workers ended up completing the final project. “The local community is very happy that we came in and picked up the pieces, and I think everyone is re-ally happy that they were able to make some money from the project and it wasn’t a complete loss,” Rapp says. He adds that Alterra, whose assets also include geothermal and hydro proj-ects, also made it a point to reach out to First Nations by signing a memorandum of understanding that included some capacity payments and guaranteed cer-tain levels of involvement in the project. “We have a very good track record of working with First Nations on our hydro side and now on our wind side,” he says. “First Nations recognize that

Dowen Virgo, construction executive at the company, says that meetings were held on a weekly basis to make sure that all parties were on the same page regarding road use. “We delivered all of the turbine parts, and there was not one single in-cident on the road,” he says. “That was great.” In addition to logging trucks, the road was used by the general public, so safety was a priority. Much of the com-munication was done through two-way radios. “When you’ve got a couple of hun-dred different users on the road every day, all it takes is one person to not follow the radio protocol and you have the potential for a serious encounter,” says Rapp, who praises Mortenson for its work in coordinating the traffic. “One of the things that I think they just hit the ball right out of the park on is the coordination on the roads, be-cause that could have been a huge safety and logistical challenge,” he notes.

A long history The C$228 million project consists of 48 turbines on two mountain ridges on provincial Crown land: 15 turbines are located on Johnson Col, and 33 are located on Johnson Ridge. The power goes into a 35 kV overhead collector system that goes back to a substation, where it is transformed up to 230 kV. A 7 km long interconnection line takes power to an interconnection substa-tion built by BC Hydro that ties into the provincial grid. Construction on the project be-gan in 2008 by Dokie’s original owner, EarthFirst Canada Inc., which wanted to install eight turbines in the first year and the rest the following year. How-ever, EarthFirst was unable to com-plete the project because it had to seek bankruptcy protection under Canada’s Companies’ Creditors Arrangement Act just as the global economic crisis hit. Alterra, which at the time was Plu-tonic Power, bought the Dokie wind project in 2009. Plutonic Power has since merged with Magma Energy to form Alterra, which owns 51% of the

The project’s heavily forested location proved challenging. Photo courtesy of Alterra Power Corp.

Copyright © 2011 Zackin Publications Inc. All Rights Reserved.Subscription information is available online at www.nawindpower.com.

the turbines in the winter due to the fairly high potential for blade icing.” The project went into commercial operation on Feb. 16, and it has not yet experienced a full winter. Regardless, there were approximately three times when Alterra had to curtail some or all of the turbines for a short period of time due to blade icing. The area also experienced heavier-than-normal snow fall. “Snow clearing was a real issue – keeping access to the turbines – espe-cially since we were trying to do that through construction as well,” says Rapp. “During construction, you need access to everything all the time.” The severe winters in this area allow for a limited construction time frame. “From a construction, and opera-tions and maintenance point of view, the window of opportunity to get in and do anything heavy in winter is short because we have these long, cold, snowy winters,” says Rapp. “Then, in the spring, road access is actually limit-ed because the roads are thawing out.” Another challenge was the remote-

ness of the location. A fully functional temporary office was set up at the site. Instead of an Internet connection, sat-ellite – which is very slow comparative-ly – was utilized. In addition, UPS and FedEx deliveries took a week rather than a day or two, and mail delivery was only available in town. Virgo says that it if it were up to him, he would not have worked through the winter months. “If we had a choice, we would not have done that,” he says. “I think what mainly determined the start of the project and whether or not you work through winter is the owner has cer-tain deadlines that they have to meet. In this case, we had to work through winter in order to meet that deadline.” But this extreme cold – and the winds that accompany it – is actually a boon to the Dokie project itself. The majority of British Columbia’s power comes from hydroelectricity, which the province has a lot of. In fact, there was a glut of hydropower this past spring resulting from the runoff from the heavy snow that fell during the winter.

But there is much more wind in the region during the winter months, so Dokie can provide power when there is not as much hydro available. This cre-ates a great balance, says Rapp. “The good thing about Dokie is that it fits in very well because our highest winds come in the winter, which is when BC needs more power, and our lowest winds come in the spring,” he says. “So the annual en-ergy profile for Dokie fits very well for BC.” Alterra has a 25-year power pur-chase agreement with BC Hydro, which includes a time-of-year and a time-of-day pricing component. “The power is more valuable to BC Hydro in the winter, so we get a little bit more [money] in the winter, and there is a discounted price during the spring,” says Rapp. “For Dokie, in particular, it works well because we are weighted toward the winter en-ergy – it’s a good site from that point of view. It’s a good site for BC because its energy profile fits in the demand profile.” w