AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

-

Upload

tuannguyen9694 -

Category

Documents

-

view

170 -

download

2

Transcript of AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

1

AISC-ASD89-1

Title

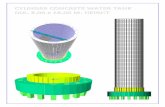

Design of Compression Member

Description

Check the adequacy of a W10 45 section by Allowable Stress Design. A36 steel is usedand service loads are 50 kips dead load and 110 kips live load.

Compression Member

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

Verification Example

2

Theoretical Results (AISC-ASD89)

Compute slenderness ratio

( ) 1.0(30)1283.3

4.32

x

x

KL

r= =

( ) 1.0(15)1289.6

2.01

y

y

KL

r= =

Compute allowable stress aF . Compare the /KL r with cC to determine whether the

shoter or long column fomular applies

2 22 2 29,000126

36c

y

EC

F

= = =

Since the controlling /KL rof 89.6 is less than cC , the allowable stress is based on the

parabolic equation for inelastic buckling. Thus, by calculation or from ASD

NUMERICAL VALUES TABLE 32

2

3

3

( / )1

214.3 ksi

5 3( / ) ( / )

3 8 8

y

c

a

c c

KL rF

CF

KL r KL r

C C

= =

+

Comparison of stresses

[ ]160

12.0 ksi 14.3 ksi13.3a a

g

Pf FA= = = < =

Results by the MIDAS/Gen

------------------------------------------------------------------------------------------MIDAS/Gen - Steel Code Checking [ AISC-ASD89 ]=====================================================

*.DEFINITION OF LOAD COMBINATIONS WITH SCALING UP FACTORS.

-------------------------------------------------------------------------------------------------------------LCB C Loadcase Name(Factor) + Loadcase Name(Factor) + Loadcase Name(Factor)

-------------------------------------------------------------------------------------------------------------1 0 DL( 1.000) + LL( 1.000)

-------------------------------------------------------------------------------------------------------------

*. UNIT SYSTEM : kip, in

*. SECTION PROPERTIES : Designation = W10x45Shape = H - Section. (Rolled)

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

AISC-ASD89-1

3

Depth = 10.100, Top F Width = 8.020, Bot.F Width = 8.020Web Thick = 0.350, Top F Thick = 0.620, Bot.F Thick = 0.620

*. DESIGN PARAMETERS FOR STRENGTH EVALUATION :Ly = 3.60000e+002, Lz = 3.60000e+002, Lu = 3.60000e+002

Ky = 1.00000e+000, Kz = 5.00000e-001

*. MATERIAL PROPERTIES :Fy = 3.60000e+001, Es = 2.90000e+004, MATERIAL NAME = A36

*. FORCES AND MOMENTS AT (I) POINT :

Axial Force Fxx =-1.60000e+002

===================================[[[*]]] CHECK AXIAL STRESS.

===================================

( ). Check slenderness ratio of axial compression member (Kl/r).[ AISC-ASD89 Specification B7. ]

-. Kl/r = 89.6 < 200.0 ---> O.K.

( ). Calculate allowable compressive stress (Fa).

[ AISC-ASD89 Specification E2. (E2-1) ][ 2*(Pi^2)*Es ]

-. Cc = SQRT [ ----------------- ] = 126.10[ Fy ]

-. Kl/r < Cc[ (Kl/r)^2 ][ 1 - ----------- ]*Fy[ 2*Cc^2 ]

-. Fa = ------------------------------- = 14.258 kip/in^2.5 3*(Kl/r) (Kl/r)^3--- + ---------- - -----------3 8*Cc 8*Cc^3

( ). Calculate axial compressive stress of member (fa).-. fa = Fxx/Area = -12.030 kip/in^2.

