Advancing the Supercapacitor Materials and Technology Frontier … · 2016-04-27 · Advancing the...

Transcript of Advancing the Supercapacitor Materials and Technology Frontier … · 2016-04-27 · Advancing the...

The Electrochemical Society Interface • Fall 2010 57

Advancing the Supercapacitor Materials and Technology Frontier for Improving Power Quality

by Prashanth Jampani, A. Manivannan, and Prashant N. Kumta

I n the ongoing effort for energy sustainability, electrochemical supercapacitors are emerging as

devices of prime importance owing to their superior characteristics unmatched by any other charge storage device. These include: high power densities at relatively high energy densities and long cycle life. These characteristics have already been exploited in various applications such as power electronics, large scale transport systems comprising subway trains and buses, energy storage at intermittent generators including windmills, and smart grid applications. Smart Grid needs will include grid stability, frequency smoothing, peak shifting, and frequency regulation, as discussed in the earlier articles in this issue. The future market for batteries and supercapacitor storage systems is expected to grow to $8 billion in 2017.1

Table I shows the performance of state-of-the-art commercial supercapacitors suitable for various diverse applications.

Supercapacitor V

Separator

I

-- -

-+

+

+

+++++ +++++

+

--

+

------- -- -- -- -

-

+

+

-

+

-

+ +

--

-

-

-- -

+++ ++

---

-----

++

++ +++++

+

+

+

+++++++++++

-

-

- --

-

-

--- - - -----

-----

+++

+

++ ++++

+

+

++

+

+

+

+

+

-

-

-

-

-

--

-

+

+

Anode -

Cathode

Electrolyte

Separator

I

-- -

-+

+

+

+

+

+

+

+

-

+

-

-

-

-

-- -

-

--

--

+

-

+

-

+ +

- -

-

+ +

-

-

--

-

+

+

+

+ +

+

+

++

+

+

+

+

+

++

+ +

+

+

-

-

-

- -

-

--

- -

--

-

-

---

++

+

+

+

+

+

+

+++

+

+

+

+

+

+

++

-

-

-

-

-

-

-

+

+

Cathode

Anode

+

-

-

-

-

-

++++Electrolyte

charges-+

electronic dir. (neg. charge)

current dir. (pos. charge)

ions-+

pos. electrode eg. Activated carbonelectronically conductive

neg. electrode eg. Activated carbonelectronically conductive

electrolyte eg. Sulfuric acid

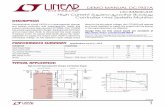

Fig. 1. Schematic diagrams of an electrochemical double layer type capacitor showing the charged (left) and discharged (right) states.

Table I. Commercially available capacitor properties.2

Manufacturer Capacitance (F) Voltage (V) Equivalent Series Resistance (mΩ)

Power Star China 50300600

2.72.72.7 1

Panasonic 0.022-70 1-5.5 200-350

Maxwell 6394

12575

1815

Vinatech 10-6003-350

2.32.7

20-4008-90

Nesscap 3351

15340

2719

Since supercapacitors are characterized by fast discharge rates and low maintenance, the demand for them is predicted to be most extensive in frequency regulation applications. The other area for significant growth is in regenerative braking for grid-connected light rail systems. Conventionally, supercapacitors have been categorized into two types: electrochemical double layer capacitors (EDLCs) and pseudocapacitors based on the Faradaic electrochemical redox mechanism of charge storage. The electrochemical interface between an electrode and electrolyte has long been known to behave like a capacitor and thus the name “double-layer” is often commonly used while referring to the capacitor phenomenon. The rapid response of the interface to changes in electrode potential and high reversibility have been exploited in EDLCs. Pseudocapacitors on the other hand are devices based on electrode charge storage

accompanied by highly reversible Faradaic electrochemical redox surface processes. Materials targeted for EDLCs have primarily been high surface area carbons while pseudocapacitor research has largely been dominated by oxides such as those of ruthenium and manganese. A schematic diagram for an EDLC is shown in Fig. 1.

