AE 08 Shinzato

-

Upload

cesar-augusto-miranda -

Category

Documents

-

view

217 -

download

0

Transcript of AE 08 Shinzato

-

7/28/2019 AE 08 Shinzato

1/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

1

PERFORMANCE OF SUGARCANEHARVESTERS IN OKINAWA

By

YOSHIAKI SHINZATO1, KAZUMI UEHARA2 and MASAMI UENO3

1Okinawa Prefectural Agricultural Research Center,

820 Makabe, Itoman, Okinawa 901-0336, Japan2Okinawa Prefectural College of Agriculture,

1-15-9 Okita, Nago-city, Okinawa 905-0019, Japan3Faculty of Agriculture, University of the Ryukyus,

1 Senbaru, Nishihara-cho, Okinawa 903-0213, [email protected]

KEYWORDS: Sugarcane Harvester,Small Size, Compaction, Ratooning.Abstract

MORE THAN 300 SMALL-SIZED sugarcane harvesters (SSHs) are used in Okinawa andKagoshima in Japan. Engine output is 5095 kW and the weight of machines rangesfrom 4 t to 7 t. There are several models of small machines developed by three Japaneselocal companies and one Australian company. In Okinawa, 97 large- and middle-sizedharvesters and 165 SSHs were used in the 201011 (DecemberMarch) harvestingseason to mechanically harvest 40% of the sugarcane fields (2516 ha and 128 000 t).Sugarcane crops in Okinawa are larger than in Kagoshima, especially summer plantcane, and this creates problems in the operation of SSHs. These were field-tested to

evaluate their performance and adaptability with the aim of improving their operationunder wet conditions caused by frequent rains during the harvesting season. SSHs

performed better than larger machines in wet fields, harvesting 120 t/ha of yield andlodged sugarcane. Harvesting losses of SSHs were almost the same as those of middle-sized harvesters (MSHs) in small fields with narrow headlands. Stool damage, stools

pulled out and extraneous matter in wet fields where SSHs were used were lower thanwhere MSHs were used. Because MSHs caused higher soil compaction and deepertracks than did SSHs, it was difficult to use small-size cultivators and two-wheeledtractors after harvesting by MSHs. However, these machinescould be used afterharvesting by SSHs without any difficulty. In addition, SSHs can work in the narrowrow spacings that result in increased productivity. Overall, it was shown that SSHs hadhigh adaptability in the wet sugarcane fields of Okinawa.

IntroductionSugarcane is grown in the 16 islands of Okinawa. Mechanised harvesting started in 1990

(Department of Agriculture of Okinawa Prefecture, 2011) in Okinawa Island, the main island ofOkinawa, but later than in the other islands. Aging of farmers and a shortage of labour haveaccelerated the adoption of mechanical harvesting.

Initially, medium-sized harvesters (MSHs) equipped with 150 kW engines were introduced.Green-cane harvesters were developed about 30 years ago and introduced to replace burnt-caneharvesters used in limited areas such as Minami-Daito Island.

MSHs have been adopted in some islands but, in many, mechanisation has not advancedbecause of the size of sugarcane fields; many less than 0.3 ha. To overcome such situations, a localcompany developed a small-sized green-cane harvester (SSH). The mass and engine power ofharvesters has tended to increase gradually because of the change to green-cane harvesting.

-

7/28/2019 AE 08 Shinzato

2/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

2

Guidelines for use of large-sized harvesters (LSHs) were developed to reduce extraneousmatter levels (as in Whiteing et al., 2001) and further improvements were made to minimise caneloss and the proportion of extraneous matter, especially roots and dirt (Davis and Norris, 2005; R.J.Davis et al., 2005). However, the configuration of the first generation of SSHs was not welldeveloped and their capacity of work was rather low. SSHs also had many performance problems,especially with extraneous matter, damage to stalks and stools and cane losses due to the small sizeof the machines, and frequent interruptions to operation through choking have prevented their

practical use. Three local Japanese makers have continued considerable efforts to developcompetitive models, leading to the wide introduction of SSHs with improved performance. Theadoption of MSHs has remained restricted because there are few areas in Okinawa to utilise theirincreased mass and power.

