AFS 2005_2

-

Upload

zeljko-ristic -

Category

Documents

-

view

231 -

download

0

Transcript of AFS 2005_2

-

7/30/2019 AFS 2005_2

1/66

AFS 2005:2

Manufacture of certainVessels, Piping andInstallationsProvisions of the Swedish Work Environment Authority on Manufacture of certainVessels, Piping and Installations, together with General Recommendations on the

implementation of the Provisions

Translation

In the event of disagreement concerning the interpretation and content of this text, the printed Swedishversion shall have priority.

The Work Environment Authoritys Statute Book

-

7/30/2019 AFS 2005_2

2/66

The Swedish Work Environment Authority was formed througha merger of the Swedish National Board of Occupational Safetyand Health and the Labour Inspectorate, on 1st January 2001.

Provisions adopted by the Swedish Work Environment Authorityare published in the Statute Book of the Swedish WorkEnvironment Authority. Provisions earlier published in theStatute Book of the Swedish National Board of OccupationalSafety and Health simultaneously still apply. Both StatuteBooks names are abbreviated AFS.

Please note that references to statutes always give the original

number of the document concerned, regardless of anysubsequent amendments and reprints.

Concerning amendments to and reprints of Provisions of theSwedish National Board of Occupational Safety and Health andof the Swedish Work Environment Authority, reference is madeto the latest Statute Book Register (in Swedish). A list ofOrdinances, General Recommendations, Directions andNotices is also published in English.

Swedish Work Environment AuthoritySE-171 84 SOLNA , Sweden

Telephone: +46 8 730 90 00Telefax: +46 8 730 91 67

Publishing Services, telefax: +46 8 735 85 55

www.av.se

http://www.av.se/http://www.av.se/ -

7/30/2019 AFS 2005_2

3/66

Contents

Provisions of the Work Environment Authority on theManufacture of Certain Vessels, Piping and Installations. ..5General ......................................................................................5Scope.........................................................................................5 Definitions ..................................................................................7Vessels and piping...................................................................10Classification of contents .........................................................10Classification of vessels...........................................................10Classification of piping .............................................................11General provisions ...................................................................12Essential safety requirements..................................................12Control of vessels and piping ...................................................13Delivery documentation and marking.......................................14Installations ..............................................................................15Classification of installations ....................................................15General provisions ...................................................................16Essential safety requirements..................................................16Installation control ....................................................................16Concluding provisions..............................................................18Work on pressurised systems..................................................18Mutual recognition clause ........................................................19

Fields of accreditation ..............................................................20Penal Provisions ......................................................................20

Entry into force and interim provisions .....................................20Essential safety requirements..................................................22General Recommendations issued by the Swedish WorkEnvironment Authority for the implementation of itsProvisions on Manufacture of Certain Vessels, Piping andInstallations ............................................................................44Background..............................................................................44Guidance on certain sections...................................................46General ....................................................................................46Definitions ................................................................................47

Vessels and piping...................................................................50Installations ..............................................................................59

Concluding provisions..............................................................65

-

7/30/2019 AFS 2005_2

4/66

-

7/30/2019 AFS 2005_2

5/66

AFS 2005:2

Provisions of the Work EnvironmentAuthority on the Manufacture of CertainVessels, Piping and Installations.

Published 22nd February 2005

Adopted 27th January 2005

The following Provisions are issued by the Swedish WorkEnvironment Authority pursuant to Section 18 of the WorkEnvironment Ordinance (SFS 1977:1166).1

General

Scope

Section 1These Provisions apply to the design, manufacture and erectionof vessels, piping and installations, with the following exceptions:

Vessels excluded.

Vessels covered by the Provisions of the National Board ofOccupational Safety and Health (AFS 1999:4) on PressureEquipment or by corresponding rules in any other country ofthe EEA.

Vessels covered by the Provisions of the National Board ofOccupational Safety and Health (AFS 1993:41) on Simple

1Information has been provided in compliance with Directive 98/34/EC of the EuropeanParliament and of the Council of 22 June 1998 laying down a procedure for the provisionof information in the field of technical standards and regulations (OJ L 204, 21.7.1988, p.37, Celex 31998 L0034), amended in Directive 98/48/EC of the European Parliament andof the Council of 20 July 1998 (OJ L 217, 5.8.1988, p. 18 Celex 31998 L0048).

5

-

7/30/2019 AFS 2005_2

6/66

AFS 2005:2

Pressure Vessels or by corresponding rules in any othercountry of the EEA.

Tanks intended for flammable liquid for which Provisionshave been issued by authority of the Flammables andExplosives Ordinance (SFS 1988:1145).

Vessels intended to be used for international transport asreferred to in the European Agreement concerning theInternational Carriage of Dangerous Goods by Road (ADR).

Vessels intended to be used for international transport as

referred to in the Regulations concerning the InternationalCarriage of Dangerous Goods by Rail (RID).

Vessels intended to be used for international transport asreferred to in the Technical Instructions for the SafeTransport of Dangerous Goods by Air (ICAO-IT).

Vessels intended to be used for such national transport ofdangerous goods as is covered by Provisions issuedpursuant to the Carriage of Dangerous Goods Act (SFS1982:821).

Vessels intended for nuclear installations concerning whichthe Nuclear Power Inspectorate has issued stipulations andconditions pursuant to the Nuclear Activities Act (SFS

1984:3).

Piping excluded.

Piping covered by AFS 1999:4 or by corresponding rules inany other country of the EEA.

Piping intended for flammable liquid, for which Provisionshave been issued by authority of the Flammables andExplosives Ordinance (SFS 1988:145) and which is usedbetween, to or from the tank.

Piping intended for natural gas for which Provisions havebeen issued by authority of the Flammables and ExplosivesOrdinance (SFS 1988:145).

Piping intended for water having a temperature of not morethan +65 C.

Installations excluded.

Installations and part of installations constituting assemblies.

6

-

7/30/2019 AFS 2005_2

7/66

AFS 2005:2

Nuclear installations for which the Nuclear PowerInspectorate has issued stipulations and conditions pursuantto the Nuclear Activities Act (SFS 1984:3).

Definitions

Section 2The following definitions shall apply for the purposes of these

Provisions.

Assembly Several pieces of pressure equipmentassembled by a manufacturer toconstitute an integrated and functionalwhole. For the purposes of theseProvisions, however, assemblies shallonly count as such if covered by AFS1999:4 or by corresponding rules inany other country of the EEA.

Installation All pressure retaining devices erected

within the operational area of anestablishment.

Protection circuit Part of a processing plant or aninstallation which is separatelyprotected and can be shut-off from theprocess or the rest of the installation.

Vessel A collective term for vacuum vessels,pressure vessels, tanks and low-pressure gas tanks.

Tank A housing (vessel) designed to containliquid where the gas pressure abovethe liquid does not exceed atmosphericpressure by more than 0,5 bar.

EEA The European Economic Area.

7

-

7/30/2019 AFS 2005_2

8/66

AFS 2005:2

Fluid Gases, liquids or vapours in purephase as well as mixtures thereof.A fluid may contain a suspension ofsolids.

Hot oil Oil used as a heat carrier in heatingsystems with a temperature exceeding110 oC.

Requirement G The requirement that essential safetyrequirements in Annex 1 be satisfied.

Requirement K The requirement of control by a controlbody as referred to in Section 22.

Low-pressuregas tank A vessel designed to contain gas with

a gaseous pressure not exceeding0,5 bar.

Erection Erection of pressure retaining devices

at an establishment and theirintegration with an installation.

Natural gas A gaseous mixture consistingpredominantly of methane.

Permanent joints Joints which cannot be disconnectedexcept by destructive methods.

Processing plant Several pressure retaining devicestogether making up an integrated,functional unit intended for a particular

process.

Piping Piping components intended for thetransport of fluids, when connectedtogether for integration into a pressuresystem. Piping includes in particular apipe or system of pipes, tubing, fittings,

8

-

7/30/2019 AFS 2005_2

9/66

AFS 2005:2

expansion joints, hoses, or otherpressure-bearing components asappropriate.

