Adjustable Height Workstation Kit

Transcript of Adjustable Height Workstation Kit

Ergonomic Workstations

Adjustable Height Workstation

Assembly GuideInstallation and MaintenancePublication Number: 8981 500 300 7/02

Adjustable Height Workstation Kit

2

All rights are held by BOSCH REXROTH CORPORATION andROBERT BOSCH GMBH, also regarding patent claims. We retainall powers of disposition, such as for copying and/or for passing-on tothird parties.

We reserve the right to make technical changes at any timewithout notice.Errors and omissions excepted.© 2002 Bosch Rexroth Corporation

Table of Contents

Important Safety Information ........................................................................................................................................3

About This Manual ..........................................................................................................................................................5

Technical Data .................................................................................................................................................................6

Application and Function ...............................................................................................................................................6

Recommended Tools .....................................................................................................................................................7

Design and Detailed Description ................................................................................................................................8

Parts List ............................................................................................................................................................................8

Before You Begin ......................................................................................................................................................... 10

Table Top Assembly .................................................................................................................................................... 11

Using T-bolts and T-nuts ............................................................................................................................................ 13

Joining Profiles .............................................................................................................................................................. 13

Attaching the Cross Braces ...................................................................................................................................... 14

Attaching the Table Top ............................................................................................................................................. 15

Control Box Mounting ................................................................................................................................................. 16

Installing the Cross Brace .......................................................................................................................................... 17

Mounting Telescoping Acturator Assembly ........................................................................................................... 18

Assembling the Base Frame...................................................................................................................................... 20

Mounting Base Frame to the Telescoping Acturators ........................................................................................ 21

Final Assembly .............................................................................................................................................................. 22

Operation and Maintenance ...................................................................................................................................... 23

Warranty Information ................................................................................................................................................... 24

Liability ............................................................................................................................................................................ 24

Environmental Protection ........................................................................................................................................... 24

3

IMPORTANT SAFETY INFORMATIONIMPORTANT: This assembly and operation manual should be reviewedwith all equipment operators as part of your operator training program.

SAFETY FIRST!

Important safety information is contained throughoutthis manual to alert you to potentially dangeroussituations and help prevent accidental injury andproperty damage.

The safety warning symbol above has been includedto warn you of hazards that can hurt or kill you andothers, and/or cause serious damage to the equipmentand other property.

In addition, the following safety alert words are used:

DANGER! Means that you or others willbe seriously or fatally injured ifinstructions are not followed.

WARNING! Means that you or others maybe seriously or fatally injured ifinstructions are not followed.

CAUTION! Means that you or others maybe injured if instructions arenot followed.

Material Hazards:

Some components, such as gearboxes, containlubricants or other materials that can represent apotential health hazard if handled, stored, or disposedof improperly.

Please contact Bosch for copies of the MaterialSafety Data Sheets (MSDS) for the lubricating oilused in gearboxes and other potentially hazardousmaterials.

Review All Safety Information:

Please review the safety information included onpage 4 and throughout this manual with all installers,operators, and maintenance personnel of thisequipment.

4

WARNING!Please read all assembly, and maintenance instructionscarefully before beginning set-up of the components inthis document.

Where appropriate, warning symbols have beenincluded in this publication to alert you of potential orimpending danger.

• Be sure to read and observe all safety warnings inthis document as well as those attached to theindividual modules. Failure to do so could result inpotential risks to your health and safety as well asthose around you.

• Covers and guards have been designed toeliminate pinch points and exposure to movingcomponents. DO NOT operate the adjustableheight workstation or any machinery with theguards removed. Serious injury may result!

• All set-up maintenance and repair work shouldbe performed only by properly trained, qualifiedpersonnel. All operators must be properly trainedin the use of this equipment.

• Be sure to follow all local, state and federalregulations when installing electrical devices ofany type

• Unplug the workstation before beginningmaintenance or repair work of any type on theadjustable height workstation.

• The adjustable height workstation is designed to beused in assembly operations where ergonomicconsiderations dictate the need for a heightadjustable workstation. Table top maximum width is1400 mm. The minimum width is 1000 mm.

It will accommodate extension arms for tool

holders, balancers, lights, parts bins and powerstrips. Maximum workstation load must not exceed400 lb (181.5 kg), either centered or distributed.Exceeding published specifications will result inpremature wear, damage, or failure of the motor,gearbox, seals and/or other components.