Compaction over the stools leads to considerable yield loss, and this can be minimisedthrough controlled traffic and wider row spacings such as 1.75 m (Torres and Pantoja, 2005). Incontrast, we expect that SSHs will enable us to avoid stool damage and soil compaction because of

their lower mass and narrow width of the body. The narrower row spacing and lower soilcompaction should result in an increase or maintenance of the yields achieved with manualharvesting. SSHs also show superior trafficability in wet field conditions; on the first day afterrainfall of about 20 mm, crawler-type SSHs could operate without noticeable trouble while MSHsstopped operation (Akachi et al., 1994). In addition, the initial cost of SSHs is relatively lowcompared with that for MSHs or LSHs. This is somewhat offset because farmers pay more forcontract harvesting with SSHs than with larger machines.

The adaptability of SSHs to the wet, narrow and high yield sugarcane fields is discussed inthis paper. In addition, the performance of associated small-sized tractor-attached cultivators orstable-shavers and two-wheeled tractors was checked.Materials and methods

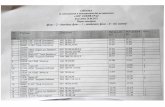

In Okinawa, sugarcane harvesters are classified according to engine output, row spacing towhich they are adapted and the size of the farms on which they are used. SSHs have a mass belowabout 8 t, MSHs 811 t and LSHs above 11 t. Other characteristics of harvesters used in Okinawaare given in Table 1.

Table 1Characteristics of different groups of harvesters used in Okinawa.

Performance tests of SSHsWe carried out three field tests of the performance of SSHs in Miyako Island (Table 2).

Here, summer-plant cane is the main cropping type and it has a reasonably high yield because of an18-month growth period. Spring-plant cane grown for 12 months was used in one trial as anadditional check of the performances of SSHs. Two types of SSHs were tested for performance andadaptability in those fields and were compared with one MSH (Table 3). Ground speed, capacity ofwork, productivity and extraneous matter (%) were evaluated; the Matumoto SSH was checked onlyfor extraneous matter in the third trial.

-

7/28/2019 AE 08 Shinzato

3/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

3

Table 2Characteristics of the test fields in Miyako Island.

Parameter First trial Second trial Third trial

DatePlanting

Row spacing (m)VarietyCane yield (t/ha)

19 January2004Summer

1.34NiF866

20 January 2004Summer

1.22NiF8122

20 January 2004Spring

1.38NiF868

SSHs are equipped with a bag at the rear to store about 1 t of chopped billets. One operatorwas sufficient because the accompanying transporter was not necessary. Another person wouldusually assist in the operation, especially for changing the bag.

Table 3Specifications of SSHs and MSH tested.

Uotani UT-120K Matumoto MCH-30-W-E

Uotani UT-170-A

SSH MSH

Parameter Uotani UT-120KMatumoto MCH-30-

W-E

Uotani UT-170-A

Length (m) 6.05 6.96 7.80

Width (m) 2.80 2.25 2.50

Height (m) 4.15 3.70 4.35

Mass (t) 7.95 6.20 8.90

Engine output (kW/rpm) 78/2200 71.3/2200 135/2200

Contact area (m ) 1.93 1.60 0.92

Running gear Crawler Crawler Wheel

Ground contact pressure (kPa) 40 38 96

Adaptability of SSHs

In Okinawa, it is generally cloudy and rainy and the temperature is relatively low during theharvesting season. Most sugarcane fields are small with no or narrow headlands and some are notrectangular. Soils are heavy clays.

We compared the adaptability of a SSH with that of a MSH (Table 4) tested on 2 and6 March 2004, respectively. The test fields had a heavy clay soil called Jaagaru and grew variety

Ni11 yielding 83 t/ha. The crop was a ratoon with 1.4 m row spacing.Soil-moisture content was measured before the test. Soil-penetration resistance was

measured by a SR-2 type Soil Penetrometer DIK-5502 (Daiki Rika Kogyo Co., Ltd, Japan) beforeand after harvesting.

