ACS 2014_Free Swell Potential of Lime Treated Gypseous Soil

-

Upload

gigarostom-alger -

Category

Documents

-

view

11 -

download

0

description

Transcript of ACS 2014_Free Swell Potential of Lime Treated Gypseous Soil

-

uimans,, Mos

Swell potentialWettingdryingCuring conditionsMicrostructural changes

nhespdyonsinedof soil (i.e. gypseous soil) when used in the construction of road and pavement

on typd behaear str

Applied Clay Science 102 (2014) 93103

Contents lists available at ScienceDirect

Applied Cla

.ecombination of these two methods, to create an improved soilmaterial that possesses the desired engineering properties (Little,

Ca++ +2[OH]+ Al2O3 CAH alumina gel1995; Puppala et al., 2004). Chemical soil stabilization by limeseveral techniques are available in geotechnical engineering prac-tice such as mechanical stabilization, chemical stabilization, or asoil. Therefore, the construction of engineering structures founded ongypseous soils is highly risky as they can suffer from several engineeringproblems such as cracks, tilting or differential settlement and structurecollapse (Aibn et al., 1998; Cooper, 1998, 2008).

In order to improve the engineering behavior of these soils,

Ca(OH)2 Ca++ +2(OH)

Ca++ +2[OH]+ SiO2 CSH silica gel(CaO or Ca(OH)2) is a proven technique forof gypseous soils (Kota et al., 1996; Puppal

Corresponding author.E-mail address:[email protected]

http://dx.doi.org/10.1016/j.clay.2014.10.0150169-1317/ 2014 Elsevier B.V. All rights reserved.ength, especially uponum dissolution inducedand permeability of the

CaO + H2O Ca(OH)2wetting. This behavior is mainly due to gypsby water ow, thus increasing the porosity1. Introduction

Gypseous soils are the most commvariety of engineering properties ansettlement (collapsing) and low shThe results show that increasing the gypsum content decreased the swell potential of the untreated soilsamples. On the other hand, the swell potential values of soil samples started decreasing after the rstwettingdrying cycle then reached equilibrium. Lime treatment results show that the suppression ofswelling in lime-treated soil samples without gypsum was partly lost after the rst cycle, especially forshort curing periods and for both temperature values (20 C and 40 C), while long-term curing periods(more than 28 days) gave good results with respect to the suppression of swell potential values. Limetreatment of gypsum-containing samples showed an adverse effect on swell potential. The swell potentialvalues increased with curing period and curing temperature, due to the formation of ettringite. Lastly,wettingdrying cycles caused an increase in the swell potential values of gypsum-containing samples,cancelling out the benecial effect of lime treatment to control swell.

2014 Elsevier B.V. All rights reserved.

e of soils, and exhibit aviors, such as excessive

Ouhadi, 2007). The immediate effect of lime stabilization is astrong exothermic reaction between CaO and water present in thesoil, forming calcium hydroxide. The main chemical reactions thatoccur during lime stabilization can be summarized as follows:Gypseous soilsLime treatment

str

tructures. Mineralogical and microstructural studies (porosimetry, X-ray diffraction and scanning elec-on microscopy) were carried out to evaluate the cementitious materials and the presence of ettringite.Keywords: term behavior of this typeResearch paper

Free swell potential of lime-treated gypseo

Abdulrahman Aldaood a,b, Marwen Bouasker a, Muzaha Centre de Recherche sur la Matire Divise, CRMD and Laboratoire PRISME, Universit d'Orlb Mosul University, College of Engineering, Civil Engineering Department, Al-Majmooah Street

a b s t r a c ta r t i c l e i n f o

Article history:Received 17 March 2014Received in revised form 4 October 2014Accepted 24 October 2014Available online 13 November 2014

Lime treatment generally ereported an adverse effect,derlying mechanisms, a stuinuence of curing conditiswell potential of ne-gra

j ourna l homepage: wwwimproving the strengtha et al., 2003; Yong and

(M. Al-Mukhtar).s soil

Al-Mukhtar a,Franceul, Iraq

ances the geotechnical properties of the soils. However, some studies haveecially in the presence of gypsum. To develop an understanding of the un-of ne-grained soil with different amounts of gypsum was carried out. The(curing period and curing temperature) and wetting-drying cycles on thesoil with (0, 5, 15 and 25%) gypsum was investigated to assess the long-

y Science

l sev ie r .com/ locate /c layCation exchange begins to take place between the ions associatedwith the clay particles and the calcium ions of the lime (Bergaya andLagaly, 2006; Bergaya et al., 2006). This process is primarily responsiblefor modications in the soil engineering properties, such as workabilityand reduced plasticity (Al-Mukhtar et al., 2012; Bell, 1996; Little, 1995;

-

swell due to the presence of certain chemical elements within the soilmatrix which in the right conditions create crystalline structures and

94 A. Aldaood et al. / Applied Clay Science 102 (2014) 93103force the matrix apart as the crystals grow. Generally, when soilscontaining soluble sulfates (such as gypsum) are mixed with lime orother calcium-based stabilizers and given access towater, highly expan-sive calciumaluminatesulfatehydrate minerals form (Hunter, 1988;Ouhadi and Yong, 2008; Petry and Little, 1992). In the present state ofknowledge, not all these complex reactions have been completelyidentied. The most common and the most inuential mineral forengineering practice is ettringite.

The crystallization of ettringite is expansive and, in addition, is sub-jected to further large volume changes as it takes inwater. Ettringite for-mation causes soil heave and cracking of pavement structures, andthese problems lead to a reduction in stability and loss of bearing capac-ity (Hunter, 1988; Little et al., 2010; Mitchell and Dermatas, 1992;Puppala et al., 2005). Several studies on gypseous soils have shownthat the onset of problems associated with these soils depends on theinitial sulphate levels in soils prior to chemical stabilization (Adamset al., 2008; Hunter, 1988; Petry and Little, 1992).

