ADVANCING WATER - Garney

Transcript of ADVANCING WATER - Garney

AUGUST 2010

ADVANCING WATER MAY 2012

ADVANCING WATER

QUICK FACTS Project Name: WTP No. 2, Phase II

Location: Midlothian, Texas

Owner: City of Midlothian, Texas

Design Engineers: Schrickel, Rollins &

Associates, Inc. / Freese & Nichols, Inc.

Contract Amount: $18.4 million

CMAR Award: May 2010

Construction Start: October 2011

Final Completion: March 2013

The Midlothian WTP No. 2 Phase II is owned and operated by the City of Midlothian, Texas. When completed, this will be a 9 MGD membrane filtration surface water treatment plant. Prior to this contract, the plant was composed of a high service pump station and 3 MG storage tank. Additional facilities being constructed under our contract include the following major items:

Influent metering and flow control

Conventional pretreatment flocculation

and sedimentation basins

MF/UF membrane filtration process

Chemical feed systems

Disinfection system (UV oxidation)

Administration and laboratory building

New access road

Why build this project?

This new treatment plant will achieve two objectives. First, the City’s other water treatment plant on Tayman Road is built out and cannot be expanded. Tayman also draws raw water from Joe Pool Lake just north of the City. The new water treatment plant gives the

FEATURE PROJECT: MIDLOTHIAN WATER TREATMENT PLANT by Anthony Mravunac, Justin Reese, and Mike Gardner

City a new expandable asset. In addition, the raw water comes from Tarrant Regional Water District’s two main lines that originate at Cedar Creek Reservoir and Richland Chambers Lake in eastern Texas. The different raw water sources for the two plants gives the City more flexibility in times of poor water quality or drought conditions. Why use the CMAR delivery method?

Construction Management at Risk (CMAR) is a means of delivering a construction project in an alternate way versus traditional design-bid-build. The CMAR contractor is usually selected on a combination of categories other than just a hard bid price including safety record, past performance, client references, team member’s experience, and several other qualifications-based factors. The CMAR contractor is selected early in the design phase to provide constructability input to allow the team to economize the design and for the Owner to focus on where money is spent. The CMAR contractor helps validate the initial project cost estimate and ultimately establishes a final Guaranteed Maximum Price (GMP). Several significant factors led the City

to choose the CMAR delivery method:

Desire to get a contractor on board using

factors other than low price, such as previous work experience, references from past clients, timely completion of projects, ability to fulfill necessary construction activities to control the project’s destiny, financial stability, contractor cost estimates, and proposed project team members.

The desire to have constructability reviews

during the design phase to analyze actual costs on design variations as they are derived.

Help in getting local participation from

local contractors on this large project.

Use a rating matrix on equipment and

subcontractor proposals that allow the Owner/Engineer to make a selection that provides the overall best value to the project versus just the initial cost.

Receive constructability reviews during

the design that evaluate items such as maintenance feasibility, longevity, and cost, and assist the Owner in making the selection that best satisfies their needs.

Page 2

The Project’s CMAR Selection Process...

With help from the project’s design engineers, the City composed and advertised a Request for Proposal (RFP) for a CMAR. The RFP requested information such as previous work experience, past clients references, timely completion of projects, ability to fulfill necessary construction activities to control the project’s destiny, financial stability, and proposed project team members. Pricing was requested on the following:

Pre-Construction Services Fee, which

included constructability reviews, scheduling, and quality management, all used during the design phase.

Procurement Services Fee, which

included items such as assembling bid packages, bid soliciting, pre-bid conferences, bid opening, and deriving options for costs exceeding the budgets.

Construction Service Fee, which included

administration cost to manage the project during construction and other items such things as schedule updates, cost controls, quality management and start-up management.

Performance and Payment Bonds, which

included the cost for providing these bonds for the entire project.

General Insurance

Builder’s Risk Insurance

Contingency Fund

After evaluation of the RFPs and pricing, firms were selected for an interview. With input from the design engineers, the City then rated all applicants and selected the CMAR contractor—Garney Construction. Being awarded Construction Manager at Risk on this project at the 30% design phase meant Garney was able to assist with finalizing the design and provide constructability reviews, equipment analyses, subcontractor pre-qualifications, project solicitation, schedule evaluations, and cost estimates on design variations. When Garney first came on board, the construction estimate was just over $26 million, yet the City’s budget was only $18 to 19 million. Robert Millwee, Scott Parrish, Mel Spangler, and Joey Perell took the early lead on design meetings and helped shape the plant design. This group was instrumental in the membrane equipment selection and getting Siemens signed up early enough so that submittals and manufacturing lead times could parallel design completion and expedite construction. In addition, the initial design originally incorporated a raw water building, flocculation/sedimentation basins, conventional filter basins, chemical feed building, lagoons, and a membrane and administration building. Through the design process it was apparent that it would be in the best interest of the project to reduce the number of proposed buildings to three. It was also decided to delete the conventional filters and add UV oxidation process. These major design revisions, and other items changed throughout the first phase of constructability review, helped reduce the cost model to a budget of approximately $21 million. As design progressed, the torch was passed off to the construction team to help nail down the final design elements. Eric Coe, Mike Gardner, Dave McEntee, Scott Setter, Joey Perell, Marcus Grace, Justin Reese, and Anthony Mravunac, along with key trade firms, the design firms, and City staff, were all involved with design meetings to help bring the design within an acceptable budget. Budget became the major driving factor in design and many ideas were brought to the table to help bring the pricing down. Many of these cost savings were derived in “design workshops” where construction experts from

various disciplines met with the project team to discuss ideas to reduce the specific discipline and the overall project cost. Another benefit of the CMAR approach is being able to begin construction before the final design is derived. In this project’s case, as the design was being finalized it was decided that the project would be broken into 24 separate bid packages to help solicit participation from smaller local contractors. As design continued it was also decided that the packages would be broken up into two bid sets to allow phased construction to begin before final design. The first bid set included the dirt work package, sedimentation basin concrete construction, and most importantly included the bids for the raw water pipeline material, large diameter valves, and major equipment. Bidding these items allowed purchase orders and construction to begin while final details of design were being completed. Although Garney was awarded the Construction Management of the project, we were not guaranteed any of the actual construction. Any package that Garney wanted to self-perform had to be submitted on at bid time with all other contractors. This posed a unique challenge to the CMAR team. It was decided that since Garney was the CMAR and acting as representative of the City of Midlothian, during the bid process a