The primary purpose behind the burgeoning effort in supercapacitor devices is the need to bridge the gap between conventional capacitors and batteries with regards to energy/power performance. For supercapacitors to be commercially viable for large-scale applications there is a need for greater energy densities and reduction in cost. Greater energy densities can be obtained by increasing either the electrode capacitance or the electrolyte voltage window. The former is achieved by using high capacitance electrode materials and the latter through use of non-aqueous electrolytes with larger window of electrochemical stability. This has spurred research into a large number of alternative electrode materials including nanocomposites to improve capacitance largely exploiting the faster electronic and ionic transport characteristics of nanoscale systems. Increasing the voltage window however, has been suggested as a more prudent approach to improving the energy density on account of the squared dependence of energy density on voltage as well as the lack of problems associated with an increase in the RC-time constant on increasing capacitance to achieve higher energy density (leading to a drop in rate capability).3 The trend toward this direction is observed in Fig. 2.

58 The Electrochemical Society Interface • Fall 2010

High Capacitance Electrodes: Carbon-based Materials

Early investigations on supercapacitor materials primarily involved carbon based compounds that exhibit double layer type capacitance. Prominent among these materials were activated carbons and carbon gels, which exhibited highly reversible surface adsorption/desorption of ions but were limited in energy density on account of the surface phenomenon (capacitances ranged between 50 and 130 F/g in aqueous electrolytes).5 It was expected that increasing surface areas would lead to an increase in the gravimetric capacitance and hence energy density. This was attempted by creating porosity in the carbons through activation of the carbons or by use of templates, as well as generating the carbons from transition metal carbides or even silicon carbide by selectively etching of the electropositive metal or semiconductor in acidic environments.6, 7 Following this approach, TiC derived nanoporous materials have been shown to exhibit energy densities of 10.8 Wh/l (120 F/g capacitance) at a voltage of 2.7 V.8

It was however observed that the double layer type capacitance did not directly scale with surface area in many instances on account of the pores being too small for electrolyte to enter. Investigations into this phenomenon lead to the conclusion that an optimal porosity of the size of two solvated ions was ideally necessary to obtain maximum capacitance. An interesting twist to this understanding came from the results of the work by Gogotsi et al. who showed that sub-nanometer pores allowed for ion desolvation and thus contributed to a significant increase in gravimetric capacitance arising from a smaller distance of charge separation.9 It was also found that the pore size required for desolvation was solvent dependent and that this phenomenon leads to shape distortion in the cyclic voltammograms.10, 11 Maximum capa-citance has also been realized in the case of non-aqueous electrolytes when the ion size is almost comparable and equal to the pore size (see Fig. 3). It has been previously shown that large pores can be accessed quickly while the accessibility of smaller pores are much more kinetically limited.12 Various carbons with porosities varying between 9 and 14 AO were electrochemically cycled in KOH and it was determined that carbons with 9 AO pores had relatively lesser capacitances. This effect and its implications are yet to be however analyzed in the case of sub-nanometer size pores.

Fig. 2. Plot showing trends in supercapacitor research leaning toward higher energy densities rather than higher voltages.4

Other carbon materials being considered for supercapacitor applications are carbon nanotubes (CNTs), graphene, and conducting polymers. CNTs were considered to hold a distinct advantage over activated and high surface area carbon powders in that the nature of the pores was more in the mesoporous than in the microporous range. Combined with their good conductivity and linear current to voltage response in lithium based electrolytes, they were thought to be ideal supercapacitor materials. Capacitance values upto 135 F/g were reported with multi-walled carbon nanotubes (MWNTs)14 using aqueous electrolytes over a 0.8 V window range. It has been found that the carbon nanotube capacitance depends on the diameter of the tubes and accessibility of the inner channel to ions in electrolyte similar to observations on carbon based capacitors discussed earlier.

Single walled carbon nanotubes (SWNTs) are also attractive due to their high electrical conductivity and possibly larger voltage window of stability.15 A recent study on SWNTs in an organic electrolyte (1 M Et4NBF4/acetonitrile) has shown capacitance similar to commercial activated carbons.16 Gravimetric capacitance has also been observed to vary in the range of 7 and 20 F/g for SWNTs as compared to 9-32 F/g for activated carbons.

Though the inherent capacitance of carbon nanotubes is small, their high electronic conductivity, mechanical strength and unique three-dimensional morphology have made them very useful templates for high power applications wherein pseudocapacitor materials such as conducting polymers or metal oxides are deposited on the carbon nanotubes and the composite is used as electrode for supercapacitors.