The objective of this study was to identify the impact of wettingdrying cycles on the swell potential of lime-treated gypseous soil. Anattempt has also been made to assess the coupled effects of gypsumcontent and curing temperature on the swelling behavior of treatedsoil samples at both short and long-term curing periods of up to360 days. Two curing temperatures were used (20 C and 40 C). Theformation and development of ettringite minerals during curing condi-tions were monitored. Gypseous soils are found in several countriesacross the world, and are present in the majority of arid and semi-aridzones (FAO, 1990, 1993) The gypsum content varies widely from low,less than 5%, to very high, sometimes exceeding 50% (Boyadgiev andVerheye, 1996). In order to conduct a precise parametric study, all thetested samples were prepared in the laboratory, as literature datashow that the gypsum content in nature varies widely. Thus, to controlthe exact percentage of gypsum in the different samples tested and inorder to study a broad range of gypsum soil behavior, samples wereprepared with three percentages of gypsum: 5, 15 and 25% by drymass of soil.

2. Materials and methods of testing

2.1. Materials

The soil tested was a ne-grained soil from Jossigny to the east ofParis, France. The liquid limit (L.L.) was 29%, with a plasticity index(P.I.) of 8% and the specic gravity of the solid (Gs) was 2.66. Based onthe Casagrande plasticity chart and according to the Unied Soil Classi-cation System (USCS), the soil was classied as a low plasticity claysoil. The grain size distribution analysis is 17% sand, 64% silt and 19%clay.

The quicklime added, supplied by the French company LHOIST, is avery ne lime and passes through an 80 m sieve opening. The activityMathew and Rao, 1997). In addition to the immediate effect caused bycation exchange, there is a long-term effect of lime stabilization calledthe pozzolanic reaction which produces calcium silicate hydrates(CSH), calcium aluminate hydrates (CAH), and calcium alumino-silicate hydrates (CASH). Pozzolanic reactions are time and curing tem-perature dependent and thus the strength develops gradually over along period (Al-Mukhtar et al., 2010a,b; Little, 1995).

Environmental conditions such as wettingdrying cycles cause vari-ation in the moisture content of soil, resulting in cyclic swelling andshrinkage. Soil in nature undergoes volume change in several ways:swelling or collapsing due to an increase in water content, rebounddue to release of load, settlement due to load application and shrinkagedue towater loss. Another pattern of volume change is soil heave or soilof the lime used was 94%.The gypsumused in this study, supplied by theMerckKGaA company,Germany, is a very ne gypsum and passes through an 80 m sieveopening, and with a purity of more than 99%.

2.2. Sample preparation

A standard Proctor compaction effort (ASTM D-698) was adopted inthe preparation of the soil samples. To prepare the soil samples, theoven-dried soil (2 days at 60 C) was rst crushed and passed througha 4 mm sieve. After grinding, the required amount of soil was mixedwith gypsum under dry conditions. Then the required amount of watercorresponding to the optimum moisture content of natural soil (11%)was added to the soilgypsummixtures. All mixing was done manually,and proper care was taken to prepare homogeneous mixtures. The mix-ture was then placed in plastic bags for a mellowing time of 24 h.

For lime treatment, the soil samples were stabilized by 3% lime,which represents the optimum lime content based on the ASTMD6276 (2006) which used pH to estimate the soillime proportion re-quirement for Soil Stabilization. This test is derived from the Eadesand Grim test (1966). The soillime mixtures were rst prepared bythoroughly mixing dry predetermined quantities of soil, gypsum andlime to obtain a uniform color. Then the required amount of waterwas added and again mixed to obtain a uniform moisture distribution.Themixturewas then placed in plastic bags and left for a 1 hmellowingtime (Little, 1995).

After that, the soil samples were statically compacted in rigid stain-less steel rings (71 mm in diameter and 20 mm in height), at a strainrate of 1 mm/min, until they reached the maximum dry unit weight ofthe natural soil (17.7 kN/m3). After compaction, the soil samples (i.e.soil and the ring) were immediately placed in plastic bags to avoid sig-nicant variations in moisture content till testing. The lime-treated soilsamples were immediately wrapped in cling lm and coated with par-afn wax to avoid moisture loss, then left to cure for 2, 7, 28, 180 and360 days at two temperature values (20 C and 40 C).

2.3. Mineralogical and microstructural analysis

Themineralogical andmicrostructural aspect of the lime-treated soilsamples was studied using scanning electron microscope (SEM), X-Raydiffraction (XRD) and mercury porosimetry tests. The main objective ofthe mineralogical and microstructural investigations was to determinechanges due to lime treatment and to detect the formation of cementi-tious materials. These tests were conducted on all the soil samples.

For the scanning electron microscopy test (SEM), the preparation ofthe specimens followed the method suggested by Tessier (1984) anddescribed byAl-Mukhtar et al. (1996) in order to preserve the soil fabric.Soil samples (volume of 1 cm3) were injected by epoxy x resin,polished, gold-coated and then scanned by a high resolution scanningelectron microscope (PHILIPS XL 40 ESEM). All the soil samples wereprepared in the same manner.

For XRD observations, fractured samples produced after the uncon-ned compression test were powdered, sieved through a 400 m sieveand dried for 24 h at 40 C. A PHILIPS PW3020 diffractometer wasused for XRD analysis. The diffraction patterns were determined usingCu-K radiationwith a Bragg angle (2) range between 460 runningat a speed of 0.025/6 s.

Pore size distribution tests were carried out using a Pore SeizerPorosimeter, in which the mercury pressure was raised continuouslyto reach more than 210 MPa and measure the apparent pore diameterin the range of 3.6 nm to 350 m. The method assumes a cylindricalpore geometry using a modied YoungLaplace equation, generally re-ferred to as the Washburn equation (Giesche, 2006).

P 1r1 1r2

2 cos

rpore

-

It relates the pressure difference across the curvedmercury interface(r1 and r2 describe the curvature of that interface) to the correspondingpore size (rpore) using the surface tension of mercury () and the con-tact angle () between the solid andmercury. Pore size distribution datagenerated by mercury porosimetry are primarily useful in comparativestudies of similar materials.

