ADI DAYS - Franco Bonollo

-

Upload

zanardi-fonderie-spa -

Category

Engineering

-

view

1.031 -

download

3

Transcript of ADI DAYS - Franco Bonollo

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Irons: a Solution for Lightweight and Materials Efficiency

Prof. Franco BONOLLODipart. di Tecnica e Gestione dei Sistemi IndustrialiUniversità di Padova, sede di Vicenza

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

ContentsIntroduction

Advanced Cast Iron

The Lightweight perspective

Advanced Cast Iron as a Lightweight solution

The Materials Efficiency perspective

Advanced Cast Iron as a Materials efficiency solution

The Raw Materials Sustainability perspective

Advanced Cast Iron as a Raw Materials Sustainability solution

Concluding Remarks

References & Contacts

2

3

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast IronIntroduction

4

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Mn

Mg

Al alloysNa

SrTe

Ni*

CuMn

Si

P

Tical V Zr

AgMo

La

CoCr

BeLa

Fe

ModificationSolid solution strengtheningGrain refiningEutectic Silicon homogeneisationSilicon refiningElements for slag control

Die Extraction

Advanced Cast IronDesign of MaterialModern High Performance materials (Superalloys, HSLA steels, Primary Al alloys, etc)are DESIGNED

5

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast IronAdvanced Cast Irons are Designed Materials

Diameter &Roundnessof Graphite

nodules

Size of Ferrite

needles

%C in Austenite

Size of Austenite

grains

Number of Graphite nodules per mm2

6

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast IronAdvanced Cast Irons are Designed Materials

Diameter &Roundnessof Graphite

nodulesSize of Ferrite

needles

%C in Austenite

Number of Graphite nodules per mm2

Size of Austenite

grains

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveWeight in Automotive

7

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

steel / iron

light metals

thermoplasticsother metals

elastomers glass / ceramics

thermosetspaint, undersealingtextiles,

other compounds

electric/electronics

thermoplastic elastomers

other materials

consumables(incl. fuel)

Total weight: 1935 kgSource: BMW

The Lightweight perspectiveWeight in Automotive

8

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveWeight in Automotive

Safety

Comfort

Performance

9

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveReducing CO2 Emissions

10

Eco-sustainability

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveWeight & CO2 Emissions

11

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveWeight & Fuel Consumption

12

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveEffects of Lightweight Design

13

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition

14

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition- spaceframe

15

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition- spaceframe

16

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition- spaceframe

17

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition- spaceframe

18

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition- spaceframe

19

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveMaterials in Competition- spaceframe

20

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveRoad vs Rail vehicles

21

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveRoad vs Rail vehicles

22

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveRoad vs Rail vehicles

23

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveRoad vs Rail vehicles

24

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveAttributes & Impacts in Rail vehicles

25

26

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Lightweight perspectiveCost saving in Lightweight

27

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Lightweight solutionPerformance of Advanced Cast Iron

28

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Lightweight solutionPerformance of Advanced Cast Iron

29

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

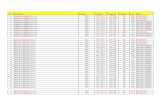

Material Microstructure nod/ mm2

Es

[GPa] R

[MPa] p02

[MPa] A [%]

HB

DI 400 100% Ferrite 220 160 440 305 19 150

100% Ferrite 290 160 449 315 >30 168

DI 600 35% Ferrite-65% Pearlite 310 165 722 426 10 220

25% Ferrite-75% Pearlite 240 165 727 435 12 239

DI 700 5% Ferrite-95% Pearlite 244 161 805 487 8.0 244

5% Ferrite-95% Pearlite 310 161 862 500 8.8 275

IDI Pearl.-Ferr. Interconnected 220 170 758 455 10 240

Pearl.-Ferr. Interconnected 290 170 957 645 15 292

ADI 800 Ausferrite 244 170 858 551 15 270

Ausferrite 310 170 1084 757 17 321

ADI 1050 Ausferrite 244 163 1110 794 13 330

Ausferrite 244 163 1160 831 12 350

Ausferrite 310 163 1118 805 10 345

ADI 1200 Ausferrite 310 148 1355 1150 10 410

Ausferrite 310 148 1363 1046 11 410

Advanced Cast Iron as a Lightweight solutionPerformance of Advanced Cast Iron

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Lightweight solutionProperties

ADI 800ADI 1050ADI 1200IDI

30

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Lightweight solutionSpecific Properties

ADI 800ADI 1050ADI 1200IDI

31

32

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveGeneral strategies

33

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveMaterials Properties in Design Process

34

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveMaterials Properties in Design Process

35

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveMaterials Properties in Design Process

36

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveMaterials Properties in Design Process