Ratooning practices such as subsoiling, inter-row cultivating and hilling-up were carried outafterwards as normal, while a non-subsoiled part in the test field was prepared to evaluate thesubsoiling effect on growth and yield after harvesting by a SSH and MSH. Cane growth wasmeasured in May, 2 months after harvest. The yield and growth of the ratoon crop were determinedat the following harvest.

-

7/28/2019 AE 08 Shinzato

4/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

4

Table 4Specifications of the SSH and MSH harvesters compared foradaptability and outline of the test field.

UT-120KW

(SSH)

TS3500

(MSH)

55mrow

direction

Small sizeharvester

Road used head land(Width : 4.9m)

Middle sizeharvester

35m

Length (m) 5.60 7.15

Width (m) 1.70 2.60

Height (m) 4.30 3.62

Mass (t) 6.85 9.34

Engine output(kW/rpm)

78/2200 170/2400

Running gear Crawler Half-track

Performance test of a small sugarcane cultivatorWheeled LSHs and MSHs and the tractor-attached high-dump wagons cause considerable

soil compaction. Inter-row cultivation using the small-sized machines after harvesting is difficultbecause of this intensive compaction. In Kita-Daito Island, some farmers have no middle-size orlarge-size tractors and frequently do not cultivate ratoons. In Okinawa Island, farmers oftencultivate fields of less than 1 ha. Small machines, such as two-wheeled tractors, are popular.

The adaptability of SSHs to minimise compaction was determined by measuring the shapeof surface ruts after harvesting with a LSH or a SSH. Soil-penetration resistance was measured atthe same time. We also checked whether different tractors are capable of inter-row cultivating after

harvesting by a SSH. Three machines were checked after harvesting in Okinawa Island: a two-wheeled tractor, a small tractor with an attached rotary tiller, and a small tractor with an attachedstubble shaver. The small tractor with attached stubble shaver allows subsurface application offertilisers and application of herbicide at the same time (Table 5).

Table 5Specifications of machinery used for ratoon cultivation.

Two-wheeled tractorSmall tractor with attached rotary

tillerSmall tractor with attached stubble

shaver

Overall width (m) 0.85 1.10 1.10

Working width (m) 0.80 0.80 0.60

Power (kW) 6.6 12.5 12.5

PracticesCultivating,hilling-up

Cultivating, hilling-upStubble-shaving, subsurfaceapplication, of fertilisers (10 cmdepth), applying herbicide

Tillage depth (cm) 1520 1520

Results and discussion

Performance test of SSHsSSHs were tested in fields with heavily lodged and tangled cane caused by typhoons passing

close to Miyako Island. There was 16 mm of rain on 16 January 2004, 3 days before the first trial.

-

7/28/2019 AE 08 Shinzato

5/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

5

On 19 January, there was 8 mm of rain at trial sites 1 and 2, and on 20 January there was 4 mm ofrain at the third trial site.

The SSHs could harvest the sprawled and tangled sugarcane with cane yields up to 120 t/ha.They could also operate in all of the three trials, despite the high soil moisture that meant MSHscould not operate.

In the three trials, the average ground speed and the productivity of the Matumoto andUotani machines were about 0.40 m/s and about 6.4 t/h, respectively (Table 6). These were about75% and 80% of those achieved by a MSH in other tests (Akachi et al., 1998). The extraneousmatter produced by MSHs was more than 20% under similar conditions as in the test fields and theaverage extraneous matter in Miyako Island is about 1516% (Okinawa Seito, 2006, 200809). Theextraneous matter produced by the tested SSHs was lower than that normally produced by MSHs,although that from the Uotani harvester was higher than that from the Matumoto machine in each ofthe three trials (Table 6).

SSHs demonstrated the superior performance under wet soil conditions, while MSHs were

forced to cease work because of deep ruts. Although the capacity of SSHs was lower than that of theMSH, the total amount harvested was almost the same because the SSHs could keep working longerduring the harvesting season in Miyako Island (Department of Agriculture of Okinawa Prefecture,2005). Therefore, we recommended replacing the wheel-type MSHs with crawler-type SSHs.