.Pipeline A piping intended for the conveyance

of fluids to or from an installation.

Pressure Pressure relative to atmosphericpressure, i.e. gauge pressure. As aconsequence, vacuum is designatedby a negative value.

Pressure vessel A housing designed and built tocontain fluids under pressure includingits direct attachments up to thecoupling point connecting it to otherequipment. A vessel may becomposed of more than one chamber.

Pressure equipment Pressure vessel, piping, safetyaccessories and pressure accessories.

For the purposes of these Provisions,however, only pressure equipmentcovered by AFS 1999:4 shall count assuch.

Pressure retainingdevice A collective term for pressure vessel,

vacuum vessel, tank and piping.

Vacuum vessel A housing designed in such a way thata pressure below atmosphericpressure prevails or can be achievedin it.

Open tank A tank having an open connection withthe atmosphere, where the gaseouspressure above the surface of theliquid does not normally deviatesignificantly from the atmosphericpressure.

9

-

7/30/2019 AFS 2005_2

10/66

AFS 2005:2

Vessels and piping

Classification of contents

Section 3The contents of vessels and piping are classified as 1a of a fluidis present which is

explosive highly flammable

extremely flammable

oxidizing

toxic

very toxic

corrosive; R35 only

carcinogenic; R45 and R49 only

mutagenic; R46 only

fertility-impairing; R60 and R61 only

hot oil

or a fluid used in a device whose maximum temperature exceedsthe fluids flash point.

Contents are classified as 2a if they have not been classified as1a.

Classification of vessels

Section 4Vessels are subject to requirements according to volume andcontents, as follows:

Requirement G: contents 1a and volume exceeding 1000litres.

Requirement K: contents 1a and volume exceeding 5000litres.

Requirement G: contents 2a at a temperature exceeding+65 C and volume exceeding 50000 litres.

10

-

7/30/2019 AFS 2005_2

11/66

AFS 2005:2

Requirement K: contents 2a at a temperature exceeding+65 C and volume exceeding 500000 litres.

Section 5Vessels containing two or more chambers are classified as perSection 4 for all chambers and relevant contents.

The vessel is then classified in accordance withrequirement G if in any respect it has for this purposebeen classified in accordance with requirement G.

The vessel is then classified in accordance withrequirement K if in any respect it has for this purposebeen classified in accordance with requirement K.

Classification of piping

Section 6A pipeline is subject to requirements according to nominaldiameter, pressure, temperature and contents as per diagrams6-9 in Annex 2 to AFS 1999:4. For this purpose

diagrams 6 and 7 shall be applied to gas, condensed gas,gas liquefied under pressure, vapour and liquids whose

vapour pressure at the maximum allowable temperature isgreater than normal atmospheric pressure (1,013 bar) bymore than 0,5 bar.

diagrams 8 and 9 shall be applied to liquids whose vapourpressure at the maximum permissible temperature does notexceed normal atmospheric pressure (1,013 bar) by morethan 0,5 bar,

diagrams 6 and 8 shall be applied to piping with contents 1a,

diagrams 7 and 9 shall be applied to piping with contents 2a.

For this classification, PS in diagrams 6-9 shall be plotted asthe highest pressure used by the manufacturer in thedimensioning of mechanical strength.

For this purpose, the piping is classified as comprising thefollowing of requirements G and K:

Requirement G: Categories I, II and III in diagrams 6, 7, 8and 9.

11

-

7/30/2019 AFS 2005_2

12/66

AFS 2005:2

Requirement K: Categories II and III in diagrams 6, 7, 8 and9.

For classification purposes, take-off pipes of smaller diameterthan their main pipe shall be classified as belonging to the sameup to and including the first shut-off valve counted from the mainpipe.

Classification will not include those parts of a pipeline whichhave contents 2a and an operating temperature not exceeding120 oC and which are positioned in such a specially protectedmanner as to afford adequate safety; these need not beclassified as subject to requirement K.

General provisions

Section 7All vessels and piping with appurtenant safety accessories shallbe designed and manufactured in compliance with the soundengineering practice of any country of the EEA. Considerationshall, however, be paid to specific local conditions, such as the

effects of climate on devices positioned outdoors.

Sound engineering practice includes the devices affordingadequate safety in terms of material, design, workmanship andequipment. In addition, they shall be designed and manufacturedin such a way that the maintenance and supervision needed forsafety reasons can be performed in a satisfactory manner.

Essential requirements

Section 8Vessels and pipelines subject to requirement G as referred to in

Sections 4-6 and appurtenant safety accessories shall meet therelevant essential safety requirements listed in Annex 1 orequivalent rules applying in another EEA country.

The device shall be designed and manufactured in compliancewith the principles set forth in Annex 1. Risks emanating directlyfrom pressure are not, however, normally considered of

12

-

7/30/2019 AFS 2005_2

13/66

AFS 2005:2

importance for vessels to which these Provisions refer. Thedevice shall furthermore be designed and manufactured in sucha way that prescribed inspection and control can be carried outin a satisfactory manner. The manufacturer of the device shallhave a quality management system for ensuring that the devicemanufactured complies with the requirements specified in itsdesign.

Control of vessels and piping

Section 9Vessels and pipelines to which requirement K is applied underSections 4-6 may be delivered for taking into service only if theyhave undergone design control as referred to in Section 10 andproduction control as referred to in Section 11.

Section 10Design control shall have been carried out by a control body asreferred to in Section 22. The design control must have includedscrutiny of the manufacturers compliance with the requirementsof Section 8. To this end the basis of production shall have been

scrutinised with regard to material, design, workmanship and theextent of destructive and non-destructive testing. If a satisfactorymethod of calculation is lacking, the design shall have beenassessed through suitable examination, e.g. strain gaugemeasurement. In the course of design control the device shallhave been assessed with reference to these Provisions.

Section 11Production control shall have been carried out by a control bodyas referred to in Section 22. The production control must haveincluded scrutiny of the manufacturing documents, internal andexternal examination and pressure control.

In the examination of manufacturing documents, it shall havebeen verified that design control was performed with satisfactoryresults, and that other documents important for the safety of thedevice are in order.

13

-

7/30/2019 AFS 2005_2

14/66

AFS 2005:2

In the course of internal and external inspection it shall havebeen verified that the device is constructed in accordance withmanufacturing documents examined in the design control andwith these Provisions, and that there is no non-compliancematerial to safety.

Delivery documentation and marking

Section 12Vessels and pipelines subject to requirement G as provided inSections 4-6 shall be marked as appropriate and labelled inaccordance with point 3.3 of Annex 1. This does not apply,however, to tanks and low-pressure gas tanks which areintended for incorporation in buildings and are CE-marked incompliance with the rules of Council Directive 89/106/EEC of 21December 1988 on the approximation of laws, regulations andadministrative provisions of the Member States relating toconstruction products.

Section 13Vessels and pipelines subject to requirement G as provided in

Sections 4-6 shall, when delivered for taking into service, beaccompanied by an assurance from the manufacturer that thedevice meets the requirements of Section 8. This does not apply,however, to CE-marked tanks and low-pressure gas tanks whichare intended for incorporation in buildings and comply with therules for confirming compliance with technical specifications inthe EC Construction Products Directive. The devices shall alsobe accompanied by operating instructions in Swedish, inaccordance with the requirements of point 3.4 of Annex 1.

14

-

7/30/2019 AFS 2005_2

15/66

AFS 2005:2

Installations

Classification of installations

Section 14For this classification, the installations are divided into protectioncircuits.

A protection circuit is subject to requirement G if intended to

contain any of the following: a vessel subject to requirement G as set forth in Sections 4-5

pressure vessels and piping belonging to any of categories I,II, III and IV as provided in AFS 1999:4

simple pressure vessels as referred to in AFS 1993:41, withPxV exceeding 200 bar litres.