CastIron

37

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveMaterials Properties + Process Characteristics in Design Process

38

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveProcess as a variable for Design

39

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Materials Efficiency perspectiveProcess as a variable for Design

40

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

A liquid metallic alloy is poured into a mould,then it solidifies, achieving the desired shapeand finally is cooled up to room temperature. The key-stages of the process(melting – pouring – filling – solidification – cooling) may (?) generate defects & imperfections

melting solidifyingfillingpouring cooling

The Materials Efficiency perspectiveWhat is (basically) a Casting Process

41

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Permanent Mold (Die)

DisposableMold

PermanentPattern

DisposablePattern • Investment

casting• Lost Foam

• Green sand• Shell molding• Plaster molding• Disamatic process• V-Process• Low Pressure Sand Casting• ……

• Gravity Casting• Low Pressure Die Casting• High Pressure Die Casting• Vacuum HPDC• Semi-solid Casting• Squeeze Casting

tooling

tooling

filling

The Materials Efficiency perspectiveClassification of Casting Processes

42

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Pouring in the die/mould Pouring in a pre-chamber Gravity pouring Pouring under pressure (i.e. injecting)

Sand mould Ceramic mould Patterns Steel mould (i.e. die), permanent Sand cores Ceramic cores/Salt cores Metallic cores (i.e. inserts)

Without air evacuation With air evacuation By gravity Under moderate (i.e. low) pressure Under high pressure

Spontaneous heat transfer from alloy to mould/die Enhanced (cooling channels + air/gases) heat transfer Enhanced (cooling channels + water/oil) heat transfer

solidifying cooling

pouring

filling

tooling

Sand Gravity Casting

The Materials Efficiency perspective

43

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Weight from few grams to tons

Minimum Thickness 4 mm

Maximun Thickness no limits

Minimum diameter of holes(achieved with cores) 7 mm

Degree of complexity- internal very high- external very high

Tolerances + 2 on 250

Sand Gravity Casting

The Materials Efficiency perspectiveProduction rate 2

Equipment Cost 4

Time for prototyping 4

Metallurgical efficiency 0(product weight/cast weight)

Level of pressure tightness 2

Degree of automation 2-3

Possibility of heat treating 4

Net shape castings 2

Surface quality 1

4

3

2

1

0

Best

Worst

44

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

• Molten metal flows into small sections in the molten cavity, hence any complex shape can be easily produced.• Practically any type of material can be cast.• Ideal method is by producing small quantities.• Any size of casting can be produced like up to 200 tons.• Casting is the often cheapest, most direct way of producing a shape with certain desired mechanical properties.• Certain metals and alloys such as highly creep resistant metal-based alloys for gas turbines cannot be worked mechanically and can be cast only.• Heavy equipment like machine leads, ship’s propeller etc. can be cast easily in the required size rather than fabricating them by joining several small pieces.• Casting is best suited for composite components requiring different properties in different direction. These are made by incorporating preferable inserts in a casting.

The Materials Efficiency perspectiveThe advantages of Casting Process

45

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Casting Vs Other processesIt is fact that in some cases, the casting process must give way to other methods of manufacture, where they may be more efficient. For example, forging helps developing fiber strength and toughness in steel, machining produces smooth surfaces and dimensional accuracy not obtainable otherwise, welding provides a easy way of fabricating wrought or cast products into complex structures while stamping produce lightweight sheet metal parts.

Casting vs Forging:It should be recognized that castings and forgings start from very similar beginnings and castings can have some very distinct advantages over other product forms, including forgings.Some of the key Advantages of Casting over Forging can be with respect to the following:Design flexibility High production rate Large and complex parts

Weakness of CastingRequires close process control and monitoring, Shrinkage porosity may occur, Metallic projections, Cracks, hot tearing, coldshuts, Laps, oxides, Misruns, insufficient volume, Inclusions

The Materials Efficiency perspectiveThe advantages of Casting Process

46

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Process vs Microstructure (& Defects) vs Performance

The Materials Efficiency perspective

Role of Casting Geometry (e.g. thikhness) on microstructure and properties

47

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

• Defects• Poor Microstructure• Poor Mech. Propert.• Scraps

• Few Imperfections• Good Microstructure• Good Mech. Propert.• Suitable for use

Control of Process Path

The Materials Efficiency perspective

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Materials Efficiency solutionIntegrated Design

48

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Materials Efficiency solutionTailoring Properties and their Distribution

49

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Raw Materials Sustainability perspectiveCriticality of Raw Materials

50

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Raw Materials Sustainability perspectiveIron Group Criticality Assessment (Global)

51

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Raw Materials Sustainability perspectiveCriticality Assessment for EU (2013)