FEATURE PROJECT: MIDLOTHIAN WATER TREATMENT PLANT

Page 3

FEATURE PROJECT: MIDLOTHIAN WATER TREATMENT PLANT

clear line had to be drawn between CMAR solicitation and Garney solicitation. It was decided that Anthony Mravunac would be the lead for the CMAR solicitation and conduct the pre-bid meetings and field all questions pertaining to the bidding process. Under Mike Gardner’s guidance, several others including Bret Crandall would solicit the scope of work and supply what Garney needed to complete their bid package proposals. This separation allowed for a smooth bid process. Civil work on site began in late October. A local dirt work subcontractor, Ronco Excavating, was successful in procuring the civil work and part of the miscellaneous site concrete package. Garney was successful in procuring the construction of the sedimentation basin, construction of the concrete piers at the membrane and chemical feed building, the underground process piping, above ground process piping, miscellaneous metals installation, equipment installation, and parts of the miscellaneous onsite concrete construction. A large milestone was reached in late spring with the completion of a 90” x 30” and a 72” x 30” tap onto Tarrant Regional Water District’s main raw water lines that feed close communities

including Waxahachie, Mansfield, Arlington, Benbrook, and Fort Worth. Currently, crews are nearing completion of the sedimentation basin concrete work and are transitioning to the installation of underground piping, above ground piping, miscellaneous metals, and equipment at the sedimentation basin. Hasen Construction was successful in procuring the construction of the chemical feed and the membrane/administration building. Hasen is currently forming and pouring grade beams on both buildings and if Hasen’s schedule holds true, their ability to get these two buildings constructed in a five month timeframe will be a huge shot in the arm for the overall CPM schedule. Completing these two buildings by late August will give Garney’s crews three to four months to complete the interior process piping, equipment installation, and start up in the chemical and membrane portions of the project. This duration will leave Garney in a good position to complete this fast-paced project on time for the City of Midlothian. Overall, the final build out of the future phases of the Midlothian WTP No. 2 Phase II will serve the needs of the citizens of Midlothian until the town of 15,000 residents grows to 65,000 residents. Current growth in the area would put the final build out of this facility around 2037. Garney is proud to put their name on the first major upgrade of this facility. Big thanks go out to Project Manager Anthony Mravunac, Superintendents Justin Reese and Raul Arvizu, Project Engineers Bret Crandall

and Kyle Puskas, and crew members Ruben Munoz, Colby Diamond, Manuel Rodriquez, Luis Arvizu, Esau Olvera Arredondo, Arturo Torres, Keith Neal, Alfonso Grifaldo, Rafael Rodriquez, Jose Grifaldo, Juan Grifaldo, Noe Grifaldo, Javier Alvarez and David Aredondo. ◊

Page 4

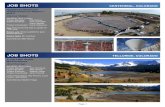

PROJECT SPOTLIGHT: RUESTER HESS DAM AND RESERVOIR

The Rueter Hess Dam and Reservoir Project

was developed to meet current and future

municipal and industrial water supply needs in

the service areas of Parker Water &

Sanitation District, and the Towns of Castle

Rock, Stonegate, and Castle Pines North.

Construction began in 2004 with the first

phase substantially complete in 2007. The

second enlargement phase started in 2008

and was substantially complete as of May 1,

2012. Rueter Hess Dam is a multi-zone

earthen dam, classified as high hazard

because of the size and location. The

reservoir maximum depth is 188 feet, with a

surface area of 1,260 acres and 72,000 acres

of storage capacity.

The project is located east of I-25 in

northeastern Douglas County and is 3.4 miles

southwest of Parker, Colorado. Major project

elements included embankment, a zone-filled

structure with a central/upstream clay core,

chimney drain, drain blanket, and toe drain

collection system. Before any embankment

work began, a pressurized grout was injected

into the ground the entire length of the dam,

creating a grout curtain. The maximum dam

height is 196 feet in the valley section, and is

7,675 feet long with a 25-foot wide dam crest.

The embankment is placed over four major

shear keys in the alluvial valley section. The

total earth material in the embankment is 16

million yards of different zones of material.

The upstream slope protection for the dam

consists of 325,000 cubic yards of soil cement,

which is an on-site screened sand mixed with

10% Portland cement. There was more than

40,000 cubic yards of concrete poured for the

structures. The project included 18,500 feet of

48” ductile iron pipe that is used to fill the

reservoir with water from the Cherry Creek

Pump Station, a key component to the

reservoir that was also a Weaver Construction

Management project.

The gate tower is 188 feet tall and consists of

three chambers and seven hydraulic actuated

water control gates that are installed at various

elevations to regulate flow releases into the

outlet works system. The gate tower also

includes un-gated service spillway ports near

the top of the downstream chamber. The low

level conduit upstream of the structure is 900

LF of 78” steel pipe. There are also two 78”

conduits installed from the gate tower to the

terminal facilities that are 1,300 LF for each

pipe. 2,700 LF of 48” steel pipe was installed

from the terminal facilities to the future Rueter

Hess Water Treatment Plant site.