A protection circuit is subject to requirement K if intended tocontain any of the following:

a vessel subject to requirement K as set forth in Sections 4-5

pressure vessels and piping belonging to any of categories II,III and IV as provided in AFS 1999:4

simple pressure vessels as referred to in AFS 1993:41, withPxV exceeding 1,000 bar litres.

Section 15A party erecting a processing plant or part of an installationwhich is not an assembly and comprise one or more pressurecontainment circuits subject to requirement G as provided inSection 14 shall draw up installation documentation with a flowchart.

The documentation shall contain a description of the extent of

the installation and its division into protection circuits. In order forthe protection circuits to be classifiable as provided in Section14, a list of the assemblies and devices to be included isrequired, together with requirement specifications. Thedocumentation shall also include the operating conditions towhich the classification is subject.

15

-

7/30/2019 AFS 2005_2

16/66

AFS 2005:2

General provisions

Section 16All installations shall be constructed and erected in such a wayas to afford adequate safety. They shall also be designed in sucha way that the maintenance and supervision needed for safetyreasons can be performed in a satisfactory manner.

Essential safety requirements

Section 17Processing plants or other parts of installations consisting ofprotection circuits which are subject to requirement G and arenot assemblies shall meet the basic safety requirements forinstallations as stated in Annex 1.

Before such installations are erected, the risks shall have beenanalysed or other measures taken which can ensure that theinstallations can be designed and assembled so as to affordadequate safety. These measures shall also have formed thebasis of the specifications of requirements for the pressure

retaining devices and assemblies included. They shall also bedesigned in such a way that the prescribed inspection andcontrol can be performed in a satisfactory manner.

The same applies concerning installations or those parts of thesame which are include in technical systems, where implied byrequirements in another Provision stating that they are to complywith essential safety requirements.

Installation control

Section 18Processing plant or other parts of installations consisting ofprotection circuits subject to requirement K as set forth in Section14 may be put into service only if they have undergoneinstallation control as provided in Sections 19 and 20. Thecontrol shall have been carried out by a control body as referredto in Section 22. In addition, installations and constituent devices

16

-

7/30/2019 AFS 2005_2

17/66

AFS 2005:2

shall meet the conditions to which their taking into service ismade subject by another Provision.

Installation control can also be carried out when implied bymeasures founded on requirements in another Provision for theuser to show, by means of control, that an installation or part ofthe same meets essential technical safety requirements.

Section 19Installation control shall have included examination ofcompliance with the requirements of Section 17. The installationdocumentation prepared in compliance with Section 15 and therequisite instructions for erection shall have been examined priorto erection.

The installation shall have been examined after erection, to verifythat it is constructed in compliance with assessed installationdocumentation, instructions for erection and these Provisions,and that there are no deviations important for safety.

In the case of constituent vacuum vessels, tanks and low-

pressure gas tanks for which production control is requiredunder Section 11, it shall have been verified that the controlwas carried out and that the devices are suitable for inclusionin the installation, having regard to the calculation modelsand operating conditions for the installation.

In the case of constituent CE-marked pressure equipment,CE-marked simple pressure vessels and CE-markedassemblies, the declaration of conformity and other requisitedocuments shall have been examined to assess whetherthese devices and assemblies are suitable for inclusion in theinstallations, having regard to the calculation models andoperating conditions of the installation.

In the case of constituent CE-marked tanks and low-pressuregas tanks which are intended for inclusion in buildings, theapproval or confirmation of conformity with technicalspecifications shall have been examined with a view tojudging whether these tanks and low-pressure gas tanks aresuitable for inclusion in the installation, having regard to the

17

-

7/30/2019 AFS 2005_2

18/66

AFS 2005:2

calculation models and operating conditions of theinstallation.

In the case of other constituent pressure retaining devices,an assessment shall have been made of their suitability forinclusion in the installation, having regard to the calculationmodels and operating conditions of the installation.

In the case of constituent devices complying with the rules ofProvisions issued by another Swedish authority or withcorresponding rules in some other country of the EEA, an

assessment shall have been made of the suitability of thevessel for inclusion in the installation, having regard to thecalculation models and operating conditions of theinstallation.

Section 20The installation control shall have included design control, asprovided in Section 10, and production control, as provided inSection 11, of joints between the following items:

vessels subject to requirement K as set forth in Sections 4-5,

pressure vessels and piping in categories II, III and IV asreferred to in AFS 1999:4,

simple pressure vessels, as referred to in AFS 1993.41, withPxV exceeding 1,000 bar litres,

connected pipelines subject to requirement K as set forth inSection 6,

Pressure accessories and safety accessories pertaining tothe said devices.

Concluding provisions

Work on pressurised systems

Section 21When additional devices or new parts are fitted to an installationor pipeline which has already been commissioned or met theconditions for delivery for taking into service as stated in Section18, the relevant part of the installation or pipeline shall normallyby shut down and depressurised.

18

-

7/30/2019 AFS 2005_2

19/66

AFS 2005:2

Only companies specially certified for such work by a certificationbody as referred to in Section 22 may assemble and fit pressurevessels, vacuum vessels and piping to protection circuits andpipelines which have not been shut off and depressurised.

Mutual recognition clause

Section 22An control body which is to carry out control as provided in

Sections 9-11 and 18-20 and point 3.1.2 of Annex 1, acertification body which is to carry out assessment/certificationas provided in Section 21 and point 3.1.2 of Annex 1, and alaboratory which is to carry out non-destructive testing asreferred to in point 3.1.3 of Annex 1 shall have obtainedaccreditation for the task in question under the TechnicalInspection Act (SFS 1992:1119). Control, assessment,certification and non-destructive testing of this kind can also beperformed by a control agency, certification body and third partylaboratory respectively from another country within the EEA, if:

the control body is accredited for the task with reference tothe requirements of the relevant standard in the EN 45 000

series by an accrediting body which meets and applies to thisassessment the requirements of ISO TR 17010 or otherwiseoffers corresponding guarantees with regard to technical andprofessional competence and guarantees of independence.

the certification body is accredited for the task with referenceto the requirements of the relevant standard in the EN 45 000series by an accrediting body which meets and applies to thisassessment the requirements of EN 45 010 or otherwiseoffers corresponding guarantees with regard to technical andprofessional competence and guarantees of independence.

the laboratory is accredited for the task with reference to theISO/IEC 17025 standard by an accrediting body which meets

and applies for assessment the requirements of EN 45 010or otherwise offers corresponding guarantees of technicaland professional competence and independence.

19

-

7/30/2019 AFS 2005_2

20/66

AFS 2005:2

Fields of accreditation

Section 23For the accreditation of bodies as referred to in Section 22, thefollowing fields of accreditation apply:

control pursuant to Sections 9-11 and 18-20,

control pursuant to point 3.1.2 in Annex 1,

certification pursuant to point 3.1.2 of Annex 1, certification pursuant to Section 21,

non-destructive testing pursuant to point 3.1.3 of Annex 1.

Penal Provisions

Section 24The Provisions of Sections 10, 11 and 18 and of Section 21 (2)constitute prescriptions as referred to in Chap. 4, Section 2 of the

Work Environment Act (SFS 1977:1160). Under Chap. 8, Section2 of the same Act, offences against these prescriptions arepunishable by fines.

Entry into force and interim provisions

Thee Provisions enter into force on 1st January 2006. TheProvisions of the National Board of Occupational safety andHealth (AFS 1999:6) on Pressure Vessels and Other Pressure-Retaining Devices, and Notice 1978:37 from the National Boardof Occupational Safety and Health concerning Application of the

Piping Code issued by the Pressure Vessel Commission arerepealed with effect from the same date.

The new Provisions do not, however, preclude vessels, pipingand installations referred to in Section 1 and complying with theProvisions of the National Board of Occupational safety andHealth (AFS 1999:6) on Pressure Vessels and Other Pressure-Retaining Devices, as worded on 31st December 2005, being

20

-

7/30/2019 AFS 2005_2

21/66

AFS 2005:2

placed on the market, delivered for taking into service or put intoservice up to and including 31st December 2006. Vessels, pipingand installations complying with such rules and placed on themarket not later than 31st December 2006 may also thereafterbe delivered for taking into service or be taken into service.

