AI PN. 5940337-5501 SN… · landing gears vvorkshop nose landing gear faa aapy 004 c md 80 nose...

Transcript of AI PN. 5940337-5501 SN… · landing gears vvorkshop nose landing gear faa aapy 004 c md 80 nose...

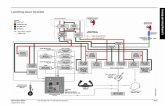

• I • Landing Gear Assy Status

Allitalia I-DATN 'Ref. Date: 25 May 2005

'. '. ~d ~ ~~ TTR :

0" 8o",' " .. "

Ale PIN SIN , , . " h h "::::~.'

-'

DAlN 5940337550 I CP129-1 I 0 ANTERIORE AllESTIMENTQ 34950 27010 3302 641 16500 2920 "13198 2079 270203

DArN 5!J3059355061\Z S0090 A.sc;,I~~JlI= CARREllO PRU-JCIPAlE DX 39416 32824 ·14456 3147 20000 3650 5544 503 101096

DATN 593098955'19 S0277 CARRELlQ PRINCIPAlE SX 38328 34402 6 97 20000 3650 19994 3553 040305

' .. -

;)

Alitalia I-DATN Ref. Dole: 21 Apr 2005

Ale PIN SIN DESCRIZIONE

DATN 59403375501 CPl291 CARRELlO ANTERIORE AllESTIMENTO

DATN 59305935506AZ S0090 ASSIEME CARREltO PRINCIPAlE DX

DATN 59309995519 50277 ASSIEME CARREllO PFUNCIPAlE SX

• / • Landing Gear Assy Status

TT TSO T80 TTR On Board since .. .~ J~, d h .. c .-: . A':' h ,; 'p 'I'd h C d

34949 27008 3300 808 16500 2920 13200 2112 270203

39415 32822 14454 3114 20000 3650 5546 536 101096

38326 34401 5 64 20000 3650 19995 3586 040305

"j) \"t,··;} /~ AZ Aircrafi Planning mgr: ---'.ff----,~L----="==-- (Gioacchino Venzi)

.I

Pagina I di 1

'·:1······

,'., .. ·i ~ I .' "

.' ;

" ' "'. " ..

/ /

•

•

• . / I

.dItitech Prot: .~ C4/ t .... Data: lk .7:,. !Cj~

DEFERRED ITEM J~ ki""> '2-1/1 ~ ~ I

•

PIN MatDre . .,.... SIN Mo!ate. /:-__ Pos .....-

F/HAlm .g~.d~CicliAlm A~,t?i~ OocumentaziOne ·~""-"t"""·I'''''Ol'""'.('''''''G~ <fi RifBrfmelllO ~Q,(,,""j>ab

'-----._------------------Prowedlmantiprawisoli: ~l\~I¢.l) 111.,,(,.. j',.s,.7ol'l fiS.<.G.H~\-'y ~tl S€Ld1;Y:i:C&~ ·At: ~/t-i .E£5:.:J..,..Q,.4Jbg,=--__ -C-_~'""__

Causafec!e/rirwiO;i,..\!\\~~T\Qj.\ iU.?p!?rli.!> Ok' Cb<>€[ ..(3, ~~~~_E~~~~q~~OQ~C~~~C~1~2L_ ______________________ _

Materiale richi_: PIN QTA

~Rcq~..!L .J Descri<:ione .. )?, s,7"Pti

,----------~ ----- ----.------~-~ .. ---------_ .. - .... ---_.

Rilerimento Documen13Zione Tect1ic:a (AMM -E.O .• SAM ele) . ~- 32 ---------------_.-._ .. _-,----,----

. Fi""e Responsabile oi Manuteftliane

'---'~~:ib' ne QC AZ

Mod AMO AZ-«r.J 0SI,1I9

10 . Bd JO~Zf9,9900<--

;WOIl! ID::tLLLY ••• Inl.~~nJrQn nr;ot cn. ~n/CT lOSZC9S990 YV& lS:ZZ ~ SO ~O/Sl

• t t

tL ~ .....

... o ~i! C"')., "

~:'.- . ., . ., <=>.

~.

'" ' . ... •• N N

'" <=> .., <> "-'" ...

•

•

2 n u

..·· .. M •• """''''"'''O .... ,'''

. .

II~ S;x.. P!,O

• I •

" .,.

:-.-

•

•

--

..4Itltech ~t.: ~O,\*

DEFERRED ITEM [DI I X~6 III of I

0..; .La -2.-$006"

CJJenIv b..": 17.,4 i\ -.imI ..... AIM.h:t:!l\T..t.L .... !C t 'f.Qjf PIN MaIoIe ._:." ___ SiN Yorare. ../ JOv. eC __

FIH A/rft 211L413 Cil:liAAl'l .if; f;!£P _Doan..,... "'-~---"I dI AIIIrI.... I~ rnl# .

-_ .. -....._---_ ... _--------------ProwediI1Ml'lll ~ __ --=-_!1JIIoJ....:.· ________ _

.---------------------.------------------c:.marecteJrinvia: b\!1,r$i,.,CM PErOh"?? Ow j3.~Oc:.\C .d) ~~ S=P~"I\ • ...L.... tTl' pb5 "CIOPPt(Ct

MI\lIriaIe ri\lllie9ta: PIN QTA D a_. ~J kbph . ;7q} _ ~L

=:t:. c

~iZ? ---:: ~ =::=::'--'7~; __ L _ _ -_ -_

----- "'-----------------Prowa:llmen~etmmitidiall&lUlonll: Ri P'Mf :r\:\f, Bin Ott w~

, .... Q@,\,{ _I-I ~L~~ IlT_ .. :-rTQ AQ:'.a'(5 @YPl e <, .-----~,--,-----------.. , .......... 0-- ___ ~ ___ . _____ ~_ .•. e. _____ ....... _ ••••• _ •• _. ___ .. ___ ... __________ ._~ ___ • ~_._ ...... ______ _

~ RIIP ___ crel el""111 II........... 11; ..........

~~=~~~-~ r-::=:--::-~

1-(3'1/ A7AiAa .. 1. _AM04G:I$"'" ..

IU~U9npOD<--liJ:l IOl7<-

H~3ULtl ddS HJ31IL~

IOi~6otIUD r':ll ~O, rO/Rr 609760llRO ££:~l ~O-£O-Rl

• J • • I

'·' "; . ~1 :~

• . , ., .'" . '" "I :.'

.... .. , CO .. .. ..

<

I CJ..~ . • Itidia I t.lII. '-,.1.' '1 MohAxlf o,.~cIOTliio~~~&-- !J'l. Ii t- BIGlIIEEllIHG · .. ·MHlf'!afAllce r P,N - .,.; '. D.,", --"" CiTi,'I::

laM . "-- 1:1t~ -.~~I·...A i- IQ

~'I··:"''''''D··T .. ·~+u

,

.'~ r "'-..-LA" . ." .. J - J •

iEi~u~'u,,~ ·~··~at===~·::::===:rr~~:l={::==::::==::::::::::::j ,I~ 'M~ . II" : IfVI'. ' . • ~ rIO .. I ~ QJl_GlJflQE~ /"

li.~- . . CAUSAL1 _ .-7 Il II r; In, : -_ .... ~

IO' ..... ·~ .. """ ;-

Pro .... I_~"IIlm"*l\dl ..... zbla 0 Non h' i .... ,~_._~_:::·

~DIA.,.Z T;.I,..- "'If., 0...., t IA"'~.I> I. ... nr ~j'r~ . "

-- -c'

- . R.. c..1. PilO

",,... II!I '" .. ...