52

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

The Raw Materials Sustainability perspectiveCriticality Assessment for EU (2013)

53

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Raw Materials Sustainability solutionThe Competitors for Cast Iron

54

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

16CrNi4 Carbon, C 0.13 - 0.18 % Manganese, Mn 0.70 - 1 % Phosphorous, P 0.035 Sulfur, S 0.035 Silicon, Si 0.15 - 0.40 % Chromium, Cr 0.80 - 1.10 % Molybdenum, Mo - Nickel, Ni 0.80 - 1.10 %

18NiCrMo5 Boron, B 0.0010 - 0.0050 % Carbon, C 0.12 - 0.21 % Chromium, Cr 0.85 - 1.2 % Iron, Fe 96% Manganese, Mn 0.45 - 0.70 % Molybdenum, Mo 0.45 - 0.60 % Nickel, Ni 1.2 - 1.5 % Phosphorous, P <= 0.035 % Silicon, Si 0.20 - 0.35 % Sulfur, S <= 0.040 %

Domex 700 Carbon, C 0.12 % Manganese, Mn 2.10 % Phosphorous, P 0.025 % Sulfur, S 0.010 % Silicon, Si 0.10 % Alluminium, Al 0,015% Niobium, Nb 0,09% Vanadium, V 0,20% Titanium, Ti 0,15%

Class I Type D Ni-Hi-Cr Martensitic White Cast Iron Carbon, C 2.5 - 3.6 % Chromium, Cr 7.0 - 11 % Iron, Fe 78% Manganese, Mn <= 1.3 % Molybdenum, Mo <= 1.0 % Nickel, Ni 5.0 - 7.0 % Phosphorous, P <= 0.10 % Silicon, Si 1.0 - 2.2 % Sulfur, S <= 0.15 %

Advanced Cast Iron as a Raw Materials Sustainability solutionThe Competitors for Cast Iron

55

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Class II Type C 15% Cr-Mo-HC Martensitic White Cast Iron Carbon, C 2.8 - 3.6 % Chromium, Cr 14 - 18 % Copper, Cu <= 1.2 % Iron, Fe 74% Manganese, Mn 0.50 - 1.5 % Molybdenum, Mo 2.3 - 3.5 % Nickel, Ni <= 0.50 % Phosphorous, P <= 0.10 % Silicon, Si <= 1.0 % Sulfur, S <= 0.060 %

Class III Type E 25% Cr Martensitic White Cast Iron Carbon, C 2.3 - 3.0 %

Chromium, Cr 23 - 28 %

Copper, Cu <= 1.2 %

Iron, Fe 65%

Manganese, Mn 0.50 - 1.5 %

Molybdenum, Mo <= 1.5 %

Nickel, Ni <= 1.5 %

Phosphorous, P <= 0.10 %

Silicon, Si <= 1.0 %

Sulfur, S <= 0.060 %

Crucible Steel CPM® 10V® (AISI A11) Tool Steel Carbon, C 2.45 % Chromium, Cr 5.25 % Iron, Fe 81.25 % Molybdenum, Mo 1.3 % Vanadium, V 9.75 %

HARDOX 500

Carbon, C 0.30 %

Silicon, Si 0.70 %

Manganese, Mn 1.60 %

Phosphorous, P 0.025 %

Sulfur, S 0.0.10 %

Chromium, Cr 1.50 %

Nichel, Ni 1.50 %

Molybdenum, Mo 0.60 %

Boron, B 0.004 %

Advanced Cast Iron as a Raw Materials Sustainability solutionThe Competitors for Cast Iron

56

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Critical materials: List of materials considered as critical to the EU due to supply risk of the raw materials from which they are derived.Critical materials are mostly defined in terms of elements.

Advanced Cast Iron as a Raw Materials Sustainability solutionThe Competitors for Cast Iron

“Stand by” elements

57

58

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Advanced Cast Iron as a Raw Materials Sustainability solutionThe typical Composition of ADI

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Concluding Remarks

59

Advanced Cast Irons

Designed Materials Microstructure controlled by the Process

Solution for Lightweight Absolute & Specific Properties

Solution for Materials Efficiency Advantages of Casting Process

Solution for Raw Materials Sustainability Good for Substitution

60

Austempering, A Technology for Substitution

ADI DAYS 2016 6th – 7th October Minerbe

Contacts

Prof. Franco BONOLLO

Dipart. di Tecnica e Gestione dei Sistemi IndustrialiUniversità di Padova, sede di VicenzaStr. S. Nicola, 3 – 36100 Vicenza (Italy)e-mail: [email protected].: +39 0444 998743fax: +39 0444 998889

www.gest.unipd.it/metallurgia