( ). Check ratio of axial stress (fa/Fa).fa 12.030

-. ---- = ------------ = 0.844 < 1.000 ---> O.K.Fa 14.258

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

Verification Example

4

Comparison of Results

Reference

CHARLES G. SALMON, JOHN E. JOHNSON, Steel Structure,Example 6.11.1

Reference MIDAS/Gen

( ) /y yKL r (slenderness ratio) 89.6 89.6

cC (limit slenderness ratio) 126 126

aF (allowable compressive stress) 14.3 ksi 14.3 ksi

af (axial compressive stress) 12.0 ksi 12.0 ksi

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

1

AISC-ASD89-2

Title

Design of Laterally Supported Beam

Description

Select the lightest W or M section to carry a uniformly distributed dead load of 0.2 kip/ft

superimposed (i.e., in addition to the beam weight) and 0.8 kip/ft live load. The simply

supported span is 20ft. The compression flange of the beam is fully supported against

lateral movement. Use Allowable Stress Design with A36 steel.

Laterally Supported Beam

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

Verification Example

2

Theoretical Results (AISC-ASD89)

A36 steel. Assume compact sectionsince nearly all sections satisfy the width/thickness

limits : thus, the allowable stress bF would be

0.66b y

F F=

Note that rounded values (i.e., 0.66 times 36 = 23.8 ksi ; use 24 ksi) are accepted values inaccordance with ASD-NUMERICAL VALUES TABLE

The superimposed service load (1kip/ft) bending moment is2 2/ 8 1.0(20) / 8 50 ft-kipsM wL= = =

Required 350(12)

25 in24

x

b

MS

F= = =

Try W12 22 : 325.4 inxS =

Check compact limits (p

) of ASD-Table B5.1

4.034.7 10.8

2 2(0.425)

f

f

b

t= = < (Table 7.4.2) OK

12.3147.3 107

0.260w

d

t= = < (Table 7.4.2) OK

Note that ASD uses overall depth dwhereas LRFD uses the supported height ch of the web

even though the limit is the same.

Check the flexural stress :21.022(20) /8 51.1 ft-kipsM = = (including beam weight)

[ ]51.1(12)

24.1 ksi 24 ksi25.4

b b

x

Mf F

S= = = = OK

Use W12 22, 36 ksiy

F =

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

AISC-ASD89-2

3

Results by the MIDAS/Gen

------------------------------------------------------------------------------------------MIDAS/Gen - Steel Code Checking [ AISC-ASD89 ]

=====================================================

*.DEFINITION OF LOAD COMBINATIONS WITH SCALING UP FACTORS.--------------------------------------------------------------------------------------------------------------

LCB C Loadcase Name(Factor) + Loadcase Name(Factor) + Loadcase Name(Factor)--------------------------------------------------------------------------------------------------------------

1 0 Load( 1.000) + Self Weight( 1.000)--------------------------------------------------------------------------------------------------------------

*. UNIT SYSTEM : kip, in

*. SECTION PROPERTIES : Designation = W12x22

Shape = H - Section. (Rolled)Depth = 12.310, Top F Width = 4.030, Bot.F Width = 4.030Web Thick = 0.260, Top F Thick = 0.425, Bot.F Thick = 0.425

*. DESIGN PARAMETERS FOR STRENGTH EVALUATION :Ly = 2.40000e+002, Lz = 2.40000e+002, Lu = 0.00000e+000Ky = 1.00000e+000, Kz = 1.00000e+000

*. MATERIAL PROPERTIES :Fy = 3.60000e+001, Es = 2.90000e+004, MATERIAL NAME = A36

*. FORCES AND MOMENTS AT (1/2) POINT :Bending Moments My = 6.13250e+002, Mz = 0.00000e+000

==================================================[[[*]]] CHECK BENDING STRESSES ABOUT MAJOR AXIS.

==================================================

( ). Check depth-thickness ratio of web (DTR).

[ AISC-ASD89 Specification B5.1 ]-. DTR = Dweb/tw = 44.077

-. DTR < 640/SQRT[Fy] ---> COMPACT SECTION !( ). Check width-thickness ratio of flange (BTR).[ AISC-ASD89 Specification B5.1 ]

-. h/t = 44.08 < 70. ---> kc = 1.0

-. BTR = bf/2tf = 4.74-. BTR < 65/SQRT[Fy] ---> COMPACT SECTION !