• CAUTION–Tip over hazard! Extension arms withtool holders and parts bins can present a potentialtip over hazard under certain height and loadconditions. Table tops with overhangs also presenta potential for tip over. Be sure the load is alwayscentered on the table top. If it is not possible tocenter the load, be sure it is evenly distributedfrom side to side and front to back. DO NOT sit,stand or lean on table tops! DO NOT exceed themaximum allowable moment of 500 Nm as shownin the diagram below! For maximum stability andsafety Bosch Rexroth recommends anchoring theworkstation to the floor. A number of flooranchoring options can be found in the Boschaluminium structural framing catalog availablethrough your local distributor.

SAVE THESE INSTRUCTIONS!

IMPORTANT SAFETY INFORMATION

Allowable Moment=500 Nm Maximum

5

About this manual

The manual is divided into the following sections tomake it easier to use:

• Technical Data – Provides the most importanttechnical specifications.

• Application and Function – Gives generalinformation about the Adjustable HeightWorkstation.

• Design and Detailed Description – Supplies anoverview of the modules that make up theAdjustable Height Workstation. This section willfamiliarize you with the modules individualcomponents.

• Assembly – Lists step-by-step assemblyinstructions for the Adjustable Height Workstation.

• Operation – provides valuable operatinginformation.

• Maintenance – None required over life of unit.

If this module was ordered as CE compliant, pleasecontact our applications engineering department fora copy of the latest manufacturer's CE declaration, ifrequired for your records.

6

Application and Function

The Adjustable Height Table Frame Kit is used inassembly operations where ergonomic considerationsdictate the need for height adjustability.

Height adjustment is accomplished with simple push-button up/down control supplied with the unit. 110VAC motors inside the telescoping actuators supplythe power for the height adjustment. The two motorsare synchronized electronically by a control modulealso supplied with the unit.

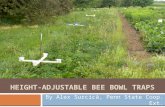

Figure 1

Technical Data

Functional dimensions for the Adjustable Height TableFrame Kit are shown in Figure 1 below.

The minimum height is nominal since the position ofthe height adjustment studs and thickness of the tabletop will effect this dimension.

The table frame is constructed of 6063 T6 aluminumprofile. It is clear anodized to give a professionalfinished appearance.

The Adjustable Height Table Frame Kit is powered bytwo 110 VAC, 60 Hz motors. The telescoping actuatorshave a maximum adjustment range of 500 mm, and willsupport a maximum load of 400 lb (181.5 kg).

Table Top Max. 1400mm

Table Top Min. 1000mmFrame 990mm

Max

. 13

02m

m

802

mm

64

0mm

15mm 595mm

500 NmMaximumMoment

595mm

555mm

7

Recommended Tools

The following tools are recommended to assemble the Adjustable Height Table Frame Kit:

1 13 mm and 19 mm combination wrench

1 5, 6, 8, and 10 mm allen wrenchs

1 flat tip screwdriver

1 electric drill

1 soft faced mallet

1 adjustable wrench

1 #1 and #2 phillips screwdriver

1 tape measure

1 square

1 2 mm and 3 mm drill bits for drilling pilot holesin the table top.

1 level

Specifications

Adjustable Height Workstation Kit Part Number ........................................................................... 8981 021 140

Frame Height .................................................................................................................. 802 – 1302 mm Adjustable

Frame Width ................................................................................................................................. 990 mm (38.976 in)

Table Top Width .....................................................................................................1000 mm min. – 1400 mm max.

Frame Depth ................................................................................................................................. 595 mm (23.425 in)

Maximum Load, Centered .............................................................................................................. 400 lb (181.5 kg)

Maximum Load, Distributed ........................................................................................................... 400 lb (181.5 kg)

Maximum Moment @ .................................................................................................................... 500 Nm (Static)

Shipping Weight W/Out Table Top:

Carton 1 – Telescoping Actuators and Components ...........................................................40.5 lb (18.4 kg)

Carton 2 – Frame Components ..................................................................................................45.5 lb (20.7 kg)