•• • I • . -1.1:· . , . .~

3'

~ 5884 CS

PIN o SIN o 1T.145.0031 ~ MDBO w.o. o LANDING GEARS

VVClRKSHOP NOSE LANDING GEAR FAA AAPY 004 C

MD 80 NOSE LANDING GEAR - WORK SHOP ROUTERS TRANSLATION II ; FeS'. a $ntb * +4

N° DESCRIZIONE DEGLI STEPS DEI CICLI DI LAVOR() REFER TO WSR WORK SHOP ROUTERS STEPS DESCRIPTION

1 SGRASSAGGIO TUnl ALL Cleaning

2 IDENTIFICAZIONE • RILIEVI DIMENSIONALI - DISALLESTIMENTO TUnl ALL Identification-In~pection for Condition & Dimension-Disassembly

3 CONTROLLO GEOMETRICO (NLG) TUnl ALL geometric check

4 SVERNICIATURA - PREPARAZIONE ISPEZ. LlQUIDI PENETRANTI (NLG) TUnl ALL Paint stripping - cleaning for inspection

5 PULIZIA - SVERNICIATURA Tunl ALL Cleaning- Stripping 6 RIMOZIONE CHIMICA RIPORTO SUMERFICIALE Tunl ALL Strip chorme plate

7 DISTENSIONE Tunl ALL Stress Relieve 8 ISPEZIONE CON LlQUIDI PENETRANTI FLUORESCENTI Tunl ALL Ipenetrant flow inspection

9 ISPEZIONE PER CONDIZIONI GENERALI - CONTROLLI DIMENSIONALI -RICONDIZIONAMENTO

TUnl ALL Inspection for Condition & Dimension - geometric check

10 ISPEZIONE PARTING PLANE (NLG) TUnl ALL ispection parting plane 11 RIPARAZIONE PARTING PLANE (NLG) TUnl ALL repair partin~ plane

12 CONTROLLO DUREZZA (NLG) TUnl ALL hardeness misurement

13 RIMOZIONE ELEnROLITICA RIPORTI ANTIUSURA TUnl ALL cadmium plate strip

14 ISPEZIONE POLVERI MAGNETICHE Tunl ALL magnetic particle inspection

15 RIPARAZIONE CON MACCHINE UTENSILI Tunl ALL machining/grinding to remove defects

16 ISPEZIONE PER SURRISCALDAMENTO Tunl ALL examination for heat damage reworked areas

17 DISTENSIONE POST LAVORAZIONE Tunl ALL Stress Relieve

18 SABBIATURA Tunl ALL Sand blasting.

19 APPLICAZIONE RIPORTI ANTIUSURA Tunl ALL cadmium plate

20 DEIDROGENAZIONE Tunl ALL embrittlement relieve

21 RILAVORAZIONE PER FINITURA Tunl ALL hand finish

22 RIPORTO PROTEnlVO SUPERFICIALE Tunl ALL chorme. plate

23 ISPEZIONE RIPORTI ANTIUSURA Tunl ALL check chrome plate

• • • 1 &ia.L\~

)toe: ,;1i(,W~ f( .\'4.

r---~~~~~~~~~------~~~~----~~~~--------~~------~----~--__ ~~~~~~~" ~p~, . ...... MD 80 W.O. 0 ALiTALIA REPAIR STATI

~ • PIN 0 SIN 0 IT. 145.0031 LANDING GEARS

VVORKSHOP NOSE LANDING GEAR FAA AAPY 004 C

MD 80 NOSE LANDING GEAR - WORK SHOP ROUTERS TRANSLATION II N' DESCRIZIONE DEGLI STEPS DEI CICLI 01 LAVORO REFER TO W.SR WORK SHOP ROUTERS STEPS DESCRIPTION 24 ALLESTIMENTO BOCCOLE STANDARD Tunl ALL standard bushings installation 25 ALLESTIMENTO BOCCOLE MAGGIORA TE Tunl ALL oversize bushings installation 26 ALESATURA BOCCOLE (NLG) Tunl ALL refinish I hone buschings 27 FINITURA CON MACCHINE UTENSILI Tunl ALL machininG. refinish 28 PROTEZIONE PER VERNICIATURA· Tunl ALL mask for j)aint 29 VERNICIATURA Tunl ALL p.aint 30 TRA nAMENTO ANTICORROSIVO PARTI CAVE ACCIAIO STEEL Apply corrosion preventive compound to interior 31 PASSIVAZIONE ACCIAIINOX INOX STEEL Passivation 32 REIDENTIFICAZIONE Tunl ALL reidentify 33 ISPEZIONE A VISTA PER CONDIZIONI GENERAL! Tunl , ALL igeneral visual inspect 34 VERIFICA ESISTENZA FIRME su OPERAZIONI RICHIAMATE Tunl ALL Signature check

ON THE WORK SHOP ROUTERS, SOME. SYMBOLS ARE BROUGHT BACK. THEY MEAN HOW MUCH FOLLOWS:

+ SE NECESSARIO + IF NECESSARY

++ FACOLTATIVA ++ OPTIONAL

* OPPURE % BARRARE LA RISPOSTA APPLICABILE * TO CROSS THE APPLICABLE ANSWER

** OPPURE %% BARRARE LA CASELLA DEL COLORE RILEVATO ** TO CROSS THE CASE OF THE FOUND COLOR

• • I • ~U'l-Aq t..

1i4. '0 ,,~' c:... .

.A .....,.{::..l..OJ

......... ~_ ..... L _ I • "i"',.: "'I"'i . .JJ,Ii. J..J ..

MD80 W.O. 0 ALiTALIA REPAIR STATION

PIN 0 SIN o 11.145,0031 LANDING GEARS

VVC>RKSHOP MAIN LANDING GEAR FAA AAPY 004 C

MD 80 MAIN LANDING GEAR - WORK SHOP ROUTERS TRANSLATION N' IU",!: Ut;(jLl ;, I :r-;, Dt:1 CICLI 01 _REFER_l J W.SR :SMUr- KUU I t:K:S :s I t:t-':s '!lUN

1 SGRASSAGGIO TUTTI ALL Cleaning 2 IDENTIFICAZIONE - RILIEVI DIMENSIONALI- DISALLESTIMENTO TUTTI ALL Idenlification-Inspection for Condition & Dimension,Disassembly

3 Step 03-IOENTIFICAZIONE MAGGIORAZIONE FILETTATURA INFERIORE

CILINORO CYLINDER Step 03-

CILINORO (ALLOGGIAMENTO GHIERA ) - MAGGIORAZIONE (YES) (NO) Mark o/sp,ackingnut, fl.erformed(YES) INOL 4 IDENTIFICAZIONE TIPO DI MAGGIORAZIONE RILEVATA AlLO Step- 03 CILINDRO CYLINDER Check oversize performed on step 03

Step 03.b IDENTIFICAZIONE MAGGIORAZIONE FILETTATURA PERNO Mark ols on cylinder boss threadlstruct lower link retaining nul -5 DI COLLEGAMENTO'CILINDRO I CONTROVENTATURA- Cll/NDRO CYLINDER performed (YES) (NO)

MAGGIORAZIONE (YES) (NO)

6 IDENTIFICAZIONE TIPO DI MAGGIORAZIONE RILEVATA ALLO Step- 03 b CILINDRO CYLINDER Check oversize performed on step 03b 7 PULIZIA - SVERNICIATURA TUTTI ALL Cleaning - Paint Stripping 8 RIMOZIONE CHIMICA RIPORTO SUMERFICIALE TUTTI ALL Chemical Stripllin.ll 9 DISTENSIONE TUTTI ALL stress Relieve

10 ISPEZIONE CON LlQUIDI PENETRANTI FLUORESCENTI TUTTI ALL Fluorescent Penetrant Check

11 ISPEZIONE PER CONDIZIONI GENERALI- CONTROLLI DIMENSIONALI -

RICONDIZIONAMENTO TUTTI ALL

Inspection for Condition & Dimension

12 RIMOZIONE ELETTROLITICA RIPORTI ANTI USURA TUTTI ALL Chemical Stripping 13 ISPEZIONE POLVERI MAGNETICHE TUTTI ALL Magnetic particle Inspection 14 VERI FICA INTRODUZIONE MODI FICA S.B. MDSO 32-241 (YES) (NO) CILINDRO CYLINDER Check for S.B. MD80 30-241 15 INTRODUZIONE MODIFICA 5.B. MDSO 32-241 (YES) (NO) CILINDRO CYLINDER Enbodiement of S.B. MD80 30-241 16 RIPARAZIONE CON MACCHINE UTENSILI TUTTI ALL Machinin~ Grinding to Remove Defect 17 PALLINATURA TUTTI ALL Shot Peening 18 MAGGIORAZ. FILETTATURA INFERIORE CILINORO (ALLOG. GHIERA) CILINORO CYLINDER Machining Cylinder Gland Nut Threads Repair 19 IDENTIFICAZIONE MAGGIORAZIONE ESEGUITA SU CILINORO CILINORO CYLINDER Mark Performed Rework 20 COSTRUZIONE GHIERA MAGGIORATA (ACC. CILINDROIGHIERA) CILINDRO CYLINDER Fabricate New Packing Nut 21 IDENTIFICAZIONE DELLA GHIERA MAGGIORATA CILINDRO CYLINDER Mark New Packing Nut

22 MAGGIORAZIONE FILETTATURA PERNO COLLEGAMENTO CILINDROI

CILINDRO CYLINDER Machining/Repair Cylinder struct door crank attach boss

CONTROVENTATURA 13.e

23 IDENTIFICAZIONE MAGGIORAZIONE ESEGUITA SUL PERNO 13.e CILINDRO CYLINDER Performed identification "o/s boss thread rework" on cylinder boss thread

24 COSTRUZIONE GHIERA MAGGIORATA (PERNO COLL CIUCONTROV) CILINDRO CYLINDER Fabricate New Nut for struct lower link retaining nut

h

• • J • hL (l1:>. U J..