Table 6Performance of SSHs in the three field trials.

Trial MachineGround speed

(m/s)Capacity ofwork (h/ha)

Productivity (t/h)Extraneousmatter (%)

FirstMatumoto 0.39 12.7 5.1 15.1

Uotani 0.44 10.6 6.1 22.7

SecondMatumoto 0.30 20.8 5.9 11.6

Uotani 0.27 16.9 7.2 17.5

ThirdUotani 0.50 8.8 7.8 16.8

Matumoto 12.5

Adaptability of SSHsIt was raining on 2 March and there had been 10 mm of rain the day before, so only the SSH

could operate. The MSH could only be tested 4 days later. Soil moisture was 43% when the SSHwas tested and 39% when the MSH was tested.

The SSH could turn easily using the headland side road. However, the MSH had to make acomplicated turn because the road was too narrow this meant that the MSH required a longerworking time than the SSH (Table 7). The capacity and the other performance indices showed the

SSH to be superior (Table 7). There was no significant difference in harvesting losses.Overall, the MSH showed poor performance under such wet field conditions and in a smallfield.

Table 7Performance comparison of the different size harvesters.

MachineGround

speed (m/s)Capacity ofwork (h/ha)

Productivity(t/h)

Extraneous matter(%)

Harvesting loss(%)

SSH 0.43 11.5 7.2 8.1 7.1

MSH 0.45 20.8 4.0 23.7 5.5

The soil penetration resistance after harvesting by the SSH was less than that under theMSH (Figure 1). This means that soil compaction caused by the operation of mechanical harvesteroperation could be reduced considerably when SSHs are used. In addition, the traffic of largemachines such as the wagon and the dumper over the stools results in further significant compaction

-

7/28/2019 AE 08 Shinzato

6/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

6

(Torres et al., 1989). Stool damage and yield reduction by SSH harvesting was less than that for theMSH harvesting.

Fig. 1Penetration resistance after mechanical harvesting interesting patternsrelativelyhigher surface compaction with MSH within depth of 020 cm.

The MSH found it difficult to enter the field from the headland each time because the fieldwas lower than the road. This resulted in some stools being removed by the crop lifters and manystalks were damaged by the basecutters or other parts of the MSH. This meant that there wereconsiderable gaps in those parts of the field close to the road. Stalk populations at the followingharvest were 74 000/ha for the SSH and 63 000/ha for the MSH, while there was little difference in

the height or diameter of stalks (Table 8). Hence, the resultant cane yield (21 January 2005) washigher where the SSH had been used. Subsoiling after harvest further improved the subsequentyield of the ratoon cane after harvesting by the SSH.

Table 8 Performance of the subsequent ratoon crop (21 January 2005) afterharvesting with different machines.

ParameterMSH

(Subsoiling)SSH

(Subsoiling)SSH

Stalk population (/ha) 63 000 74 000 73 000Stalk height (m) 2.2 2.1 2.0Stalk diameter (mm) 21 21 21Cane yield (t/ha) 58 78 65

Performance test of a small sugarcane cultivatorMechanical farming and harvesting in wet soil conditions causes deep surface ruts and

compaction. Usually, a tractor of about 90 kW power is required to repair such ruts through acombination of paratill/scarifying implements (H.B. Davis et al., 2005). Small-sized machines areexpected to do this in Okinawa.

Soil penetration resistance reached 3.0 MPa due to the long-term use of the LSH in Kita-Daito Island (Figure 2). The operation of the SSH did create deep surface ruts in wet soilconditions, but the overall impact was less than that of the heavier harvester (Figure 2).