( ). Calculate allowable bending stresses (FBCy,FBTy).[ AISC-ASD89 Specification F1.1 (F1-1) ]

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

Verification Example

4

-. FBCy,FBTy = 0.66*Fy = 23.760 kip/in^2. if Fy < 65 ksi.

( ). Calculate actual bending stresses of member (fbcy,fbty).-. fbcy = (My*Ccom)/Iyy = -24.196 kip/in^2.-. fbty = (My*Cten)/Iyy = 24.196 kip/in^2.

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

AISC-ASD89-2

5

Comparison of Results

Reference

CHARLES G. SALMON, JOHN E. JOHNSON, Steel Structure,Example 7.5.1

Reference MIDAS/Gen

bF (allowable stress) 0.66 23.8 ksib bF f= = 0.66 23.8 ksib bF f= =

/ 2f fb t (width-thickness ratio of flange) 4.7 4.7

bf (flexural stress) 24.1 ksi 24.2 ksi

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

1

AISC-ASD89-3

Title

Design for Combined Bending and Axial Load

Description

Investigate the acceptability of a W16 67 used as a beam-column under the loading shown

in Figure. The total service loads areP= 350 kips andM= 60 ft-kips, and yF = 60 ksi. Use

Allowable Stress Design.

Beam-column with Combined Bending and Axial Load

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

Verification Example

2

Theoretical Results (AISC-ASD89)

Column effect

15(12)73

2.46y

KL

r= =

/ 730.747

97.7c

KL r

C= =

0.381(60) 22.8 ksia c y

F C F= = =

350

17.8 ksi19.7ag

P

f A= = =

17.80.78 0.15

22.8

a

a

f

F= = >

Beam effect

76 76(10.235)8.4 ft

60(12)

f

c

y

bL

F= = = (controls)

or

20,000 20,00011.6 ft

( / ) 2.40(60)12c

f y

Ld A F

= = =

12,000 12,00027.8 ksi 0.60

/ 15(12)(2.40)b y

b f

F FL d A

= = = <

15(12)65.5

2.75

b

T

L

r= =

2 2( / ) (65.5)40.0 40.0 29.9 ksi

425 425

b T

b

L rF = = =

1 20.6 0.4( / ) 0.60mC M M= =

60(12)6.15 ksi

117

bf = =

0.6(6.15)0.12

29.9

m b

b

C f

F= =

15(12)25.9

6.96x

KL

r= =

' 223 ksieF =

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

AISC-ASD89-3

3

where thex-axis is the axis of bending. The magnification factor is

'

1 1.0 1.01.09

1 17.8 / 223 1 0.07981 /a ef F= = =

Check of ASD FormulasFor stability, Formular (H1-1)

'

1.0( ) 0.78 0.12(1.09) 0.91 1.01 /

a m b

a b a e

f C f

F F f F+ = + = O.K.

( ). Calculate allowable compressive stress (Fa).

[ AISC-ASD89 Specification E2. (E2-1) ][ 2*(Pi^2)*Es ]

-. Cc = SQRT [ -----------------] = 97.68[ Fy ]

-. Kl/r < Cc[ (Kl/r)^2 ][ 1 - ----------- ]*Fy[ 2*Cc^2 ]

-. Fa = -------------------------------- = 22.778 kip/in^2.5 3*(Kl/r) (Kl/r)^3--- + ---------- - ----------3 8*Cc 8*Cc^3

( ). Calculate axial compressive stress of member (fa).-. fa = Fxx/Area = -17.766 kip/in^2.

( ). Check ratio of axial stress (fa/Fa).fa 17.766

-. ---- = ------------- = 0.780 < 1.000 ---> O.K.Fa 22.778

===================================================

[[[*]]] CHECK BENDING STRESSES ABOUT MAJOR AXIS.===================================================

( ). Check laterally unbraced length of compression flange (Lu).