ItR~ -@'f<;.W r

~ MDBO w.o. SIN o IT. 145.0031 PIN o

o ALiTALIA REPAIR STA T/ON

LANDING GEARS VVORKSHOP MAIN LANDING GEAR FAA AAPY 004 C

MD 80 MAIN LANDING GEAR - WORK SHOP ROUTERS TRANSLATION •

ClliNDRO CYLINDER

ClliNDRO/CONTROVENT. ClliNDRO CYLINDER

ClliNDRO CYLINDER

PISTONE PISTON

• • • I , . ·····1: ; ".~ ' . " ;., .~

:1 :' .... ;: ;;

, .. :~~ . . ~;

J\L \ I:i>. U .A..

'T"12-~. ",,,,~ '- ~

~ LANDING GEARS

"ii'" .... _<':; L.~_

' .• D.~; 1): MDBO w.o. o ALITALIA REPAIR SAT/ON

PIN o SIN o IT.14S.0031 V\l'C>RKSHOP MAIN LANDING GEAR FAA AAPY 004 C

MD 80 MAIN LANDING GEAR - WORK SHOP ROUTERS TRANSLATION II . iiii .

N" DESCRIZIONE DEGLI STEPS DEI CICLI DI LAVORO REFER TO W.S.R WORK SHOP ROUTERS STEPS DESCRIPTION

49 IDENTIFICAZIONE DEL COLORE DEll' ASSAlE DEL PISTONE

PISTONE PISTON Identification color assy sliding tube

GRIGIO ( ) GIAllO( ) ROSSO ( ) BlU ( ) AlTRO () grey- yellow-red-blu-other .

50 ISPEZIONE DEL PERNO 01 SOllEVAMENTO· RIFERIMENTI NOTA 16

PISTONE PISTON Inspection Jackball - Ref. Note 16

NON APPLICABllE PER ·517 E ·518 Not Applicable for -517 and -518

51 ISPEZIONE ZONE RACCORDO ORECCHIOZZE • RIFERIMENTI NOTA 17

PISTONE PISTON Inspection

NON APPLICABllE PER ·517 E -519

52 MAGGIORAZIONE OElLA FllETTATURA ASSAlE DEL PISTONE

PISTONE PISTON Machining/Repair Cylinder

( AllOGGIAMENTO TRASOUTTORE E GHIERA ) • OX ( ) SX( )

53 IDENTIFICAZIONE ESEGUITA SUl PISTONE PISTONE PISTON Mark. Piston 54 COSTRUZIONE TRASDUTTORE MAGGIORATO OX ( ) SX ( ) PISTONE PISTON Fabricate Oversize Trasducer 55 IDENTIFICAZIONE DEL TRASDUTTORE MAGGIORATO PISTONE PISTON Identification Oversize Trasducer 56 COSTRUZIONE GHIERA MAGGIORATA OX ( ) SX_L> PISTONE PISTON Fabricate. New Packinil Nut .RH LH 57 IDENTIFICAZIONE DELLA GHIERA MAGGIORATA PISTONE PISTON Check oversize performed on Packing Gland Nut

58 VERNICIATURA FASCIA COLORATA Dell' ASSAlE DEL PISTONE

PISTONE PISTON Painting according to oversize piston

DX( ) SX() ••• GIAllO ( ) ROSSO( ) BlU ( ) RH LH --- Yellow Red Blu

59 VERNICIATURA TRASDUTTORE MAGGIORA TO

PISTONE PISTON Painting Trasducer

OX ( ) sx ( ) .•. GIAllO ( ) ROSSO( ) BlU( ) RH LH -- Yellow Red Blu

60 VERNICIATURA GHIERA MAGGIORATA

PISTONE PISTON Painting Packing Gland Nut

ox ( ) SX() .- GIAllO ( ) ROSSO ( ) BLU( ) RH LH --- Yellow Red Blu 61 TRA TTAMENTO ANTICORROSIVO PARTI CAVE ACCIAIO STEEL Apply_ corrosion preventive comp_ound to interior 62 PASSIVAZIONE ACClAJ lNOX INOXSTEEL Passivation 63 REIDENTIFICAZIONE TUTTI All Reidentify 64. ISPEZIONE A VISTA PER CONDIZIONI GENERALI TUTTI All General visual inspect 65 VERIFICA ESISTENZA FIRME SU OPERAZlONI RICHIAMATE TUTTI ALL I:;,gnatu~e cn.ecK ON THE WORK SHOP ROUTERS. SOME SYMBOLS ARE BROUGHT BACK. THEY MEAN HOW MUCH FOLLOWS:

+ SE NECESSARIO + IF NECESSARY

++ FACOL TATIVA ++ OPTIONAL

* OPPURE % BARRARE LA RISPOSTA APPLICABILE * TO CROSS THE APPLICABLE ANSWER

** OPPURE %% BARRARE LA CASELLA DEL COLORE RILEVATO ** TO CROSS THE CASE. OF THE FOUND COLOR

•

~.- "

•

• I

Allitalia

LANDING GEARS WORKSHOP

·€US:rOMER .AZPOOL . .

... CUSTOMER WORK ORDER .,. .2051097 .. :.

. DELIVERYDATE I ... FEB 032003 I . ... . . ... . ..

PN 594()3375501 SN CPI291.XLS Cover Page 1

•

• " .. : "-:" .

•

Allitalia AI LANDING ......... t<'"

VIIORKSHOP

I W.O. 2051097 I

DOCUMENT N° 23 .1

AD's and S8's STATUS

INCOMING

,-_S_H_E_E_TS_N_O ____ I QJ

PN 59403375501 SN CPI291.J<1.S Ooc2a Page 7

• • I •

A LANDING GEARS

VVORKSHOP

Faa AD's I P.A. Rai-Enac Status Incoming ALiTALIA REPAIR STATION

( (j~AR IT.145.0031 AZPOOL )w.o. 2051091

(part number: FAA AAPY004 C ~ numDer : "~I •• ,

,Oyed from Ale I·DAVU I.;.,.u. 15"9 )l:e: . 23708

[ MDSO I NOSE LANDING GEAR I ,Ii ,

A.D.I P.A. n° Ref. S.B's J BdM DESCRIPTION Already Embodied REFERENCE VERIFIED BY DATE

YES NOT FORMS SIGNATURE STAMP

A.D. 2002·04·01 rev. 00 S.B. 32-315 rev 1 ONE·TIME VISUAL INSPECTION TO OETERMINE SERIAL NUMBER.

* ONE-TIME ETCH INSPECTION TO DETERMINE WHETHER THE lOCK P.A. 2002·198 rev. 00 BdM N99-251 f 81' 3 LINK IS MADE (FORGED. FROM PLATE OR BAR).

~

------~

~ I~ -

-----------------~ ~

-NOTE: AS PER MEMIS P18 ( INFO AZ ). t

A /

Quality Approval: A/lV 5547 CS Dale: FEB 03 2003 7/71. '

MD 80 New AD Status .ls AD"s Sli\TlJS INC P111 7a

Allitalia AI LANDING .............. '"

• WORKSHOP

I W.O. 2051097 I

DOCUMENT N.· 3 I PRELIMINARY

INSPECTION

•

ATTACHEMENTS N° I 0

• PN 59403375501 SN CPI291.xLS Docn 3 Page10

• AI LANDING GEARS

WORKSHOP

I MD 80 I PRELIMINARY FORMS

DOCUMENTATION CONFORMITY

MISSING PART

DEFECT RAISED

TRANSPORT DEMAGE

OTHERS

SALVATORE

• J

I PRELIMINARY INSPECTION INCOMING ,

CUSTOMER: AZ. POOL WORK ORDER: 2051097 RECEIVED GEAR DELIVERED GEAR

PART NUMBER INC.: 5910447-5045 .. PART NUMBER OUT: SERIAL NUMBER: CPI291 . SERIAL NUMBER: REMOVED FROM AlC: I-DAVU .~ STATUS: C.S.O. 15279 I T.C. 23708 ·i C.S.O. I T.C.

l JA.A. FORM ONE:

NOSE

YES NOT NOTE VISUAL CHECk

X STRUCTURE

X LINK ASSY

X WIRING & PLUG

X OIL LEAKAGE

X OTHERS

OCT 162002

• ALiTALIA REPAIR STATION

JAA n° RAI-ENAC 031

FAA n° AAPY004C

OK NOK NOTE

X

X

NA MISSING PART

X

X

Date: FEB 03 2003

Page 10 bis

Quality Approval: S. ~ _~, -.J

PN 59403375501 SN CPI291 Preliminary Inspection

•

•

•

Allitalia A

1

LANDING GEARS WORKSHOP

I W.O. 2051097 I

DOCUMENT N° 4b

DISASSY/ASSY

WORKPACKAGE

I

1 ATTACHEMENTS N° I ~

PN 59403375501 SN CPI291.XLS Docn 4b Page 13

~l H ; STRUr:7URE

;, ?OS ;:;'4 :: 2::'4(',S

,:., ?OS 2,)62 : ~~-G~

., POS :-6~} I ::.:J:::