The new Provisions do not, however, preclude work on pressureretaining devices being done in a manner indicated by theProvisions of the National Board of Occupational safety andHealth (AFS 1999:6) on Pressure Vessels and Other Pressure-Retaining Devices, as worded on 31st December 2005, up until31st December 2006 or until certification bodies have beenaccredited for the task.

BERTIL REMAEUS

Rune Andersson Maria Hagberg Forss

21

-

7/30/2019 AFS 2005_2

22/66

AFS 2005:2

Annex 1

Essential safety requirements

These essential safety requirements are taken from Annex 1 tothe Provisions of the National Board of Occupational Safety andHealth on Pressure Equipment (AFS 1999:4), implementingDirective 97/23/EC of the European Parliament and of theCouncil of 29 May 1997 on the approximation of the laws of the

Member States concerning pressure equipment. Minormodifications have been made to adapt the requirements forapplication to vessels, piping and installations as referred to inthe present Provisions.

The term devices in this annex refers to vacuum vessels, tanks,low-pressure gas tanks and pipelines.

Introduction1. The essential requirements for devices in this annex also

apply to installations where there is a corresponding hazardpresent.

2. These requirements apply to a particular device only if acorresponding hazard is present in that device when thedevice is used in a manner which the manufacturer couldreasonably have foreseen.

3. The manufacturer of a device shall have analysed the hazardin order to establish which, having regard to the pressure, areapplicable to it. The device shall then have been designedand manufactured in the light of the analysis.

4. The essential requirements shall be interpreted and appliedin such a way that account is taken of both the state oftechnology and current practice at the time of design andmanufacture and of the technical and financial deliberations

compatible with a high level of protection for health andsafety.

1. GENERAL1.1 Devices shall be designed, manufactured and checked, andif applicable equipped and installed, in such a way as to ensuretheir safety when put into service in accordance with the

22

-

7/30/2019 AFS 2005_2

23/66

AFS 2005:2

manufacturer's instructions, or in reasonably foreseeableconditions.

1.2 The manufacturer must apply the principles set out below inthe following order: eliminate or reduce

hazards as far as isreasonablypracticable,

apply appropriateprotection measuresagainst hazardswhich cannot beeliminated,

where appropriate,inform users ofresidual hazards andindicate whether it isnecessary to takeappropriate specialmeasures to reduce

the risks at the timeof installation and/oruse.

1.3. Where the potential for misuse is known or can be clearlyforeseen, the devices must be designed to prevent danger fromsuch misuse or, if that is not possible, adequate warning giventhat the devices must not be used in that way.

2. DESIGN

2.1 General

Devices must be properly designed taking all relevant factorsinto account in order to ensure that the device will be safethroughout its intended life.

23

-

7/30/2019 AFS 2005_2

24/66

AFS 2005:2

The design must incorporate appropriate safety coefficientsusing comprehensive methods which are known to incorporateadequate safety margins against all relevant failure modes in aconsistent manner.

2.2 Design for adequate strength

2.2.1 Device must be designed for loadings appropriate to itsintended use and other reasonably foreseeable operatingconditions. In particular, the following factors must be taken intoaccount: internal/external pressure, ambient and operational temperatures, static pressure and

mass of contents inoperating and testconditions,

traffic, wind, earthquake loading, reaction forces and

moments whichresult from the

supports,attachments, piping,etc.,

corrosion and erosion, fatigue, etc., decomposition of unstable fluids.

Various loadings which can occur at the same time must beconsidered, taking into account the probability of theirsimultaneous occurrence.

For the gas pressure in a vessel not to be deemed to deviatesignificantly from atmospheric pressure, the internal pressure

must not exceed atmospheric pressure by more than 0,03 bar orfall below it by more than 0,0065 bar.

2.2.2 Design for adequate strength must, as a general rule, meetthe requirements set forth in point 2.2.3, supplemented ifnecessary by the experimental design method described in point2.2.4.

24

-

7/30/2019 AFS 2005_2

25/66

AFS 2005:2

It may, however, be based entirely on the experimental designmethod described in point 2.2.4, when the product of themaximum allowable pressure PS and the volume V is less than6,000 bar 7L or the product PS 7DN less than 3,000 bar.

2.2.3 Calculation method

(a) Pressure containment and other loading aspects

The allowable stresses for devices must be limited having regardto reasonably foreseeable failure modes under operatingconditions. To this end, safety factors must be applied toeliminate fully any uncertainty arising out of manufacture, actualoperational conditions, stresses, calculation models and theproperties and behaviour of the material.

These calculation methods must provide sufficient safetymargins consistent, where applicable, with the requirements ofsection 7.

The requirements set out above may be met by applying one ofthe following methods, as appropriate, if necessary as asupplement to or in combination with another method: design by formula, design by analysis, design by fracture mechanics.

(b) Resistance

Appropriate design calculations must be used to establish theresistance of the device concerned.

In particular:

1. The calculation pressure must not be less than the maximumallowable pressure and must take into account static headand dynamic fluid pressures and the decomposition ofunstable fluids. Where a vessel is separated into individualpressure-containing chambers, the partition wall must be

25

-

7/30/2019 AFS 2005_2

26/66

AFS 2005:2

designed on the basis of the highest possible chamberpressure relative to the lowest pressure possible in theadjoining chamber.

2. The calculation temperatures must allow for appropriatesafety margins.

3. The design must take appropriate account of all possiblecombinations of temperature and pressure which might ariseunder reasonably foreseeable operating conditions.

4. The maximum stresses and peak stress concentrations mustbe kept within safe limits,

5. The calculation for pressure containment must utilise thevalues appropriate to the properties of the material, based ondocumented data, having regard to the provisions set out inpoint 4 together with appropriate safety factors. Materialcharacteristics to be considered, where applicable, include:

yield strength, 0,2 %or 1,0 % proof

strength asappropriate atcalculationtemperature,

tensile strength, time-dependent strength, i.e. creep strength, fatigue data, Young's modulus (modulus of elasticity), appropriate amount of plastic strain, impact strength, fracture toughness

6. Appropriate joint factors must be applied to the materialproperties depending, for example, on the type of non-destructive testing, the materials joined and the operatingconditions envisaged,

7. The design must take appropriate account of all reasonablyforeseeable degradation mechanisms (e.g. corrosion, creep,

26

-

7/30/2019 AFS 2005_2

27/66

AFS 2005:2

fatigue) commensurate with the intended use of the device.Attention must be drawn, in the instructions referred to insection 3.4, to particular features of the design which arerelevant to the life of the device, for example:

for creep: designhours of operation atspecifiedtemperatures,

for fatigue: designnumber of cycles atspecified stresslevels,

for corrosion: design corrosion allowance.

(c) Stability

Where the calculated thickness does not allow for adequatestructural stability, the necessary measures must be taken toremedy the situation taking into account the risks from transportand handling.

27

-

7/30/2019 AFS 2005_2

28/66

AFS 2005:2

2.2.4. Experimental design method

The design of the device may be validated, in all or in part, by anappropriate test programme carried out on a samplerepresentative of the device or the category of devices.

The test programme must be clearly defined prior to testing andaccepted by the control body responsible for the design control,where it exists.

This programme must define test conditions and criteria foracceptance or refusal. The actual values of the essentialdimensions and characteristics of the materials which constitutethe devices tested shall be measured before the test.

Where appropriate, during tests, it must be possible to observethe critical zones of the device with adequate instrumentationcapable of registering strains and stresses with sufficientprecision.

The test programme must include:

(a) A pressure strength test, the purpose of which is to checkthat, at a pressure with a defined safety margin in relation tothe maximum allowable pressure, the device does not exhibitsignificant leaks or deformation exceeding a determinedthreshold.The test pressure must be determined on the basis of thedifferences between the values of the geometrical andmaterial characteristics measures under test conditions andthe values used for design purposes; it must take intoaccount the differences between the test and designtemperatures.