The applied mercury pressure and the intruded volume of mercurywere monitored during the test. Before applying mercury tests, soilsamples were dried by lyophilization using an ALPHA 12 Ld PlusGmbH apparatus to avoid the formation of micro-cracks.

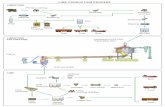

2.4. One-dimensional free swell test

To evaluate the free swell potential of the untreated and lime-treated soil samples, a free swell test was performed using the standardone-dimensional oedometer device, in accordance with the ASTMstandard (D-4546).

At the end of each curing period, the compacted soil samples in theoedometer rings were placed in a consolidation cell between twodried porous stones, and a sensitive dial gauge was xed on top of the

2.5. Cyclic one-dimensional free swell test

This testwas performed to investigate the evolution of the free swellpotential of lime-treated soil samples, subjected to wettingdrying cy-cles, due to ettringite formation. All soil sampleswere subjected to alter-nate wettingdrying cycles in the oedometer device. After calibrationwith an initial pressure of (2.75 kPa) and recording of the initial readingto estimate the swell potential, as mentioned in Section 2.4, the soilsamples were soaked with tap water and allowed to swell fully over24 h. After that, the nal reading was recorded, then the water wasdrained from the oedometer cell and the sample kept in the cell for atleast 30 min at room temperature (25 C 2 C), to keep it safe fromany damage.

The wetted sample was then extruded from the cell and oven driedfor 24 h at 60 C. After drying and before starting the next cycle, the soilsample was cooled at room temperature (25 C 2 C) for 30min. Thesoil samples in the consolidation ring were again placed in theoedometer cell, xed in the oedometer device and wetted by allowingthem to swell over 24 h. In this test, the untreated and lime-treatedsoil samples were subjected to four cycles of alternate wetting and

lite is less involved in the pozzolanic reaction than kaolinite. It is worth

((A

95A. Aldaood et al. / Applied Clay Science 102 (2014) 93103consolidation cell to measure the vertical soil displacement (Fig. 1).After calibration with an initial vertical pressure of 2.75 kN/m2

(representing the weight of the loading plate which is part of the con-solidation cell), an initial readingwas taken to estimate the swell poten-tial, following which the soil samples were soaked with tap water andallowed to swell under the vertical pressure (2.75 kPa) at a constant lab-oratory temperature (25 C 2 C). Timeswell readings were contin-uously noted during the process. The nal reading of the dial gauge(which represents the highest reading) was used to calculate the freeswell potential together with the initial height of the soil samples,using the equation below:

Swell potential HHi

100 1

where H is the vertical displacement in mm, which represents the dif-ference between initial and nal readings of the dial gauge, andHi is theinitial height of the soil sample in mm. The precision of the displace-ment measurement was 0.001 mm and so the precision of the axialstrain was 0.005%, thus satisfying the ASTM D6026 recommendationfor geotechnical data.

The time required to reach the nal reading of the dial gauge (themaximum value of vertical displacement) depends on the gypsum con-tent, curing period and curing temperature. Thus, the swell test wascontinued to (2448 h) until the dial gauge reading had stabilized.

RRinthng she

uppsam

W

pormlp

ate

rtinpe

r

ngFig. 1. Experimental setupnoting that the peaks of quartz mineral did not show a clear reduction

D

pp

Dial

Lplie

l ga

Loaed pr

aug

adinress

e

ng psure

plae 2

ate2.755 kP

SPa)

Soil sa

Por

amp

rou

ple

us sstonnedrying.

3. Results and discussion

3.1. Mineralogical and microstructural changes

Changes in the engineering properties of soils resulting from limeand gypsum addition can be attributed on the one hand to gypsum dis-solution due to water absorption which increases the porosity and thepermeability, and on the other hand to mineralogical changes. XRDwas used to highlight the mineral composition of the natural (untreat-ed) soil and the mineralogical changes induced by the chemical reac-tions between soil matrixes, as presented in Figs. 2 and 3. As shown,the main natural (untreated) soil components were kaolinite and illiteas clayminerals, and contained quartz, calcite and feldspars. Once treat-ed by lime and for all gypsum percentages, several new peaks appeared,indicating the formation of new compounds.

Two observations can be made from the XRD patterns. The rst isthat the intensities of all the kaolinite reections decreased during cur-ing, whatever the gypsum content. This behavior is attributed to the factthat kaolinite is exhausted by the pozzolanic reaction and is consistentwith the pozzolanic behavior of kaolinite. The second one is that the il-for free swelling tests.

-

96 A. Aldaood et al. / Applied Clay Science 102 (2014) 931030

200

400

600

800

0 10 20 30 40 50 60

Inte

nsity

( co

unts

/s )

G

I00

1

CSH

+ G

K KF

I003

+ Q

101

CA

H

GG

CC

QNatural soil

0% gypsum

5% gypsum

15% gypsum

25% gypsumE

CA

HL

G

C

I004

E

L

CSH

Q

K

I00

2

28 daysduring curing and lime treatment, indicating that the quartz was notsubstantially attacked by lime.

During curing conditions (curing period and curing temperature),gypsum addition inuenced the creation (formation) of new reectionssuch as Ca-hydrates in the samples. With curing, these reections seemto be reinforced, whichmeans crystallization of these new Ca-hydrates.As mentioned by Al-Mukhtar et al. (2010a,b, 2012), newly formed Ca-hydrate cannot be observed by XRD because the phases that form dur-ing long-term curing periods (i.e. 180 and 360 days) probably do nothave a well-organized crystalline structure, and therefore X-ray reec-tions are greatly weakened. Second, it is possible that reections fromthese phases overlap with both those of primary minerals of naturalsoil and/or with the reections formed during 28 days.

