Adapting Producer Gas for Small Size Single Cylinder Si Engine

-

Upload

prabesh-poudel -

Category

Documents

-

view

224 -

download

0

Transcript of Adapting Producer Gas for Small Size Single Cylinder Si Engine

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

1/16

A PROGRESS PRESENTATION

ON

ADAPTATING PRODUCER GAS FOR SMALL SIZE SINGLE

CYLINDER SI ENGINE

Supervisor: -

Dr.Bivek Baral

Assistant Professor

Undergraduate Co-ordinator

Co-supervisor: -

Sunil Prasad Lohani

Lecturer

Department of Mechanical Engineering

Group Members: -

Anant Bhusal (41055)

Amrit Shrestha (41083)

24 November2010

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

2/16

INTRODUCTION

Reason behind selection of project: -

can be used in an SI Engine as a substitute for gasolineno change in amount of carbon dioxide in environment

project is concerned with adapting producer gas to operate a stationary SI Engine

producer gas is produced from the process ofpyrolysis in gasifier

Producer gas is cleaned and cooled

and used to operate a stationary SI Engine

Problem Statement

Increases the amount of carbon particles which results in GLOBAL WARMING.

Gradual decrease in petroleum resource

Approximately 1 million gasifiers were used to operate vehicles worldwide during the war years.

(Source: Reed, T.B., SERI/SP-271-3022)

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

3/16

OBJECTIVES

The objectives of this project are: -

To design and fabricate the biomass gasifier appropriate to run the SI Engine.

To reduce the amount of tar produced in the producer gas.

To design the filter for the separation of tar from the producer gas.

To design or modify the standard SI Engine for the adaptation of the producer gas.

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

4/16

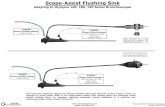

Figure: - Overall System (Source:Adapted from Skov1974)

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

5/16

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

6/16

GASIFICATION

Four basic processes of gasification

Drying of the fuel

Pyrolysis

Oxidation (Combustion)

Reduction

Gasification is a process that converts biomass, into carbon monoxide and hydrogen

by reacting the biomass at high temperatures with a controlled amount of oxygen.

CH1.4O0.6 + 1.05 O2 + 3.9 N2 -> CO2 + 0.7 H2O + 3.95 N2

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

7/16

COMPARISION OF DIFFERENT TYPES GASIFIER

Up draft gasifier: -

The updraft gasifier achieves the highest efficiency

Produces excessive amount of tarDown draft gasifier: -

Comparatively lower overall efficiency

Produces low amount of tar

Cross draft gasifier: -

Poor CO 2 reduction and high gas velocityHigh carbon monoxide, and low hydrogen and methane content

Fixed Bed Gasifier System Fluidized Bed Gasifier

Parameters Unit Countercurrent

(up-draft)

Co-current

(downdraft)

Bubbling Circulating

Particle Content

Range 0.1-3 0.02-8 1-100 8-100

Mean 1 1 4 40

Tar Content

Range 10-150 0.01-6 1-23 1-30

Mean 50 0.5 12 8

The downdraft gasifier is appropriate for the production of producer gas for operating of SI Engine

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

8/16

PRODUCER GAS CLEANING

Steps

To choose a gasifier design that minimizes production of tars and particulates.

Remove particulate (above 300oC)

Remove tars (above 100oC)

Remove Water

Use filter devices

In-line filtersOffline filters

PRODUCER GAS COOLING

purpose is to increase the density of the gas in order to maximize the amount ofcombustible gas entering the cylinder

10% temperature reduction of the gas increases the maximum output of the engine by almost 2%.

(Source: Reed, T.B., SERI/SP-271-3022)

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

9/16

DESIGN ASSUMPTION

Type Air cooled, 4 - stroke single cylinder OHC

Displacement (D) 149.2 c.c

Maximum Power 10.6 KW ( 14.3 bhp) @ 8500 rpm

Maximum Torque 12.80 N-m @ 6500 rpm

Bore x Stroke 57.3 x 57.8 mm

Compression Ratio 9.1 :1

Idle speed 1400 rpm

Ignition AMI - Advanced MicroprocessorIgnition

System

All the design is based on Assumption: @ 2500 rpm

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

10/16

OBTAINED RESULTS

Calculation of the power output of a producer gas engine

Max. air/gas intake 0.003125 m/s

M

ax. gas intake 0.001488 m/s

real gas intake is 0.001339 m/s

Thermal Power (Pg) 6.42857 kW

Maximum mechanical output (PM

max.) 1.9285 kW

Maximum electrical output (PE max.) 1.7357 kVA

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

11/16

A. Biomass consumption gasifier

Thermal power consumption 9.1836 kW

Biomass consumption 1.26 kg biomass to produce 1 kWh electricity.

B. Reactor design

dthroat 10cm

C. Further gasifies dimensions

Diameter (dr) of the fire box. dr 14.3027 cm

Diameter (drl) of nozzle top ring dn 10.4 mm

Design calculation of downdraught gasifier

The thermal efficiency of the gasifier is taken at 70%

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

12/16

DESIGNED GASIFIER

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

13/16

ISOMETRIC VIEW

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

14/16

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

15/16

CONCLUSION

Work Accomplished: -

Selection of gasifier

Design of various parts of gasifier

Work Remaining: - (for this semester)

Fabrication of gasifier

Testing the producer gas

Reason behind deviation: -

manufacturing difficulties in making gasifier

-

8/8/2019 Adapting Producer Gas for Small Size Single Cylinder Si Engine

16/16

THANKYOU