The auxiliary spillway is located at the left

abutment of the dam. Key components

consist of the apron approach channel,

labyrinth structure with 600 feet of weir crest,

and discharge channel which has three drop

structures installed with three feet in depth of

soil cement in between the drop structures.

The slopes of the discharge channel have

nine foot thick soil cement walls placed in a

stair-step method.

A completion ceremony was held onsite on

March 21, 2012, with county and state

representatives, as well as Mike Heitmann,

President of Garney Construction. The project

received the American Concrete Institute

Award of Excellence for the Water Resources

Project of the Year, and also Outstanding

Project of the Year. The project was

completed on time and under budget, with

zero lost time accidents. Parker Water &

Sanitation District and their water partners are

now able to use Rueter Hess Reservoir and

are currently filling the reservoir. This project,

along with many other projects, have been

successfully managed for Parker Water &

Sanitation District by Weaver. ◊

QUICK FACTS Project Name: Rueter Hess Dam and

Reservoir

Location: Parker, Colorado

Owner: Parker Water & Sanitation District

Contract Amount: $170.0 million

Principal-in-Charge: Wes Weaver Project Manager: John Jacob Construction Mgrs.: Doug Voss Sean Voss Jason Pacheco

JOB SHOTS

JOB SHOTS

Page 5

AMARILLO, TEXAS

OLATHE, KANSAS

Osage WTP Combined High Service and Transfer Pump Station

(City of Amarillo, TX)

Job 6535—$18.1 million Sr. Project Manager: Phil Naylor Project Manager: Jeff Cohen Superintendent: Steve Chandler Project Engineer: Ronnie Leyvas

Crew: Reyes Esquivas, Martin Casas, Carlos Alvarez, Heriberto Munoz

Top Left: March 27, 2012—Fitting the last piece of the new 42” high service pump station header.

Top Right: Inside of the pump station.

Bottom: Outside view of the pump station building.

Submitted by Jeff Cohen

Cedar Creek Wastewater Treatment Plant

(City of Olathe, KS)

Job 8026—$34.0 million Project Manager: Joey Perell Superintendents: Tim Holliday Stephen Harris Project Coordinator: Sonya Puskas

Crew: Sean Bryson, Octavio Ramirez, Manuel Galven, James Gerdes, Alex Duran, Joel Ruiz, Thomas Vannorman, Alejandro Garcia, Antonio Reyes, Jr., Johnny Bunch, Justin Gilbert, Christopher Meyer, Jorge Orduno, Alejandro Duran, Manuel Falcon, Tomas Garcia, Frank Lara, Guillermo Mojica

Top: BNR No. 1 and No. 2 nearing completion.

Bottom: Clarifiers No. 4 and No. 5 with the sludge and electrical building separating them.

Submitted by Joey Perell

JOB SHOTS

JOB SHOTS

Page 6

PUEBLO, COLORADO

COLORADO SPRINGS, COLORADO

Comanche Coal Pile Wind Fence

(Xcel Energy)

Job 6619—$1.1 million Project Manager: Joel Heimbuck Superintendents: Dennis Van Auken Alvino Roybal Project Engineers: Stephen Hagy Chance Galentin Safety Manager: Dan Stanton

Crew: Leopaldo Soto, Nemecio Lopez Vega, Dustin Hayward, Antonio Rico, Santiago Soto, Eduardo Villegas, Hugo Montanez, Jesus Paulo Esparaza, Arturo F. Santoyo

Top Left: Comanche site before pier cap work began.

Bottom Left: Drilling, setting pier rebar cage and replacing 48” concrete pier.

Far Right: Completed concrete piers and pier caps.

Submitted by Dennis Van Auken

Martin Drake Non-Potable Water Meter Vault

(Colorado Springs Utilities)

Job 6614—$223,000 Project Manager: Mike Moore Superintendent: Alvino Roybal Project Engineer: Dennis Van Auken

Crew: Leopoldo Soto, Antonio Rico, Nemecio Lopez Vega, Santiago Soto, Eduardo Villegas

Right: New non-potable flow meter house.

Inset: New non-potable flow meter and piping.

Submitted by Dennis Van Auken

JOB SHOTS

JOB SHOTS

Page 7

GOLDEN, COLORADO

AURORA, COLORADO

JCMD Ph. 1 Infrastructure—Water Storage Tanks and Pump Stations

(Jefferson Center Metropolitan District No. 2)

Job 6616—$2.4 million Project Manager: Joel Heimbuck Superintendents: Wes Conaway Tino Alvarez Project Admin: Adam Theriault

Top: Excavating for post-tensioned concrete tank.

Bottom: Pouring the base slab at pump station No. 3.

Submitted by Adam Theriault

Gun Club 42” Waterline

(City of Aurora, CO)

Job 6599—$2.4 million Project Manager: Keith Lemaster Superintendent: Phil Werner Project Admin: Taylor Osgood Project Coordinator: Janel Tannatt Crew: Rick Craig, Eloy Ortega, Vicente Govea, Jr., Jose Diaz, Manuel Diaz, Victor Diaz, Abel Espinoza, Andrew Macias, Jr.

Top Left: Excavating for the next 45’ joint of 42” steel pipe while the also backfilling material between overhead power lines and Gun Club Road.

Top Right: Setting a 45-foot joint of 42” steel pipe.

Bottom Left: Bolting up a 30” butterfly valve to a dismantling joint and reducer.

Bottom Right: Checking grade and preparing to set the next joint of pipe.