To summarize, themajor cementitious compoundswere calcium sil-icate hydrates (CSH), calcium aluminate hydrates (CAH) and ettringite

2 ()

0

200

400

600

800

0 10 20 30 40 50 60

2 ()

Inte

nsity

( co

unts

/s )

G

I00

1

CSH

+ G

K KF

I003

+ Q

101

CA

H

GG

CC

QNatural soil

0% gypsum

5% gypsum

15% gypsum

25% gypsumE

CA

HL

G

C

I004

E

L

Q

K

I00

2

E

E

CSH

0

200

400

600

800

0 10 20 30 40 50 60

2 ()

Inte

nsity

( co

unts

/s )

G

I00

1

CSH

+ G

K KF

I003

+ Q

101

CA

H

GG

CC

QNatural soil

0% gypsum

5% gypsum

15% gypsum

25% gypsumE

CA

HL

G

C

I004

E

L

CSH

Q

K

I00

2

E CSH

180 days

360 days

Fig. 2. XRD patterns of soil samples cured at 20 C.0

200

400

600

800

0 10 20 30 40 50 60

Inte

nsity

( co

unts

/s )

G

I00

1

CSH

+ G

K KF

I003

+ Q

101

CA

H

GG

CC

QNatural soil

0% gypsum

5% gypsum

15% gypsum

25% gypsumE

CA

HL

G

C

I004

E

L

CSH

Q

K

I00

2

E

CSH

28 daysmineral, which were found in all the gypseous soil samples. Ettringiteis a calcium aluminum sulfate hydrate (Ca6Al2(SO4)3(OH)1226H2O.)type mineral which is responsible for the early strength gain and isknown for its potential to cause swell.

In samples cured at 20 C, ettringite crystals were not observed inSEM images for any of the gypsum percentages used. The ettringitecrystals start to appear at 180 days of curing and for 25% of gypsum.The average length of these crystals does not exceed 5 m.

In samples cured at 40 C, the ndings are almost the same as at20 C but an early appearance of ettringite crystals at 28 days for 25%of gypsum can be observed. Moreover, ettringite crystals seem to belarger than those observed at 28 and 180 days when the curing temper-aturewas 20 C. This increase in the dimension of ettringite crystals canbe explained by the effect of thermal activation as temperature in-creased from 20 C to 40 C (Al-Mukhtar et al., 2010b). After 360 days,

2 ()

0

200

400

600

800

0 10 20 30 40 50 60

2 ()

Inte

nsity

( co

unts

/s )

G

I00

1

CSH

+ G

K KF

I003

+ Q

101

CA

H

GG

CC

QNatural soil

0% gypsum

5% gypsum

15% gypsum

25% gypsumE

CA

HL

G

C

I004

E

L

CSH

Q

K

I00

2

E CSH

0

200

400

600

800

0 10 20 30 40 50 60

2 ()

Inte

nsity

( co

unts

/s )

G

I00

1

CSH

+ G

K KF

I003

+ Q

101

CA

H

GG

CC

QNatural soil

0% gypsum

5% gypsum

15% gypsum

25% gypsumE

CA

HL

G

C

I004

E

L

CSH

Q

K

I00

2

E CSH

180 days

360 days

Fig. 3. XRD patterns of soil samples cured at 40 C.

-

for all samples cured at 20 C and 40 C, SEM images show a signicantgrowth of ettringite crystals (average length of 20 m) and the soil tex-ture seems to be dense. Table 1 illustrates the changes induced in thefabric of the soil and measured by mercury porosimetry tests. Fourranges of pores were identied to examine in depth the results of mer-cury porosimetry and to analyse the effect of gypsum content and cur-ing conditions (temperature and time) on the pore size distribution. Ingeneral, signicant differences in pore size distribution curves were ex-hibited by the soil samples cured for short periods at a low curing tem-perature, while there was a slight difference in these curves for samplescured for longer periods at a high curing temperature;most of these dif-ferences were in pores larger than (0.1 and 10 m). The pore size distri-bution of soil samples after 28 days of curing was consistently coarserthan that after 180 and 360 days of curing. This behavior is attributedto the fact that the hydration reaction (between lime and gypsum) ismuch faster than the pozzolanic reaction. The dissociation of lime pro-

3.2. Free swell potential

Swell potentials of untreated and lime-treated soil samplescompacted at optimum moisture content (OMC) and maximum dryunit weight (max) weremeasured. Fig. 6 shows the swell potential var-iation of untreated soil samples for different gypsum contents. The swellpotential decreased with increasing gypsum content. This behavior isattributed to the addition of non-expansive materials (gypsum) and toa reduction in the soil matrix, especially clay content (due to the com-plementary substitution method used in sample preparation). Theporosity also decreased with gypsum content, as presented in Table 1,since gypsum acts mainly as an inert ller and tends to reduce theswell of the soil samples. The swell potential decrement was largerwhen the addition of gypsum increased, and the reduction in swellpotential reached 70% for samples with 25% gypsum. Similar observa-tions were reported by (Yilmaz and Civelekoglu, 2009) during their

97A. Aldaood et al. / Applied Clay Science 102 (2014) 93103duced by the hydration reaction quickly leads to occulation of theclay particles, which increases the porosity of the clay matrix, whereasthe pozzolanic reaction leads to deposition of CSH and CAH on andaround the occulated clay aggregates, resulting in a reduction in thepore size of soil samples. The percentage of very small pores less thanor equal to (0.1 m) seems to be unchanged with curing period forboth curing temperatures; it represents about one third of total poresin the tested samples. The small pores (0.11 m) showed an insigni-cant reduction with increasing curing temperature from 20 C to 40 C.The percentage of these pores increases with gypsum content. Themedium-sized pores (110 m) behave inversely to small pores withcuring conditions. Finally, larger pores with more than 10 m pore en-trance sizes do not change and remain scarce (about 3%) in all testedsamples. These changes in pore size distribution reveal a global rene-ment of the internal microstructure and the evolution of this soil fabricinduced by the pozzolanic products (CSH and CAH) shown in Figs. 2 and3. The formation of ettringite, as shown in Figs. 4 and 5 respectively notonly enhanced the inter-cluster bonding strengthbut alsolled theporespace. Further, the effect of cation exchange and attraction caused clayparticles to move close to each other. These changes in pore size distri-bution inuence the swell potential.

Gypsum addition affected the pore size distribution of soil samplesby increasing the percentages of small pores, which increased withhigh gypsum content (25%) and low curing temperature (20C),while the large pores did not seem to be signicantly affected by thisaddition.