Miyoshi (1972) showed that elongation of the roots of most crops is obstructed when soilhardness by Yamanakas soil hardness test is more than 2223 mm and Ishikawa et al. (1999)showed that sugarcane roots can not penetrate into a soil layer with more than 2030 mm hardness.The value of Yamanakas soil hardness can be converted into the equivalent hardness (MPa) as

-

7/28/2019 AE 08 Shinzato

7/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

7

measured by SR-2 tester (AFFRC, 1968). The hardness of 3.0 MPa that we found after operation ofthe LSH corresponds to about 26.5 mm, which is close to the limit of hardness where roots can

penetrate into soil.In addition, the small-size cultivator is difficult to use, and the two-wheeled tractor is

unusable for the repair of surface ruts.

kPaane sPooposiPion

d

hcm

0

3000

1000

2000

nPer-row

n er-row

500

1500

2500

150cm 150cm 150cm 150cmCane sPool

posiPionn er-row

nPer-row

60

40

20

0

0

10

20

0 50 100 150 200 2500

10

20

0 50 100 150 200 250

Cane sPooolposiPion

Surface ruPSSH

(cm)(cm)

Depth(cm)

Surface ruPSSH

Cane sP ooolposiPion

Surface ruPLSH

Surface ruPLSH

After SSH After LSH

Fig. 2Soil profiles of penetration resistance and shapes of surface ruts.

Harvesting losses occur through crushing of lodged stalks, high basecutting, missed cutting,and dropping of billets from the machine. These are related to the cane stand angle. Shinzato (2006)found a linear relation between stand angle of the stalk and harvesting loss obtained in the operationof SSHs (The harvesting losses increased for the heavily lodged cane:

Y = 0.09 X + 5.8R2 = 0.577* (P

-

7/28/2019 AE 08 Shinzato

8/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

8

In addition, germination from deep positioning of the stool allows cane not only to stayerect, but also to be heavier, taller and thicker (Nakasone and Oshiro, 1984). Therefore, we advocatehilling-up of both plant and ratoon cane as an important practice in improving harvesting.

The small-size tractor with a cultivator or stubble-shaver and the two-wheeled tractor wereable to operate without any trouble after harvesting by SSH (Table 8). Inter-row cultivation afterharvesting by MSH was difficult because of the small mass of tractor.

The capacity of work of the two-wheel tractor and small tractor are one-third of that of themiddle size tractor (approximately 35 kW). However, few farmers have middle or large tractors,most having a two-wheel tractor or a small tractor. A SSH is advantageous for such farmers, but thecapacity of SSHs decreases significantly in weedy cane fields, so several cultivations are necessaryfor weed control.

Table 8Performance of a small tractor and two-wheel tractor after harvesting with SSH.

Machine

Ground speed

(m/s)

Field working efficiency

(%)

Capacity of work

(h/ha)

One-way or Two-

waySmall tractor andstubble-shaver

0.32 81.8 10.2 One-way

Small tractor andcultivator

0.17 78.3 14.7 One-way

Two-wheeled tractor 0.13 95.0 14.7 Two-way

ConclusionsIn Okinawa, SSHs could harvest heavily lodged green cane with yields up to about 120 t/ha

in spite of the wet field conditions. SSHs showed superior performance, such as productivity,capacity of work and removal of extraneous matter, in the small and wet fields. MSHs could not

cope with such bad conditions.Soil compaction and the disturbance of the soil surface by SSHs were less than those by

MSHs. In addition, ratoon cane yields were higher the year following harvesting by SSHs ratherthan harvesting by MSHs. Even higher subsequent yields were obtained when subsoiling was usedafter SSH harvesting. These yields were significantly higher than after MSH harvesting andsubsoiling.

Small tractors with an attached cultivator or stable-shaver and two-wheel tractors couldoperate without any trouble after harvesting by SSHs.

Overall, SSHs were superior than MSHs in Okinawa because of the rainy and cloudyweather during the harvesting season and the small fields. We recommend that farmers replace the

wheel-type LSH/MSHs with the crawler-type SSHs.Acknowledgements

We thank Mr Toru Akachi for his help and expertise with sugarcane harvesters. The help andassistance of staff members of Miyako Agricultural Extension Centre is gratefully appreciated.