[ AISC-ASD89 Specification F1.1 (F1-2) ]-. Lcr1 = (76*bf)/SQRT[Fy] = 100.42 in.-. Lcr2 = 20000/((d/Af)*Fy) = 138.93 in.-. Lcr = MIN[ Lcr1, Lcr2 ] = 100.42 in.-. Lu = 180.00 in. > Lcr

( ). Calculate bending coefficient (Cb).[ AISC-ASD89 Specification F1.3 ]

-. Cb = 1.000 (User defined or default value)

( ). Calculate radius of gyration (rT)-. Azz = Bf*tf + tw*(Ccom-tf)/3 = 7.7938-. Izz = tf*Bf^3/12 + {(Ccom-tf)/3}*tw^3/12 = 59.4289

-. rT = SQRT[Izz/Azz] = 2.761

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

AISC-ASD89-3

5

( ). Check ratio of Lu-rT (Lu/rT).[ AISC-ASD89 Specification F1.3 ]

-. CRrog2 = SQRT[ (510000*Cb)/Fy ] = 92.195-. Lu/rT = 65.185 < CRrog2

( ). Calculate allowable compressive bending stresses (FBC).[ AISC-ASD89 Specification F1.3 (F1-6,F1-8) ]

12000*Cb-. FBCi = -------------- = 27.786 kip/in^2.

(Lu*d)/Af2 Fy*(Lu/rT)^2

-. FBCj = [ --- - ------------------ ]*Fy = 30.002 kip/in^2.3 1530000*Cb

-. FBC = MAX( FBCi, FBCj ) = 30.002 kip/in^2.

====================================[[[*]]] CHECK COMBINED STRESSES.

====================================

( ). Check interaction ratio of combined stresses (Axial compression + bending).[ AISC-ASD89 Specification H1. (H1-1, H1-2) ]

-. fa/Fa > 0.15-. Single Curvature Bending.-. Cmy = 0.6 - 0.4*(My1/My2) = 0.600-. Single Curvature Bending.

-. Cmz = 0.6 - 0.4*(Mz1/Mz2) = 1.000-. Cmz > 1.0 ---> Cmz = 1.0

12*(Pi^2)*Es-. F'ey = ----------------- = 223.267 kip/in^2.

23*(Kl/r)^2Cmy

-. SFy = --------------- = 0.6521. - fa/F'ey

*. Check interaction ratio of combined stress at member end point.fa Cmy*fbcy Cmz*fbcz

-. Rmax1 = ---- + ----------------------- + ----------------------Fa (1-fa/F'ey)*FBCy (1-fa/F'ez)*FBCz

fa SFy*fbcy SFz*fbcz= ---- + ------------- + ------------- (H1-1)Fa FBCy FBCz

= 0.914 < 1.000 ---> O.K.fa fbcy fbcz

-. Rmax2 = ----------- + --------- + -------- (H1-2)0.6*Fy FBCy FBCz

= 0.699 < 1.000 ---> O.K.

-

5/24/2018 AISC-ASD89-2_Design Axial Member & Lateral Support Beam.pdf

Verification Example

6

Comparison of Results

Reference

CHARLES G. SALMON, JOHN E. JOHNSON, Steel Structure,Example 12.14.1

Reference MIDAS/Gen

( ) /y y

KL r (slenderness ratio) 73 73

aF (allowable compressive stress) 22.8 ksi 22.8 ksi

af (axial compressive stress) 17.8 ksi 17.8 ksi

bF (allowable compressive bending stress) 29.9 ksi 30.0 ksi

mC (equivalent moment correction factor) 0.6 0.6

'

eF (Euler stress devided by a factor of a safety) 223 ksi 223 ksi

Interaction ratio of combined stresses

(for stability)

(for yielding)

0.91

0.70

0.91

0.70

'

1.0( )1 /

a m b

a b a e

f C f

F F f F+

0.60

a b

y b

f f

F F+