The porosity measured during these tests changes with the amountof gypsum and the curing temperature in the tested samples: overall, asthe gypsumcontent increased, porosities formed early during 28days ofcuring increased and as the curing temperature increased from 20 C to40 C. Moreover, for a xed curing temperature (20 C or 40 C), poros-ities formed early during 28 days of curing seem to be unchanged withadditional curing time.

Table 1Pore size distribution from mercury porosimetry results and porosities of samples.

Results concerned the two curing temperature 2040 C

Gypsum content % Curing periodday

Very small poresb0.1 m %

Small pores0.11 m %

0 28 2430 4121180 3736 3416360 4335 3317

5 28 3732 3624180 4029 3128360 3429 3927

15 28 3235 4621180 4236 3820360 3536 5118

25 28 3231 5117180 3427 4820360 3432 5019study on the effect of gypsum addition on the behavior of expansivesoil (bentonite soil).

For lime-treated soil samples, Fig. 7 shows the effects of curing con-ditions (temperature and curing period) and gypsum content on theswell potential. The swell potential of lime-treated soil samples withoutgypsum decreased with increasing curing periods and a greater reduc-tionwas observed for samples cured at 40 C as comparedwith samplescured at 20 C. The swell potential was suppressed at 7 days for soilsamples cured at 40 C and at 28 days for samples cured at 20 C. Thisreduction is attributed to lime addition which is known to be aneffective stabilizer that reduces the swell potential of clay soils. For thegypseous soil samples, after the short curing period (i.e. 2 days) andfor both temperature values, swell potential decreasedwith gypsum ad-dition. This behavior is due to the presence of unreacted lime and gyp-sum particles which act as ller materials and tend to reduce the swellpotential, as presented above. After 2 days of curing the swell potentialof soil samples increased with gypsum content up to 5% then decreasedand more swelling occurred for soil samples cured for 28 days. In thecase of lime-treated soil samples containing 5% gypsum, the increasein swell potential can be explained by the chemical reactions causedby the presence of gypsum, alumina and lime. These reactions lead toforming an ettringite nucleus which has the ability to grow when therequisite chemical compounds become available. According to Wildet al. (1993), a colloidal product which is a precursor to the formationof crystalline ettringite initially forms on clay particle surfaces duringmoist curing in lime-treated sulfated clay soil. On soaking, this productimbibes water and swells. The amount of this product that can form iscontrolled by the relative amounts of free lime, gypsum and aluminaavailable. Ettringite is a hydrous calcium alumino-sulfate mineral thatprecipitates in environments with high pH values and sufcient sulfateconcentration (Little et al., 2010; Puppala et al., 2005). It forms in theearly stages of hydration of calcium aluminate and has a large swell po-tential, up to 250% (Adams et al., 2008).

Medium pores110 m %

Large poresN10 m %

Porosity by mercurytest %

Initial totalporosity %

3346 33 26.729.3 33.32647 32 27.028.72145 22 25.728.02339 34 26.630.6 31.52640 33 30.030.52542 22 27.927.21642 53 28.928.5 30.51642 32 28.829.11144 42 29.229.01348 43 29.630.8 28.61450 43 30.530.31155 42 30.130.2

-

360 days

28 days

180 days

5%G

5%G

5%G

15%G

15%G

15%G

25%G

25%G

25%G

Ettrin ite

Ettringite cristals Ettringite cristals Ettringite cristals

10 m 10 m 10 m

10 m10 m10 m

10 m 10 m 10 m

Ettringite

Fig. 4. SEM images show cementitious materials and ettringite development for soil samples cured at 20 C.

360 days

28 days

180 days

5%G

5%G

5%G

15%G

15%G

15%G

25%G

25%G

25%G

Ettringite cristalsEttringite cristals

Ettringite

Ettringite cristals

10 m 10 m 10 m

10 m10 m10 m

10 m 10 m 10 mEttringite

Fig. 5. SEM images show cementitious materials and ettringite development for soil samples cured at 40 C.

98 A. Aldaood et al. / Applied Clay Science 102 (2014) 93103

-

Although no crystalline ettringite was observed in soil samples with5% gypsum, the presence of an amorphous ettringite product whichcauses swell can be suggested, as mentioned by (Wild et al., 1999). Athigher gypsum content (more than 5%), the soil samples exhibitedless swelling as compared with samples having 5% gypsum, even ifthere were ettringite crystals. This is due to unreacted gypsum particleswhich act as inert ller materials, restricting the swell. These samplesalso appeared to contribute less to ettringite formation than pozzolanicreactions and hence small swell potentials were observed at increasedgypsum content. Increasing the temperature from 20 C to 40 C led toa greater reduction in swell potential. Thismaybe attributed to the ther-mal activation effect: more cementing materials were formed during

curing at 40 C than during curing at 20 C. In addition, soil samplescured at 20 C show a higher proportion of macro pores, a coarserpore structure and high porosity values compared with the soil samplescured at 40 C. Thus, small pores and porosity give little freedom, if any,for the clay particles to expand because of the cementitious materialsformed during the curing process. Moreover, a smaller pore size and po-rosity decreases the soil's ability to retain further water upon wettingand this in turn reduces the swell potential.

During long-term periods of curing (180 and 360 days), the swellpotential values of soil samples increased with increasing gypsum con-tent, and the maximum values were recorded for the samples cured at40 C rather than 20 C. For the samples with 25% gypsum and curedat 20 C, the free swell potential values were 2.1% and 3.5% after 180and 360 days, respectively, against 2.8% and 4% when the soil sampleswere cured for the sameperiods but at 40 C.When the gypsumcontentexceeded 5%, the reaction between soil, lime and gypsum dominatedthe limesoil reactions. High swell potential values were recorded at

0

1

2

3

0 10 20 30Gypsum Content (%)

Free

Sw

ell (

%)

Fig. 6. Free swell of untreated soil samples with different gypsum content.