REFERENCESAgriculture, Forestry and Fisheries Research Council (AFFRC). (1972). The measurement of

soil properties. Yokendo, Tokyo, 312 pp.Akachi, T., Ishiki, G., Oshiro, T. and Miyahira, M. (1994). The adaptability of sugarcane

harvester for the rain Bull. Stud. Sugarcane, Assoc. Okinawa Sugarcane Stud.,21: 558-559.

Akachi, T., Morita, T., Miyahira, M. and Shoda, M. (1998). Characteristics and performances ofmajor sugarcane harvesters introduced to Okinawa. Okinawa Prefectural AgriculturalResearch Center. pp. 920.

-

7/28/2019 AE 08 Shinzato

9/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

9

Davis, H.B., Friday, N.W. and Dey, A.D. (2005). Progress with mechanising field operations in theGuyana sugar industry. Proc. Int. Soc. Sugar Cane Technol., 25(2): 364370.

Davis, R.J. and Norris, C.P. (2005). An investigation of the feeding characteristics of the forward-feeding zone of chopper harvesters: development of a research harvester. Proc. Int. Soc.Sugar Cane Technol., 25(2): 316325.

Davis, R.J., Schembri, M.G. and Kingston, G. (2005). Optimising machine component layout forenhanced harvester feeding performance in lodged crops. Proc. Int. Soc. Sugar CaneTechnol., 25(2): 326331.

Department of Agriculture of Okinawa Prefecture. (2005). The annual report of sugarcaneproduction in Okinawa Prefecture 2004/2005. Okinawa Prefecture, Naha. pp. 6364.

Department of Agriculture of Okinawa Prefecture. (2011). The annual report of sugarcaneproduction in Okinawa Prefecture 2010/2011. Okinawa Prefecture, Naha. p. 73.

Ishikawa, T., Matsumoto, N., Kawashima, T. and Sugimoto, A. (1999). Crop roots and the hardsoil layer in northeast Thailand. Root Research, 8: 3538.

Miyoshi, H. (1972). Correlation between root system spreading in good soil condition and effectivesoil depth. Jap. Soc. Soil Sci. Plant Nutrit., 43(3): 9297Nakasone, S. and Oshiro, K. (1984). The development of ratoon practices. Bull. Stud. Sugarcane,

Assoc. Okinawa Sugarcane Stud., 12: 218219.Okinawa Seito Co., Ltd. (2006, 200809). The daily and annual report summary for sugarcane

harvesting. Okinawa Seito, Miyako.Shinzato, Y. (2006). Ratoon practices to increase sugarcane yields after harvest with small size

harvester. Proc. Assoc. Okinawa Sugarcane Stud. Ann. Meet., 33: 3845.Torres, J. and Pantoja, J.E. (2005). Soil compaction due to mechanical harvesting in wet soil.

Proc. Int. Soc. Sugar Cane Technol., 25(2): 332339.Torres, J.,Yang, S. and Villegas, F. (1989) . Soil compaction and sugarcane stool damage due to

semi-mechanised harvesting in the wet season. Proc. Int. Soc. Sugar Cane Technol.,20(2): 9921000.Whiteing, C., Norris, C.P. and Paton, D.C. (2001). Extraneous matter versus cane loss: finding a

balance in chopper harvested green cane. Proc. Int. Soc. Sugar Cane Technol.,24(2): 276-282.

-

7/28/2019 AE 08 Shinzato

10/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

10

PERFORMANCE DE RECOLTEUSES DECANNE A SUCRE A IN OKINAWA

Par

YOSHIAKI SHINZATO1, KAZUMI UEHARA2et MASAMI UENO3

1Centre de RechercheAgricole de la Prfecture dOkinawa,

820 Makabe, Itoman, Okinawa 901-0336, Japon2Centre de RechercheAgricole de la Prfecture dOkinawa,

1-15-9 Okita, Nago-city, Okinawa 905-0019, Japon3Facult dAgriculture, Universitde laRyukyus,

1 Senbaru, Nishihara-cho, Okinawa 903-0213, Japon

[email protected] CLES: Rcolteuse Canne Sucre,Petites Machines, Compactage, Repousses.

