Allis Chalmers 185 Tractor Service Manual · snap ring. T he seal assembly is springloaded and is...

Transcript of Allis Chalmers 185 Tractor Service Manual · snap ring. T he seal assembly is springloaded and is...

Diesel iesel

"CI"~I'LC:~ INC. WITHOUT THE AUTHORIZATION OF :;CE=:SS;ORS. ALLIS CHALMERS AND IT'S SUCCESSORS

THE QUALITY OR ACCURACY OF THIS MANUAL.

CONTAINED AND USED HEREIN ARE THOSE OF OTHERS, PTIVE SENSE TO REFER TO THE PRODUCTS OF OTHERS.

Make: Allis Chalmers Model: 180 Years Made: 1968-

1973

FRONT OF TORQUE HOUSING FLANGE ON EITHER

SIDE

HP-PTO: 64.01 HP-Engine: HP-Orawbar: 55.2 Year Beginning Serial Number

HP-Range: 64 Engine-Make:

AC Engine-Fuel: DIESEL 1968 2682

Engine-Cyl(s)-CIO: 6/301 Transmission-

Optional: STO: CM

1969 6094

Fwd/Rev Standard: 8/2 Fwd/Rev

Mfwd-Std/Opt: Optional:

1970 9235

Tires-Std Front: 7.50-16 Tires-Std Rear:

Wheelbase-Inch: 18.4-28

1971 10561

Pto Type: Pto Speed: 540 CAT 1-3pt Hitch: False 1972 11729

CAT 11-3pt Hitch: True CAT 111-3pt

Hitch Lift: Hitch: False

1973 12447

Hydraulics-Type: OPEN Hyd-Cap: Hyd-Flow:

Hyd Std Outlets: 2 Cooling

Capacity: Fuel Tank Capacity: Paint Codes 180

Cab-Stdm A/C; Rops: Weight: 6510 New Price: 7474 Location I MFG Color Name

MAIN BODY OF TRACTOR ACPERSIANORANGE2

Make: Allis Chalmers Model: 185 Years Made: 1970-

1981 FRONT AND REAR WHEELS ACCREAM

HP-PTO: 74.87 HP-Engine: HP-Orawbar: 65.0

HP-Range: 75 Engine-Make:

Engine-Fuel: DIESEL AC

FRONT OF TORQUE HOUSING FLANGE ON EITHER

SIDE

Engine-Cyl(s)-CIO: 6/301 Transmission-

STO: CM Optional: Year Beginning Serial Number

Fwd/Rev Standard: 8/2 Fwd/Rev

Mfwd-Std/Opt: Optional:

1970 1001

Tires-Std Front: 7.50-16 Tires-Std Rear:

Wheelbase-Inch: 99.2 16.9-28

1971 1952

Pto Type: LIVE Pto Speed: 540 CAT 1-3pt Hitch: False 1972 2935

CAT 11-3pt Hitch: True CAT 111-3pt

Hitch Lift: Hitch: False

1973 3763

Hydraulics-Type: OPEN Hyd-Cap: Hyd-Flow: 6.6 1974 4961

Hyd Std Outlets: 1 Cooling Fuel Tank Capacity:

Capacity: 18 24.6 1975 6542

Cab-Stdm A/C; Rops: Weight: 6200 New Price: 18891 1976 8367

1977 10025

Paint Codes 185 1978 11626

Location MFG Color Name 1979 13160

MAIN BODY OF TRACTOR ACPERSIANORANGE2 1980 14672

FRONT AND REAR WHEELS ACCREAM 1981 15648

REAR RIMS ACALUMINUM

Litho in U. S. A.

180-185 TRACTOR

INDEX

Section

DIESEL ENGINE. . • . • • • • • • • • • • .

TRACTOR. • • • • • • • • • • • . • • • • •

HYDRAULICS • • • • • • • • • • • • • • •.

OPTIONAL EQUIPMENT & ACCESSORIES. • ..

IMPORTANT: This Service Manual Section has been supplemented to be applicable to both 180 and 185 Tractors with differences as noted.

One-Eighty 1

F.E.S.M. Supplement No. 86

180 AND 185 TRACTOR ENGINE

INDEX

ADAPTOR PLATE & CRANKSHAFT REAR OIL SEAL Rear Oil Seal . • . . • Removal & Inspection • • • • • . . . • • . • •

CAMSHAFT & CRANKSHAFT GEAR & THRUST PLATE General. • Inspection. • . • . Removal . • • • . Thrust Plates. . .