8

Parts List

Item No. Qty. Part Number Description

1 2 8981 992 026/870 Profile, 45x45 –/–2 1 3842 990 644/867 Profile, 45x45 D17/D173 2 8981 021 266 Profile, 45x60 W/S12x30 screws4 2 8981 021 148 Profile W/Inserts, P45x60H5 1 8981 021 147 Profile, 45x90H D17/D17 SPCL6 1 8981 021 145 Profile, 45x90L D9.5/D9.5 SPCL7 2 8981 021 127 Telescoping Actuator (TMA) with 8–Hex Nuts8 2 8981 021 129 Plate, Mounting9 2 3842 500 923 Bolt Connector Kit, 90 mm10 2 3842 500 921 Bolt Connector Kit, 45 mm11 16 3842 197 091 T-bolt12 16 3842 345 081 M8 Flange Nut13 8 3842 242 493 T-Nut, 10mm, M814 16 2910 131 238 Screw, DIN 7984-M8x16-8.8-CZ15 4 3842 513 560 Economy Leveling Stud, M1216 2 2915 051 119 Nut, ISO4036-M-1217 4 3842 502 387 WS58N12 Washer, Lock (Zinc)18 4 2910 141 350 Screw, DIN 912-M12x50-8.8-CZ19 8 2910 141 207 Screw, DIN 912-M6x35-8.8-CZ20 8 3842 502 384 WS58N6 Washer, Lock (Zinc)21 4 2910 611 014 3.5x22-CH-CA screw (DIN7981-ST)22 4 8981 021 193 Rectangular Nut23 8 3842 523 537 Plastic Adapter, 8mm to 10mm24 8 3842 515 473 Adjustable Angle Gusset25 10 3842 523 558 Gusset, 45x4526 6 3842 523 563 Round Cover Cap, 45x4527 6 3842 515 122 End Cap, 45x60 H Black28 2 3842 511 783 End Cap, 45x90 H Black29 1 8981 021 190 Control Box30 1 8981 021 192 Switch W/Mounting Bracket31 4 3842 506 739 Cable Carrier, 10mmNot shown 4 8981 010 500 Cable Tie, Black 8.0 x 0.1 inNot Shown 2 8981 021 191 CableNot Shown 1 8981 500 290 Layout Template

Design and Detailed Description

The Adjustable Height Table Frame Kit contains all ofthe components necessary to build an electric liftheight adjustable table frame. The lift mechanism

consist of two motors synchronized with an electrotoniccontrol. The frame components are made from extrudedaluminum profiles. Tabletops are sold separately andinclude 4 mounting screws and flatwashers.

9

3031

29

282726

12 14

11 13

16

15

21

8

22 23 24 252018 1917

1 2 3 4 5 6

109

7

10

Before you begin

Before you begin to assemble the Adjustable HeightWorkstation, read through this manual to familiarizeyourself with the assembly procedure. Check all partscarefully against the parts list on page 8. The profilescan be easily identified by the part number/bar codetag applied to each profile.

Figure 2

Figure 2 below shows the location of each profile asit relates to the parts list. You may find it helpful tophoto copy the parts list page and refer to it as youassemble the table.

1

1

2

3

3

4

5

7

6

4

7

11

Figure 3

Table Top Assembly

NOTE: The adjustable table is assembled upsidedown. In the following steps make sure thetable top is positioned with the bottom side up.

Locate the layout template in your parts kit. Unroll itand center it on the bottom side of your tabletop.Carefully align the front and back edges of the templatemaking sure it is centered between the left and rightedges of your table top as shown in Figure 3, thentape it in place.

HELPFUL HINT: When drilling pilot holes in thetable top, measure the depth on your drill bitfirst and mark it. Then wrap tape around the drillbit to show how far to drill.

Drill 2 mm pilot holes 18 mm deep for the control boxin each of the 4 locations indicated on the layouttemplate as shown in Figure 3.

Decide which switch location you are going to use.Then drill 2 mm pilot holes 18 mm deep at each of the3 indicated locations for the switch as shown inFigure 3.

Drill 3 mm pilot holes 30 mm deep at each of the 4corner locations on the layout template as shown inFigure 3.

Check carefully to insure that you have drilled all of thenecessary pilot holes.

OptionalSwitch Mounting

Tape Template ToBottom Of Table Top

12

Figure 4

Table Top Assembly Continued

Locate the following parts and lay them out as indicatedon the template as shown in Figure 4.

2 8981 021 266 Profile, 45x60 with S12x30Connection Screw

1 8981 021 147 Profile, 45x90H

2 8981 992 026/870 Profile, 45x45

These profiles will form the frame for the underside ofthe table.

NOTE: The Inset Drawing on Figure 4 is shownreversed for clarity.

Slide the head of a S12x30 connection screw,attached to the 45x60 profile, into the 45x90 profileT-slot as shown in the Inset drawing on Figure 4.