Among such composites, the CNT/ polypyrrole system has been extensively explored.17-19 Conducting polymers such as polypyrrole exhibit pseudocapacitance behavior through p- or n-type doping. Capacitances as high as 192 F/g were reported with polypyrrole composites with MWNTs synthesized using electrochemical templating.20

An often-neglected aspect when using highly conductive materials such as CNTs is the contact resistance between the current collector and the material itself. Shaijumon et al.21 have shown that significant improvement in rate capability is noticed on tailoring the interface between CNTs and the current collector including templating. Accordingly, CNTs using gold contacts have been synthesized using alumina templates and power densities as high as 48 kW/kg have been demonstrated.

Another notable development is the emergence of graphene as a possible supercapacitor material. Ruoff et al. pioneered the research into generation of chemically modified graphene and has recently demonstrated capacitances of 99 F/g and 135 F/g in non-aqueous and aqueous electrolytes, respectively.22, 23 Recently, Chen et al. have reported capacitances as high as 205 F/g with graphene synthesized by chemical reduction of graphene oxide using hydrazine.24 Electrochemical tests were performed in an aqueous electrolyte over a 1 V window. Energy densities as high as 28.5 Wh/kg at 10 kW/kg have been demonstrated in a two electrode cell. Graphene’s superior properties have been attributed to higher accessible surface area (~2600 m2/g due to lack of agglomeration), very high conductivity (~100 S/m), and excellent chemical stability. Capacitor performance of

Jampani, et al.(continued from previous page)

The Electrochemical Society Interface • Fall 2010 59

Fig. 4. Charge storage in crystalline and amorphous MoO3 showing effect of crystallinity on intercalation supercapacitance.(See Ref. 39. Reproduced with permission from Macmillan Publishers Ltd.)

Fig. 3. Figure showing effect of pore size on capacitance. Optimal capacitance is obtained when pore size and electrolyte ion size are almost equal.(See Ref. 13. Reproduced with permission from Elsevier.)

graphene is also independent of the nature of porosity due to the 2D structure afforded by cleaving of the graphite sheets, thus bypassing most of the complications involved with other carbon based materials.

Carbon based supercapacitors are also being considered for free-standing, flexible applications such as electronic papers and roll-up displays.25 Graphene shows great promise based on its excellent mechanical properties. Graphene/polyaniline composites were made by electropolymerization of polyaniline onto graphene paper formed by membrane filtration of graphene suspension.26 Capacitances of about 230 F/g were reported in sulfuric acid over a 1 V window. Higher capacitances of about 530 F/g at 200 mA/g were also reported for polyaniline-doped graphene synthesized by in situ polymerization within graphene oxide before reduction.27

Transition Metal Oxides

Transition metal oxides have been widely explored for supercapacitor applications because of their layered structure and ability to adopt wide variety of oxidation states. Electrochemical behavior of oxides is pseudo-capacitative in nature due to either highly reversible surface chemical reactions or extremely fast and reversible lattice intercalation. Oxides of a wide variety of transition metals have been explored for this purpose and the most outstanding among them are ruthenium and manganese oxides. Ruthenium oxide has been demonstrated to have very high capacitances of about 900 F/g for hydrous ruthenium dioxide.28, 29 However the prohibitive cost of ruthenium oxide makes it impractical

for commercialization. Efforts in this front are on-going to form composites with other oxides, conducting polymers or carbon based materials to retain performance while reducing the noble metal content.30 In one such work, ruthenium dioxide was electrodeposited into poly (3,4-ethylenedioxythiophene) and electrochemically cycled at 50 mV/s in 1M H2SO4 over a 1 V window.31 Energy densities of 28Wh/kg at power densities of 20 kW/kg have been reported. Manganese dioxide on the other hand is a cheap alternative to ruthenium oxide, but has much less (~110-260 F/g) capacitance and thus efforts are on-going to improve its capacitance and rate capability.32 Low conductivity of MnO2 and poor proton transport through the active material have been

shown to lead to drop in capacitance and columbic efficiency on increasing film thickness.33, 34 MnO2 has thus been deposited onto CNTs and conducting polymers such as polypyrrole in order to overcome the problem of inherent low conductivity.35-37

