ALLEGHENY BRADFORD CORPORATION - Structure...•Straight or U-Tube design When it comes to heat...

Transcript of ALLEGHENY BRADFORD CORPORATION - Structure...•Straight or U-Tube design When it comes to heat...

ALLEGHENY BRADFORD CORPORATION

CERTIFIED BY

ALLEGHENY BRADFORD CORP.MAWP 150 PSI AT 300 °FMDMT -20°F AT 150 PSIMAWP 150 PSI AT 300 °FMDMT -20°F AT 150 PSISN 12490–02Y/B 1997

W

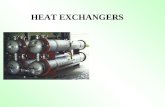

Keep Your Cool With QualityHeat Exchangers For Ultra-Pure Applications

Tailored To Your Thermal Transfer Needs

Because each application is different, we designevery heat exchanger individually to meet yourunique processing needs. Fabricated with precisiondown to the last detail, Allegheny Bradford heatexchangers feature:

• All stainless steel construction for corrosion resistance and product integrity

• Contact surfaces polished to Ra values less than 10 microinches for ultra-pure applications

• Free-draining design to eliminate product hold-up

• Unique double tubesheet construction to prevent cross contamination of process and utility fluids

• Straight or U-Tube design

When it comes to heat exchangers, AlleghenyBradford sets the industry standard. Quality isthe cornerstone of our heat exchangers fromstart to finish. Our engineering specialists workclosely with you to custom design the mostefficient, cost-effective heat exchanger for your thermal transfer requirements.

From the documentation of raw materials incompliance with ASME codes, to the precisionCNC machining of tubesheets and bonnets, tofinal finishing, testing and documentation,Allegheny Bradford Heat Exchangers aremanufactured to deliver superior performanceand trouble-free operation, even in the mostdemanding ultra-pure processing environments.

Allegheny Bradford

Corporation

Advanced Technology AndTesting For Peak Performance

Our state-of-the-art fabrication technology useshigh-pressure hydraulic expansion to seal the tube-to-tubesheet joints. This reduces the risk of rollerexpansion damage, as well as work-hardeningeffects and excessive thinning of the tubing. In addition, our proprietary integrated doubletubesheet virtually eliminates tube-to-tubesheet jointstress. The result is consistent performance,reduced maintenance and extended equipment life.

Prior to shipment, every heat exchanger undergoesrigorous testing and documentation procedures thatmay include:

• Hydrostatic pressure testing

• Dye penetration examination

• X-ray analysis

• Saline testing

• Computer-verified performance

• Profilometer readings of surface finish to ensure mechanical and electropolished surface finishes to less than 10 microinches Ra

• Fiber optic, borescopic tube inspection and videotaping of product contact surfaces

• ASME Code Stamping with National Board Registration

You receivecompletedocumentation tocomply with yourrequirements,including datareports, seismiccalculations,

production drawings, material test results, andcertifications of hydrotest, passivation, surface finishand electropolishing.

Expanded Facilities For Faster Response

To meet our client's growing needs, AlleghenyBradford has added new fabrication facilities andupgraded our equipment for increased capacity and

improvedoperationalefficiency. As aresult, we can meetyour heat exchangerrequirements fasterand more cost-effectively than everbefore.

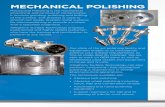

State-Of-The-Art Electropolishing:The Ultimate Surface Finish

Allegheny Bradford's on-site electropolishing services will deliver the ultra-smooth finish your processingdemands, regardless of the design and size of yourheat exchanger. Our advanced proprietary techniquesare designed to increase corrosion resistance, removecontaminants, maximize passivation and reducesurface friction.

As part of our comprehensive electropolishingprocesses, heat exchangers undergo precision pre-cleaning, final high-purity cleaning and rinsing, andpost-electropolishing protection. Because we offer thisservice at our own facility, we can produce the finish youneed with quick turnaround and competitive pricing.

Your Single Source For Stainless Steel Equipment

When you need stainless steel components andequipment for your ultra-pure process, AlleghenyBradford Corporation delivers the quality custom heatexchangers, tanks, filter housings, pumps, valves,fittings and process skids you require - on time andon budget. For more information on our full range ofproducts and services, call us today at 800-542-0650.

For more than 25 years,Allegheny BradfordCorporation has built areputation for quality in thedesign and manufacture ofstainless steel shell andtube heat exchangers forpharmaceutical, biotech-nology and other ultra-pureindustries. As the recog-nized leader in the indus-try, we offer today's mostadvanced stainless steelprocessing technology,along with a team of dedi-cated professionals whoare committedto providing youwith productsthat deliverunparalleledperform-ance anddependability,along with theresponsive cus-tomer serviceyou need.

Quality Stainless SteelEquipment From TheIndustry Leader

CustomSanitaryShell & Tube HeatExchangers

Allegheny Bradford Corporation 1522 South Avenue, Lewis Run, PA 16738

800-542-0650 Fax: 814-362-2574www.abccorporate.com