NOTE: Position the 45x60 profile to extendslightly beyond the end of the 45x90 profile.This will allow room for the end cap that will beinstalled in a later step.

Align the edges over the outline on the layout template.Then use a 8mm allen wrench and tighten the S12screw through the access hole in the back side of the45x90 profile.

Attach the remaining 45x60 profile with S12x30 tothe other end of the 45x90 profile.

45x60Profile

W/Inserts

45x90Profile

8mmAllen Wrench

AccesHole

SlotS12x30Connection

Screw

45x60H ProfileS12x30 Connection Screw

P/N 898 102 1266

45x45 ProfileP/N 898 199 2026/870

45x90H ProfileP/N 898 102 1147

Bottom Of Table TopAnd Template

INSET

13

Figure 6

Joining Profiles

Locate 2–45x45 gussets. Use a flat tip screwdriver toremove the alignment tabs from one side of a gussetas shown in Figure 6. Be sure to remove thealignment tabs from only one side of the gusset.

Locate 4–T-bolts and 4–M8 flange nuts. Then start aflange nut onto each T-bolt just 1 or 2 turns.

Place a gusset onto the 45x60 profile with theremaining centering tabs positioned into the profileslot.

Slip a prepared T-bolt/flange nut combination throughthe slot in the gusset and slide the gusset against theadjoining 45x90 profile. Do not tighten the flange nutyet.

Slip a T-bolt/flange nut combination through theremaining slot in the gusset and tighten it. Thentighten the remaining flange nut.

Mount the remaining gusset at the other end of the ofthe 45x90 profile with T-bolt/flange nut combinationsnot shown.

Using T-bolts and T-nuts

The Bosch Adjustable Height Workstation Kit usesprofiles connected using the T-slot principle (Figure5). Insert the T-bolt into slot (A), and tighten down thenut. As it tightens, it will turn the T-bolt 90° in the slot(B), creating a friction lock (C). The same principleapplies to T-nuts. The maximum allowable torque is25 Nm (18.5 lb-ft).

ASSEMBLY HINT: T-bolts have a mark on the endof the threaded shaft that is in line with the T-bolthead. The T-bolt is correctly positioned when thismark is perpendicular to the T-slot.

Figure 5

A

B

C

Mark

45X45Gusset

M8 Flange Nut

T-bolt/Flange Nut

Combination

T-Bolt

45x60 Profile

45x90 Profile

FlatbladeScrewdriver

CenteringTab

CenteringTabs

Slot

Gusset

INSET

CenteringTab

14

Attaching The Cross Braces

Locate 4 more 45x45 gussets.

NOTE: The centering tabs on these gussets do notneed to be removed.

Locate 8–T-bolts and 8–M8 flange nuts. Then start aflange nut onto each T-bolt just 1 or 2 turns.

45x45Gussets

45x45 ProfileCross Brace

45x60 Profile

M8 Flange Nut

T-Bolt

Slot

Gusset

Figure 7

Place a gusset into the corner of a 45x45 and 45 x60profiles as shown in Figure 7.

Slip prepared T-bolt/flange nut combinations througheach slot in the gusset but do not tighten the flangenuts yet.

Install gussets at the 3 remaining locations on Figure 7.

Align the 45x45 profile cross braces over the layouttemplate outlines. Then tighten gusset hardware.

15

Attaching The Table Top

Locate 4 remaining 45x45 gussets. Then remove thealignment tabs from both sides of each gusset.

Remove the template between the underside of thetable top and profiles.

Locate the 4 mounting screws and 4 flat washers thatcame with the table top (purchased separately). Thenuse that hardware to attach the gusset to the tabletopas shown in the inset drawing on Figure 8.

Locate 4–T-bolts and 4–M8 flange nuts. Then start aflange nut onto each T-bolt just 1 or 2 turns.

Slip prepared T-bolt/flange nut combinations throughthe slot in the gusset and tighten the flange nut.

Attach the gussets to the table frame at the other 3locations as shown in Figure 8.

Locate 2–45x60 end caps and place them on theexposed ends of the 45x60 profiles. Tap lightly intoplace with a soft mallet.

If you do not intend to use Accessory Uprights(purchased separately), place 2–45x90 end caps onthe exposed ends of the 45x90 profile at this time.