Submitted by Taylor Osgood

JOB SHOTS

JOB SHOTS

Page 8

MANHATTAN, KANSAS

HUDSON, FLORIDA

Water Treatment Plant & Well Field Improvements

(City of Manhattan, KS)

Job 8025—$16.4 million Project Manager: Steve Hermes Superintendent: Joe Ross Field Engineer: Justin Mahan Project Coordinator: Sally Miller

Crew: Alfredo Flores, Alan Bolich

Top Left: Completed lime system and instrumentation paneling.

Top Right: Removal of aerator media.

Bottom: Completed disinfection building.

Submitted by Steve Hermes

Hudson to Shady Hills Wastewater Diversion

(Pasco County, FL)

Job 3044—$6.5 million Project Manager: Dan Smolik Superintendents: Steve Mertz Project Engineer: Cassandra Marshall

Crew: Tim Burrage, Travis Stewart, Steve C. Mertz, Steve Vasseur, Herb Finks, Ricardo Lopez

This project consists of taking the current Hudson WWTF offline and sending the flows to the Shady Hills WWTF, and includes the installation of 35,000 LF of 24” force main, 1,070 LF of 36” wastewater force main and three centrifugal pumps.

Top: Working on above ground piping at the Hudson Booster Pump Station.

Bottom: 30” tie-in diverting the flows from the Hudson WWTF to the Shady Hills WWTF.

Submitted by Cassandra Marshall

JOB SHOTS

JOB SHOTS

Page 9

BRIGHTON, COLORADO

WICHITA, KANSAS

ECCV Northern Water Supply Project—Membrane Water Treatment Facility

(East Cherry Creek Valley Water & Sanitation District)

Job 6561—$25.0 million Project Manager: Ruben King Superintendents: Les Cushman Chuck Krier Jeff Dickhausen Eric Griffin Project Engineers: Solange Huggins Matt Davis Mike Duesterbeck

Crew: Rich Maestas, John Geppkens, Joe Yriarte, Jovan Amaya, George Ramirez, Bill Beckett, Tommy Barth, Kevin Smolinski, Ken Margetts, Josue Alvarez, Miguel Vasquez, Super Steve Jordan, Josh Odenbaugh, Justin Leicht, Gus Garfio, Manny Perez, Jerry Rodriguez, Russ Newbold, Humbierto Montez, Herbierto Munoz

Submitted by Solange Huggins

ASR Phase II Northern Diagonal Transmission Main

(City of Wichita, KS)

Job 4370—$10.5 million Project Manager: Ed Rolf Superintendents: Joe Lewis, Jr. Humberto Del Cid Steve Morris Project Admin: Bryan Muench

Crew: B. Lewis, D. Cokerham, J. McClure, R. Berstresser, O. Torres, L. Allen, P. Hall, F. Keith, H. Walker, R. Dell, A. Lopez, G. Pereida, R. Martinez, J. Jimenez, G. Byers

Top Left: Installation of 48” steel pipe.

Top Right: Installation of 66” steel pipe.

Bottom: Left Crews removing the existing out-of-service cast iron pipe.

Bottom Right: Installation of 30” steel pipe and 10” double check valves.

Submitted by Bryan Muench

JANUARY 2011

APRIL 2012

JOB SHOTS

JOB SHOTS

Page 10

PUNTA GORDA, FLORIDA

PUEBLO WEST, COLORADO

Regional Integrated Loop System—Phase 1A Interconnect Project

(Peace River Manasota Regional Water Supply Authority)

Job 3019—$16.0 million Project Manager: Dan Smolik Superintendent: Chris Vanlerberg Project Admin: Rob Fults

Crew: Bryan Taylor, Jeff Jones, Jerry “Bo” Burt, Steve Warren, Keith Durrance

Right: High service pump station room.

Inset: Aerial view of our marine subcontractor, Ed Waters & Sons, installing 30” HDPE across Peace River.

Submitted by Rob Fults

Southern Delivery System Raw Water Pipeline, Segment S2

(Colorado Springs Utilities)

Job 6597—$25.9 million Project Manager: Bill Williams Superintendents: Gil Duran Jeff Riddle Project Admin: Ryan Schulte

Crew: Gene Lopez, Alice Duran, Ramon Cortez, David Garcia, Lorenzo Reyes, Ondray Johnson, Iram Aragon, Clayton Hoff, Diomedis Avila, Victor Cortez, Dustin Hayward, John Backman, Larry Pacheco, Jesus Chavez, Nicolus Flores, Arturo Moreno, Cory Walker

Top: Gil’s crew with the new CAT 390D excavator.

Bottom Left to Right: Brian McEwen, the “grill master” cooks for a crew lunch; Inspectors perform at random “dig up” weld-after-backfill test; Busy job site

Submitted by Ryan Schulte

JOB SHOTS

JOB SHOTS

Page 11

NASHVILLE, TENNESSEE

PALATKA, FLORIDA

Washington CSO Control Facility

(Metro Water Services)

Job 3032—$17.0 million Project Manager: Lloyd Soeters Superintendents: Mike Gonazles Pedro Munoz Rob Grant Project Engineer: Jake Gabbard

Top: Left Looking at the southeast side of the control facility and weir gates.

Top Right: View of the northwest portion of the control facility. The bar screens can be seen in the middle bay of the facility.

Bottom Left: Placing a section of concrete paving at the south end of the control structure.

Bottom Right: Influent channel fillets, hung walls, and columns inside the Washington CSO Control Structure.

Submitted by Jake Gabbard

Rice Creek Enhancement Project—Effluent Pipeline

(Georgia-Pacific)

Job 3054 Project Manager: Dan Smolik Superintendent: Mike Hall Project Admin: Robbie Butler

Crew: Greg Pilgrim, Dean Pilgrim, Exequiel Penaloza, Mario Penaloza, Mike Maples, Ramon Herrera

Top Left: Installation of 36” ductile iron effluent force main pipeline.