RsumPLUS DE 300 PETITES RCOLTEUSES de canne sucre (SSHs) sont utilises Okinawa et Kagoshima auJapon. Le rendement des moteurs est de 5095 kW et le poids des machines varie entre 4 et 7 t. Il y aplusieurs modles de petites machines dveloppes par trois entreprises Japonaises locales et une entrepriseAustralienne. A Okinawa, 97 rcolteuses de grande et moyenne taille et 165 SSHs ont t utilises durant lacampagne de rcolte 20102011 (dcembre mars) pour rcolter 40% des champs de canne sucre (2516 haet 128000 t). Les rendements canne Okinawa sont plus importantes qu Kagoshima, surtout la canne

vierge tablie en t, ce qui cause des problmes pour lutilisation des SSHs.Ces derniers ont t tests auchamp pour valuer leurs performances et adaptation dans le but damliorer leur opration en conditionshumides dcoulant de pluies frquentes pendant la rcolte.La performance des SSHs dans les champshumides avec un rendement de 120 t/ha et des cannes couches tait meilleure que celle des plus grossesmachines. Les pertes en cours de rcolte dans les petites parcelles avec des fourrires troites taient presqueles mmes quavec les rcolteuses de taille moyenne (MSHs). Larrachage et les dgts aux souches ainsi quela matire trangre dans les champs humides o les SSHs taient utilises taient infrieurs aux champsrcolts par les MSHs. Comme les MSHs causaient plus de compactage et laissaient des ornires plusprofondes que les SSHs, il tait difficile dutiliser des petits cultivateurs et des motoculteurs aprs une rcoltepar des MSHs. Toutefois, ces machines pouvaient tre utilises sans difficults aprs une rcolte par desSSHs. De plus, les SSHs peuvent oprer dans des espacements entre-rangs troits qui donnent une meilleureproductivit. Dans la globalit, il a t dmontr que les SSHs avaient une forte adaptabilit dans les champshumides de canne sucre dOkinawa.

-

7/28/2019 AE 08 Shinzato

11/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

11

DESEMPEO DE COSECHADORAS DECAA DE AZCAR EN OKINAWA

Por

YOSHIAKI SHINZATO1, KAZUMI UEHARA2 y MASAMI UENO3

1Okinawa Prefectural Agricultural Research Center,

820 Makabe, Itoman, Okinawa 901-0336, Japan2Okinawa Prefectural College of Agriculture,

1-15-9 Okita, Nago-city, Okinawa 905-0019, Japan3Faculty of Agriculture, University of the Ryukyus,

1 Senbaru, Nishihara-cho, Okinawa 903-0213, Japan

PALABRAS CLAVE: Cosechadora de Caa de Azcar,Tamao Pequeo, Compactacin, Socas.

ResumenMS DE 300 COSECHADORAS pequeas de caa de azcar (CPCA) son usadas en Okinawa yKagoshima en Japn. La potencia del motor es de 50-95 kW y el peso de estas mquinas fluctaentre 4 y 7 t. Hay varios modelos de mquinas pequeas desarrolladas por tres compaas locales

japonesas y una compaa australiana. En Okinawa, en el periodo de cosecha 2010-11 (Diciembre a

Marzo) se usaron 97 cosechadoras de tamao medio a grande y 165 CPCA con las cuales secosech mecnicamente el 40% de los campos de caa de azcar (2516 ha y 128 000 t). La caa deazcar en Okinawa es ms grande que en Kagoshima, especialmente las plantillas de verano, y estocrea problemas en la operacin de las CPCA. Estas fueron probadas en el campo para evaluar sudesempeo y adaptabilidad con el objetivo de mejorar su operacin bajo las condiciones hmedascausadas por las lluvias frecuentes durante la estacin de cosecha. Las CPCA se desempearonmejor en los campos hmedos que las mquinas grandes, cosechando hasta 120 t/ha de caavolcada. Las prdidas de cosecha de las CPCA en campos pequeos con zonas de volteo estrechasfueron casi las mismas que las de las cosechadoras de tamao mediano (CMCA). El dao a lascepas, cepas arrancadas y materia extraa en los campos hmedos donde se usaron CPCA fueronmenores que aquellos donde se usaron CMCA. Debido a que las CMCA causaron mayor

