Adiabatic Cooling

description

Transcript of Adiabatic Cooling

1

Adiabatic Cooling

Adiabatic air cooling additive systems

2

Typical areas we serve:

• Air cooled chil lers • Refrigeration• Dry Coolers • Air intake• Unitary

3

Typical problems we solve:• Increase in the electricity bill• Partition close to the equipment or installation of

new equipment around the existing units leading to air recirculation and poor unit operation

• Units located in places with higher air temperatures

• Equipment fitted with high pressure refrigerant suffering ambient air limitations

• Reduction of the available power supply • Additional cooling capacity required

4

How is solved:Reduces condensing air

temperature inlet due to:• Air recirculation • Summer peak

temperatures • Avoids high pressure cut-

outs

The compressors operates in better conditions and its life cycle is increased:

• Lower discharge temperature

• Lower oil temperature• Lower winding

temperature

5

Efficiency:• Reduction in the unit’s

power consumption• Maintain equipment at

full+ load during peak season

• Improved cooling capacity

Benefits:• Shading effect

The mesh placed in front of the coils shades and overcomes the solar radiation effect on coils, resulting in an additional 2°C to 3°C temperature drop.

• Self-cleaning filterThe mesh also acts as a self-cleaning filter keeping the coils clean longer and protecting them against dust and etc.

6

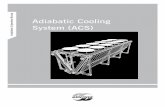

Adiabatic cooling uses the thermo dynamic properties of water and its evaporative cooling effect.

Concept is based on intermittently and efficiently evaporating water on a large mesh on the way of air stream. The evaporating water makes the air temperature drop before it reaches the condenser.

The water spraying towards the mesh, evaporates on the mesh and does not reach the coil.

How it works:

7

8

9

10

Diagrams for typical office buildings:Graphical view of power input depending on Outdoor air temperature. Points n` are shifted by adiabatic cooling and show power input reduction of adiabatic additive system .

11

Standard maintenance schedule:3M• Check for any scale or dirt / debris build up on mesh.

Remove in accordance with manufacturers recommendations.

• Check for any leak in pipe work or nozzle heads. • Check spurge system for correct operation in

particular the solenoid valve operation. If faulty replace the solenoid valve.

• Check spurge controller for correct settings. Adjust if necessary.

6M (Winter isolation if applicable)• Drain the pipe work and isolate both the water circuit and

the controller.• Check the mesh tensions and leave them in-situ.• Clean meshes if there is any debris / dirt.6M (Summer activation if applicable)• Open main water valve and activate the controller.• Test the spray operation and mesh wetting patterns. If any

of the nozzles blocked clean them.• Clean meshes.

12

ANNUAL• Check for any scale or dirt / debris build up on mesh.

Remove in accordance with manufacturers recommendations.

• Check for any leak in pipe work or nozzle heads. • Check spurge system for correct operation in

particular the solenoid valve operation. If faulty replace the solenoid valve.

• Check spurge controller for correct settings. Adjust if necessary.

SITE REQUIREMENTS• Power supply 220V.• Clean water supply with available flow and pressure

min.2bar.