CAMSHAFT BEARINGS Clearance. General. • . • • . Removal • • • •

CONNECTING RODS & CONNECTING ROD BEARINGS. General. . Ins pection. • • . • • • • • . . Removal. . • . • • • • • • • •

CRANKSHAFT & CAMSHAFT GEAR Installation • • Removal • • • • • • • • • • • Timing Marks. • • • • • • • •

CRANKSHAFT & CRANKSHAFT GEAR Crankshaft Gear Removal & Installation • General. • . • • • . • • • • • • • • Main Bearing Caps (Location). • • ••

CRANKSHAFT PULLEY & DAMPER ASSY. Removal. • • • • Installation • • • . • • • •

CYLINDER BLOCK. • . • . CYLINDER HEAD & VALVES

General Information • Installation • • • • • • Torquing Sequence. • • Valve Lash Adjustment. Valve Operating Mechanism Valve Spring. • . • • •

CYLINDER SLEEVES Ins pection & Removal Installation • . • • • • Reseating Sleeve Reseating Sleeve Tool •

ENGINE Assembly. Disassembly •• Run In Schedule •

ENGINE COOLING SYSTEM. • Cleaning • • . • . • • • • • • Draining • . • • • • • Fan Belt & Adjustment Filling • • • • • • . General Maintenance. • Thermo stat. . . • . •

ENGINE SPECIFICATIONS ENGINE TORQUE SPECIFICATIONS •

One-Eighty !J. _ 1

A- 61 A- 62 A- 61

A- 70 A- 73 A- 70 A- 7l

A- 75 A- 75 A- 75 A- 83 A- 83 A- 86 A- 83

A- 53 A- 52 A- 53

A- 87 A- 87 A- 89

A- 42 A- 42 A- 95

A- 27 A- 31 A- 33 A- 34 A- 29 A- 35

A- 96 A- 97 A-IOO A-lOO

A-I04 A-I03 A-I04 A- 13 A- 15 A- 15 A- 16 A- 15 A- 14 A- 16 A- 4 A- 11

F.E.S.M. Supplement No. 86

180 AND 185 ENGINE INDEX (Cont'd)

FITS & TOLERANCES ••••••• FL YWHEEL & RING GEAR

Wear Sleeve ReITIoval & Installation FRONT SUPPORT PLATE ••...• FUEL PUMP DRIVE GEAR & PUMP DRIVE SHAFT.

*FUEL INJECTION PUMP SPECIFICATIONS .... GEAR TRAIN & FRONT SUPPORT PLATE •••.

HYDRAULIC PUMP DRIVE ASSEMBL Y AsseITIbly • • DisasseITIbly. Ins pection. • • • • Installation ReITIoval

IDLER GEAR & IDLER GEAR SHAFT Installation ReITIoval

LUBRICATION SYSTEM.

MAIN BEARING CAPS Locations • • ReplaceITIent. . • •

MAIN BEARINGS ReITIoval, Inspection, Installation ReplaceITIent (Engine Installed)

OIL PAN ReITIoval & Installation

OIL PRESSURE PUMP AsseITIbly • DisasseITIbly. General Inspection. Installation ReITIoval

PISTONS & PIS TON RINGS AsseITIbly (Connecting Rod to Piston) Fitting (Piston to Cylinder Sleeve) Fitting (Pistons to Pi ston Rings) Gener al • • • . • • • • • • • • Inspection (PistOD 8. Piston Rin~) • Installing- (Piston, Connecting Rod &

Connecting Rod B-earing) • • • • Installing (Piston Rings) • • • • • ReITIoval (Connecting Rod & Bearing) • ReITIoval (Connecting Rod & Piston Rings). •