Top Right: End of the diffuser line.

Bottom: Gators on the job!

Submitted by Robbie Butler

JOB SHOTS

JOB SHOTS

Page 12

FAYETTEVILLE, ARKANSAS

ST. JOSEPH, MISSOURI

Highway 265 Water & Sewer Main Replacement

(City of Fayetteville, AR)

Job 4364—$5.1 million Project Manager: Chad Sharbono Superintendent: Jackie Gass Project Admin: Casey Nelson

Crew: Manuel Fernandez, Chester Rigsby, Bobby Ledbetter, Charles Herns, Richard Morris

Right: Pouring concrete in parking lots with the crew and Beaver Lake Concrete.

Submitted by Casey Nelson

Water Protection Facility— Disinfection Facilities and Effluent Pump Station

(City of St. Joseph, MO)

Job 4380—$18.0 million Project Manager: Brian Schultz Superintendent: Tim Diamond Field Engineer: Jared Keating

Crew: Matt McCann, Rudy Puskas, Jason Gerdes, Josh Dunn, Fernando Mendoza, Alan Bolich

Both Photos: In-plant duct bank installation.

Submitted by Brian Schultz

JOB SHOTS

JOB SHOTS

Page 13

MIDWEST CITY, OKLAHOMA

Pollution Control Facility Improvements

(City of Midwest City, OK)

Job 4382—$47.1 million Project Managers: Bart Slaymaker Steven Hermes Superintendents: Wade Pierpoint Chris Hannaford Art Turner Mark Campbell Antonio Cruz Field Engineers: Jesse Dull Justin Mahan Bryan Clark Lou Jauregui Project Coordinator: Sally Miller

Crew: Terry Miller, Eric Henderson, Christian Hook, Felix Alarcon, Joe Morris, Angel Perez, Danny Servan, Alfredo Solis, Javier Escamilla, Pablo Bustamante, Joshua Butler, Andrew Dias, Oscar Gomez, Miguel Ramirez

Submitted by Bart Slaymaker

NASHVILLE, TENNESSEE

Whites Creek WWTP Optimization & Disinfection

(Metropolitan Government of Nashville & Davidson County)

Job 3040—$5.5 million Project Manager: Jordan Brooking Superintendent: Mike Terry

Crew: Jeff Felts, Jeremy Felts, Daniel Peery, Billy Haggard, Danny Clawson, Carlos Munos, Jose de Jesus Castro, Exiquio Talavera, Cancesio Alaniz-Hernandez

Right: UV Channel 4 and influent wall rebar.

Inset: UV Channels 1 and 2 slab pour.

Submitted by Jordan Brooking

Top Left: Pouring the lower mud slab for the headworks / influent pump station. Top Right: Ready-mix concrete supplier erected a mobile batch plant on site. Left: Project team members (left to right) Dave Farkas, Bart Slaymaker, Jesse Dull, Wade Pierpoint, Justin Mahan, Steve Hermes, Mike Gardner, and Bryan Clark, participated in the Midwest City Chamber of Commerce Annual Golf Tournament to help raise money for the Chamber.

JOB SHOTS

JOB SHOTS

Page 14

NASHVILLE, TENNESSEE

102" Sanitary Sewer Relocation at 25th Avenue North and Brandau Place

(North American Properties)

Job 3067—$960,000 Project Managers: John Evans Scott Kelley Superintendent: Tony Southerland Project Admin: Jordan Carrier

Right: Pipe Crew (left to right): Henry Hobbs, Travis Meredith, Jonathan Evans, Tommy Fathera, Tony Southerland; not pictured: Brian Southerland

Below: Installing 9’ x 8’ precast box culvert for the relocation of an existing 102” brick sewer.

Submitted by Jordan Carrier

HIALEAH, FLORIDA

Hialeah Reverse Osmosis Water Treatment Plant

(Hialeah Water LLP)

Job 3016—$7.0 million Sr. Project Manager: Mark Abram Project Manager: Josh Petro Superintendents: CJ Cahoy Jay Rivera Josh Greene

Crew: Armando Hernandez, Jeff Griffin, Kevin Nauss, Tyler Boehning, Zach Trombly, Lee Bennett, Duane Dennis, Grover Lee Ryans Jr., McKinley Wallace Jr., Patrick Williams, Ronald Mays

Submitted by Josh Petro

BIOFILTER

DEGASIFIER

JOB SHOTS

JOB SHOTS

Page 15

FOUNTAIN, COLORADO

Harold D. Thompson Regional Water Reclamation Facility

(Lower Fountain Metropolitan Sewage Disposal District)

Job 9103—$17.9 million Project Manager: John Jacob Superintendent: Jeff Burst Project Engineer: Tyler Ammerman

Crew: Kurt Walters, Bill Burst, Gordon Cole, Adam Roeder, Ronny Burst, Gerry Buckner, Eric Klopfenstein, Matt Brady, Craig Wold, Bill Howard, Matt McBride, Chris McBride, Doug Bloss, Danny Reck, Manuel Bencomo, Miguel Luna

Top: Backfill of clarifer piping and manhole valve vaults.

Bottom: View from inside the headworks building with two bar screens in the foreground.

Submitted by John Jacob

SANFORD, FLORIDA

SR 46 Reclaimed Water and Force Main

(Seminole County, FL)

Job 3037—$3.7 million Project Manager: Dan Smolik Superintendent: Billy Newton Project Admin: Will Poczekaj

Top: Stringing 24” PVC force main along State Road 46.

Below: Abraham Espinosa helps assemble a 30” gate valve for the reclaimed water line.