compactacin del suelo y huellas ms profundas que las CPCA, fue difcil usar cultivadorespequeos y tractores de dos ruedas despus de la cosecha con CMCA. Sin embargo, estas mismasmquinas pudieron ser usadas despus de la cosecha con CPCA sin ninguna dificultad. Adems, lasCPCA pueden trabajar con espacio entre surcos ms angosto lo que resulta en incremento de la

productividad. En general, se demostr que las CPCA tuvieron alta adaptabilidad a los camposhmedos de caa de azcar de Okinawa.

-

7/28/2019 AE 08 Shinzato

12/12

Shinzato Y. et al. Proc. Int. Soc. Sugar Cane Technol., Vol. 28, 2013______________________________________________________________________________________

12

DESEMPENHO DE COLHEDORAS DECANA-DE-ACAR EM OKINAWA

Por

YOSHIAKI SHINZATO1, KAZUMI UEHARA2 e MASAMI UENO3

1Okinawa Prefectural Agricultural Research Center,

820 Makabe, Itoman, Okinawa 901-0336, Japo2Okinawa Prefectural College of Agriculture,

1-15-9 Okita, Nago-city, Okinawa 905-0019, Japo3Faculdade de Agronomia, University of the Ryukyus,

1 Senbaru, Nishihara-cho, Okinawa 903-0213, Japo

PALAVRAS-CHAVE: Colhedora de Cana-de-Acar,Pequeno Porte, Compactao, Soqueira.

ResumoMAIS DE 300 COLHEDORAS de pequeno porte (SSHs) so usadas em Okinawa e Kagoshima noJapo. O rendimento do motor de 50-95 kW e o peso das mquinas varia de 4 a 7 toneladas. Hvrios modelos de mquinas compactas desenvolvidos por trs empresas japonesas locais e umaempresa australiana. Em Okinawa, 97 colhedoras de grande e mdio porte e 165 colhedoras de

pequeno porte foram utilizadas na safra 2010-11 (dezembro-maro) para colher mecanicamente40% das plantaes de cana (2516 ha e 128 000 t). As culturas de cana em Okinawa so maiores doque aquelas em Kagoshima, especialmente a cana planta de vero, e isso cria um problema naoperao das colhedoras de pequeno porte. Elas foram testadas em campo para avaliar odesempenho e a adaptabilidade com o objetivo de aprimorar sua operao sob condies deumidade causadas pelas chuvas frequentes durante a safra. As colhedoras de pequeno porteapresentaram melhor desempenho do que as colhedoras maiores em campos midos, colhendo com120 t/ha de rendimento e cana tombada. As perdas de colheita por colhedoras de pequeno porteforam praticamente as mesmas daquelas experimentadas por colhedoras de mdio porte em campos

pequenos com promontrios estreitos. Danos em touceiras, touceiras arrancadas e impurezas emcampos midos em que as colhedoras de pequeno porte foram utilizadas foram menores do que nos

locais em que colhedoras de mdio porte foram utilizadas. Pelo fato de as colhedoras de mdioporte causarem maior compactao no solo e deixarem trilhas mais profundas do que as colhedorasde pequeno porte, tornou-se difcil utilizar cultivadores de pequeno porte e tratores de duas rodasaps a colheita por colhedoras de mdio porte. Entretanto, essas mquinas poderiam ser utilizadasaps a colheita por colhedoras de pequeno porte sem qualquer dificuldade. Alm disso, ascolhedoras de pequeno porte podem operar em espaamentos estreitos entre linhas, o que resulta emmaior produtividade. De modo geral, comprovou-se que as colhedoras de pequeno porte possuemalta adaptabilidade nos campos midos com plantaes de cana de Okinawa.