ROCKER ARMS, ROCKER ARM SHAFT 8. PUSH RODS

A- 5

A- 60 A- 51

A-48, A- 57 A4-a, b, c, d

• • • • A- 47

A- 46 • • A- 46

A- 46 A- 47 A- 46

A- 49 A- 49

A- 63

A- 94 A- 94

A- 91 • • A- 92

A- 64

· • A- 68 A- 67 A- 66 A- 68 A- 69 A- 66

.•• A- 81 • A- 79 • A- 80 • A- 78 • A- 79

A~ 82 • A- 81

A- 78 A- 79

DisasseITIbly, ReITIoval & Inspection . • • • • • • • . • • • A- 30

* Also found in Fuel Injection Data Section of this Manual

F.E.S.M. Supplement No. 86 One-Eighty

A-2

180 AND 185 ENGINE INDEX (Cont'd)

THRUST PLATES. • . • . . . . • • . . . • . •. • • • TIMING GEAR COVER & CRANKSHAFT FRONT OIL SEAL

Crankshaft Front Oil Seal. Front Plate & Gear Cover. Timing Gear Cover. . • •

TROUBLE SHOOTING Air Intake System . . • . Checking Compression Pressure. Cooling System. • Engine Fuel System. . Instruments·. • Lift of Recommended Service Tools Lubricating System. • • • . • • • Service Tools • • • • • • • • • • •

VALVE GUIDES & VALVE SEAT INSERT Size Chart. • . . . • '. • • • • • Valve Face & Valve Seat Grinding •

VAL VE LIFT ERS Inspection. Installation Removal

WATER PUMP Assembly .• Disassembl y . Installation Removal

One-Eighty

A- 55

A- 45 A- 44 A- 45

A-lll A-I08 A-lli A-IDS A-lID A-114 A-1l5

• A-Il2 •• A-llS

•• A- 38 • A- 39

A- 77 A- 77 A- 77

• A- 21 • A';' 20

A- 23 • A- 19

F.E.S.M. Supplement No. 86

CONNECTING RODS (Cont'd)

4.

5. 6.

7.

8. 9. 10. 11. 12. 13. 14.

Inside diameter of connecting rod bushing - finished bore after installation .. Outside diameter of connecting rod bushings. Bearing bore (without bearing, cap in place and capscrews tightened to specified torque) ... Connecting rod bearing -to -crankshaft journal clearance (with capscrews tightened to specified torque) . Connecting rod width at lower end . Side clearance-to-crankshaft journal. Piston pin diameter . Piston pin bushing length in connecting rod .. Piston pir. to connecting rod bushing clearance Torque for tightening connecting rod capscrew s Bore in connecting rod for piston pin bushing

EXHAU ST VALVES

l. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Valve lift (at valve wi. 015" lash. Valve lift (at cam) Seat Angle Valve seat contact width .. Val ve lash (cold) . Valve lash (Normal operating temperature) Head diameter . Overall length. Stern diameter • Valve must be rece ssed (in head) •

EXHAUST AND INTAKE VALVE SPRING

1.2527" - 1.2532" Split type

2.5620" - 2.5625"

. .0009" - . 0034" .1.1935" - 1.495" . • 0035" - • 008" 1.2515" - 1.2517"

1. 391" - 1.411" • 001" - . 0017"

45-501bs.ft. 1.3750" - 1.3755"

I 354" • 246"

45 0

3/32" · 0 18" · 0 15"

1. 439" - 1. 449" 5.997"

.3705" -.3710" Minimum. 0485"

1. Valve spring free length. 2.968" approx. 2. Valve spring length (valve closed). 2.223" 3. Valve spring length (valve open). 1. 836" 4. Spring load at 2.223" length .41-45 Ibs. 5. Spring load at 1. 836" length 73-81 lbs. 6. Install new spring when old spring is 5% below the low limit or 50/0 above the high limit.

INT AKE VAL VES

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Valve lift (at valve (w/. 015" lash). Val ve lift (at cam) .•.. Seat angle Valve seat contact ,vidth .. Valve lash (cold) . Valve lash (normal operating temperature). Head diameter Overall length Stern diamctc r Valve must be recessed (in head)

.4005" · 277"

30 0

3/32" • 0 18" · 0 15"

.1.615" 1.625" 5.996"

. 3715" - .3720" l\1inimum .0345"

EXHAUST VAL VE SEAT I~SER T (Service Only Prior to Eng. SIN 2D-03143)

1. 2. 3. 4. 5. 6. 7.

8. 9. 1 O.