In recent work, Brezesinski et al. have shown the importance of retaining meso-porosity and crystallinity in nanoparticles to obtain maximum pseudocapacitance. Improvement in charge storage capacity has been shown to depend on the porosity of the external walls.38 The meso-porosity and resulting nanoparticulate nature is important to achieve large surface and easy intercalation. At the same time, it is important to maintain crystallinity (see Fig. 4) to reduce grain boundaries

60 The Electrochemical Society Interface • Fall 2010

and their resulting mass transfer effects. They have demonstrated this using both TiO2 and MoO3 synthesized by template methods. Upon comparison with sol-gel derived materials, template-synthesized materials have been shown to have more developed and ordered pores allowing easy diffusion of electrolyte into inner pores, thus leading to increase in both capacitance and intercalation.39

Inorganic Non-Oxide Materials: Transition Metal Nitrides,

Sulfides, and Carbides

Unlike oxide materials, which have been extensively studied for supercapacitors, nitrides and sulfides have received sparse attention. Conventionally, some nitrides are known to have better conductivity than oxides and are hence more suitable for high rate devices like capacitors. Molybdenum nitride was first explored by Conway et al. and has been shown to have promising supercapacitor properties.40 Thomson, Jr. et al. studied the capacitance properties of nitrides synthesized by temperature programmed nitridation of various oxides including molybdenum and

vanadium, and reported capacitances as high as 100 mF/ cm2.41 Following this, Daiwon et al. have explored various nanostructured nitrides in aqueous media and obtained capacitance values as high as 1340 F/g.42-44 Vanadium nitride (VN) nanoparticles synthesized by a two step ammonolysis followed by passivation have been shown to exhibit these excellent capacitance values due to the formation of a thin amorphous oxide/oxynitride layer present on the surface of the nitride (see Fig. 5). Glushenkov et al. have also explored supercapacitor properties of VN with much higher loadings than reported by Daiwon et al. and have reported capacitances between 150 and 180 F/g in different aqueous electrolytes.45 Supercapacitance properties of nitrides have been found to be loading dependent, resulting in a decrease in capacitance values with increased materials loading. This is primarily due to the inferior electronic conductivity of the nanocrystalline oxide/nitride nanocomposite, which could be solved by tailoring the desired functionality by generating various architectures and composite designs with improved electronic conductivity as in the case of MnO2. Though nitrides have been shown to possess very high capacitances, they suffer from stability problems limiting their cycle life, an issue that needs to be overcome to

achieve commercialization of these materials. Other than nitrides, copper and cobalt sulfide films have also been explored for supercapacitor applications and results have indicated capacitance values in the range of 100-200 F/cm2.46-48

Non-aqueous Electrolytes and Cell Design

A large body of recent work on supercapacitors has focused on the use of non-aqueous electrolytes for supercapacitor applications. This is due to the squared dependence of energy density on the voltage window of the cell. Aqueous electrolytes are inherently limited on account of gas evolution due to decomposition at high voltages. To overcome this, commonly used lithium-ion battery type electrolytes and ionic liquids have been used to test various oxides and carbon based electrode materials discussed in the previous sections.49-53 Among these electrolytes, tetraethyl ammonium tetraflouroborate (Et4NBF4) in acetonitrile is most commonly used. Energy densities of 5 Wh/kg and very high power denisities of 1200 W/kg were reported using polyaniline electrodes in organic acid (CF3COOH) with a supporting electrolyte of tetramethyl ammonium methanesulfonate.54

Fig. 5. Schematic diagrams showing the presence of a thin oxide layer over nanoparticle VN generated by a two-step ammonolysis approach, shown to exhibit very high capacitances of up to 1340 F/g.(See Ref. 42. Reproduced with permission from Wiley-VCH Verlag GmbH & Co. KGaA.)