45x45Gusset

45x45Gusset

45x60End Cap

45x90Profile 45x60

Profile

45x60End Cap

45x90End Cap

Table TopMountingScrew

Flat Washer

INSET

T-boltand

Flange Nut

Figure 8

16

Electronic Control Box Installation

Locate the Electronic Control Box and 4–3.5x22screws.

Use 4–3.5x22 screws to mount the control box to thetable top as shown in Figure 9. Use the holes drilledpreviously. See Figure 3 on page 11.

45x45Gusset

45x45Round Cover

Cap

ElectronicControl Box

3.5x22 Screws

INSET

Figure 9

Locate 8–45x45 round cover caps.

Place a round cover cap over each 45x45 gusset tocover the exposed mounting hardware. Tap lightly intoplace with a soft mallet. See the inset drawing onFigure 9.

17

Installing The Lifting Columns

Locate 2–45x90 Bolt Connector Kits, (P/N 3842500 923) and follow the steps below to install themin the 45x90 profile, (cross brace) as shown inFigure 10 and 11.

1. Refer to Figure 10 and install a bolt connectorwith the flat side positioned as shown into themachined profile hole.

2. Keep the bolt connector centered in the machinedhole and insert two alignment tabs, square endfirst, into each center bore of the profile.

3. Install a bolt connector and two alignment tabs onthe opposite end of the 45x90 cross brace andtemporarily set it aside.

4. Locate 4–M8 rectangular nuts and the 4–M8button head screws that came with the boltconnectors. Start a rectangular nut onto each M8screw (one or two turns only). Firmly push thescrew and nut assembly into the crescent shapedopening behind the bolt connector on the 45x90cross brace as shown in Figure 11. Make sure theshoulder on the screw is seated against the flatside of the connection bolt and the screw ispressed below the surface on the T-slot. Place acover cap over the connection screw.

5. Install rectangular nuts, screws and cover caps atthe other three locations on the 45x90 crossbrace.

NOTE: It may be helpful to wrap tape or a rubberband around both ends of the 45x90 cross brace tohold the bolt connector assemblies in place beforeproceeding with the following step.

Locate 2–telescoping actuators and place them asshown in Figure 12.

Slide the cross brace assembly from the bottom of theattachment plate upward until the edge of the 45x90profile is 15 mm from the end of the attachment plate.Tighten the four bolt connector screws in the ends ofthe cross brace to hold it in place.

Figure 10

Figure 11

Figure 12

Telescoping Actuators

AttachmentPlate

45x90Profile

Assembly

15mm

M8 Screw Cover Cap

M8 RectangularNut

45x90Profile

Cover Cap

Screw and NutAssembly

BoltConnector

Flat Side

AlignmentTab

45x90Profile

P/N 3842500923

18

Mounting Telescoping ActuatorAssemblies

Locate 8–adjustable gussets and break off the tabson the short side of all 8 gussets. Break off the tabs onthe long side of 4 of the gussets. On the remaining 4gussets install 8 mm to 10 mm plastic adapters ontothe tabs on the long side of the gusset. These adapterswill be used at the outboard mounting locations asindicated by the bold arrows in Figure 13.

Locate the 8–hex actuator mounting nuts that camewith the actuators and push them into the 8 smallpockets on the top of the gearboxes. Check to be surethat holes in the nuts line up with the holes in thehousing.

Use 8–M8x16 Low Head Screws (P/N 2910 131238) and attach the short side of the gussets to thetelescoping actuators. Be sure the gussets with plasticadapters are mounted at the outboard locations asindicated by the bold arrows in Figure 13. Make theseconnections finger tight for now.

Locate 8–M8 T-nuts and 8–M8x16 Low Head Screws.Insert the M8x16 screws into the long side of eachgusset and loosely attach a T-nut on the screws. Nowset the Telescoping Actuator assembly down onto thetable frame as shown in Figure 13, aligning the T-nutswith the profile T-slots.

NOTE: It may be helpful to have an assistanthelp hold and steady the Actuator assembly aseach T-nut is maneuvered under each adjustablegusset.

Carefully center the actuator assembly on the tableframe and tighten all 16–M8x16 mounting screws.