Seat angle . Seat contact ,\·idth. Seat run out Insert pres s fit. Insert O. D. not in stall ed Bore in cylinder head for insert Depth of counterbore in cylinder bottom deck of head) .

he ad for insert (from

45 0

3/32" . . .. .002" ..001" - .003"

l.d825" - 1.4835" 1. 4805" - 1. 4815"

.4465" -.4485" Overside insert ... Insert in Production Engine: Insert availabe for service:

• ODS" over standard 2800 Prior to SiN 2D-03143 - XO; Eff. ,vi S N 2D-03143 YES

2800 YES;

Litho in U.S.A. One-Eighty

A-7 F. E. S. M. Suppl. No. 72

CYLINDER HEAD

1. Val ve sequence (front to rear) No. 1 cylinder . No. 2 cylinder No. 3 cylinder No. 4 cylinder No. 5 cylinder No. 6 cylinder

LUBRICATING OIL PRESSURE PUMP

1. 2. 3. 4. 5. 6.

7. S.

9. 10. 11.

Radial clearance - gears to pump body . End clearance - pump gears. 1. D. in pump body for oil pump drive shaft O. D. of dri ve shaft . O. D. of idler shaft. I. D. in gear driver for drive shaft Fit-drive shaft to gear driver. Clearance - O. D. of dri ve shaft to bore in oil pump body 1. D. in lower pump body for idler gear shaft Fit-idler gear shaft to body . 1. D. in idler gear Clearance - idler shaft to gear. 1. D. in drive gear-for drive sh Lit Fit-shaft-to-drive gear.

WATER PUMP

1. 2.

3.

4.

Clearance - impeller to plate Bearing: Bearing O. D. Bore in water pump body (for bearing) Fit-bearing O. D. to body. Impel! er: Bore in impeller for shaft. Shaft diameter. Fit - shaft diameter to impeller bore. Hub - for water pump pulley: Bore in hub for shaft . Shaft diameter. Fit - shaft diameter to hub bore

IDLER GEAR ASSEMBLY

1. Idl erg ear b ea ring: Bearing bore (I. D. for idler shaft) Shaft diameter. Fit - shaft to bearing Bearing O. D. Bore in idler gears. Fit-bearing O. D. to idler gear Bore in cylinder block for 'idler gear shaft Idler shaft O. D. Fit-idler shaft to bore in cylinder block.

HYDRAULIC PUMP DRIVE ASSEMBLY

1. Hydraulic pump drive bearing: Bearing bore (1. D. for hydraulic pump drive shaft) . Shaft diameter. Fit-shaft to bearing Bearing O. D. Bore in hydraulic pump dri ve housing for bea ring Fit-bearing O. D. to h\,draulic pump drive housing

One-Eighty A-9

intake - exhaust exhaust - intake intake - exhaust exhaust - intake intake - exhaust exhaust - intake

.00075" - . 00175" . 002" - . 004"

· 6235" - . 6245" · 6220" - . 6225" .61S5" - .6190" · 6200" - . 6210"

· 001" - . 0025" tight . 001" - . 0025"

· 6 16 5" - . 6175" · 001" - . 0025" tight

· 6200" - . 6210" . 001" - . 0025"

.6205" - .6215" · 0005" - . 002" tight

. 0 15"

1.4995" - 1. 5000" 1. 498" - 1. 499"

.0005" - . 001" tight

· 6225" - . 6235" · 6262" - . 6207"

· 0027" - . 0042" tight

· 7435" - . 7H5" · 7460" - . 7465"

· 0015" - . 0030' tight

1.000" - 1.000S" . 9990" - 1.0000"

. 0000" - . 0018" loose 1. 980" - 1. 9S1"

1.9785" - 1. 97 0 5" · 0005" - . 002 =j" tieht

.998" - . 909" · 9 0 90" - 1.000"

· 0000" - . 002" tight

1.500" - 1.5005' 1. 4995" - 1. 5005"

.0005" - . 00 10" loose . 2.5625" - 2.5635"

2.5635" - 2. 5b45" . 0000" - . 002" loose

F. Eo S. M. Suppl. No. 64

yl \~o

~\

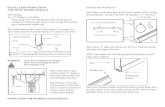

WATER PUMP INSTALLED

1. Volute 2. Water Pump 3. Front of Cylinder Block

snap ring. T he seal assembly is springloaded and is pressed into the pump body forming a leakproof seal at this point.

A carbon sealing surface is bonded to the seal assembly and contacts a ceramic seal insert bonded to the pump impeller. Proper positioning of impeller on shaft creates a 9 to 13 pound load on the seal assembly forming a tight seal.