(b) Where the risk of creep or fatigue exists, appropriate tests

determined on the basis of the service conditions laid downfor the device, for instance hold time at specifiedtemperatures, number of cycles at specified stress-levels,etc.

(c) where necessary, additional tests concerning other factorsreferred to in point 2.2.1 such as corrosion, external damage,etc.

28

-

7/30/2019 AFS 2005_2

29/66

AFS 2005:2

2.3 Provisions to ensure safe handling and operation

The method of operation specified for the device must be suchas to preclude any reasonably foreseeable risk in operation ofthe equipment. Particular attention must be paid, whereappropriate, to: closures and openings, dangerous discharge of pressure relief blow-off, devices to prevent

physical accesswhilst pressure or avacuum exists,

surface temperaturetaking intoconsideration theintended use,

decomposition of unstable fluids.

Devices fitted with an access door must be equipped with anautomatic or manual device enabling the user easily to ascertain

that the opening will not present any hazard. Furthermore, wherethe opening can be operated quickly, the device must be fittedwith a device to prevent it being opened whenever the pressureor temperature of the fluid presents a hazard.

2.4. Means of examination

(a) The device must be designed and constructed so that allnecessary examinations to ensure safety can be carried out.

(b) Means of determining the internal condition of the devicemust be available, where it is necessary to ensure the

continued safety of the device, such as access openingsallowing physical access to the inside of the device so thatappropriate examinations can be carried out safely andergonomically.

(c) Other means of ensuring the safe condition of the devicemay be applied: where it is too small for physical internal access, or

29

-

7/30/2019 AFS 2005_2

30/66

AFS 2005:2

where opening the device would adversely affect theinside, or

where the substance contained has been shown not to beharmful to the material from which the device is made andno other internal degradation mechanisms are reasonablyforeseeable.

2.5. Means of draining and venting

Adequate means must be provided for the draining and ventingof device where necessary:(a) to avoid harmful effects such as water hammer, vacuum

collapse, corrosion and uncontrolled chemical reactions. Allstages of operation and testing, particularly pressure testing,must be considered,

(b) to permit cleaning, inspection and maintenance in a safemanner.

2.6. Corrosion or other chemical attack

Where necessary, adequate allowance or protection againstcorrosion or other chemical attack must be provided, taking dueaccount of the intended and reasonably foreseeable use.

2.7. Wear

Where severe conditions of erosion or abrasion may arise,adequate measures must be taken to:

minimise that effect by appropriate design, e.g. additionalmaterial thickness, or by the use of liners or claddingmaterials,

permit replacement of parts which are most affected,

draw attention, in the instructions referred to in 3.4, tomeasures necessary for continued safe use.

2.8. Installations

Installations must be so designed that:

30

-

7/30/2019 AFS 2005_2

31/66

AFS 2005:2

the components to be assembled together are suitableand reliable for their duty,

all the components are properly integrated andassembled in an appropriate manner.

2.9. Provisions for filling and discharge

Where appropriate, the device must be so designed and

provided with accessories, or provision made for their fitting, asto ensure safe filling and discharge in particular with respect tohazards such as:

(a) On filling:- overfilling or overpressurisation having regard in

particular to the filling ratio and to vapour pressure at thereference temperature,

- instability of the device.

(b) On discharge: the uncontrolled release of the pressurisedfluid.

(c) On filling or discharge: unsafe connection and disconnection.

2.10. Protection against exceeding the allowable limits ofdevices

Where, under reasonably foreseeable conditions, the allowablelimits could be exceeded, the device must be fitted with, orprovision made for the fitting of, suitable safety devices, unlessthe device is intended to be protected by other protective devicesintegrated within a protection circuit. Safety devices can be

common to the protection circuit which the device is fitted to, ifthe device and the piping connecting it to all the parts of theprotection circuit are designed for this. If a shut-off valve issituated between the protective device and a device which it isintended to protect, the device can only be considered protectedif this shut-off valve is interlocked in open position. If there is anyother type of valve or equipment between the device concerned

31

-

7/30/2019 AFS 2005_2

32/66

AFS 2005:2

and the protective device, then it shall be ensured in the sameway that the connection between the device and the safetyaccessories is kept open. The safety device or combination ofsuch devices must be determined on the basis of the particularcharacteristics and intended use of the device or installation.

Suitable protective devices and combinations thereof comprise:

(a) safety accessories and,

(b) where appropriate, adequate monitoring devices such asindicators and/or alarms which enable adequate action to betaken either automatically or manually to keep the pressureequipment within the allowable limits.

2.11. Safety accessories

2.11.1. Safety accessories must:

(a) be so designed and constructed as to be reliable and suitable

for their intended duty and take into account the maintenanceand testing requirements of the devices, where applicable,

(b) be independent of other functions, unless their safetyfunction cannot be affected by such other functions,

(c) comply with appropriate design principles in order to obtainsuitable and reliable protection. These principles include, inparticular, fail-safe modes, redundancy, diversity and self-diagnosis.

2.11.2. Pressure limiting devices

These devices must be so designed that the pressure will notpermanently exceed the maximum allowable pressure PS;however, a short-duration pressure surge in keeping with thespecifications laid down in 7.3 is allowable, where appropriate.

32

-

7/30/2019 AFS 2005_2

33/66

AFS 2005:2

2.11.3. Temperature monitoring devices

These devices must have an adequate response time on safetygrounds, consistent with the measurement function.

2.11.4 Vacuum limitation devices

Vacuum limitation devices shall be so designed that the pressurewill not prolonged exceed the maximum allowable vacuum.

2.12. External fire

Where necessary, devices must be so designed and, whereappropriate, fitted with suitable accessories, or provision madefor their fitting, to meet damage-limitation requirements in theevent of external fire, having particular regard to intended use.

3. MANUFACTURING

3.1. Manufacturing procedures

The manufacturer must ensure the competent execution of theprovisions set out at the design stage by applying theappropriate techniques and relevant procedures, especially witha view to the aspects set out below.

3.1.1. Preparation of the component parts

Preparation of the component parts (e.g. forming andchamfering) must not give rise to defects or cracks or changes inthe mechanical characteristics likely to be detrimental to thesafety of the device.

3.1.2. Permanent joining

33

-

7/30/2019 AFS 2005_2

34/66

AFS 2005:2

Permanent joints and adjacent zones must be free of anysurface or internal defects detrimental to the safety of the device.

The properties of permanent joints must meet the minimumproperties specified for the materials to be joined unless otherrelevant property values are specifically taken into account in thedesign calculations.

For devices, permanent joining of components which contributeto the pressure resistance of device and components which aredirectly attached to it must be carried out by suitably qualifiedpersonnel according to suitable operating procedures. For joiningdevices which are subject to requirement K as set forth inSections 4 and 6, operating procedures and personnel must beassessed and approved by a control and certification bodyrespectively as provided for in Section 22.

To carry out these approvals the body must performexaminations and tests as set out in the appropriate harmonisedstandards or equivalent examinations and tests or must havethem performed.

3.1.3. Non-destructive tests

Non-destructive tests of permanent joints in devices which aresubject to requirement K as set forth in Sections 4 and 6 musthave been carried out by a laboratory pursuant to Section 22.

3.1.4. Heat treatment

Where there is a risk that the manufacturing process will change

the material properties to an extent which would impair the safetyof the pressure-retaining device, suitable heat treatment must beapplied at the appropriate stage of manufacture.

3.1.5. Traceability

34

-

7/30/2019 AFS 2005_2

35/66

AFS 2005:2

Suitable procedures must be established and maintained foridentifying the material making up the components of theequipment which contribute to pressure resistance by suitablemeans from receipt, through production, up to the final test of themanufactured device.

3.2. Final assessment

Devices must be subjected to final assessment as described inpoints 3.2.1-3.2.3.