., 'OS !)E3 L~NK A53':' i}??ER :'OCK 27'-;~3 I 20::~

'~i 59102':)9501 SIN MEC229 ;, ?OS DES A.'<."!'ICOLAZIO:-.I£ SUP, PER COtlTROVWT.".TUM ::O62~ , 23704

SlN NEC236 A POS DES ARTICOLAZrCN£ ?E:t CONTE\OV.£NTA7t,;f\A :::: A. ::062 : I 23704

S(j~ C?l i. 53:; ., PGS ~ 7299 :?:DIi 38

~ ?/:'l 592062951.9 SIN C?I907 ., 'OS DES PISTON .r..$SY 20312 / 20202

.,!C';C3509 SIN CPI901 .; POS DE5 PIS70NE 3E:NZ."" ASSAL£~'AL RIEl!BO r-,:" iU? 1,}311 , 20202

: ?(:~ 5927079509 SIN CPIS26 A POS DES CROCIERA AMMORTIZZATORE G.4,P.R,AN'!' .:·![;30 17033 I 13133

?/N 5:1403J~501 s/:-/ (?1291 ;, 'OS DES :<OSE GE:AR STRUT A$$Y 30623 23697

~ 6~ 60 :'2 ~ql

A POS Af DES 'lAi..VE-N,L.G, :>T::ERrNG 3'iPASS ACTR 6H9~ 665·:6

• SIN crI2<l4 ;.. POS DE::: BRACC:O • SE ~J,G ZERO VWI -51)7 ?R.:: t-:or J:-3:3e 2635)

SIN CPIl449 A POS DES SRACCIO • SE HAG ZERO VEDI -509 ?R:: ~:o::: 1"205 13286

.~~ -~. DE:S .~~~ ..... ~ ••••• ~ ... ~ ••• - •• - ••• - •••• - •••• -.,

'. A LANDING

WORKSHOP

..: .;~

. :1\:.'.

, ., • \

ENGINEERING ORDERS LIST

CUSTOMER: AZPOOL WORK ORDER: 2051097 RE;CEIVED GE~R DELIVERED GEAR

PART NUMBER INC.: 5910447-5045 PART NUMBER OUT: 5940337-5501· . SERIAL NUMBER: CPI291 SERIAL NUMBER: CPI291 .'

REMOVED FROM NC: I-DAVU STATUS: OVERHAULED C.S.O. 15279 I T.C. 23708 C.S.O, 0 I T.C. 23708

JAA. FORM ONE: 0250001522

I MD80 I NOSE

~NGINEERING ORDER N DESCRIPTION

• J02-048 HOUSING ASSY - CORROSION REMOVAL

NOTE: • ENAC APPROVED VALID ALiTALIA ANMM ONLY,

• , . :"~I: . ',' . i::-. . . '.': ....... )~

. ',i

ALiTALIA REPAIR STATION. JAA n' RAI-ENAC 031

FAA n' AAPY004C

NOTE

SEE WSR 32-21-04-800-0418

Quality Approval: S. CURTO Date: FEB 03 2003 Page 15 bis

PN 59403375501 SN CPI291.XLS Engineering Order List

• • / •

AI LANDING GEARS

Faa AD's I P.A. Rai-Enac Status Outgoing I ALiTALIA REPAIR STATION

rGEAR IT.14S.0031 IW.O. 2051097 IPar 1 number W,.5501 FAA AAPY 004 C ISar ial numoer:

WORKSHOP j from AJe ·DAVU Status: ~ .. 0 IT:C:

MDSO I NOSE LANDING GEAR I A.D. I P.A. nO Ref. S.S·. I SdM DESCRIPTION STATUS REF. DOCUMENTATION DATE

rev SEE MEMIS P 18 ( INFO AZ) AZ 355 FEB 25 2005

JOB CARD 0° 0450000925 AZ 355 FEB 25 2005

Quality Approval: PONTESILLi Dale: FEB 25 2005

MD 80 AO FORMS.xls AD's STATUS INC

• ':" . • ! , . ••••

.AI AO'S-S8's & AOL STATUS OUTGOING'

LANDING GEARS WORKSHOP

I MD 80 I I MODIFICATION REF. BdM AZ

BM RD n° 32-0120

SB TBC n° DC9-32A340 N01-169 STEP 01

NOTE:

PN 59403375501 SN CP1291.xl

NOSE

DESCRIPTION

INSPECTION I MODIFY UPPER LOCK LINK

AD's SB's Slatus Out

. ALITAlIA ~AIR :;TATION JAA n° RAI-ENAC 031

FAA n° AAPY004C

STATUS REF. JOB CARD (DOC 4aJDOC 7c)

PERFORMED See Job Card N° 0.250.0.0.0482 (Doc 7c 1

Date: FEB 03 2003 Page 17 bis

"'; • • ,J ,,:. , '. AI I LIFE LIMIT PARTS LIST l LANDING GEARS

WORKSHOP CUSTOMER: AZ. POOL WORK ORDER: 2051097

RECEIVED GEAR DELIVERED GEAR f-LiTALIA REP_AIR STATIO.

JAA n° RAI-ENAC 031 PART NUMBER INC.: 5910447-5045 PART NUMBER OUT: 5940337-5501 FAA n° AAPY004C

SERIAL NUMBER: CPI.291 SERIAL. NUMBER: CPI;!91. REMOVED FROM AlC: I-DAVU STATUS: OVERHAULED C.S.O. 15279 I T.C. 23708 C.S.O. 0 I T.C ... 2370.8

J.AA FORM ONE: 0250001522

I MD80 NOSE LANDING GEAR

RECEIVED GEAR DELIVERED GEAR DESCRIPTION PART NUMBER

SERIAL PART NUMBER

SERIAL OPERATOR WORK ORDER LIFE LIMIT

NUMBER COND

NUMBER

LINK ASSY LOWER LOCK 3913968- 3913968-513 CPI018 ALiTALIATEAM 2036337 59333

3) ARM 3914464- 3914464-503 DWM 473 AZ. POOL 4024745 46500

1) HOUSING ASSY 5927079-509 5927079-509 CPI826 ALiTALIA TEAM 2040367 2) 1.29800

,

REMARKS: 1) LIFE LIMIT AS PEH FAA FORM 8110-3 ATTACHED TO E.O. N" J02-048. 2) LIFE LIMIT STARTING FROM THIS SHOP VISIT. 3) SIN DWM 473, HAS REPLACED THE PREVIOUS INSTALLED SIN WPI273 ON JAN 14 2(105,

/\ /if / '\

Quality Approval: PONTESILLI FABIO Date: FEB 27, 2005

TOTAL CYCLES

29405

30105

13133

.... \~,r7 Page 16 bis

PN 59403375501 SN CPI291 XLS Life Limit Parts List

Approving National Aviation A,liiilority I Country - i. ,~ " . . ... --" -.. , -----~---.-.- Form Tracking Number • , I

AUTHQf, .. JISED RELE!E CERTIFI(?\ TE 3.

ENA_nte Nazionale per Numero di TracciabiliM del Modulo

I'Avi ne Civile I ITALY JAA FOR ONE 0250001537 AutoriM Aeronautlca Nszions/e Approvante I Stato Certificato di Approvazione

4. Approved Organisation Name and Address: ENGINEERING & MAINTENANCE 5. Wor1l: Order/ContracUinvolce Nome de/l'Organizzszione Approvala e Indirizzo:

P.za Almerlco da Schlo Omine rli lavoro/ConfrattolFattura

Ailitalia lIflee Aeree Italiane S_p.A. Aeroporto L. da Vinci 2051737

00054 Flumlclno • Roma -ITALY

~":.:; 7. Description a. Part Number 9. ~ 10.Q.~ 11. SerlallB~tch No. 12. StaluslWork Oesaizione N· Gategoric;o Q.I N" di Serie/l.otto SlafO/Tipo di intervento

1 LINK ASSY-DRAG UNIT

3920208-515 T.B.D. 1 CPI291 OVERHAULED -

13. Remarks 138. Total Time 13b. TSO/CSO 13c. TTR 13d. TAG.No.

Note 30621 0 H 44282980

-1'3'e.TOi81 Cycles --- ,3[' TNE --- l-ng~shciTPerfod' ------ 13~-Shop - - -- ---

ATTACHMENTS: 23704 UNLIMITED 500 JOB-CARD : YES --~. Purchase Order

._-- I-cc·- ---- ._-----TRANSFER RECORD TAG : YES 131. location 13k: Track No. - --. 131.