A pulley hub, pressed on front end of water pump shaft, provides a mounting for the water pump pulley and fan blade as sembI y.

WATER PUMP REMOVAL

Drain the cooling system at radiator and cylinder block. Loosen clamps and remove inlet and outlet radiator hoses. Remove radiator assembly and radiator supports from tractor. Remove the alternator assembly from tractor. Remove capscrews, fan and pulley from water pump hub.

Remove by-pas s tube from water pump body and thermostat housing. Remove caps crews and water inlet pipe from water pump body. Remove caps crews and water pump body assembly from the outlet sections, called the water outlet volute. The pump body is sealed to volute with an O-ring seal.

WATER PUMP VOLUTE INSTALLED

1. Volute 2. Cylinder Block 3. Timing Gear Cover

• \--+--2 e

BACK SIDE OF VOL UTE

1. O-Ring 2. Cylinder Block 3. Volute

Remove caps crews and volute from cylinder block. The volute is sealed to cylinder block wi th an 0- ring seal.

One-Eighty A-19 F. E. S. M. Suppl. No. 64

2

5 4

MAIN BEARING CAPS LOCATION

1. Rear Main Bearing Cap 2. Thrust Main Bearing Cap 3. Front Main Bearing Cap

and premature failure will result. The crankshaft should turn freely after all lock bolts are properly torqued. Never file or shim a bearing cap to make the bearing shell fit; install new bearing shells if fit on the crankshaft is unsatisfactory.

g. Check end play of the crankshaft using a dial indicator as illustrated. Tap crankshaft with a soft headed hammer in one direction to take up slack or end play. After dial indicator is set in place, force crankshaft with a pry bar in opposite direction to obtain end play reading. The specified end play is .004" to .009" and must not exceed. 015". The end play is controlled by thrust flanges on the number 4 main bearing shell. If end play is not within the specified range, replace the bearing shell.

h. Install connecting rod bearing caps and shells and check side clearance between connecting rods and crankshaft journals.

i. Install the oil pump and complete the rest of the installation by a direct reversal of the removal procedure. See headings "Crankshaft Removal" and "Crankshaft Inspection".

j. Fill the cooling system and fill the engine crankcase to the proper level with the specified oil.

4. Intermediate Main Bearing Caps 5. Bearing Cap Position Numbers

(t (I 2 ~ ®

~~\§))\ :,,)0/ ~~. 'If I I, !

r! ('" I //~~ 1(, •. , /

I, ,\ I,' , 1/: \~'\\ \\,'~

910 /

MEASURING END PLAY OF CRANKSHAFT

1. Pry Bar (OTC PB-24) 2. Crankshaft 3. Dial Indicator (KM J -5959)

CRANKSHAFT GEAR REMOVAL AND INST ALLATION

The crankshaft gear may be removed from the crankshaft by the use of tools similar to those shown in illustration. The gear may be removed either with the crankshaft installed in the engine or after the crankshaft has been removed.

One-Eiahtv '"' -A-89 F. E. S. M. Suppl. No. 64

180 AND 185 TRACTOR

INDEX

B RAKE OPERATION • • . Brake Pedal Adjustment Ins talla tion Removal. •

BELT PULLEY. . Assembly • • • Disassembly .• Installation Removal

DIFFERENTIAL ASSEMBLY Adjust Differential Bearings Assemply • • • • • • • • Disassembly. • • • • • • • • • • • • Install Ring Gear to Differential Housing Reinstall in Transmission Housing Spe cifications • • • • • • . • • • • • •

ENGINE CLUTCH Adjustment Installation Removal •••• Safety Start Switch Adjustment.

ENGINE CLUTCH SHAFT Installation Removal

FINAL DRIVE BEARING FITS & TOLERANCES FINAL DRIVE & REAR AXLE ••••

Installation Removal ••••••

FRONT AXLE SUPPORT Installation Removal •• . • • • • • • • •

FRONT END WEIGHT • • • FRONT SUPPORT WITH INTERCHANGEABLE FRONT AXLE WITH INTERNAL STEERING RACKS

Adjust Bearings on Steering Racks • Install Front Support Assembly. • Install Power Steering Racks Install Steering Spindle Shaft Remove Front Support Assembly •• Remove Power Steering Racks Remove Steering Spindle Shaft. •

FRONT WHEEL FOR DUAL & ROLL SHIFT Axle Front Wheels and Bearings Seal Kit. • • . • • •••

