Air Conditioning Inspections for Buildingscourses.stroma.com/postaircon4/content/Training...

Transcript of Air Conditioning Inspections for Buildingscourses.stroma.com/postaircon4/content/Training...

.

Air Conditioning Inspections for Buildings

Free Cooling

PRESENTED BY NIRAJ MISTRY [email protected]

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Free Cooling

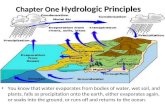

What is Free Cooling?

Broadly defined as: “that amount of cooling which can b obtained to wholly or partly offset the load on mechanical refrigeration plant”.

Take advantage of favourable weather conditions to enable chiller plant to: " Be shut down for long periods " Saves significant amounts of energy " Cuts carbon emissions

The technology is neither complex or new, but opportunities to make use of it are often overlooked or not understood.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Categories

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Suitability

Waterside Free Cooling

" Is there a significant cooling load during the winter months, for instance greater than 20% of the design full cooling load?

" Is the installed capacity of the chiller plant greater than approx. 1 MW?

" Is the winter cooling load present on a 24h basis?

" Is a relatively high chilled-water temperature acceptable?

" Is there spare cooling tower capacity such as a standby tower, and/or are the tower(s) known to be oversized or more than adequate to meet the peak summer load?

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Suitability

Airside Free Cooling

Majority of devices and techniques that can be used to provide free cooling in airside systems can also provide heat recovery in the winter.

Heat recovery capability that is likely to save the most energy.

Modern design practice - very unlikely that an air-side system would be designed without some form of free cooling or heat recovery capability – now standard practice.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Waterside

BLUE DENOTES FREE COOLING CYCLE

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Indirect Waterside

Basic configuration of an indirect tower-based free cooling

system.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Load Shaving

Load shaving describes a technique that allows simultaneous mechanical and free cooling when ambient conditions are favourable.

A load shaving system takes advantages of the months when a degree of free cooling is possible, but some mechanical cooling is also necessary to satisfy the cooling load.

During this period, a standard water-side indirect system would have to operate in mechanical cooling mode and will stay that way until colder weather arrives and the cooling load can be met entirely by free cooling.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Load Shaving

Load shaving system using existing cooling towers.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Direct Waterside

Thermodynamics of Refrigeration

SATURATED MIXTURE OF LIQUID/VAPOUR

SUBCOOLED LIQUID

SUPERHEATED VAPOUR

Basic configuration of a direct tower-based free cooling system.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Direct Waterside

Direct free cooling using a common condenser water

header.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Direct Waterside

Evaporation 1→2

Low pressure liquid refrigerant (1) in evaporator.

Absorbs heat energy from its surroundings (air water, other process liquid).

Fuels change of state to a saturated vapour.

At evaporator exit (2) refrigerant vapour is slightly superheated.

Direct free cooling using a dedicated tower and chiller arrangement.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Thermosyphon Waterside

A basic thermosyphon chiller arrangement (arrows indicate flow in thermosyphon mode).

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Multiple Thermosyphon

A multiple chiller thermosyphon system.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Buffered Thermosyphon Single chiller Thermosyphon system with a thermal buffer (arrows indicate flow in thermosyphon mode).

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Airside

Modulating damper system without humidity control.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Airside

Modulating Damper Systems With Humidity Control

Non-Adiabatic: Steam humidification:

has the advantage of operating at temperatures sufficient to kill any micro-organisms that may be present in the water supply, but it does not provide an evaporative cooling effect.

Adiabatic: Four basic types:

sprayed cooling coils

evaporative humidifiers

direct injection pneumatic humidifiers direct injection ultrasonic humidifiers.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Adiabatic Airside

• Sprayed cooling coils

• Sprayed cooling coils provide a large surface area for water to evaporate into the air stream and incorporate a sump for water recirculation.

• While the low water temperature in the sump is unlikely to propagate bacteria, the combination of water recirculation and the creation of aerosols is particularly undesirable from a health point of view. Although sprayed coils provide a simple method of humidification, a strict maintenance regime is required to ensure system cleanliness. Sprayed cooling coils have traditionally been used with systems operating under dewpoint control, but are rarely used today.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Thermodynamics

Flashing 1 & 7

Outlet of the expansion device & inlet to evaporator do not lie on the saturated liquid line.

At lower temperatures the refrigerant cannot contain as much heat.

This excess heat causes the refrigerant to evaporate during expansion.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

Evaporation 1→2

Evaporator contains refrigerant.

Refrigerant boils or evaporates at low pressure.

Refrigerant absorbs heat from surroundings during this process.

Cooling effect of the evaporator is governed by:

Temperature difference between medium being cooled and the evaporating refrigerant. The greater the

temperature difference the greater the rate of heat transfer.

The size and design of the evaporator.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

Superheat 2→3

Refrigerant absorbs heat from ambient temperature air around suction line between evaporator and condenser.

Superheating should be minimised by insulation to maintain efficiency.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

Compression 3→4

Compressor compresses refrigerant vapour from low pressure of evaporator to the high pressure of the condenser.

Refrigerant vapour also heats up during this process.

Compressor capacity is affected by:

Compressor displacement (m3/s).

Difference between evaporating and condensing temperature (temperature lift). Pressures of evaporator

and condenser are proportional to respective temperatures.

Superheated suction vapour temperature.

Properties of the refrigerant.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

De-Superheat 4→5

High pressure refrigerant vapour flows from the compressor to the condenser.

Small amount of heat energy is lost to ambient air.

This should be maximised for best efficiency.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

Condensation 5→6

Condenser contains refrigerant which is changing from a superheated vapour into a liquid at high pressure.

A lot of heat energy is released during this process, which is rejected to ambient air or cooling water.

Condenser capacity is affected by:

Temperature of cooling air or water.

Size and design of the condenser.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

Sub-Cooling 6→7

The liquid refrigerant flowing between condenser and expansion device usually loses heat to ambient air.

Sub-cooling is beneficial to system as it increases refrigeration capacity without increasing the power input.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Hardware

Expansion 7→1

Expansion device maintains the pressure drop between the condenser and the evaporator.

The refrigerant saturation temperature also reduces as the pressure drops. Expansion device sized to pass the required amount of refrigerant and the

minimum likely pressure drop across the system.

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Mechanical Refrigeration

Reversabilty

SA AC REGIONAL 1 © STROMA CERTIFICATION LTD v1.4

Reference Material

“Heating, Ventilation, Air Conditioning and Refrigeration”, CIBSE Guide B, Chartered Institute of Building Services Engineers, 2005

“CIBSE KS13: Refrigeration”, CIBSE Knowledge Series, Chartered Institute of Building Services Engineers, 2008

Carbon Trust Good Practice Guide GPG280 – “Energy efficient refrigeration technology – the Fundamentals”

“ASHRAE Handbook: Fundamentals”, American Society of Heating, Refrigeration and Air Conditioning Engineers, 2001

ROGERS and MAYHEW: “Engineering Thermodynamics: Work and Heat Transfer”

TROTT, A. R. (2000), “Refrigeration and Air-Conditioning (3rd ed.)”

WANG, S. K.: “Handbook Of Air Conditioning And Refrigeration”

JONES, W. P.: “Air Conditioning Applications and Design”