WORK PACKAGE : NO (AVAILABLE ON FILE AZ) 0130330

13m Certifies thallhe work specified in block 12113 was carried out in accordance w·~h FAR Part 43 and in

respect to that work the partes) is(are) approved for return to service. Pertinent delails of the r n file al this repair slation under Order NO .

0

. ~ SIGNED

• : AAPYOO4C

• 14. Celtlfies that the Items IdentlRed above were manufactured In confonnlty to; 19. ESJ JAR·145.50 Release to Service 0 Other regulations specified In bloek 13 < 0

.-~ .. ---~"~ Riammissione in Servfzio Anre normative specificate al punto 1.1 E 0 o approved design data and are In condition for safe operation Celtlfles that unless otherwise specified in block 13, the wortlldentlfied in block 12 and described In ~

« documentazione dl progello approvata e sono 1M eondlZIOn! n Imp/ego slcuro block 13, was accomplished In accordance with JAR 145 and In respect to that work Ihe items are

:! considered ready for releasa 10 service.

~

0 non.approved design data speclffed In bl Si certif!ea che se non d~:f:jrmente specificato nel punlo 13. illRvoro identificato nel punto 12

~ documentazlone dl progetto non app a speciflCata nel punlo 13 e desc"tto net punto 13, tat0.,c~m~::,:ato i~ g~cordo alia JAR 145 e ,ispello a tale lavoro i particolari sono considera· ronti ar iI ilascio er 1/ servjzio.

~ ". Authorised Sl~ 16. Approval/AuthOrisation Number 20. Authoris.d Slgn.~ h.. 21. Certlflcate/Approval Reference Number 0 Firma Autorizzala APprovazionelNumero di Autorizzaz/one Firma Autorlzzata C/c CerlificatOINumero di Ri(. di Approvazione 0 w

RAI-031 0 ~'. ~

~ 17. Na;v lB. Dsteldfmlyl 22. Name

S. ci.u«c>t1 23. Date (dImly)

0 ~ Data 'g/mla Nome Data (glmla

~ 5547 CS 27-01-03 . Installer must cross-check eligibility with applleabl9 tBch"lcnl data' L Ins/allatore dave veriffcare /lmplegablliM sulla dOr;!lmentazlone lecnIC8 apP/lcabile

USERIiNSTAlLER RESPONSIBILITIES RESPONSAB/UTA' DELL 'UT/LllZA TOREltNSTALLA TORE 1. It Is Important 10 understand thai the existence of the Document alone does not automatically constitute 1. E' importanle tenere presenle che l'esistenzB del Documento da solo non coslituisce automaticamente autorire authority to Installillerartlcomponentlassembly. 2. Where the userllnstaller works In accordance with the per instal/are la psrlelcomponenlelassieme. 2. Se I'InSiallatore/utifizzatore lavora con i regalament; nazionali di natlonaf regulations 0 an Airworthiness AuthOrity different from ltIe AirworthIness Authority specified In una Af/toriM di Aeronavigebilitll differente dall'Autorita di AeronevigabiliM specirICata ne/ punlo {I} I! essenziafe che block (1] fl 19 essential that the userllnsleller ensures that hlslher Airworthiness Authority accepts rufifizzatoreRnstaflatore sf 8cceni che la propria AutoriM di AeronavlgabiliM accella fe partilcomponentilassiemi parts/components/assemblles from the Airworthiness Authoritj specified In block [1). 3. Statements 14 da/fAutoriM di AenmavigabifiM speclflcata nel punto If}. 3. Le dichiarazionl 14 e 19 non costituiscono and 19 do not conslitute Installation certification. In all cases the aircraft maintenance record must contain certificazione afl'instaflazione. In tutti I casi Ie registrazioni di manutenzlone de/taeromobi/e devono cofltenere una an Installation certmcatlon Issued In accordance with the national regulations by the usernn9t~lIer before certificaz/one dc/l'installazlone emessa in aecomo con Ie nomre nAzionali dslfuliftzzarorelfnstallatore prima che the aircraft may ba flown. f'Beromoblle possa essere portsto in volo.

I

'"1"'" II 1111' "III' 11111 I"" III" "'" 11111 11111 11111111111"" 11111 1111' "" ""

~litalia WORKSHOP JOB CARD Customer I Clients Worle Order I ODL

SCHEDA LA VORO OFFICINA AZ POOL 2051737

Technical Operations

• Reason for Removal I MotivQ della rimozione Reference No Tag Number ALTRE CAUSE 0250001537 44282980

Description IDescrizione In..shOer Oate J/C Printed On LINK ASSY-DRAG UNIT 10-1 -02 27-01-03

Part Number t Serial Number AlC Type Ale Name Removal Date 3920208-515 CPI291 M080 I-DAW 09-10-02

) ",_x~ ~,'.r Ass'l P,rt Number Next Higher Assy Serial Number Position Station Task Planned

FCO P

, :=ligrlt Time i T errii:·o di Vola TSI TST TSO TaO TSN TNE TTR After Task

i Hours! are 2300 12970 12970 30621 ® Cycles I Cicli 23704 flf , O::::.ys , t;iom; I

I

( Irr;.wl. :hn Shop/AOL Contractor Follow-Up Reliability Warranty Itemised I :154 .. ;c 724 500 YES TW NO • I ,

WORK SUMMARY I SOMMARIO LAVORI --..... , S1°ft. iUS ( WORK FAILURE I A VARIA REMARrS I NOTE

; [JJ Inspected GJ COnfinmed

(1er bv!~J ~ [EJ Re..,aired [1J Not Confinned

• !0rested . IJJ Justified I iii Not Justified ~ RcpairedlTested

[ _ OVerhauled . @J" '" d I PARTS REPLACED

REGISTERED DATA CHANGES I MOD/FICHE ANAGRAFICHE r_ o •• "C ,. IP. I r;1 [M]

I W So,apped I! w...J List on PIN I SIN : D. Maintenance Reoort

~EFERENCE GOCUMENTS SB OnlV ADDmONAL INSPECTION WORK COMPLETED BY WORK INCOMPLETE cOCUt .... €Nn DI ,q;F€RIMENTO Solo 80M CONTROl1.DADDIZJONAJ.E LAVORO COMPLETA1ODA LA VORO INCOMPLETO

'!,~ i Description I Number Rev Kit Type Imputation D.

s'.?n 110 Hr. and/or S18n;tp Auth. Nr. Stamp ._'..!.oo DesClizioJ:rJ / Numero Commessa Stamp

OHI ~) 'lh ,

,)'2-11- '1 i .J 1 '-'

I I

I

• ,

i : I I

I , , , ,

, <

: ! i ,

~ ----:.iaintenance ~epult Release Date Product Release I Rjlasao Prodotto CRS to be Issued I Emissione CRS

• , .- Issued Ljl day me-nth ~ 0 0 L1J year I-

I 7") 1 Emessc 2.17 Oli 01; RF..c:;:)rto di Mar.utenzione JAA FAA

11I1I11I11lll !IIIII 11111111 ""'1111111111 "U 11111 111111111/ 1111111111111111111 1111111111111111111 Page I Pagina 1 of I di

• -' .: .. •

AI MDBO PIN 5940337-5501 CPI291

2051097

LANDING GEARS VVORKSHOP NOSE LANDING GEAR

/

. " .

~'. :.' '. " '.". ',':

....... , ······;·/I·;rr .•. . '.: ..... ,f1 . :,', -; . < :.':~~~

" . ,. ~ -:-ff , , . ':': : _.: '. 'J.<",

ALIT ALIA REPAIR STATION

EASA IT.145.0031

FAA AAPY 004 C

DOC 7c b HARD TIME LIST II * ITEM DESCRIPTION PIN SIN NOTE n°

1 NLG.-LlNK ASSY LOWER LOCK 3913968-513 CPI018 2 N.LG.-LlNK ASSY UPPER LOCK 3914464-503 DWM 473 3 NLG. - LINK AY DRAG UNIT 3920208-515 CPI291 4 N.LG. - UPPER LOCK LINK ASSY 5910446-11 DWM 473 5 LINK ASSY UPPER DRAG LH 5920209-501 MEC 229 6 LINK ASSY UPPER DRAG RH 5920209-502 MEC 236 7 CYLINDER ASSY 5920602-509 CPI 1539 8 PISTON ASSY 5920603-1)09 CPI907 9 PISTONASSY ( WITH AXLE) 5920629-519 CPI907 10 HOUSING ASSY 5927079-509 CPI826 11 N.LG. STRUT ASSY 5940338-501 CPI291 12 NLG. VLV - STEERING ACTR 5956101-5501 EFS 25892 13 N.LG. VLV - STEERING ACTR 5956101-5501 HDS 324 14 TORQUE ARM 5958412-511 CPI244 15 TORQUE ARM 5958412-513 CPI1449

Quality approval: PONTESILLI FABIO F.1'~ 884 CS

date: FEB 23 2005 Page 1 of 1

MD 80 NLG HT List .xls WSR HT LLP LIST Pag 10

) • '. J' ~~":' '.