GENERA TOR - DELCOTRON. Air Gap. • • • • • • • • Checking Voltage Setting Closing Voltage Field Relay Unit • • Point Opening • • • Voltage Regulator • • • • Voltage Setting. • • • • •

IDLER SHAFT & GEARS Ins talla tion Removal. • • • • • •

Litho in U. S. A. One-Eighty

B-1

.B-48

.B- 51

.B-48

.B-48

.B-23

.B- 23

.B-23 • .B- 24 • .13-24

.B-40 • .B-4l • .B-40

• ••• B-40 .B-42

• .B-42 • • • .B-42

• .B-14 .B-13

· .B-13 .B-14

• .B-21 .B-22

• .B- 21

.B-47

.B-43

.B-44

.B-43

.B- 8

.B- 8

.B- 5

• .B-ll • .B-12

.B-12 • .B-12

.B-12

.B-ll

.B-l2 · . . .B-ll

• .B- 6 · .B- 6

• • • • .B- 56 • B-6l, B-62

• .B- 63 • • • • B- 61 • • • .B- 61

B-61,B-62 • B-60,B-62

.B-62

• .B-19 .B-20

• .B-19

F. E. S. M. Suppl. No. 72

INPUT SHAFT Installation

180 AND 185 TRACTOR INDEX (Cont'd)

Removal . . • • . . • • . • • INTERMEDIA TE SHAFT &: GEARS

Ins talla tion RemO\-al . • . • .

LIFT ARM &: HOUSING Installation Removal . . • • .

MAIN PINION SHAFT &: GEARS Pres sing Into Housing • • • • • Removal . • . • . • . • .

PEDESTAL &: SPINDLE (Dual Front Wheel) Ins talla tion • • • • . • •

PINION SHAFT &: BEARINGS Installation. • • • • • • Removal . • • • • • • .

POWER DIRECTOR CLUTCH Assembly .• Disassembly • • • • • • Removal . • • • . • • •

POWER DIRECTOR CLUTCH SHAFT Hollow Clutch Shaft wi 26 T Gear. • Installation. • • Removal . • . •

POWER TAKE-OFF Assemble Clutch Disassemble Clutch Install Front PTO Shaft &: Gear (wi 0 Clutch) Install PTO Housing . • • . . • • • Install PTO Shaft &: Gear (w/Clutch). PTO Clutch Specifications PTO Gear Train .•••.•••• PTO Speeds. • • . . • • . • • • •

B-33 B-33

B-18 B-18

B-53 B-53

• B-37 B-39

• B- 34

B- 7 B- 7

• B-45 B-46 B-45 B-30 B-3l

• B-30 B-30

B-17 • B-17

B-17 B-25

• B-26 B-26 B-28 B-29 B-27

• B-27

Remove Front PTO Shaft &: Gear (wi 0 Clutch) • • • • Remove PTO Housing From Torque Housing •

• B-29 B-29 B-28 B-25

Remove PTO Shaft &: Gear (wi Clutch) • • • • •

REAR POWER TAKE-OFF SHAFT Installation. • • • • • • Removal . • • . . • • •

ROLL SHIFT FRONT AXLE.

SPINDLE &: TIE ROD (Roll Shift Front Axle)

TACH-HOUR METER - DRIVE Installation. • • Removal . • . • . • • . .

TORQUE HOUSING Remove Torque Housing Assembly

TRACTOR TORQUE SPECIFICATIONS TRANSMISSION COUNTERSHAFT ( 180 Tractors) •

Install Countershaft &: Gears • Install Reverse Shaft &: Gears. Remove Counter shaft &: Gear s Remove Rever se Shaft &: Gear s

• B-25

B-52 B-52 B- 9

• B-lO

B-55 B-54

B-15 •• B-3,B- 4

B-35 B-36 B-36 B-35

TRANSMISSION &: DIFFERENTIAL HOUSING (180 Tractors) B-35 B-32

Remove Transmission Assembly •.•••• TRANSMISSION MAIN SHAFT (180 Tractors) TRANSMISSION (185 Tractor) • • • • • WIRING DLA.GRAM (180 Diesel) ••.••

One-Eighty F. E. S. M. Suppl. No. 72 B-2

• B-32 • • • . • • • B- 34

.B-71 Thru B-78 • • • • • . B- 66

Litho in U.S.A.