Jampani, et al.(continued from previous page)

The Electrochemical Society Interface • Fall 2010 61

A more prominent direction in the supercapacitor field has been toward the use of asymmetric cells using a capacitor type electrode in conjunction with a battery type electrode. Following pioneering work by Amatucci et al.55 using the lithium titanate/acetonitrile/activated carbon cell, various other materials have been similarly tested and shown to have very high energy densities(~10 Wh/kg). MnO2 has also been tested in a 2.2 V aqueous hybrid cell with activated carbon and shown to have energy densities as high as 21 Wh/kg. Zheng et al. have also shown that energy densities of asymmetric cells are dependent on the electrode mass ratios and the ionic concentration of the electrolyte.56 Consequently, electrode matching of the active materials content is very important for asymmetric cells and Li et al. have proposed a theoretical model for electrode matching validating it using a LiMn2O4/activated carbon system.57

Conclusion

The importance of the need to develop the electrochemical capacitor technology has only recently been realized. This has spurned a large number of interesting technologies including the evolution of new materials such as graphene, which shows great promise owing to its excellent electronic properties. In addition, various composite electrodes have been developed and effort has been placed into tailoring the architecture of electrodes to retain high energy density at high rates. Similarly, transition metal oxides have been researched quite extensively with relatively few reports on transition metal nitrides, which appear quite promising as well. Finally, the use of non-aqueous electrolytes and ionic liquids has led to various new cell configurations with very high energy densities. The challenge however, lies in maintaining cyclability and stability at high rates maintaining these attractive characteristics and therefore research efforts are focused in this direction. Despite the research advances, it is clear that development of supercapacitor materials is extremely vital for the improvement of power quality with the advantage being a faster access to the stored energy up to 106 times charge/discharge cycles.

Acknowledgement

PNK would like to acknowledge the support of NSF, DOE, and the Edward R. Weidlein Chair Professorship Funds for support of this work. Ms. YiAn Sun is also acknowledged for preparing Figure 1.

About the Authors

Prashanth h. JamPani is a graduate student pursuing his PhD in the Chemical and Petroleum Engineering Department at the Swanson School of Engineering, University of Pittsburgh. He is working in the area of nanostructured transition metal nitride and composite based supercapacitors in Prashant N. Kumta’s research group. Mr. Jampani holds a BTech degree in chemical and electrochemical engineering from Central Electrochemical Research Institute, Karaikudi, India, and an MS degree in materials science and engineering from Carnegie Mellon University. He may be reached at [email protected].

a. manivannan is a materials scientist at the U.S. Department of Energy’s National Energy Technology Laboratory (NETL). Prior to joining the U.S. DOE, Dr. Manivannan was working as a faculty at the Physics Department at West Virginia University where he currently serves as an adjunct professor. He has carried out research in multidisciplinary areas in materials science for more than 25 years in academia. His research interests and expertise includes materials for energy conversion and storage involving photoelectrochemical cells, solid oxide fuel cells, electrochemical energy storage devices such as Li-ion batteries, supercapacitors, thermoelectric materials, catalysts, etc. Dr. Manivannan has been active in performing several international research collaborations and participates as an adviser in the NRC Research Associateship Programs. He may be reached at [email protected].

Prashant n. Kumta is the Edward R. Weidlein Chair Professor in the Swanson School of Engineering at the University of Pittsburgh. He holds appointments in the Departments of Bioengineering, Chemical and Petroleum Engineering, Mechanical Engineering and Materials Science as well as Department of Oral Biology in the School of Dental Medicine. His research interests span the broad areas of energy storage including lithium ion batteries, supercapacitors, proton exchange membrane fuel cells, hydrogen storage and generation, electrolysis, and solar cells, as well as novel biomaterials and composites for biotechnology, stem cell, and tissue engineering applications. He holds BTech, MS, and PhD degrees and is currently the Editor-in-Chief of Materials Science and Engineering B: Advanced Functional Solid-State Materials. He may be reached at [email protected].

References 1. G. Allen, “Nanomarkets Smart Grid

Analysis Group Issues, Papers on Smart Grid Sensors and Smart Grid Supercapacitors” (2009), cited 2010 July 22, http://www.nanomarkets.net/ index.php/news/ar t ic le/nanomarkets_publishes_report_on_batteries_and_supercapacitors_for_smart_gri/.

2. K. Sahay and B. Dwidevi, “Supercapacitors Energy Storage System for Power Quality Improvement: An Overview”, J. Elec. Systems, 5, P8 (2009).

3. W. G. Pell and B. E. Conway, J. Electroanal. Chem., 500, 121 (2001).

4. R. Ball, “Supercapacitors See Growth as Costs Fall” (2006), http://www.electronicsweekly.com/Articles/2006/03/03/37810/Supercapacitors-see-growth-as-costs-fall.htm.