19

T-Nut

Adjustable GussetWith Adapters

Adjustable GussetWith Adapters

Adjustable GussetWith Adapters

M8 x 16 Low HeadScrew

(2910 131 238)

M8 x 16 Low HeadScrew

(2910 131 238)

Telescoping ActuatorAssembly

ActuatorMounting

Nut

Break OffTab

ShortSide

8mm To 10mmPlastic Adapter

AdjustableGusset

Figure 13

20

Assembling the Base Frame

Locate 2–45mm Bolt Connector Kits,(P/N3842500921). Install one bolt connector intoone end of the remaining 45x45 profile, cross braceas shown in Figure 14. Then push the square end ofan alignment pin into the center bore of the profile andinto the bolt connector to secure the connector intoplace as shown.

Install a bolt connector at the other end of the 45x45profile and secure with an alignment pin.

Locate 4–M8 T-nuts and 4–M8 screws. Start eachM8 screw into the a M8 T-nut. Then insert each screwassembly into the bolt connector slot on both ends ofthe 45x45 profile. Snap in cover caps to hold thescrews in place. Then insert the T-nuts into the slot onthe 45x60 profile as shown. Adjust the distance to271 mm as shown, then tighten the bolt connectorassembly screws with a 8 mm allen wrench.

Flat Side

BoltConnector

AlignmentPin

45x45 Profile(3842 990 644 1867)

45x45Profile

CoverCap

45x60Profile

(898102148)

271mm

M8 Screw

M8 T-Nut

Figure 15

Figure 14

21

Mounting the Base Frame to TelescopingActuators

NOTE: Remove and discard any protective coveringthat may be attached to the ends of the telescopingacturatorss by removing the screws holding it inplace.

Locate 8–M6 x 35 screws and 8–M6 lockwashersand 2–mounting plates.

Attach a mounting plate to each telescoping acturatorwith 4–M6 x 35 screws and 4–M6 lockwashers asshown in the inset drawing on Figure 16.

Locate 4–M12 x 50 screws and 4–M12 lockwashers.

M12 Nut

Threaded Insert Flange

45x60End Cap

M12Leveling

Stud

M12x50Screw

M12x50Lockwasher

15mm

Bottom FrameAssembly

MountingPlate

M6x35Screw

M6 Lockwasher

TelescopingActuator

Make sure the flanges on the threaded inserts are upas shown in Figure 16. Then mount the base assemblyonto the telescoping acturators with 4–M12lockwashers.

Locate 4–M12 Leveling Studs and 4–M12 nuts.

Screw a M12 nut onto each leveling stud. Then screwleveling studs into the inserts on each 45x60 profile atthe locations shown. Position each Leveling stud soit is 15mm from the bottom of the profile, then tightenthe M12 (jam) nut.

Mount a 45 x 60 end cap at both ends of each 45x60base profile.

Figure 16

22

Final Assembly

Mount the switch assembly with slider plate to thetable top using the pilot holes drilled previously. Usethe 3 screws that came with the switch. See insetdrawing #1 on Figure 17.

CAUTION: The plugs on the switch cable andtelescoping actuator cables are polarized andwill fit only one way in the control box andtelescoping actuator connector sockets. Usecare not to bend the pins when making theseconnections.

Plug the free end of the cable on the switch into theconnector socket HS on the control box.

Plug one end of a telescoping actuator cable into theconnector on one of the telescoping actuators. Plugthe other end of the cable into MOT 1 on the controlbox.

ControlBox

Cross BraceProfile

Cable Carrierand Tie

SliderPlate

Switch

PilotHoles

3.5x22Pan Head

Screw

Cable Carrierand Tie Cable

TieCableCarrier

INSET #1

INSET #2

Plug one end of a telescoping actuator cable into theconnector on the other telescoping actuator. Plug theother end of the cable into MOT 2 on the control box.

Insert a cable carrier into the side slot on the table topcross brace and twist 90° to lock it in place. See Inset#2. Then insert a cable tie through the slot on thecable carrier and around the cables.

In the same manner, install cable carriers and cableties at the other 3 locations on the table top crossbraces.

Figure 17

This completes the assembly of the Adjustable HeightWorkstation. With the help of an assistant, positionthe workstation upright and proceed to Operationand Maintenance on the next page.

23

Operation and Maintenance

Initializing the Telescoping actuators

Before putting the Adjustable Height Workstation intooperation, connect the unit to a properly grounded 110VAC receptacle and perform the following initializationtest.

1. Press the “Down” arrow on the Switch Panel. Holdthe button down, the desk will stop moving.

2. Continue holding the “DOWN” arrow. After about 5seconds the desk will begin to slowly move again. Itwill continue moving down until it reaches the absoluteend of the travel position and then stop.