4

52 days

7 daysA

99A. Aldaood et al. / Applied Clay Science 102 (2014) 931030

1

2

3

0 10 20 30

Free

Sw

ell (

%)

Gypsum Content (%)

28 days

180 days

360 days0

1

2

3

4

5

0 10 20 30

Free

Sw

ell (

%)

Gypsum Content (%)

2 days7 days28 days180 days360 days

B

Fig. 7. Free swell of lime treated soil samples with curing periods (A) at 20 C and (B) at40 C.high gypsum contents. The presence of lime and reactive alumina atthese amounts of gypsum appeared to contributemore to ettringite for-mation than pozzolanic reactions and hence high swell potential valueswere recorded. This observation along with the previous one for theshort-term periods leads to the important conclusion that criticalamounts of calcium, reactive alumina and gypsum must be present inlime-treated soil to form ettringite.

Ettringite crystal formation and growth are one of themain phenom-ena of the swell potential of lime-treated gypseous soil. The ettringitecrystals are generally formed in the soil voids during the initial reactions.This formation is expected to occur within a few days to several weeks(Kota et al., 1996). These crystals will then start to accumulate with thecombined reactions between soil, lime and gypsum system, at high pHconditions (more than 10.5). When the existing pore void space of soilsamples cannot accommodate any more ettringite crystals, the soil sam-ples will start to swell. Additional swell potential can be attributed to thehydration reactions of ettringite minerals formed inside the soil matrix(Puppala et al., 2005). Another factor that may increase the swell poten-tial with curing period and gypsum content is osmotic swelling. It is sug-gested in (Mehta, 1983;Wild et al., 1993) that osmotic swellingmay takeplace within colloidal layers in regions of high sulfate concentration inclose proximity to the developing ettringite rods at the clay particle sur-faces.When in a saturated condition, ettringite grows and develops fromthis colloidal product. During this growth, colloidal ettringite possessesthe capability of imbibing large amounts of water, dramatically increas-ing the swelling potential of lime-treated gypseous soil samples.

3.3. Cyclic free swell potential

Soil in nature is often under conditions of changeable water contentand undergoes cyclic wettingdrying. This phenomenon has a marked

0

1

2

3

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% GFig. 8. Cyclic free swell of untreated soil samples with wettingdrying cycles.

-

inuence on the properties of soil. Fig. 8 shows the swell potential of un-treated soil samples with different amounts of gypsum, correspondingto the number of wettingdrying cycles. The swell potential of untreat-ed soil samples decreased with increasing wettingdrying cycles. Themaximum signicant reduction in the swell potential values was re-corded after the rst cycle and this reduction gradually reached equilib-rium at the 4th wettingdrying cycle. Further, it is observed that theeffects of wettingdrying cycles on the swell potential of the untreatedsoil samples depended on the amount of gypsum addition: the maxi-mum reduction in swell potential occurred for samples with a high gyp-sum content (i.e. 15% and 25%). At the same time, it was observed thatthe trend of reduction in swell potential of soil sampleswithout gypsumis similar to that of samples with gypsum. The reduction in swell poten-tial is attributed to destruction of the soil matrix (especially the claystructure matrix) during wettingdrying cycles, as well as to partialbreakdown of the soil particles by reconstruction of the structure of ag-gregates that occurred during these cycles (Yazdandoust and Yasrobi,2010). The results obtained in this investigation are in agreement withthose reported by (Dif and Bluemel, 1991; Guney et al., 2007). Duringwettingdrying cycles, the soil sampleswithout gypsumcracked as a re-sult of shrinkage and low tensile strength, whereas there were no obvi-ous cracks in the gypseous soil samples, especially those with highergypsum content, as shown in Fig. 9. Crack propagation occurred whenthe tensile stress due to the increase in suction was equal to or higherthan the cohesion forces. In the untreated samples, as the percentageof gypsum increases, the percentage of clay in the sample decreases (re-placement method) and consequently the shrinkage diminishes. More-over, gypsum in the soils acts as a ller and participates in the reductionof suction induced in the clayey parts of the soil. It is worth noting thatafter the last wettingdrying cycles most cracks were found to be

situated at the same locations as after the rst cycle and the followingcycles enhance only these phenomena. Concerning shrinkage, the di-mension can be millimetric and the visible cracks have a homogeneousdistribution and can reach a millimeter.

Figs. 10 and 11 show that the swell potential of the lime-treated soilsamples increased with increasing number of wettingdrying cycles. Atthe short-term curing periods (from 2 days to 28 days) and for bothtemperature values, themaximumswell potential valueswere recordedafter the rst wettingdrying cycle. Thereafter, swell values reachedequilibrium or decreased slightly with increasing wettingdrying cy-cles. Long-term curing periods (more than 28 days) suppressed theswell potential of the soil samples without gypsum, even with increas-ing wettingdrying cycles. This behavior is attributed to more cementi-tious materials being formed during these periods. For the soil samplescontaining gypsum, the swell potential values increased with wettingdrying cycles up to the 2nd cycle, then stabilized or decreased slightly.The results obtained at short-term periods of curing and for both curingtemperatures indicate that the benecial effect of lime treatment is lostwith wettingdrying cycles. These results support the study carried outby (Khattab et al., 2007). It can be stated that the wettingdrying cyclescaused the gradual destruction of the pozzolanic reaction of lime-treated soil samples.

In the treated samples, the claylime reactions are certainly higherthan the suction developed in these soils, which explains why noshrinkage or cracks were observed.

Moreover, ettringite formation andwater absorption also resulted inincreasing the swell potential of the lime-treated soil samples contain-ing gypsum. Swelling in gypseous soil samples is normally associatedwith absorption of water during ettringite formation (Hunter, 1988;Mitchell and Dermatas, 1992). Wild et al. (1993) reported that swelling

25%G15%G5%G0%G

100 A. Aldaood et al. / Applied Clay Science 102 (2014) 93103180 days at 40C

180 days at 20C

UntreatedFig. 9. Crack propagation of soil samples with wettingdrying cycles.

-

00.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G

5% G

15% G

25% G

2 days

7 days

28 days

180 days

360 days

Fig. 11. Cyclic free swell of lime treated soil samples cured at 40 C with wettingdryingcycles.