Submitted by Will Poczekaj

JOB SHOTS

JOB SHOTS

Page 16

OKLAHOMA CITY, OKLAHOMA

SPRING HILL, FLORIDA

North Central Transmission Mains

(Pasco County Utilities)

Job 3049—$13.0 million Project Manager: Dan Smolik Superintendents: Joe Monteleone Thad Anderson Curtis Hefley Project Admins: Jacob Johnson Sam Marston

Crews: Rito Mata, Sam Harris, Mike Wilson, Leroy Wilson, Eric West, Pedro Vasquez, William Merritt, Robert Harman, Wayne Mercer, Cirillo Correa, Luis Bautista, Robert Munroe, Jose Rivas

Top Left: Installing 36” ductile iron pipe.

Bottom Left: Pipe on concrete caps. Piles were driven in a sink hole with depths varying from 40’ to 140’ and pile caps were poured on top for pipes to rest in.

Far Right: 16” PVC on pile caps.

Submitted by Jacob Johnson

48" Water Main Improvements, Phase II

(City of Oklahoma City, OK)

Job 4358—$9.3 million Project Manager: Chad Sharbono Superintendent: Mike Swift Project Admin: Kahle Loveless

Crew: Truitt Thompson, Fletter Stoudemire, Jay Robertson, Juan Nino, Alfonza Stoudemire, Charles Griffin, Dwayne Harper, Jeff VanderWolde

Top: Dwayne Harper, Charles Griffin and Jeff VanderWolde bolt up a tapping saddle for a 36” interconnect line.

Bottom: Golf course in south OKC. Part of the surface finishing was to construct a berm to replace the tree line that has been removed for the water main. Fletter Stoudemire got to use his creativity in building these berms and the owners were very pleased.

Submitted by Kahle Loveless

Page 17

BIG SPRING, TEXAS

Ward County Water Supply Expansion—Pump Stations

(Colorado River Municipal Water District)

Job 4383—$22.0 million CMAR Project Manager: Marcus Grace CMAR Superintendent: Richard Scholz CMAR Assistant Supts: Charley Senne Cole Rawson Bid Package 5 Supt: Ubaldo Esparza Project Coordinator: Laurie Grace

Crew: Leonel Gomez, Joel Carbajal, John Yazzie, Jesus Tapiz, Jacob Mendoza, Jose Grijalva, Martin Sanchez Ayala, Mario Longoria, Adalberto Gomez, Juan Tapia, Abel Benevidez, Jose Luis Mendoza, Manuel Montes, Javier Alvarez

Submitted by Marcus Grace

JOB SHOTS

PLUMBING GRADS

On May 1, 2012, Danny Servan and Art Turner graduated from the Associated Builders & Contractors’ Plumbing Apprenticeship program. This four-year program focuses on classroom and on-the-job training for topics that relate to the plumbing industry. They are preparing to take their Master Plumbers exam this summer. Congratulations!!

APWA AWARD

BIG SPRING, TEXAS

Page 18

BENEFITS BRIEF

STRESS: THE BODY’S NATURAL RESPONSE TO CHANGE Everyone experiences stress at one time or another in their lives. Stress is the body’s natural response to change and can stem from issues at work, home, financial challenges, and personal relationships. While stress can cause minor conditions such headaches or sleep loss, too much stress can raise your risk for serious health problems or worsen current health conditions. When you face or perceive threat, an alarm sounds in the part of your brain that controls your emotions. This triggers your adrenal glands to release hormones to prepare your body for a “response or reaction.” The hormone called adrenaline increases your heart rate and raises your blood pressure. Another hormone called cortisol causes your body to tap its supply of glucose for extra energy. It also interrupts bodily functions related to immune responses, digestion, growth, and reproduction. The extra energy can help you act fast, but if you remain in this state for an extended period of time, you put yourself at risk of serious health issues including:

High blood pressure Heart disease Sleep disorders

People under stress have a greater tendency to engage in unhealthy behaviors, like abuse of alcohol and drugs, cigarette smoking, and making poor exercise and nutritional choices. When experiencing stress, the symptoms and signs are different for each person. Something can be overwhelming stress for one person and may not be perceived as stress by another. Stress is a normal part of life. You cannot control what happens but you can control how you react or handle certain situations. Here are some tips for dealing with stress:

LIVE HEALTHY. Eat healthy, exercise and sleep. BE REALISTIC. Set realistic goals, accept things you cannot change and say no, but be positive. PRIORITIZE. Set priorities, focus on one thing at a time, make a list, plan ahead, and do not procrastinate. COMMUNICATE. Share your feelings and be open with your loved ones, friends and co-workers. RELAX. Try relaxation techniques, take a walk, take a bath, and create some time to do something for you.

If you think your stress level is more than you can handle, look for professional help or talk to your family doctor. Remember, it is always better to use preventive care!

Depression Digestive problems Obesity

ESTRES: LA RESPUESTA NATURAL DEL CUERPO A LOS CAMBIOS Todo el mundo se siente estresado en algún momento de su vida. El estrés es la respuesta natural del cuerpo al cambio. Puede estar relacionado con problemas en el trabajo, hogar, desafíos financieros o relaciones personales. El estrés puede causar trastornos relativamente menores como dolores de cabeza o insomnio, pero la exposición prolongada a altos niveles de estrés puede elevar su riesgo de problemas de salud graves y empeorar trastornos médicos existentes. Cuando se enfrenta a una amenaza o incertidumbre, suena una alarma en la parte del cerebro que controla sus emociones. Esto hace que sus glándulas adrenales liberen un torrente de hormonas para preparar al cuerpo para una “respuesta o reacción”. Una hormona llamada adrenalina aumenta su frecuencia cardíaca y eleva su presión arterial. Otra hormona llamada cortisol (hidrocortisona) hace que su cuerpo utilice su suministro de glucosa para obtener más energía. También interrumpe las funcione corporales relacionadas con la respuesta inmunitaria, la digestión, el crecimiento y la reproducción. La energía adicional puede ayudarle a actuar rápidamente, sin embargo, permanecer en este estado por un período prolongado puede ponerlo en riesgo de problemas de salud graves, entre ellos:

Presión arterial elevada Enfermedades cardíacas Trastornos del sueño

Las personas que sufren estrés tienden a engancharse en comportamientos de abuso de alcohol, drogas, fumar, no hacer ejercicio y mala nutrición. El estrés presenta diferentes síntomas y señales en cada persona. Algo que puede ser abrumadoramente estresante para una persona puede percibirse como no estresante para otra. El estrés es parte normal de la vida, usted no puede controlar lo que sucede pero usted puede controlar como reacción ante ciertas situaciones. Estos son algunos consejos para combatir el stress:

VIVA SALUDABLEMENTE. Coma, haga ejercicio y duerma bien. SEA RELISTA. Establezca metas realísticas, acepte las cosas que no puede cambiar y aprenda a decir no pero sea positivo. ESTABLEZCA PRIORIDADES. Designe prioridades, enfóquese en una cosa primero, haga una lista, planee con anticipación y trate de no posponer. COMUNÍQUESE. Comparta sus sentimientos con sus seres queridos, amigos y compañeros de trabajo. RELÁJESE. Pruebe técnicas de relajación, camine, tome un baño de tina, disponga de un tiempo para hacer algo para usted.

Si piensa que su nivel de estrés está más allá de su control, obtenga ayuda profesional o hable con su médico. Recuerde, es siempre mejor utilizar servicios médicos de prevención!

Depresión Problemas digestivos Obesidad

Dificultades de la memoria Dolor muscular o de espalda Trastornos de la piel como eczema

Memory difficulties Muscle or back pain Skin conditions such as eczema

Page 19

SAFETY SEGMENT by Neal Timmons

VINNY’S STORY PART III

Part III: Lessons We all learned lessons that day. When we ask the steel

erector subcontractor if he could have done anything

differently, he said if he would have been directed not to store

the beams on the hoist way, he could have staged all of them

on the bottom floor. The project manager admitted that he was

much too lax when dealing with the major subs and allowing

Vinny to have full authority to perform his work without any

oversight. When pressed, several employees on Vinny’s crew

stated this wasn’t the first time Vinny was a little out of control

and they probably should have refused to move the beams

because they felt it was unsafe. Vinny himself told us, if he had

to do it over again, he would have waited for the contractor to

remove the beams rather than expose himself and his entire

crew to injury or death. Vinny’s wife told me several times that

she wished she would have told him that morning not to keep

taking chances at work.

There are always lessons

learned whenever there is an

accident on our one of our

projects, but the cost of these

lessons can be tremendous and

far reaching.

Hindsight is 20/20… It was ironic—after the accident, the amount of ideas and

changes that were put into place to prevent this from ever

happening again were tremendous. A material staging plan

was developed. The subcontractors were reigned in and

brought under control. A guard rail was installed around the

hoist shaft. Fall arrest equipment was required on all open

floors. An emergency action plan was implemented. All

personnel received mandatory fall protection training and,

finally, the rules and regulations were enforced.

If everything we did after the accident had been implemented

prior to Vinny’s accident, we could very well have saved the

life-changing injuries to Vinny and the tremendous costs to his

family and the project.

If hindsight of an accident is 20/20, then foresight must be

clarity in the understanding of the risks associated with

the operations we perform and using the knowledge to

safeguard ourselves and our fellow employee-owners.

Thank you for taking the time and interest to read Vinny’s story. I hope you were able to take your own lessons from this story and use it to prevent accidents on your projects.

CHAMPIONS OF BUSINESS AWARD

On May 18, 2012, Garney Construction was recognized as a “Champion of Business” presented by the Kansas City Business Journal, UMB Bank, Deloitte & Touche LLP, Polsinelli Shughart, and Teva Neuroscience Inc. This annual awards program honors Kansas City area for-profit companies that set the gold standard for financial performance, innovation and community involvement. Garney was recognized during an awards luncheon along with 14 other Kansas City area firms. The companies were also highlighted in a special supplement in the KC Business Journal. Mike Heitmann gave a wonderful acceptance speech wearing his brand new cowboy boots. Congratulations to all employee-owners for receiving this very deserving award!

Page 20

PROMOTION ANNOUNCEMENT

At the Western region annual awards dinner on February 24, 2012, a special announcement was made: Mike Graeve has been promoted to the position of Director – Western Plant Operations. Mike has been an integral part of the success of Garney’s plant operations in the West and he is well-deserving of this recognition. Mike will be working closely with Wayne O’Brien to oversee our plant operations in Colorado and the West. With the departure of Robert, Mel, and Scott Terry, the importance of this role is significant. The respect that Mike garners from his peers in the water and wastewater community will ensure that Garney continues to maintain our position as an industry leader. Mike’s extensive experience and commitment to safety, quality and customer service emulate the characteristics that all Garney employee-owners should strive for. In addition, Mike will be attending Officer Team meetings and providing input on overall company operations.

EASTERN KENTUCKY UNIVERSITY AWARD

At the 6th Annual Construction Management Recognition Banquet at Eastern Kentucky University, Garney was presented the Hall of Fame Constructor Award in recognition of our support for the Construction Management program at EKU. This award recognizes contractors that have had a positive impact on EKU’s Construction Management program, including hiring EKU students and providing outside learning opportunities. Consideration is given to innovation that reduces financial and natural resource waste and/or promotes collaboration. The award has been in existence since 2007. Jordan Brooking and Zack Bloomfield, as well as Jordan Carrier (who could not attend the banquet), are all esteemed alumni of EKU and currently serve in positions of significant responsibility within the Garney organization. These young men recently made a presentation to EKU students and some faculty which included an overview of Garney’s history, our company goals and philosophies, geographic locations, and a brief overview of each of their current projects. They then fielded questions from the students, which ranged from specific questions about the projects to what classes they felt were most applicable to their current positions with Garney. It was indicated at the banquet by some of the faculty that their presentation was one of the most professional and well-organized presentations they have ever observed.