. . I. \0 .,.1 • • , Approving National Aviation Authority I Country 2.

AUTHO::.ISED 3. Form Tracking Number

ENAC - Ente Nazionale per RELEASE CERTIFI(c"'~ TE NumerO di Tr8cciabilita del MotJulo j

l'Aviazione Civile I ITALY JAA FORM ONE 0250001545 Autoflta Aeroneulica Naziona/e ApprO'llanl6 I Stato Certificate di Approvazione

4 Approved Organisation Name and Address: ENGINEERING & MAINTENANCE 5. Work Order/ContracUlnvolce Nome delJ'Orgsllizz8zione Approvals e Indirizzo: Drdine di lavorolContrattolFattura

Allitalia' P .za Almerico da Schio

Linee Aeree Italiane S .p.A. Aeroporto l. da Vinci 2051746 00054 Fiumlcino • Rama -ITALY

~~ 7. Description •• Part Number 9. EI= '0. Q.~ 11. Serial/Batch No. '2. StatuslWork Oescrizione N° Categorico 1m' Q.I N° di SerieA.otto StalolTipo di in/ervenlo

1 NOSE GEAR STRUT ASSY

5940338-501 T.B.D. 1 CPI291 OVERHAULED

13. Remarks AlW:alia 13 a. Total Time 13b lso/eso 13 c, TTR 13d. TAG. No. Note

£NGI"!:;;~!W.it: MAINTENANCE 30623 0 C 16500 C 45069110 C2Tjified cTr~ ~py

·"13'e'.-"'yotal -Cy-des-'" .. ----.... "i)'C-YNE ... _---" -_. __ ..... -1"3'9: 'Shelf "Period' "'-_.--- . jill.'

.... _ ... _. -_ ... __ ... .-. _. .. D,,,: JA..J p.~~ Shop I nspc::,:Jr:: . _ ___

ATTACHMENTS : .~;/ 23697 UNLIMITED 500

JOB CARD : YES

FILE 0 -,-j-i. ···Lociiiion- --- - 13j. .. - ---_.,- -.-~ -- . ._-- -_.----"

TRANSFER RECORD TAG : YES Purchase Order 'iYk, -Tiick No:-·· .. -13T

WORK PACKAGE : NO ( AVAILABLE ON 01 I

13m. Certifies that the work specified in block 12113 was carried out in accordance Wml FAR Part 43 and in

respeclto that work the part(s) is(are) apprO'led for return to service. Pertinent details of the repair are on

file allhis repair station under Order No

;;

~:'~~~;'F:~;TE'~o" SIGNED

• , · AAPYOO4C · • Certifies that the items identified abo'le were manufactured in confonnity to: 0 < 14. - 1~ JAR·145.50 Release to Service Other regulations specified in block 13 0 Riammissione in Selvizio Altre normative specificate al punto 13, E .-.-.. -~-~ 0 o appro .... ed deSign data and are In condition for safe operation Certifies that unless othelWlse speCified in block 13, the work identified in block 12 and described in ~

< elocumelltazlOn9 dl progerlo approl/ara a son~ IfI cond/zlon un Implego s/curo block 1 J, was accomplished In accordance with JAR 145 and in respect to that work the items are

:! considered ready for release to service. , 0 non-appro .... ed doslgn data specified In bl 3 Si certifica che se n~rsamenle specificato nel punto 13, it /al/ol'o identificato no/ punto 12 or

\!; documelltaZione d/ progetto non ap a speclflcata net punta 13 e descritto net pu~~ ~ ~~atO/:~~Pletato in accordo aI/a JAR 145 e rispetto a tala lal/oro i N

partieo/ar; sono can ider . ronti r iI ri/ascio per iI serl/ili.o. . q '5. Authori,ed S;9n~~ , .. Approval/Authorisation Number 20. Authorised Sl9nature~ M' 2' Certificate/Approval Reference Number i!l Finna Autoriaata Approl/azionelNumero di Autorizzazione Finna Autorizlata ../... CertificalolNumero di Rif eli Approvalione u w 0 RAI-031 iii -<>

~ 17.

Na:;:v ,. Date (dimly) 22. Name iEulTO 23 Date (dimly)

0 Nom Data (gJmta) Nome Data (glmla)

~ 5547 CS 28-01-03 . .. -Installer must cross-check eligibility with applicable technical data / L Instal/atore deve venflcare flmplegablflt;} sulJa documental/one tecnlC8 appllcabiJe

USERIINSTALLER RESPONSIBiLITIES RESPONSAB/LiTA' DELL 'UT/LiZZA rOREllNSTALLATORE 1. It Is important to understand that the existence of the Document alone does not automatically constitute 1. E importante tenere presente che I'esk>tenza del Documento da solo non costituisce automaticamente autorita authOrity to Install tho rartlcomponenuassembly. 2. Where the user/Installer works In accordance with the per instal/are ta partelcomponenteJassieme. 2. Se I'insta/iatorelufllizzatora lavora can i regolamenti nal~na/i di naUonal regulations 0 an Airworthiness Authority different from the Airworthiness Authority specified In una Autorita di Aeronal/igabilila differente dalrAutorit~ di Aeronavigabilita specificata ne/ punto If} e essen~/ale .che. block (1) It Is essential that the user/installer ensures that his/her Airworthiness AuthOrity accepts I'utillzzatorei;nstal/atore si accerti che /a propria Autorila di Aeronal/igabilila accetta Ie partilcompo"e"ti!a~s,eml parts/components/assemblles from the Airworthiness Authortty specified In block (1). 3. Statements 14 dail'Autorita di AeronavigabiliM speclficata ne/ punto II}. 3. Le. diChiarazioni 14 B 19 non coslituiscono and 19 do not constitute installation certification. In aU cases the aircraft mainlenallco record must contain certificazione alJ'installazione. In tutti i cas; Ie registrazioni di manuteOl/one def/'aeromobiJe devona con/enere una an inslallaUon certification Issued in accordance with tho national regulations by thc user/installer before certificazione dell'instal/azione emessa in accorrJo con Ie norme nazionali da/(utilizzatorelinstallalore prima eM the aircraft may be flown. I'aeromobile possa essere partato In volo.

.;. • / • -" - Ente Nazionale per AUTHO-':-:tSED RELEASE CERTIFIC~ TE

3. Form NumerodTT~~~.b.&'d""~du~

l'Aviazione Civile I ITALY JAA FORM ONE - 0250001545

linee Aeree Italiane S. A.

NOSE GEAR STRUT ASSY 1 5940338-501

13. Remarks Note

ATTACHMENTS JOB CARD YES

YES TRANSFER RECORD TAG WORK PACKAGE NO ( AVAILABLE ON FILE AZ )

Certifies that Ihe items identified above were manufactured in conformity to: Si certiflca che gli artieofi sopra idenlifieali sano stati Coslruili in conformita a:

o o

approved design data and are in condition tor' ,s~a~f.:;~:;:~~::~o documentazione di progetto approvala e sona in c; sicuro

non-approved design data specified' doeumenlazione di progelto non

• Installer must applicable deve

USER/INSTALLER RESPONSIBILITIES 1. It Is important to understand that the existence of the Document alone does nol automatically COnstitute authority to instaIl1h8rarttcomponenua$Sembly. 2. Where the userlinstafler works in accordance with the naUonal regulations 0 all Airworthiness Authority differenl from the Airworthiness AuthOrity specified In block [1J It is essential thai Ihe user/installer ensures that hlslher Airworthiness Authority accepts parts/components/a~semb1ies f~m the ~irworthiness AuthOrity s~ocified In block I1J. 3, Statements 14 and 19 do nol consutute Installation certification. In all cases the aircraft maintenance record must contain an Installation certification issued In accordance with the national regulations by the userllnstaller before the aircraft may be Rown.

13 e.

ENGINEERING & MAINTENANCE P.za Almerico da Schio

Aeroporto L. da Vinci i

1

30623

CPI291

o C TNE ---'-'--

Orctine

2051746

OVERHAULED

siuii;'Period"

UNLIMITED

'location--- -_. P~,,,,.,;cj;d;;;· ." t·" k .. 'Track Nf).

01

500

13 m. Certifies thaI the WOI"k specified in block 12/13 was carried out in accordance with FAR Pall 43 and in respect 10 thai work the part(s) isfara) approved for return to service. Pertinent details of the repair are on

file atlhis repair statioO'"'~U"~d:e:'~O~':d:"~N:O:'_-,= __ =,",::::::::~======:::::=::::::----

NAME SIGNED

No.