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

0

0.5

1

1.5

2

0 1 2 3 4 5No. of Cycle

Free

Sw

ell (

%)

0% G5% G15% G25% G

2 days

7 days

28 days

180 days

360 days

Fig. 10. Cyclic free swell of lime treated soil samples cured at 20 C with wettingdryingcycles.

101A. Aldaood et al. / Applied Clay Science 102 (2014) 93103

-

102 A. Aldaood et al. / Applied Clay Science 102 (2014) 93103in a kaolinitelimegypsum system is related to ettringite formationand that the swelling increases with an increase in gypsum contentand also increases linearly with water absorption. Generally, there willbe insufcient water to dissolve very much gypsum at the end of thecuring period, especially for long-term periods as shown in Table 2;moreover, the drying process caused a large reduction in water contentvalues (water content approximately equal to zero). Thus, unless extrawater is able to enter the soil samples, no appreciable swell will occur,even if high amounts of gypsum and lime are present. Themeasured re-sidual water content of lime-treated soil samples decreased with in-creasing both curing periods and curing temperatures. Further, asgypsum content increased the residual water content decreased withcuring conditions, as illustrated in Table 2.

Another phenomenon that may help to interpret the increase inswell potential is that of osmotic suction. Duringwettingdrying cycles,water absorption is dominated by osmotic suctionwhich is a function ofgypsum content in the soil samples. The suction potential of soil sam-pleswill increasewith gypsummovement, resulting in higherwater ab-sorption and hence causing an increased swell potential. Lastly, thelime-treated soil samples did not show any crack propagation duringwettingdrying cycles, as illustrated in Fig. 9.

4. Conclusions

The following conclusions can be drawn from this study.

1. Lime addition and curing conditions (curing periods and curing tem-perature) enhanced the swell potential of soil samples withoutgypsum.

2. In the presence of gypsum and available water, the lime-treated soilsamples show an increase in total pore volume and in swell potentialdue to ettringite formation. This distress increases with increasingcuring conditions.

3. Osmotic suction, created by the presence of soluble gypsum in soilsamples, caused additional water absorption and therefore contrib-uted to increasing swell potential. Ettringite nucleation and growthcaused the same action. Changes in the engineering properties andbehavior of soils are due to a set of parameters including gypsumdis-solution, pore size distribution and soil fabric changes revealed byXRD, SEM images and mercury porosimetry tests.

4. The benecial effect of lime treatment in controlling the swell poten-tial of soil samples (especially gypseous soil samples) is partially lostduring wettingdrying cycles. The rst wettingdrying cycle causesmore distress than subsequent cycles for the soil samplewith gypsum

Table 2Residual water content of lime treated soil with curing conditions.

Gypsum (%) aResidual water content (%) at 20 C40 C

2 days 7 days 28 days 180 days 360 days

0 10.39.8 9.69.5 8.67.7 7.46.4 6.85.75 9.89.4 9.39.1 8.07.1 6.75.7 6.15.115 9.69.2 9.19.0 7.56.9 6.25.0 5.54.525 9.59.1 9.08.8 7.26.1 5.94.8 5.14.0

a Initial value of water content of all soil samples is = 11%.content.5. Based on the results presented in this paper, lime treatment could be

effective in stabilizing gypseous soils containing a small amount ofgypsum (5%), and in enhancing their swell properties, especiallyin areas within arid or semi-arid zones.

Finally, provided that precautions are taken to prevent gypsum dis-solution, gypseous soils could be carefully used in the liners of sanitarylandlls in those regions where wetdry cycles have a signicant effecton swelling properties and crack propagation. Further, when gypsumsalts are present in soils and stabilization is required, measurementssuch as gypsum content, compaction energy and water content, curing

Puppala, A.J., Wattanasantichatoen, E., Intharasombat, L., Hoyos, L.R., 2003. Studies to un-derstand soil compositional and environmental variables effects on sulfate heave

problems. Proceeding of 12th Pan-American Conference on Soil Mechanics and Geo-technical Engineering, Cambridge, Massachusetts, pp. 833839.

Puppala, A.J., Grifn, J.A., Hoyos, L.R., Chomtid, S., 2004. Studies of sulfate-resistant cementstabilization methods to address sulfate-induced soil heave. Journal of Geotechnicalconditions and clay contentmust bemade to counter the adverse effectsof lime addition. Such measurements aim to reduce the action ofettringite formation.

References

Adams, A.G., Dukes, O.M., Tabet, W., Cerato, A.B., Miller, G.A., 2008. Sulfate induced heavein Oklahoma soils due to lime stabilization. Geo-congress, Conference Proceedings.ASCE, pp. 444451.

Aibn, S.A., Al-Abdul Wahhab, H.I., Al-Amoudi, O.S.B., Ahmed, H.R., 1998. Performanceof a stabilized marl base: a case study. Construction and Building Materials 12,329340.

Al-Mukhtar, M., Belanteur, N., Tessier, D., Vanapalli, S.K., 1996. The fabric of a clay soilunder controlled mechanical and hydraulic stress states. Applied Clay Science 11(2), 99115.

Al-Mukhtar, M., Lasledj, A., Alcover, J.F., 2010a. Behaviour and mineralogy changes inlime-treated expansive soil at 20 C. Applied Clay Science 50, 191198.

Al-Mukhtar, M., Lasledj, A., Alcover, J.F., 2010b. Behaviour and mineralogy changes inlime-treated expansive soil at 50 C. Applied Clay Science 50 (2), 199203.

Al-Mukhtar, M., Khattab, S., Alcover, J.F., 2012. Microstructure and geotechnical propertiesof lime-treated expansive clayey soil. Engineering Geology 139, 1727.