Pictured (left to right): Scott Arias, Professor of Construction Management, poses with Steve Ford, Gary Goff, Jordan Brooking, and Zack Bloomfield with their Hall of Fame Award.

Page 21

FAMILY CORNER

EMPLOYEE-OWNER SPOTLIGHT: WALLY ESPARZA

Wally is a 10-year veteran Superintendent currently working on Garney’s Ward County Water Supply Project in Big Spring, Texas. Wally has always led by example by being responsible, focused, and hard working. He is not afraid to try new things or challenge the status quo. Wally is always part of the solution, and never the problem. He is always looking for ways to save money on his jobs and looking out for our ESOP accounts. His enthusiasm and optimism are invigorating to those around him. He takes his work very seriously, but never himself. He never leaves the job – even when he is not on site, he is always thinking about getting to the finish line. His phone is always on, and if someone needs help or advice, he is there unconditionally. Wally’s effect on his crew is like an NFL football coach rallying his team on game day; he is one heck of a crew motivator. Wally’s wife, Naomi, and their little girl, Bryssa, are at home in Phoenix waiting patiently for his return. They understand firsthand how difficult it is that daddy is not home every night to tuck her in to bed. They also understand that he is needed in other areas to help enforce Garney’s goals, philosophies and company culture in new and emerging markets. As one of ESOP Man’s ambassadors, Wally is a constant reminder of what 100% employee ownership means and how it makes our organization stronger than any other company around.

John Miller, Project Engineer based in Colorado, his wife, Kelly, and their 2-year-old daughter, Teagan, welcomed the birth of their baby boy, Crosby Griffin Miller, on March 13, 2012, at 8:45 A.M. Crosby weighed 8 lbs., 14 oz. and was 21.75” long.

Donna Gutierrez, Nashville Estimator, and her husband, Juan, are excited to announce the birth of their grandson, John Lucas, son of John and Kristyn Gutierrez. John Lucas was born on April 15, 2012, at 5:02 A.M. weighing 6 lbs., 6 oz. and 18.5” long.

New employee-owner, Eric Malvin, Senior Project Manager based in Atlanta, poses with his wife, Kris, and their daughters, from left to right, Kendall (age 6), Madison (age 11), and Taylor (age 8).

Jesse Dull, Central Region Project Engineer, and his wife, Riley, and son, Michael, welcomed their new baby boy, Nathan Douglas Dull, on February 9, 2012. Nathan weighed 7 lbs., 10 oz. Jesse was a little worried because the baby came out really quickly—his head was out before the nurse returned to the room, but thankfully she made it in time to catch the rest of him. Jesse almost had to cut the cord with his pocket knife!

Page 22

MIDWEST CITY PARTNERING EVENT

GO

AL

S A

ND

P

HIL

OS

OP

HIE

S

FO

CU

S

This issue focuses on our goal of “Allow all employee-owners to achieve their full potential.”

Charles Garney began this company with this philosophy and it continues to this day. Charles believed

that by giving your employees the tools they need to be successful, combined with the freedom to use

them, they have the potential to do great things. This mindset has proven successful for Garney for the

past 50 years and counting.

This goal encourages two things: first, it encourages upper management to create an environment that

facilitates the success of our employee-owners. This is achieved by setting clear directions and

eliminating obstacles that slow our employee-owners down or makes it more difficult for them to do their

jobs. Second, this goal intends to let our employee-owners know that they have a tremendous

opportunity at Garney. This goal encourages you to suggest new ideas, develop better ways of doing

things, and find new ways for the company to be profitable. This goal has been a significant reason

behind the growth of our company over the last couple of decades.

The company’s profitability and our strong ESOP statements will always be huge motivators for us.

However, achieving great objectives, pursuing new ventures, and being part of a successful team are

also fundamental sources of workplace happiness. These are the kind of results this goal is striving to

achieve. So think about your personal and professional goals and take a small step toward them today.

Written by: ESOP MAN

The Midwest City, Oklahoma, Project Team hosted a partnering event at the local bowling alley to get to know the Engineer and Owner on a more personal level. These events go a long way to building a strong relationship throughout the project duration. Everyone had a great time!

PARTING SHOTS

TYLER IS FAMOUS!

Page 23

SEMPER FI

Garney Project Administrator Tyler Bain, right, poses with City of Thornton Construction Coordinator Hal Harrick. The Cooley West Raw Water Pipeline and 30 MGD Pump Station Project was featured in a recent issue of Colorado Public Works Journal.

COMMUNITY WORKERS MONTH

Garney employee-owner, Colby Esquibel, visited his son, Preston’s, pre-school during Community Workers Month. Colby talked with the kids about construction safety and what he does at Garney.

They wrote him a letter of appreciation saying, “Thank you for coming to our class! We like learning about construction. We like seeing big pipes and the toy trucks.” - Love, The Blue Class

PARADISE RETREAT?

On a recent family vacation to the U.S. Virgin Islands, this is Mike Gardner’s idea of “getting away from it all”….which apparently does not include bid days!!

Lance Corporal Ryan Puskas, son of Garney employee-owners Sonya and Rudy and brother to Kyle, also a Garney employee-owner, is pictured here in his Marine Corps attire. Ryan is leaving on his first deployment this month. Thank you, Ryan, for helping defend our freedom!