180 AND 185 TRACTORS

HYDRAULICS INDEX

BREAK-AWAY COUPLER. . . . . . C-14

CONTROL VALVE - INLET SECTION C-23

HOSE COUPLER ASSEMBLY . . . . C-15 HYDRAULIC LIFT SYSTEM. . . . . C-16 HYDRAULIC PUMP - 180 . . . . . . C-2

LIFT AND "TRACTION BOOSTER" SYSTEM. C-8

POWER DIRECTOR CONTROL VALVE C-9 Control Valve . . . . . . . C-IO Install Control Rod and Spool. C-II Install Relief Valve . . . . . C-II Remove Control Rod and Spool C-Il Remove Relief Valve . . . C-II

POWER DIRECTOR AND PTO CLUTCH ASSEMBLY . C-6

POWER STEERING SYSTEM. C-5 Checking Valve . . . . C-5

POWER STEERING VALVE Assemble. . . . . . . . C-32 Disassemble. . . . . . . C-31 Seal Kit . . . . . . . . C-30

PTO CLUTCH VALVE ASSEMBLY Assemble. . . . . . . . . . C-13 Disassemble. . . . . . . . . C-13

PTOCONTROLVALVE. . . . . C-12 PRESSURE RELEASE FOR DETENT C-27

RELIEF VALVE Assemble. . Disassemble. Operation .

REMOTE RAM Assemble .. Disassemble.

SECTIONAL CONTROL VALVE

C-23 C-23 C-24

C-25 C-25

Remote Ram - Float C-20 Remote Ram - Hold. C-19 Remote Ram - Lift . C-19 Remote Ram - Lower C-l 9 Sensing Valve . . . C-22 Tractor Ram - Hold. C-20 Tractor Ram - Lif~ . C-21 "Traction Booster" Position . . . . C-22

SPECIFICATIONS OF GEARS AND GEAR PLATES Assemble. . . . . . . . . . . . .. C-3 Disassemble. . . . . . . . . . . .. C-3

TESTING TRACTOR HYDRAULIC SYSTEM OTC Hydraulic Tester. . . . . . . .. C-4 Pump Volume. . . . . . . . . . .. C-4 Relief Valve Pressure . . . . . . . . .. C-4

"TRACTION BOOSTER" SENSING VALVE AND OUTLET . . . C-29

TRACTOR RAM. . . . . . . . . . . . . . C-28

One-Eighty C-l F.E.S.M. Suppl. No. 72

HYDRAULIC LIFT SYSTEM

TORSION BAR PRELOAD

Remove all draft loads from draft arms by unhitching from implement. Loosen locknut and turn preload adjusting screw in approximately two turns tight and back off screw until finger tight, but no preload. Hold screw in this position and tighten locknut.

"TRACTION BOOSTER" LINKAGE

The torsion bar adjustment must be completeu before making TRACTION BOOSTER linkage adjustments. Remove implement if one is hitched to tractor. The lower draft arms must be free of all loads when making adjustments.

Place the tractor lift arm lever in the TRACTION BOOSTER posi tiona Move Position Control lever all the way forward. Move the TRACTION BOOSTER lever all the way rearward.

Set engine speed at approximately 1000 RPM and turn both nuts on the TRACTION BOOSTER support rod an equal amount until the lift arms are as near horizontal as possible.

If it is desired to decrease, or increase the sensing valve travel in relation to torsion bar linkage movement, it can be accomplished by changing link to lever ratios.

Heavy draft loads with fully mounted implements provide the most deflection in the torsion bar and the greatest linkage ITlOvement. Therefore, it may be desirable to reduce the sensing valve travel by moving the spring-loaded linkage to the rear hole in the lever and/or placing TRACTION BOOSTER link rod in the lower hole in lever.

Lighter draft loads with semi-mounted implements provide a somewhat less deflection of the torsion bar which results in less linkage movement. Therefore, it may be desirable to increase the sensing valve travel by moving the TRACTION BOOSTER link rod to the upper hole in lever and! or moving the spring loaded linkage to the forward hole in the lever.

FEED- BACK LINKAGE

The TRACTION BOOSTER system is equipped with "feed-back" linkage. The "feed-back" linkage prevents the draft arms from raising too much or lowering too much when changes in draft arm loads occur.

F. E. S. M. Suppl. No. 64 One-Eighty

C-16