ASTM D4546: Standard Test Methods for One-Dimensional Swell or Collapse of Soils.ASTM D6026: Standard Practice for Using Signicant Digits in Geotechnical Data.ASTMD6276, 2006. Standard Test Method for Using pH to Estimate the SoilLime Propor-

tion Requirement for Soil Stabilization.ASTM D698: Standard Test Methods for Laboratory Compaction Characteristics of Soil

Using Standard Effort.Bell, F.G., 1996. Lime stabilization of clay minerals and soils. Engineering Geology 42,

223237.Bergaya, F., Lagaly, G., 2006. General introduction: clays, clay minerals and clay science.

In: Bergaya, F., Theng, B.K.G., Lagaly, G. (Eds.), Developments in clay science 1. Hand-book of Clay Science 1, pp. 118 (Chapter 12.10).

Bergaya, F., Vayer, M., Lagaly, G., 2006. Cation and anion exchange. In: Bergaya, F., Theng,B.K.G., Lagaly, G. (Eds.), Developments in Clay Science 1. Handbook of clay science 1,pp. 9791000 (Chapter 12.10).

Boyadgiev, T.G., Verheye,W.H., 1996. Contribution to a utilitarian classication of gypsumin soils. Geoderma 74, 321338.

Cooper, A.H., 1998. Subsidence hazards caused by the dissolution of Permian gypsum inEngland: geology, investigation and remediation. Geological Society, London, Engi-neering Geology Special Publication 15, 265275.

Cooper, A.H., 2008. The classication, recording, data basing and use of information aboutbuilding damage caused by subsidence and landslides. Quarterly Journal of Engineer-ing Geology and Hydrogeology 41 (3), 409424.

Dif, A.E., Bluemel, W.F., 1991. Expansive soils under cyclic drying and wetting. Geotechni-cal Testing Journal 14 (1), 96102.

Eades, J.L., Grim, R.E., 1966. A quick test to determine lime requirements for soil stabiliza-tion. Highway Research Record 139, 6172.

FAO, 1990. Management of gypsiferous soil. Bulletin, No. 62, Rome, Italy.FAO (1993): World soil resources Report, 66, Rome, Italy: An Explanation of the FAO

World Soil Resource Map at a Scale of 1:25000000.Giesche, H., 2006. Mercury porosimetry: a general (practical) overview. Particle & particle

systems characterization 23 (1), 919.Guney, Y., Sari, D., Cetin, M., Tuncan, M., 2007. Impact of cycling wettingdrying on swell-

ing behavior of lime-stabilized soil. Building and Environment 42, 681688.Hunter, D., 1988. Lime-induced heave in sulfate-bearing clay soils. Journal of Geotechnical

Engineering, ASCE 114 (2), 150167.Khattab, S.A.A., Al-Mukhtar, M., Fleureau, J.M., 2007. Long-term stability characteristics of

a lime-treated plastic soil. Journal of Materials in Civil Engineering, ASCE 19 (4),358366.

Kota, P.B.V.S., Hazlett, D., Perrin, L., 1996. Sulfate-bearing soils: problems with calciumbased stabilizers. Transportation Research Record 1546, 6269.

Little, D.N., 1995. Handbook for Stabilization of Pavement Sub Grade and Base Courseswith Lime. Kendall Hunt Publishing Company, Iowa, USA (by National LimeAssociation).

Little, D.N., Nair, S., Herbet, B., 2010. Addressing sulfate-induced heave in lime treatedsoils. Journal of Geotechnical and Geoenvironmental Engineering, ASCE 136 (1),110118.

Mathew, P.K., Rao, S.N., 1997. Effect of lime on cation exchange capacity of marine clay.Journal of Geotechnical and Geoenvironmental Engineering, ASCE 123 (2), 183185.

Mehta, P.K., 1983. Mechanism of sulphate attack on Portland Cement. Cement and Con-crete Research 13, 401406.

Mitchell, J.K., Dermatas, D., 1992. Clay soil heave caused by limesulfate reactions. Inno-vations and uses of lime. ASTM Special Technical Publication 1135, pp. 4164.

Ouhadi, V.R., Yong, R.N., 2008. Ettringite formation and behavior in clayey soils. AppliedClay Science 42, 258265.

Petry, M.T., Little, M.D., 1992. Update on sulfate induced heave in treated clays; problem-atic sulfate levels. Transportation Research Record 1362, 5155 (Washington D.C.).and Geoenvironmental Engineering 130 (4), 391402.

-

Puppala, A.J., Intharasombat, N., Vempati, R.K., 2005. Experimental studies on ettringite-induced heaving in soils. Journal of Geotechnical and Geoenvironmental Engineering,ASCE 131 (4), 325337.

Tessier, D., 1984. Etude Exprimentale de l'Organisation des Matriaux Argileux(ThseDoctorat d'Etat) Universit de Paris 6, France (247 pp.).

Wild, S., Abdi, M.R., Leng-Ward, G., 1993. Sulphate expansion of lime-stabilized kaolinite.Part II. Reaction products and expansion. Clay Minerals 28, 569583.

Wild, S., Kinuthia, J.M., Jones, G.I., Higgins, D.D., 1999. Suppression of swelling associatedwith ettringite formation in lime stabilized sulphate bearing clay soils by partial

substitution of lime with ground granulated blast furnace slag. Engineering Geology51, 257277.

Yazdandoust, F., Yasrobi, S.S., 2010. Effect of cyclic wetting and drying swelling behaviorof polymer-stabilized expansive clays. Applied Clay Science 50, 461468.

Yilmaz, I., Civelekoglu, B., 2009. Gypsum: an additive for stabilization of swelling clay soil.Applied Clay Science 44, 166172.

Yong, R.N., Ouhadi, V.R., 2007. Experimental study on instability of bases on natural andlime/cement-stabilized clayey soils. Applied Clay Science 35, 238249.

103A. Aldaood et al. / Applied Clay Science 102 (2014) 93103

Free swell potential of lime-treated gypseous soil1. Introduction2. Materials and methods of testing2.1. Materials2.2. Sample preparation2.3. Mineralogical and microstructural analysis2.4. One-dimensional free swell test2.5. Cyclic one-dimensional free swell test

3. Results and discussion3.1. Mineralogical and microstructural changes3.2. Free swell potential3.3. Cyclic free swell potential

4. ConclusionsReferences