3.2.1. Final inspection

Devices must undergo a final inspection to assess visually andby examination of the accompanying documents compliance withthe requirements of these Provisions. Tests carried out duringmanufacture may be taken into account. As far as is necessaryon safety grounds, the final inspection must be carried outinternally and externally on every part of the equipment, where

appropriate in the course of manufacture (e.g. whereexamination during the final inspection is no longer possible).

3.2.2. Proof test

Final assessment of pressure equipment must include a test forthe pressure containment aspect, which will normally take theform of a hydrostatic pressure test at a pressure at least equal,where appropriate, to the value laid down in point 7.4.

For series-produced devices, this test may be performed on astatistical basis.

Where the hydrostatic pressure test is harmful or impractical,other tests of a recognised value may be carried out. For testsother than the hydrostatic pressure test, additional measures,such as non-destructive tests or other methods of equivalentvalidity, must be applied before those tests are carried out.

35

-

7/30/2019 AFS 2005_2

36/66

AFS 2005:2

3.2.3. Inspection of safety devices

3.3. Marking and labelling

Clearly visible, easily readable and durable marking shall beprovided, containing the following information:

(a) For all devices:- The name and address or other means of identification of

the manufacturer and, where appropriate, of hisauthorised representative established within the EEA.

- The year of manufacture.- Identification of the device according to its nature, such

as type, series or batch identification and serial number.- Essential maximum/minimum by the manufacturer

allowable limits;

(b) depending on the type of device:

such of the following items of information as are necessaryfor safe installation, operation or use and, where applicable,maintenance and periodic inspection such as:- The volume V of the tank, low-pressure gas tank and

vacuum vessel in litres.- The nominal size for piping DN.- The test pressure PT applied in bar and date.- Safety device set pressure in bar.- Output of the device in kW.- Supply voltage in V (volts).- Intended use.- Filling ratio kg/L.

-Maximum filling mass in kg.

- Maximum filling level in %.- Highest allowable density for liquids in tanks- Tare mass in kg.- The fluid group.

36

-

7/30/2019 AFS 2005_2

37/66

AFS 2005:2

(c) where necessary, warnings in Swedish fixed to the deviceand drawing attention to misuse which experience has shownmight occur.

The information must be given on the device or on a dataplatefirmly attached to it, with the following exceptions:

1. Where applicable, appropriate documentation may be usedto avoid repetitive marking of individual parts such as pipingcomponents, intended for the same installation.

2. Where the device is too small, the information referred to in(b) may be given on a label attached to that device.

3. Labelling or other adequate means may be used for themass to be filled and the warnings referred to in (c), providedit remains legible for the appropriate period of time.

On insulated or encapsulated vessels or pipelines, adataplate can also be attached to the insulation or outercasing. In the case of a vessel or pipelines which are buried

or in-built, the dataplate can be fitted in a suitable position,e.g. in a manhole or at the point where the pipeline or vesseljoins up with other devices.

3.4 Operating instructions

(a) When devices are placed on the market, they must beaccompanied, as far as relevant, with instructions for theuser, containing all the necessary safety information relatingto:- mounting including assembling of different pieces of

pressure-retaining devices,

-putting into service,

- use,- maintenance including checks by the user.

(b) Operation Instructions must cover information affixed to thepressure equipment in accordance with point 3.3, with theexception of serial identification, and must be accompanied,

37

-

7/30/2019 AFS 2005_2

38/66

AFS 2005:2

where appropriate, by the technical documents, drawingsand diagrams necessary for a full understanding of theseinstructions.

(c) If appropriate, these instructions must also refer to hazardsarising from misuse in accordance with point 1.3 andparticular features of the design in accordance with point2.2.3.

4. MATERIALS

Materials used for the manufacture of devices must be suitablefor such application during the scheduled lifetime unlessreplacement is foreseen.

Welding consumables and other joining materials need fulfil onlythe relevant requirements of points 4.1, 4.2 (a) and the firstparagraph of 4.3, in an appropriate way, both individually and ina joined structure.

4.1. Materials for pressure-retaining parts must meet the

following requirements:

(a) They must have appropriate properties for all operatingconditions which are reasonably foreseeable and for all testconditions, and be sufficiently ductile and tough. Whereappropriate, the characteristics of the materials must complywith the requirements of point 7.5. Moreover, due careshould be exercised in particular in selecting materials inorder to prevent brittle-type fracture where necessary; wherefor specific reasons brittle material has to be usedappropriate measures must be taken.

(b) They must be sufficiently chemically resistant to the fluidcontained in the pressure equipment; the chemical andphysical properties necessary for operational safety must notbe significantly affected within the scheduled lifetime of theequipment.

38

-

7/30/2019 AFS 2005_2

39/66

AFS 2005:2

(c) They must not be significantly affected by ageing.

(d) They must be suitable for the intended processingprocedures.

(e) They must be selected in order to avoid significantundesirable effects when the various materials are puttogether.

4.2. (a) The device manufacturer must define in an appropriatemanner the values necessary for the design calculations referredto in point 2.2.3 and the essential characteristics of the materialsand their treatment referred to in point 4.1.

(b) the manufacturer must provide in his technicaldocumentation elements relating to compliance with thematerials specifications of these Provisions in one of thefollowing forms:- By using materials which comply with appropriate

standards, as referred to in the guidance on Section 8.

-By using materials covered by a European approval ofpressure equipment materials.

- By a particular material appraisal.

For devices subject to requirement K as referred to in Sections 4and 6, particular appraisal as referred to in the third indent of (b)must be performed by the control body in charge of theproduction control for the actual device.

4.3. The device manufacturer must take appropriate measures toensure that the material used conforms with the requiredspecification. In particular, documentation prepared by the

material manufacturer affirming compliance with a specificationmust be obtained for all materials.Where a material manufacturer has an appropriate quality-assurance system, certified by a competent body establishedwithin the Community and having undergone a specificassessment for materials, certificates issued by the manufacturer

39

-

7/30/2019 AFS 2005_2

40/66

AFS 2005:2

are presumed to certify conformity with the relevant requirementsof this section.

SPECIFIC REQUIREMENTS FOR CERTAIN DEVICES

In addition to the applicable requirements of sections 1 to 4, thefollowing requirements apply to the pressure equipment coveredby sections 6.

6. Piping

Design and construction must ensure:

(a) that the risk of overstressing from inadmissible freemovement or excessive forces being produced on flanges,connections, compensators, bellows, hoses and other partsincluded in the pipeline, is adequately controlled by means

such as support, constraint, anchoring, alignment and pre-tension;

(b) that where there is a possibility of condensation occurringinside pipes for gaseous fluids, means are provided fordrainage and removal of deposits from low areas to avoiddamage from water hammer or corrosion;

(c) that due consideration is given to the potential damage fromturbulence and formation of vortices; the relevant parts ofpoint 2.7 are applicable;

(d) that due consideration is given to the risk of fatigue due tovibrations in pipes;

(e) that, where fluids of Group 1a are contained in the piping,appropriate means are provided to isolate 'take-off` pipes thesize of which represents a significant risk;

40

-

7/30/2019 AFS 2005_2

41/66

AFS 2005:2

(f) that the risk of inadvertent discharge is minimised; the take-off points must be clearly marked on the permanent side,indicating the fluid contained;

(g) that the position and route of underground piping is at leastrecorded in the technical documentation to facilitate safemaintenance, inspection or repair.

7. Specific quantitative requirements for certain devices

The following provisions apply as a general rule. However,where they are not applied, including in cases where materialsare not specifically referred to in point 7.1.2 and no harmonisedstandards are applied, the manufacturer must be able tootherwise demonstrate that appropriate measures have beentaken to achieve an equivalent overall level of safety.

The provisions laid down in this section supplement the essentialrequirements of sections 1 to 6.

