alidation Ser V ice S • IQ/OQ/PQ • Thermal maPPI ng€¦ · Red 485 Dark Blue Pantone 289 Light...

Transcript of alidation Ser V ice S • IQ/OQ/PQ • Thermal maPPI ng€¦ · Red 485 Dark Blue Pantone 289 Light...

Red 485Dark Blue Pantone 289Light Blue 58% of Pantone 289

Validation SerViceS •IQ/OQ/PQ •ThermalmaPPIng

For

SerViceS

MadgeTech, a leader in data logger technology offers a variety of validation services to assist customers in complying with regulations and meeting accreditation standards.

Red 485Dark Blue Pantone 289Light Blue 58% of Pantone 289

Validation of the MadgeTech System

MadgeTech now provides on-site IQ/OQ/PQ (Installation, Operation and Performance Qualification) services for data loggers, software and other validation processes. Our trained staff are familiar with the standard IQ/OQ/PQ protocols, and can help to validate the system, prepare a post report, and address any questions.

A member of the MadgeTech staff will provide the protocol, data loggers (if necessary) and on-site services to expedite the required MadgeTech data logging system validation. We will work with the end user to conduct test protocols including IQ, OQ and PQ. As part of this validation service, MadgeTech will provide a comprehensive final report that documents all testing that was performed and results that were obtained. Recommendations will be made for testing worst-case and normal operating conditions future performance qualification and on-going maintenance of the instruments.

Key Benefits • Custom IQ/OQ/PQ protocol generation

• On site product/protocol expertise

• On site qualification by trained individuals

• Recommendations for PQ and ongoing maintenance

• Comprehensive qualification report supplied upon completion

MadgeTech’s on site IQ/OQ/PQ services is a cost effective means to save time and ensure proper implementation of IQ/OQ/PQ with minimal disruption to staff and operations.

What can I find out from a Temperature Survey?A temperature mapping survey of a space can reveal a great deal of information about the dynamics and performance of your installation. This is just the information you need to confirm proper operation of the system or to identify and resolve suspected shortcomings in the performance.

A survey will plainly reveal: stratification of the air, hot and cold spots, anomalies in the chilling or heating system, power outages, effects of door openings, effects of introducing goods, presence of personnel, time until recovery of set temperature and much more.

On Site ServiceS

Data LOgger rentaLS

MadgeTech now offers data logger rentals to aid in validating temperature controlled systems and processes. Applications include warehouses, refrigerators, freezers, stability chambers and autoclaves. When validation is complete, users simply return the loggers to MadgeTech. MadgeTech’s rental program provides an economical way for businesses to validate their systems and processes at an affordable price.

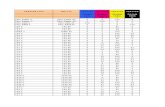

A complete report is provided after the study is performed. This report includes:

• Methodology - Methodology describes the approach that was taken.

• Summary - The summary describes the findings and recommendations for improvement.

• Map - The Map is a thermal map of the area studied.

• Box Plot - The Box Plot summarizes the distribution of data and any outliers.

• Control Chart - A Control Chart displays the mean and high and low control limits.

• Histogram - A Histogram shows temperature distribution in brackets.

• SOP - The SOP is the procedure in which we followed to perform the mapping.

The report provided contains all the data shown as multi-trace colored graphs for the entire area plus sectional breakdowns to point out differences by location, level etc. Where unexpected behavior is seen, a sectional graph will be produced to give a zoomed-in view allowing closer scrutiny of the data.

Examination of the multi-trace graphs will reveal the movement of change in temperatures in the volume so indicating air-movements, derived values of max, min and average are shown for each location in bar-graphs to help point out any zoning either by level or plan location. This will show if there is a patchy, uneven distribution of temperatures.

What systems or processes do I need to validate?Regulations have been put in place by the FDA/ICH to ensure warehouses storing pharmaceutical products and other temperature controlled equipment are “Mapped” and “Monitored”.

The purpose of mapping is to identify Hot Spots, to understand how the internal temperature is effected by climatic changes and to better manage the product or process. This should be conducted at least once in the summer and once in the winter. A temperature map is conducted either by the customer using low cost, highly accurate data loggers or by a MadgeTech representative. Regulating agencies require that minimum and maximum temperature readings be recorded at least hourly. MadgeTech data loggers, however, can produce a full thermal profile without the need to manually record readings. Downloaded information can automatically calculate min/max, averages, means, MKT, as well as standard deviation. A product life versus temperature calculation can be performed in the software.

This validation ensures compliance as well as enabling proper use of the warehouse and equipment and a more complete understanding of products effected by temperatures, such as warehouses, refrigerators, freezers, stability chambers and autoclaves.

Phone:(603)456-2011•Fax:(603)456-2012•[email protected] www.MadgeTech.com

Red 485Dark Blue Pantone 289Light Blue 58% of Pantone 289

Validation Study Process:

AutoclavesUsing the MadgeTech HiTemp150 or HiTemp150FP, autoclave validation is made simple. There is no need to run thermocouple wires, as the data loggers have internal RTD Sensors, providing fast, accurate, temperature response. The MadgeTech software provides the F0 (Kill Factor) value based on the data collected to maintain the proper Sterility Assurance Level (SAL).

An empty chamber distribution test is performed for the Operational Qualification process. This test determines the uniformity of the chamber. The data loggers are calibrated before and after testing to ensure the +/-0.25°C accuracy.

Tests are then performed with loads to determine which load items are the most difficult to sterilize and the location within the autoclave. The HiTemp150FP is used to verify SAL levels in locations such as flasks and piping. Testing is performed until the proper SAL has been reached in three consecutive tests.

Stability ChambersMost stability chamber conditions are held at 25°C, 60%RH and 40°C, 75%RH, but can vary depending on the product. It is important to ensure that this environment is maintained and stable throughout the chamber.

Using the MadgeTech MicroRHTemp or TransiTempII-RH, the entire chamber can be mapped for identification of hot or cold spots. This results in the proper usage of the stability chamber, saving time and money in products and samples.

Warehouses Using the MadgeTech TransiTempII or TransiTempII-RH, a complete temperature profile or heat distribution, can be performed to guarantee product integrity.

First, an evaluation of the storage area is prepared. This is to identify potential hot or cold spots, such as windows or HVAC vents. The number of data loggers to be used is then determined based on the evaluation and area of the storage location. They are then programmed and placed in the pre-determined locations. Typically, the data loggers record up to one week before the data is analyzed. Once the test period is over, the data loggers are retrieved and the data is downloaded.

Multiple tests can be performed to ensure consistent results.

Contact [email protected] requirements todiscussacosteffectiveandcomprehensive solution foryourvalidation needs.

Program data loggers and place in chamber

Operate chamber process Download the data to a PC and create graphs and reports to

further analyze the data