19. 1:21 JAR·145.50 Release to Service o Other regulauons specified In block 13 A/tre normative specificate al punta 13. ~ Riammissione in Sef\lizio

Certifies that unless otherwise specified in block 13, the work Identified in block 12 and described ill block 13, was accomplished in accordance with JAR 145 and in respect to that work the items are considered ready tor release to service. Si certifiea ehe sa 13. if lavoro identificato nel punta 12 e de.seriltO nef JAR 145 e rispetto a tale laVorD i

Reference Rif. di Approvazione

RAI-031

28-01-03

suI/a documentazione

RESPQN$ABILlTA' DELL 'UT/LillA TOREIINSTALLATORE 1. E'importante tenere presenle che I'esislenza de/ Doeumento da solo non costiluisce automalicamente autorita per instal/are /a partetcomponentelassieme. 2. Se tillsiaflatore/ulllizzatore tavora con i rego/ament; nazionali di una Autorita di Aeronavigabilira differente dall'Autorira di AeronavigabiJita spee/ficata nel punto ('I e essenziale che /'utilizzatorelinstalJatore si aecerti the la propria Autorita di Aeronavigabilita accet/a Ie partilcomponentilassiemi dafl'Autorita di Aeronavigabilita speciflcata net punta 11/. 3. Le dichiarazionj 14. e 19 non eostituiscono cenificazione all"inS/aOazlOne. In lutti i cas; Ie reglstrazioni di manu/ellzione delraeromobile devono contenere una eertificaziOne deJfinstallazione emessa in aceorrJo con Ie norme nazionaJi dalfuti/izzatorelinslallatore pnma che I"aeromobile possa essere ponato in vola

.. ,." ' .. ,'

~if"'!' . '.' :.' .

. . t.·

- '"'''''''' "'" """ "I" "'" "'" "'" "'" ""I "'" "'" "'" "'" """'" "" ~I lia WORKSHOP JOB CARD Customer I Cliente I Work Order I ODL

-" .. T. 2f SCHEDALAVOROQFFLC/~~ 1..0.1' - ",.~,,;-< 2051746

n

• ~.!'~~~ for Removal I Motivo della rimozione Reference No Tag Number • T "D" CAUSE 0250001545 45069110

Description I Descrizione to~~0d'_ ~~e J/C ~rinted On NOSE GEAR STRUT ASSY 10-10-02

Part Number Serial Number I~C86Ype AIC Name Removal Date 5940338-501 CPI291 I-DAVU 09-10-02

Next Higher Assy Part Number Next Higher Assy Serial Number Position Station Task Planned

FCO P

t.~~~t ~iV~o TSI TST TSO TBO TSN TNE TTR After Task

Hours I Ore 30623 0 Cy eles I Cicli 2703 15268 15268 16500 23697 1232 U TBO

Days f Giomi .. ' 2920 636 U TBO C Imputation ShoplADL Contractor Follow-Up Reliability Warranty Itemised

215578334 500 YES TW NO • WORK SUMMARY I SOMMA RIO LA VORl

STATUS I WORK FAILURE I AVARIA REMARKS I NOTE

o Inspected [1J Confinne" ~ Ese~v.to ;"ccopp;"mcl'lt P;SfoM - c; i,,,,J,,, [f] Repaired [l] Not Confinned

[£]Tested @Justlfied RDve d; tc ill ute OK o ... ,,"' @ Not Justified Ove I h~v It!J !Xl.overhauled • ~MOdified PARTS REPLACED

[YJ 1m REGISTERED DATA CHANGE I MOD, ANAr-c ,cU-"c

ill Scrapped PIN SIN

El List 0; ReDort

,n~, '"'''I DJ, ~o :a~o~~L ,~

WORK COMOI FTFO BY ~~~~NCOMPLETE

Tli: I Num'" Rev Kit 'T.pe .n Stamp Sign 110 N'. '.'O'.JI!to "" Auth. Hr. Sta,~"·

ICHt1 IOl IAzJ ? .r::

.* ' n 01 oL ~ ~-G'< . .~."l:

lei '11 32-2J-OL bl. ~,..j~I.J' .,:.: ,-

0

~ '" ~ 0

" w ;§ <; !;;I 0 Maintenance Report ,Date Product ' RUR.<rJn P~n", eRS to be Issued I Emissione CRS " "

[YJ ,;: ~ j-

day month year m 0 0 '217 Olf ,) 13 Ji

JAA FAA

1111111111111 1IIIIIIIIIIgIIIIII 11111 111111111111111 11111 tilll 11111 11111 11111 11111111111111111111111 Page I Pagina 1 of I di

,,f / .

r

•

•

-&2.;~ ~,.It~~ 1111111"" ""I """ ""I ""I "III ""1111" 111111"" 11111 "III "1111111111111111

Ailitalia WORKSHOP JOB CARD Technical Operations SCHEDA LA VORO OFFICINA

Reason for Removal I Motivo della rimozione ALTRE CAUSE

Description I Descrizione NOSE GEAR STRUT ASSY

Customer I Cliente Work Order I ODL

,IzIitB'ia =i=ealll /~ ~2 f'OOL.~

"'2051746

Reference No Tag Number 0250001545 45069110

In-Sh~ Date J/C Printed On 10-1 -02 10-10-02

Part Number Serial Number AIC Type Ale Name Removal Date 5940338-501 CPI291 MD80 I-DAVU 09-10-02

Next Higher Assy Part Number Next Higher Assy Serial Number Position Station Task Planned . . FCO P

Flight Time TSI TST TSO T80 TSN TNE TTR After Task T emDO di VOID .

Hours I Ore 30623 0 CYcles' Cicli 2703 15268 15268 16500 23697 1232 U TBO

2920 636 U TBO 1.

Days I Giom; -

Imputation ShopiADL Contractor Follow-Up Reliability Warranty Itemised

215578334 500 YES TW NO • WORK SUMMARY I SOMMARIO LA VORl

. STATUS I WORK FAILURE I AVARIA REMARKS I NOTE

[i] Inspected W Confinned tse :)vito occopp'eW\~\J) p,stoh< . c.l,.Jt" [!] Repaired [iJ Not confinned

l

r£:lrested GJ Justified f.ove J, teVlut OK o RepairedfTested [il Not Justified f" ) /. / i!J Overhauled

: ... jVer/l~v "f'.)

~Modified PA RTS REPLA CEO

[1J ~ REGISTERED DATA CHANGES I MODIFICHE ANAGRAFICHE [i] Scrapped Liston PIN I SIN 0 Maintenance ReDort

REFERENCE DOCUMENTS SB Only ADomoNAL INSPEC110N WORK COMPLETED BY WORK INCOMPL.ETE DOCUMENT! DI RIFER/MENTO Solo 8DM WITROO.OAlXllZKX>lAJE LA VORO COMPLETA TO DA LA VORO INCOMPLETO

Type Description I Number Rev Kit TV .. Imputation .n S\9" 110 Hr. and/or StalP' Auth. Nr. Star~ TiPo Descrizione I Numero Commessa Stamp

11Lz~ . _: k

, C'r(Ci :,r. .., A 06 O? .L-L...r 13:

pm L~ ,:4'1

32. -21- 01.. CL '-, ~ , .

Maintenance Report Release Date Product Release I Ri/ascio Prodotto CRS to be Issued I Emissione CRS

Issued til [Y] Emesso

day month year ~ D 0 ~e 01: -::>'-' Rappono di Manutenzione L r JAA FAA

111111111 1I1111UII 1/ 1IIIIIImllllllllllllllllllllliliU 111/11111111111111111111111111111111111111/ Page I Pagina 1 of I di

j~'

.', I • '. Ailitalia TRANSFER RECOR'U TAG AilitaliatUrRANSFER RECORD TAG SERVICEABLE INFORMATION SERVICEABLE INFORMATION Ol:scrlpUon I Descrlzlone Part Number I Numero Categorico Description I Oescrizlone Part Number J Numero Categorico

NOSE GEAR STRUT ASSY NOSE GEAR STRUT ASSY 5940338-501 5940338-501

Certificate Ref. No.1 Certificato W Q.ty IO.ta Serial I Batch No.1 W di SerieJLotto Certificate Ref. No. I Certificato N° Q.ty /O.ta Serial I Batch No. I N° di Sene/lotto

0250001545 1 CPI291 ~

0250001545 1 CPI291

Work Order/Contract/Invoice Ordine di lavorolContrattolFaitura Owner Total Time Total Cycles TAG No. Track No 0'

2051746 • 30623 23697 45069110 g

i TNE Tso/eso TIR Owner

Acceptance Task Stamp I Auestazione Task di accellazione

~ o C 16500 C I ~ ~ INSTALLATION INFORMATION •

REMOVAL INFORMATION .

r:~Numb" ] Part Number

-____ L._~ ____

REMOVED FRO M REMOVAL DATE

NHA Part Number or Airc;:rat\ Type I Po,Won

I -r-I I ' I

i INSTALLED ON INSTALLATION DATE

~ NHA Part Number or Aircraft Type Position

i 51~;):)37- '-)5"/ Zig ~ I ,1 ~I :; ~ - ~-(J •

• ~ NHA Serial Number or Alrcraft.Name ez''''. by ... • " ~ C f" I '1 - t e.l , 2 L~ ..... c_ ?Jl > ~

• REMOVAL INFORMATION

~ Pari Humber s.m., Numbdr

NHA Serial Number or Aircraft Name StaUon I SHOP 500

" ~

~

~

z REMOVED FROM REMOVAL DATE ~ o

REASON FOR REMOVAL I Completed by NHA Part Number or Aircraft Type Position

I I I NHA Serial Nlimbor or Aircraft Name StaUon SHOP

500

" " " " " " " " " " " " " '"0 AEIlN'PL OONV '" "AM OHlER NEW BACI'< NHA STORE STORE TROIJ&LE R_O

SQUAWK SQUAWK REASON ARRN ROMTP. RP,," CO'" FAIL '"OCT " " " " " ,. " " " " " " ..

