Advenira AdvenGuard™ SDN Nanocomposite Coating …ASTM D5402) Pass - MEK, Toluene, Diesel fuel,...

Transcript of Advenira AdvenGuard™ SDN Nanocomposite Coating …ASTM D5402) Pass - MEK, Toluene, Diesel fuel,...

®

Advenira®AdvenGuard™ SpecificationSheet3.0 ©AdveniraEnterprises,Inc.2017AllRightsReserved

Thisdatasheetreportsvaluesbasedonlaboratorypreparedsamplesandshouldnotbeconsideredasaproductspecification.

Advenira®AdvenGuard™SDN®NanocompositeCoatingProductDescriptionAdvenGuard™SDN®nanocompositecoatinghasbeendevelopedasahighperformancebarriercoatingforcorrosionprotectionapplications.AdvenGuard™canbeusedinconjunctionwithconversionorgalvaniccoatingsorprimers,whenrequired,toprovidesuperiorcorrosionprotection.ProductFeatures• Colorless,transparent,withexcellentgloss.• SuitableforawiderangeofpHexposure,rangingfromstronglyacidicormildlyalkalineenvironments(pH0-10).

• Excellentresistancetohydrochloricacid,sulfuricacid,andsaltwater.

• Lowwateruptake.• Compatiblewithcommercialtopcoats.Abrasion:Excellentresistancetoabrasionandmechanicaldamage.Adhesion:Excellentondegreasedandcorrosionfreesurfaces,includingsteel,aluminum,galvanizedsteel,Mg-alloys,andstainlesssteel.

ChemicalResistance:Excellentresistancetoaqueoussaltsolutionsandawiderangeofindustrialchemicals.

PreferredSurfacePreparation:SSPC-SP5/NACE1WhiteMetalBlastCleaning;WJ-1,SC-1waterjetcleaning.

Coating:Canbedepositedbyspray,dip,androdmethods.Singlecomponent.

Curing:CoatingcanbecuredtofinalpropertieswithinminuteswithappropriateUVexposure.

SolutionProperties:Property Value(s)Color Colorless/TransparentCuringTime <5min.Wt%Solids 100%Viscosity 140-150cP@25°C

(Brookfieldcone/plate)SpecificGravity 1.1FilmThickness 10–150+µmCoverage 780m2/kg/µmShelfLife(unopened) 6+months(refrigerated)

CoatingPerformanceData:(50µmcoatingthicknessunlessnoted)Property ValueAbrasionResistance(ASTM4060)

6.5mg/1000cycles2µm/1000cycles(Taber5135,1kg,CS-10)

Pull-offAdhesion(ASTMD4541)

18-20+MPa(steel,Al,stainless)

ImpactResistance(ASTMD2794)

21gaCRS:50kg-cm22gaEGS:37.5kg-cm

%Elongation(ASTMD522)

10%-ConicalMandrel

Hardness(ISO14577-1)(ASTMD3363)

16.5-17.5(microVickers)140-150MPa(Martens)6H(Pencil)

AcceleratedCorrosionResistance(SAEJ2334)(ASTMB117)

CRS,Al-5052,EGS,ZnP160cycl.SAEJ23341000hrsaltsprayscribecreep(ASTMB117):10mmonEGS,13mmofAl-5052

CorrosionResistance(AcidBubbleTest)

>250hr/µm-1MH2SO4>250hr/µm-1MHCl

ThermalCycling Pass100cycl.-50°C–125°CDielectricBreakdownStrength(AC-60Hz)

120V/µm@20°CDBV>3.5kV@25µmthickness

SolventResistance100doublerubs(ASTMD5402)

Pass-MEK,Toluene,Dieselfuel,Butylacetate,Hexane,Windex

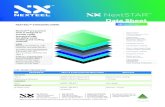

AdvenGuard™coatedpanels,160cyclesSAEJ2334testing

Substrate Rust/Blisters(ASTMD610/D714)

Maxscribecreep(mm)

(ASTMD1654)Cold-rolledsteel(CRS) 10/10 -Electro-galvanizedsteel(EGS) 10/10 2.04Aluminum-5052 10/10 2.16ZnPcoatedCRS 10/10 23.87Reference:B958P90ZnPhosphate+U32AD800E-coat(onCRS)

10/10 18.33

A B

C D

Comparisonofcoatedpanelsafter160cycleSAEJ2334testing.AdvenGuardcoatedA)EGS,B)Al-5052,C)ZnP-CRSandD)ZnP+E-coatedsystemonCRSreference

![How to clean your jewelry using windex [autosaved]](https://static.fdocuments.net/doc/165x107/5591feb01a28ab34498b4590/how-to-clean-your-jewelry-using-windex-autosaved.jpg)