3. Release the “DOWN” arrow and disconnect theelectrical cord. The desk is now ready to be put intooperation.

Operation

Before using the Adjustable Height Table for the firsttime, use a square to re-check all profiles forperpendicularity, and double check all mounting hardwarefor tightness.

Locate the wokstation in the work cell. Be sure there isa convienient power outlet within reach of the plug on theworkstation. Use a level and adjust the leveling feet untilthe workstation is level from side to side and front toback. For maximum stability, Bosch Rexroth recommendsanchoring the workstation to the floor. A number ofanchoring options can be found in the Bosch aluminumstructural framing catalog available through your localdistributor.

Plug the workstation into a properly grounded 110 VACreceptacle. Press the “UP” arrow on the switch assembly.Observe the workstation as it moves. Make sure that noexcessive strain is placed on any of the electrical wiresas the workstation is raised to its fully extended position.

Press the “DOWN” arrow on the switch assembly.Again, observe the electrical wires to verify that none ofthem will be pinched or severed as the workstationmoves to its fully lowered position.

When using the Adjustable Height Workstation, be surethe weight on the worksurface is centered and evenlydistrubuted. Maximum load is 400 lb (181.5 kg).

• DO NOT place entire load on one edge of theworktable surface.

• DO NOT lean on the table top.

• DO NOT sit or stand on the table top.

• DO NOT exceed the maximum moment of 500 Nmor tipover may occur (see the Caution on page 4).

• DO NOT use table tops wider than 1400 mm.

• DO NOT exceed the maximum payload of 400 lb(181.5 kg).

Maintenance

CAUTION: Disconnect power before

beginning maintenance work of any type.

The telescoping acturators used in the Adjustable HeightTable Frame Kit are maintenance-free. The followingcleaning and adjustment procedures, however, will helpkeep your work table in almost new condition if performedon a regular basis.

1. Remove all dirt and grease. Wipe the table clean ofany excess grease, dirt or any foreign substancesevery month.

2. Re-tighten all fasteners. Check all fastening elementsfor tightness, and re-tighten to 25 Nm (18 lb-ft) ifnecessary.

3. Check the power cord for cracks and fraying.

4. If at some point the telescoping actuators becomeuneven or out of syncronization, perform the initializingprocedure at the top of this page.

24

BOSCH REXROTH CORPORATION816 E. Third St., Buchanan, MI 49107

Hotline: (800-322-8724)In Canada (800-882-8724)Tel: (269) 695-0151 • Fax: (269) 695-5363On the Web at: www.boschRexroth-US.com

Publication No.: 8981 500 300 7/02

Module Warranty

BOSCH REXROTH CORPORATION warrants to the original purchaser the modules manufactured by us tobe free from defects in materials and workmanship under normal use and service. Our obligation under thiswarranty shall be limited to the repair or exchange of any part or parts which may thus prove defective undernormal use and service within one (1) year from date of installation by the original purchaser. THIS WARRANTYIS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED, INCLUDING THEWARRANTY OF MERCHANTABILITY OR FITNESS FOR USE, AND WE NEITHER MAKE NOR AUTHORIZEANY OTHER PERSON TO MAKE FOR US, ANY WARRANTY IN CONNECTION WITH THE SALE.

This warranty shall not apply to the modules or any part thereof that has been subject to accident, negligence,alteration, disassembly, abuse, or misuse after delivery by us. The term “Original Purchaser”, as used in thiswarranty, shall be deemed to mean the customer to whom the modules were originally sold.

Our obligation under this warranty is limited to the modules only, and excludes wear items, such as belts, etc.,and we may not be responsible for system concept, design, engineering, or function beyond this.

For further information, contact:

BOSCH REXROTH CORPORATION816 East Third StreetBuchanan, MI 49107Tel: 269-695-0151Fax: 269-695-5363

Liability:

In no event can the manufacturer accept warrantyclaims or liability claims for damages resulting fromimproper use of the equipment or as a result ofchanges made to the equipment other than thosespecified in this instruction manual.

The manufacturer will accept no claims in which non-original spare parts have been used. For informationon spare parts and replacement parts, call BoschRexroth Corporation.

Environmental Protection:

Always dispose of worn, damaged or obsolete partsin a responsible manner. Some components, such asgearboxes, contain lubricating oil which can pollutethe environment. It is the user’s responsibility todispose of all hazardous material within thecomponents following all local, state and federalguidelines.