5. A. G. Pandolfo and A. F. Hollenkamp, J. Power Sources, 157, 11 (2006).

6. J. Chmiola, G. Yushin, Y. Gogotsi, C. Portet, P. Simon, and P. L. Taberna, Science, 313, 1760 (2006).

7. Y. Gogotsi, A. Nikitin, H. H. Ye, W. Zhou, J. E. Fischer, B. Yi, H. C. Foley, and M. W. Barsoum, Nature Materials, 2, 591 (2003).

8. M. Arulepp, J. Leis, M. Latt, F. Miller, K. Rumma, E. Lust, and A. F. Burke, J. Power Sources, 162, 1460 (2006).

9. J. Chmiola, C. Largeot, P. L. Taberna, P. Simon, and Y. Gogotsi, Angew. Chem. Int. Ed., 47, 3392 (2008).

10. J. Chmiola, C. Largeot, P. L. Taberna, P. Simon, and Y. Gogotsi, Science, 328, 480 (2010).

11. P. Simon and Y. Gogotsi, Philos. Trans. R. Soc. London, Ser. A, 368, 3457 (2010).

12. D. Y. Qu and H. Shi, J. Power Sources, 74, 99 (1998).

13. R. Lin, P. Huang, J. Segalini, C. Largeot, P. L. Taberna, J. Chmiola, Y. Gogotsi, and P. Simon, Electrochim. Acta, 54, 7025 (2009).

14. E. Frackowiak, K. Metenier, V. Bertagna, and F. Beguin, Appl. Phys. Lett., 77, 2421 (2000).

15. D. N. Futaba, K. Hata, T. Yamada, T. Hiraoka, Y. Hayamizu, Y. Kakudate, O. Tanaike, H. Hatori, M. Yumura, and S. Iijima, Nature Mater., 5, 987 (2006).

16. P. W. Ruch, R. Kotz, and A. Wokaun, Electrochim. Acta, 54, 4451 (2009).

17. S. Lee, M. S. Cho, J. D. Nam, and Y. Lee, J. Nanosci. Nanotechn., 8, 5036 (2008).

18. S. W. Woo, K. Dokko, and K. Kanamura, J. Power Sources, 185, 1589 (2008).

62 The Electrochemical Society Interface • Fall 2010

19. M. Hughes, M. S. P. Shaffer, A. C. Renouf, C. Singh, G. Z. Chen, J. Fray, and A. H. Windle, Adv. Mater., 14, 382 (2002).

20. M. Hughes, G. Z. Chen, M. S. P. Shaffer, D. J. Fray, and A. H. Windle, Chem. Mater., 14, 1610 (2002).

21. M. M. Shaijumon, F. S. Ou, L. J. Ci, and P. M. Ajayan, Chem. Commun., 20, 2373 (2008).

22. M. D. Stoller, S. J. Park, Y. W. Zhu, J. H. An, and R. S. Ruoff, Nano Lett., 8, 3498 (2008).

23. Y. W. Zhu, S. Murali, M. D. Stoller, A. Velamakanni, R. D. Piner, and R. S. Ruoff, Carbon, 48, 2118 (2010).

24. Y. Wang, Z. Q. Shi, Y. Huang, Y. F. Ma, C. Y. Wang, M. M. Chen, and Y. S. Chen, J. Phys. Chem. C, 113, 13103 (2009).

25. L. B. Hu, H. Wu, and Y. Cui, Appl. Phys. Lett., 96, 183502 (2010).

26. D. W. Wang, F. Li, J. P. Zhao, W. C. Ren, Z. G. Chen, J. Tan, Z. S. Wu, I. Gentle, G. Q. Lu, and H. M. Cheng, ACS Nano, 3, 1745 (2009).

27. H. L. Wang, Q. L. Hao, X. J. Yang, L. D. Lu, and X. Wang, Electrochem. Commun., 11, 1158 (2009).

28. J. W. Long, K. E. Swider, C. I. Merzbacher, and D. R. Rolison, Langmuir, 15, 780 (1999).

29. D. A. McKeown, P. L. Hagans, L. P. L. Carette, A. E. Russell, K. E. Swider, and D. R. Rolison, J. Phys. Chem. B, 103, 4825 (1999).