TBO I.o..EB APPl.1 COM/" I: fl T K I i MAINT OTH.ER N'W ... " N~ SIORE SlOf1E 'R""'" R_ol SOUAI/',/K SQUAWII. REASON ARRN ROMT.P RPK>H ,~" ,~, ,"00'

STORE INFORMATION SYSTEM UPDATE SIGNATURE TAG No. Track No. Location Shelf Lifo

45069110 01 UNLIMITED

I

• • • A MISSING PARTS LIST OUTGOING

LANDING WORKSHOP

I MD80 I DESCRIPTION

WEELS AND TYRES ASSY

STEERING CYLINDER (Qty 2)

LIGHT ASSY TAXI

PERFORMED BY Mechanic signSiJure and/or sJj'lmp Date

S. AZZALiN ~ L £- JAN 2903 ,

c1u. L.~ j ality Approval: S. ~ . .-..;>

PN 59403375501 SN CPI291.XL

NOSE

Missing Part List Out.

PIN 3910097-

3934689-

5912589-

ALiTALIA REPAIR STATION JAA n° RAI-ENAC 031

FAA n° AAPY004C

Date: FEB 03 2003 Page 21 bis

I • • •• , Approving National Aviation Authority I country 2. 3. Form Tracking Number

ENAC - Ente Nazionale per AUTHC 11SED RELEASE CERTIFll ATE Numero di Tracciabilita del Modulo

l'Aviazione Civile I ITALY JAA FORM ONE 0250001522 AutO/ita A810naulica Nazionale Approvante I Stalo Celfificalo di APprovazione

• Approvod Organisation Name and Address: ENGINEERING & MAINTENANCE 5. Work Order/Contract/Invoice Nome de/fOrganizzazione Approve/a e Indin"lzo: Ordine di lavoro/ContrattOlFattura

Allitalia P.za Almerlco da Schio

Linee Asrse Italiane S.p.A. Aeroporto l. da Vinci 2051097 00054 Fiumicino - Rama ·IT~LY·

6.ftem 7. Description •• Part Number 9. EIIQlbil!~.· 10 Q.a 11. Sallal/Batch No. 12. StatusIWor1l. WFItg DescrjzionB N" Categol'iCO , Q.t N° di Serie/l.otto Stalaflipo di intervento

1 NOSE LANDING GEAR ASSY 5940337-5501 T.B.D. 1 CPI291 OVERHAULED

13. Romarks 13 a. Total Time 13 b. TSo/eSO 13 c. TTR 13 d. TAG. No. Nole

/lm.t:alia 30628 0 C 16500 C 44282870 l:NG;~::~ ." "j t·. ~~AINTENANCE -iie.T otarCyCie's--~'--'-- ~- -13.:-TNE------·· -13Q:ShelfPeriod---- ~Shop-----

C;:":, . ~~,: ·;;;J~PY ATTACHMENTS: Dale;'-~ ~ (J. 23708 02-02-05 500 JOB CARD : YES Inspectors: . . ...-------- ...... --~.-.-.-.--.,,--

TRANSFER RECORD TAG : YES I.~ 13 i. locaUon -'3 f~-Purchase ci;:(ae;.--·~-· 13k.--Trac'j('ND."··--·---- 1-3"i~--·-"-"···- .

WORK PACKAGE : NO ( AVAILABLE ON FILE ~ ~~ 42TER01 N.L.G. NOT COMPLETLY ASSEMBLED OVEHAULED. MISSING P TS: WHEEL AND TIRES ASSY - CYLINDER ASSY NOSE WHEELS STEERING - 13m. Certifies that the work specified in block. 12113 was carried out in accordance with FAR Part 43 and in

LIGHT ASSY TAXI respect to thai work the palt{s) is(are) approved tor return to service. Pertinent details 01 Ule repair are on

TO INSTALL ONLY ALITALIA A/C file at this (epalr station under Order No. ..... . ........

~ OATE __ ...- SIGNED · ~ ...... ........ , · OR ALIT ALIA REPAIR STATION CERTIFICATE NO. AAPYOO4C

• c '4. CetUfios that the items Identified above were manufactured In conformity to: ,. ~ JAR·145.50 Release to Service 0 Other regulaUons speclOed In block 13 0

E Si certif/ca che gli articoli sopra identificati sono stati costruiti in conformita a: Riammissione in Servizio Altre normative specificate al punto 13.

0

0 approved design data and are In condition for safe operation ~ Certifies that unless otherwise specified In block 13, the worllldentiHed In block 12 and described In ~

~ documentazlOne di propel/o approvata e sano in co~ piego sicuro block 13, was accomplished In accordance with JAR 145 and In respect to that wor1l. the Items are ~

~ considered ready for release to service.

" 0 non-approved design data specified in ~ Si eerlif~ea, ehe se noJVrsamente ~~~CifiCa.to nel punto 13. illavoro identificato nl1/,punto 12 ~

!!; documentaz/one eli progetto non a~t specificata nel punta 13 e elescntto nel punta 1 stalo comp' etato In accordo a/la JAR 145 e rispatto a tale lavoro i

N p_articolari sono con sid ra ~ronti Der ri/ascio per 11 seN/zio. .

<; 15. Authorised Sign::~ 1 •. Approval/Authorisation Number 20. A~Ori'edSI9n.tu~ d:) 21. Certificate/Approval Referenca Number ~ Firma Autonzzata AppfDvazionelNumero di Aulorizzazione 0 Firma Autonzza/a CertiflcatolNumero eli Rif. eli ApPlovazione .~

w 0 PI,...... RAI-031

~y 1 •. Data ~dlmIy) 22 Name s. ccrRiO 23. Date 1dfmly) o Nome Data gImIa) Nome Data 91m1a)

~ 5547 CS 03-02-03 . Installer must cross-check eligibilIty with applicable technical data I L Installatore deve vetifieare f,mpJegabilita sufla documentazlOlle tecnIC8 appllCsbUe

USERIINST ALLER RESPONSIBILITIES RE$PONSABILITA' DELL 'UTlUZZA TOREIINSTALLATORE 1. It Is. Important to unden;tand that the existence of the Document alone does not automatically constituto 1. E.' importante tenere presente the ':esJstenza del D,!cumento da .5.0/0 non costitu;sce automaticam~nta autonta. authonty to Install the rart/componentiassembIY. 2. Where the userllnstaller works In accordance with the per Installare fa parte/componentelasSJeme. 2. Se I'mstallatorelullJizzatore /avera con / £egalamentl nazionali dl naUonar regulations 0 an Airworthiness AuthOrity different from the Airworthiness Authority speCified In una Autorita diAeronavigabilita differente dalfAutorlta di AeronavigabiJita specificata nel punta I'I e essenziaie the block (1) fj is essential that the user/installer ensures that hlslher Airworthiness Authority accepts l'utiJizzatorennsJaltatore 51 accerti ehe la propna Autorita di Aeronavigabilita aecelta Ie partilComponentvassiemi ~rtsJcomponenlS/a8semblies from the Airworthiness Authority specified In block (1). 3. Statements 14 dalJ'Autorlta dl Aaronav~abiiila spedficata nel PIInto {1}. 3. La dich/atazloni '4 e 19 non costituiscono and 19 do not consutute Installation certification. In all cases tho aircraft maintenance record must contaIn ceffifieazione alJ'instaUazlOn8. In tutti I cas/Ie tegislrazionl di manutenzione deJfaeromObiJe devono contenere una an installation certification Issued in accordance with the national regulations by the user/installer beforo eaffilicazione del/'installaziOne emessa in accollio con Ie nonne nazlonali dalfutifizzatorelinslallalore prima che tho aircraft may be flown. l'aeromobiJe possa essere portala in vola.

":'1' ...

'~; " . ..