7.1. Allowable stresses

7.1.1. Symbols

Re/t, yield limit, indicates the value at the calculation temperatureof:- the upper flow limit for a material presenting upper and lower

flow limits,- the 1.0% proof strength of austenitic steel and non-alloyed

aluminium,- the 0.2% proof strength in other cases.

Rm/20 indicates the minimum value of the ultimate strength at

20 C.Rm/t designates the ultimate strength at the calculationtemperature.

7.1.2. The permissible general membrane stress forpredominantly static loads and for temperatures outside the

41

-

7/30/2019 AFS 2005_2

42/66

AFS 2005:2

range in which creep is significant must not exceed the smallerof the following values, according to the material used:

(a) in the case of ferritic steel including normalised (normalisedrolled) steel and excluding fine-grained steel and speciallyheat-treated steel, 2/3 of Re/t and 5/12 of Rm/20 ;

(b) in the case of austenitic steel:

-if its elongation after rupture exceeds 30 %, 2/3 of Re/t

- or, alternatively, and if its elongation after ruptureexceeds 35 %, of Re/t and of Rm/t;

(c) in the case of non-alloy or low-alloy cast steel, 10/19 of Re/tand 1/3 of Rm/20;

(d) in the case of aluminium, 2/3 of Re/t;

(e) in the case of aluminium alloys excluding precipitationhardening alloys, 2/3 of Re/t and 5/12 of Rm/20 .

7.2. Joint coefficients

For welded joints, the joint coefficient must not exceed thefollowing values:

(a) for equipment subject to destructive and non-destructivetests which confirm that the whole series of joints show nosignificant defects: 1,

(b) for equipment subject to random non-destructive testing:0,85,

(c) for equipment not subject to non-destructive testing other

than visual inspection: 0,7.

If necessary, the type of stress and the mechanical andtechnological properties of the joint must also be taken intoaccount.

42

-

7/30/2019 AFS 2005_2

43/66

AFS 2005:2

7.3. Pressure limiting devices, particularly for pressurevessels

The momentary pressure surge referred to in point 2.11.2 mustnot exceed 10 % of the maximum allowable pressure.

7.4. Hydrostatic test pressure

For pressure vessels, the hydrostatic test pressure referred to in3.2.2 must be no less than:

(a) that corresponding to the maximum loading to which thepressure equipment may be subject in service, taking intoaccount its maximum allowable pressure (PS) and itsmaximum allowable temperature (TS), multiplied by thecoefficient 1,25, or

(b) the maximum allowable pressure multiplied by the coefficient

1,43, whichever is the greater.

Vacuum vessels are tested with the vacuum for which the vesselis designed.

7.5. Material characteristics

Unless other values are required in accordance with othercriteria that must be taken into account, a steel is considered assufficiently ductile to satisfy point 4.1 (a) if, in a tensile testcarried out by a standard procedure, its elongation after ruptureis no less than 14 % and its bending rupture energy measured

on an ISO V test-piece is no less than 27 J, at a temperature notgreater than 20 C but not higher than the lowest scheduledoperating temperature.

43

-

7/30/2019 AFS 2005_2

44/66

AFS 2005:2

General Recommendations issued by theSwedish Work Environment Authority forthe implementation of its Provisions onManufacture of Certain Vessels, Pipingand Installations

The following General Recommendations are issued by the

Swedish Work Environment Authority concerning implementationof its Provisions on Manufacture of Certain Vessels, Piping andInstallations (AFS 2005:2).

General Recommendations have different legal status fromProvisions. They are not mandatory. Instead they serve toelucidate the meaning of the Provisions (e.g. by explainingsuitable ways of meeting the requirements, giving examples ofpractical solutions and procedures) and to providerecommendations, background information and references.

Background

These Provisions on Manufacture of Certain Vessels, Pipingand Installations, together with the Provisions (AFS 1999:4) onPressure Equipment, supersede the design and manufacturesections of the Provisions (AFS 1999:6) on Pressure Vesselsand Other Pressure-retaining Devices. The Provisions onPressure Equipment have transposed the Pressure EquipmentDirective 97/23/EC to Swedish law. Their contents also includerules on design and manufacture. The Provisions on PressureVessels and Other pressure-retaining devices also included ruleson the design and manufacture of a number of devices excludedfrom the scope of the Provisions on Pressure Equipment.Instead those rules are now contained in the present Provisions.With the entry into force of the new Provisions, the Piping Code(AFS 1994:36) and Notice 1978:37 from the National Board ofOccupational Safety and Health will also be repealed.

The Directive 97/23/EC of the European Parliament and of theCouncil of 29 May 1997 on the approximation of the laws of the

44

-

7/30/2019 AFS 2005_2

45/66

AFS 2005:2

Member States concerning pressure equipment addresses risksentailed by devices (pressure equipment) which aremanufactured and placed on the market to be freely delivered toall countries of the EEA. The present Provisions deal mainly withhazards of technical devices and systems containing largequantities of dangerous fluids which can kill or injure employees.Provisions on measures to be taken to prevent major emissionsof dangerous substances are contained in the Provisions of theWork Environment Authority (AFS 2001:10) on Prevention ofmajor Accidents Involving Chemicals (AFS 2001:10). ThoseProvisions are based on Council Directive 96/82/EC of 9December 1996 on the control of major-accident hazardsinvolving dangerous substances. They apply, however, toworkplaces and, depending on the quantities in which dangeroussubstances are present in the workplace, contain stipulationsconcerning risk analysis and safety reporting when newinstallations are erected. They do not, however, provide specifictechnical rules on the subjects of design, manufacture andconstruction. The present Provisions contain rules on the design,manufacture and erection of devices and installations where,according to the Directive (97/23/EC), risks cannot be deemed to

exist by reason of pressures but where risks are present due tothe devices and installations containing large quantities ofdangerous substances (fluids).

Certain kinds of manufacture and certain objects are excludedfrom the scope of the EC Directive (97/23/EC) despite thepresence of risks due to pressure. For example, part of thepreamble to the Directive reads: On the other hand, thisDirective does not cover the assembly of pressure equipment onthe site and under the responsibility of the user. This exception,as the Work Environment Authority sees it, is founded on themain purpose of the Directive being to regulate devices and

assemblies which are commercial commodities available on themarket, and not installations which are constructed on site underthe users responsibility. The same Directive makes a similarexception, even where pressure may be considered to poserisks, for pipelines. Rules for the design and manufacture of suchinstallations and piping are contained in the present Provisions.

45

-

7/30/2019 AFS 2005_2

46/66

AFS 2005:2

Guidance on certain sections

General

Guidance on Section 1These Provisions apply to the design and manufacture ofvessels excluded from the scope of the Provisions (AFS 1999:4)on Pressure Equipment and the Provisions (AFS 1993:41) onSimple Pressure Vessels. Vacuum vessels, tanks and low-

pressure gas tanks are vessels for which these Provisions definespecial requirements.

The Provisions also apply to the design and manufacture ofpiping excluded from the scope of the Provisions on PressureEquipment. Pipelines are piping of the kind for which specialrequirements are laid down in these Provisions.

The Provisions also apply to the erection and assembly ofinstallations assembled on site under the responsibility of theuser. They are applicable to installations containing:

pressure equipment within the scope f the Provisions on

Pressure Equipment, simple pressure vessels within the scope of the

Provisions on Simple Pressure Vessels,

vacuum vessels, tanks and low-pressure gas tankscoming within the scope of the present Provisions.

If a manufacturer chooses to assume manufacturersresponsibility for an installation in its entirety, this can make it anassembly excluded from the scope of the present Provisions.Instead it must then meet the requirements laid down in theProvisions on Pressure Equipment.

When pressure equipment and assemblies manufactured anddelivered in compliance with the Provisions on PressureEquipment (or corresponding rules of some other country withinthe EEA) are incorporated in a processing plant or protectioncircuit, the present Provisions apply, not to their manufacture andfinal inspection, but solely to their assembly in the processingplant or protection circuit.