30. K. Naoi, S. Ishimoto, N. Ogihara, Y. Nakagawa, and S. Hatta, J. Electrochem. Soc., 156, A52 (2009).

31. R. Liu, J. Duay, T. Lane, and S. B. Lee, Phys. Chem. Chem. Phys., 12, 4309 (2010).

32. R. N. Reddy and R. G. Reddy, J. Power Sources, 132, 315 (2004).

33. J. N. Broughton and M. J. Brett, Electrochim. Acta, 50, 4814 (2005).

34. M. Toupin, T. Brousse, and D. Belanger, Chem. Mater., 16, 3184 (2004).

35. J. K. Chang, C.T. Lin, and W.T. Tsai, Electrochem. Commun., 6, 666 (2004).

36. S. R. Sivakkumar, J. M. Ko, D. Y. Kim, B. C. Kim, and G. G. Wallace, Electrochim. Acta, 52, 7377 (2007).

37. G. X. Wang, B. L. Zhang, Z. L. Yu, and M. Z. Qu, Solid State Ionics, 176, 1169 (2005).

38. T. Brezesinski, J. Wang, J. Polleux, B. Dunn, and S. H. Tolbert, J. Am. Chem. Soc., 131, 1802 (2009).

39. T. Brezesinski, J. Wang, S. H. Tolbert, and B. Dunn, Nature Mater., 9, 146 (2010).

40. T. C. Liu, W. G. Pell, B. E. Conway, and S. L. Roberson, J. Electrochem. Soc., 145, 1882 (1998).

Jampani, et al.(continued from previous page)

41. J. Parker, M. Wixom and L. Thompson (assigned to T/J Technologies, Inc.), U.S. Pat. No. 5,680,292 (1997).

42. D. Choi, G. E. Blomgren, and P. N. Kumta, Adv. Mater., 18, 1178 (2006).

43. D. W. Choi and P.N. Kumta, Electrochem. Solid-State Lett., 8, A418 (2005).

44. D. Choi and P. N. Kumta, J. Electrochem. Soc., 153, A2298 (2006).

45. A. M. Glushenkov, D. Hulicova-Jurcakova, D. Llewellyn, G. Q. Lu, and Y. Chen, Chem. Mater., 22, 914 (2010).

46. S. J. Bao, C. M. Li, C. X. Guo, and Y. Qiao, J. Power Sources, 180, 676 (2008).

47. Z. Stevic and M. Rajcic-Vujasinovic, J. Power Sources, 160, 1511 (2006).

48. F. Tao, Y. Q. Zhao, G. Q. Zhang, and H. L. Li, Electrochem. Commun., 9, 1282 (2007).

49. M. Armand, F. Endres, D. R. MacFarlane, H. Ohno, and B. Scrosati, Nature Mater., 8, 621 (2009).

50. A. Balducci, U. Bardi, S. Caporali, M. Mastragostino, and F. Soavi, Electrochem. Commun., 6, 566 (2004).

51. A. Balducci, R. Dugas, P. L. Taberna, P. Simon, D. Plee, M. Mastragostino, and S. Passerini, J. Power Sources, 165, 922 (2007).

52. E. Frackowiak, G. Lota, and J. Pernak, Appl. Phys. Lett., 86, 164104 (2005).

53. M. Lazzari, M. Mastragostino, and F. Soavi, Electrochem. Commun., 9, 1567 (2007).

54. F. Fusalba, P. Gouerec, D. Villers, and D. Belanger, J. Electrochem. Soc., 148, A1 (2001).

55. G. G. Amatucci, F. Badway, A. Du Pasquier, and T. Zheng, J. Electrochem. Soc., 148, A930 (2001).

56. J. P. Zheng, J. Electrochem. Soc., 150, A484 (2003).

57. J. L. Li and F. Gao, J. Power Sources, 194, 1184 (2009).

The Benefits of Membership

Join now for exceptional discounts on all ECS publications, meetings, and short courses.

• Journal of The Electrochemical Society

• Electrochemical and Solid-State Letters

• ECS Transactions

• Interface, the ECS Member Magazine

• Discounts on Meetings and Publications

• Professional Development and Education

• Honors and Awards Program

• Career Center

• Member Directory

www.electrochem.org

Can Be Yours!