46

-

7/30/2019 AFS 2005_2

47/66

AFS 2005:2

When simple pressure vessels manufactured and delivered incompliance with the Provisions on Simple Pressure Vessels (orcorresponding rules of some other country within the EEA) areincorporated in a processing plant or pressure containmentcircuit, the present Provisions apply, not to their manufacture andfinal inspection, but solely to their assembly in the processingplant or protection circuit.

Rules corresponding to AFS 1999:4 in some other country of theEEA are defined as the rules which the country concerned hasintroduced for transposing Directive 97/23/EC of the EuropeanParliament and of the Council of 29 May 1997 on theapproximation of the laws of the Member States concerningpressure equipment to its national legislation.

Definitions

Guidance on Section 2

The terms taken from the Provisions on Pressure Equipment are

identically defined for present purposes. The same definitionsare also employed in the Provisions of the Work EnvironmentAuthority on Inspection of Pressure Retaining Devices.

Assembly An assembly can take the form of aprocessing plant or some other part of theestablishments installation incorporatingpressure equipment which have beenassembled by a manufacturer, under hisresponsibility, and delivered to the user incompliance with the rules of the EUPressure Equipment Directive. An

installation without any such pressure-equipment, e.g. a pneumatic assemblycomprising simple pressure vessel withsafety accessories, cannot become anassembly in this sense of the term.

47

-

7/30/2019 AFS 2005_2

48/66

AFS 2005:2

Installation This term refers to the system of allpressure retaining devices existing in theactive sphere of a specific workplace(establishment). The term workplaceimplies the existence of an employer incontrol of the same. Permanentworkplaces are listed in a register kept byStatistics Sweden (SCB), which allotsthem CFAR numbers.

Tank The term liquid as used here refers tofluid in the liquid state. A vessel intendedfor condensed gas with a vapour pressure(absolute pressure) not exceeding 1,513bar at the highest service temperature, is atank if no extra gas pressure has beenadded. A tank of this kind can, forexample, be an insulated vessel in whichgas is kept in the condensed state byallowing it to slowly boil down. Vessels forliquids having a higher vapour pressure at

the maximum service temperature (e.g. anLP gas storage tank which has risen toroom temperature) are pressure vesselswithin the scope of the Provisions onPressure Equipment. Section 3 of theProvisions on Pressure Equipmentexcludes tanks from the scope of thoseProvisions.

Fluid A solid substance which has absorbed orotherwise bound a gas or a liquid is ipsofactonot a fluid. Dynamite is a possible

instance of this type of solid, consisting asit does of liquid nitro-glycerine absorbed insolid kieselguhr.

48

-

7/30/2019 AFS 2005_2

49/66

AFS 2005:2

Low-pressuregas tank A gasometer is one example of a low-

pressure gas tank. Section 1 of theProvisions on Pressure Equipmentexcludes low-pressure gas tanks from thescope of those Provisions.

Natural gas Natural gas is normally taken to mean gasconforming to Deutsche Vereinigung desGas und Wasserfasches e.V. (DVGW)Technische Regeln, Arbeitsblatt G 260,edition of January 2000, and thespecifications in table 3 of the same.

Processing plant Processing plant can be instanced with aboiler unit, an air conditioning and heatpump installation or a pneumaticinstallation.

Pipeline Section 3 of the Provisions on PressureEquipment excludes pipelines from the

scope of those Provisions. The Provisionson Pressure Equipment also lay down thatstandard pressure equipment such as maybe found in pressure reduction stations orcompression stations do not count as partof the pipeline.

Open tank In order for the gas pressure above thesurface of the liquid not to be deemed todeviate significantly from atmosphericpressure, the open connection to theatmosphere should be such that the

pressure above the surface of the liquidcannot exceed atmospheric pressure bymore than 0,03 bar or fall below it by morethan 0,0065 bar.

49

-

7/30/2019 AFS 2005_2

50/66

AFS 2005:2

Vessels and piping

Guidance on Section 3

Classification of contents agrees to a great extent with fluidgroups 1 and 2 in the Provisions on Pressure Equipment, savethat in these Provisions a few risk phrases have been added andthe designations accordingly changed to 1a and 2a. But the

classification remains the same as in the Provisions of the WorkEnvironment Authority (AFS 2005:3) on Inspection of Pressure-retaining Devices. Further guidance on the classification will befound in the guidance on AFS 2005:3.

In the case of contents with the following risk phrases, only thosewith the danger codes mentioned in Section 3 are classified as1a, while the other danger codes mentioned here are classifiedas 2a:

corrosive R34

carcinogenic R40

mutagenic R68 toxic to reproduction R62, R63

Guidance on Section 4

For vacuum vessels, tanks, low-pressure gas tanks and piping,the present Provisions define three levels of requirement.

All devices must comply with the general provisions onSection 7.

Those subject to requirement G must meet the essentialsafety requirements of Section 8.

Those subject to requirement K must undergo designcontrol and production control as referred to in Sections10 and 11.

50

-

7/30/2019 AFS 2005_2

51/66

AFS 2005:2

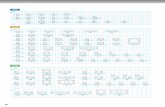

Classification in tabulated form

Vessels

1a G K&G

2a T 65C G K&G

0 1,000 5,000 10,000 50,000 100,000 500,000 Litres

Guidance on Section 5

A vessel which can be classified by more than one criterion andwhich consists of two or more chambers differing in volume orcontents (of class 1a and 2a) or having different maximumoperating temperatures, is classified as being subject torequirement G or K if any one of its chambers is subject torequirement G or K. A vessel should not, however, beconsidered to be intended or designed for a particular purpose or

type of contents if the facto making it classifiable as intended forthat purpose only occurs very occasionally and has little bearingon safety. A vessel can be considered as having two or morechambers if these are not interlinked. Chambers which are in thesame vessel and are interlinked are added togethervolumetrically for classification purposes. Vessels which are alsopressure vessels within the meaning of the Provisions onPressure Equipment are completely excluded, under Section 1,from the scope of the present Provisions.

51

-

7/30/2019 AFS 2005_2

52/66

AFS 2005:2

Guidance on Section 6

Diagrams 6-9 from Annex 2 of the Provisions on PressureEquipment, with the classification inserted.

Diagram 6

52

-

7/30/2019 AFS 2005_2

53/66

AFS 2005:2

Diagram 7

53

-

7/30/2019 AFS 2005_2

54/66

AFS 2005:2

Diagram 8

54

-

7/30/2019 AFS 2005_2

55/66

AFS 2005:2

Diagram 9

In order to judge whether a pipeline is positioned in such aspecially protected manner as to afford adequate safety, themanufacturer must analyse the risks entailed by the piping,which is a requirement for pipelines coming under requirementG, and judge whether the way in which it is positioned affordsadequate protection for the general public and employees. Themodes of positioning for such piping can, for example, comprise

burying it in the ground at sufficient depth,

placing it in a culvert or special conduit to which no onehas access while operations are in progress,

making it double-jacketed, so that the surroundings willbe protected by an outer tube of sufficient mechanicalstrength.

District heating distribution systems can constitute the type ofpipeline referred to in this section.

55

-

7/30/2019 AFS 2005_2

56/66

AFS 2005:2

Guidance on Section 7

The requirement that the devices be designed and manufacturedin compliance with sound engineering practice means the designand manufacture complying with principles accepted on thebasis of experience which have proved to afford adequatesafety. In this connection account should be taken of technicaland scientific progress and of the experience accruing frombreakdowns and incidents. It is important that the measure takenin order to comply with the general provisions should be viewedin relation to the consequences of a possible breakdown.Examples of sound engineering practice are to be found instandards and codes.

It is important that pressure retaining devices should be made ofa safe material for the prevention of leakages and breakdowns.The material should therefore

be correctly described in the specification of materials,

have known and documented properties,

have the requisite mechanical strength at maximumservice temperature,

have the requisite impact strength at minimum servicetemperature,

have the requisite fracture elongation,

have good ageing resistance,

have good weldability (where applicable),

have good resistance to the media and environmentinvolved.