Acoustical Material

-

Upload

ritikaritika -

Category

Documents

-

view

42 -

download

12

description

Transcript of Acoustical Material

Slide 1

MODERN ACOUSTICAL MATERIALSACOUSTICS PRESENTATION ONSUBMITTED TO :AR.MANITA SAXENASUBMITTED BY :AVNI PATNI,ITISHA KSHATRIYA,HEENA PARDESHI,ABHIJIT SINGH BAGHEL,HITESH MULEY,ABHAY SINGH HOLKAR,ANAND SOMANI,KARAN SEJWANI,ANKIT SIR,SIDDHARTH SIR,PRANJAL AGARWAL,PAYAL JAIN,NAVNI NAIK,PALLAVI SHARMA,PARIDHI BABEL.

MODERN ACOUSTICAL MATERIALSWith the change in time, the buildings and the materials changed and so did the acoustical materials.

Acoustics was recognized as a scientific phenomenon, which led to the discovery of new acoustical materials.

These new materials evolved on the basis of the scientific study of sound, especially of its generation, transmission, and reception.

Science of production, control, transmission, reception, and effects of sound. Its principal branches are architectural, environmental, musical, and engineering acoustics, and ultrasonic.

Due to high competition, and a lot of companies in the market the Architect and the client have wide variety of acoustic materials to choose from. Sound absorbers : These materials are used to eliminate sound reflections to improve speech intelligibility, reduce standing waves and prevent comb filtering.

Sound diffusers : These devices reduce the intensity of sound by scattering it over an expanded area, rather than eliminating the sound reflections as an absorber would.

Noise barriers and vibration control : These materials range from dense materials to Block the transmission of airborne sound to devices and compounds used to isolate Structures from one another and reduce impact noise.

Fiberglass and Glass woolFiberglass: A covering material made of glass fibers in resins. lightweight, doesnt give extra load on the structure.Generally covered under PVC for protection.Glass wool is an insulating material made from fiberglass, arranged into a texture similar to wool. Glass wool is produced in rolls or in slabs, with different thermal and mechanical properties.

Glass woolCeiling bafflesThermoplasticsA thermoplastic, also known as a thermo softening plastic. It is a polymer that turns to a liquid when heated and freezes to a very glassy state when cooled sufficiently.- It is used in various places as an acoustical material.

False CeilingsPVC ceiling system is light in weight, moisture resistant and reduces condensation and subsequent dripping from ceiling onto work surfaces. Its cleanable, non-absorbent surface is UV stable and will not discolour. This extremely practical ceiling system is suitable for any area requiring a fixed, non-porous, non-fibrous and non-absorbent ceiling.

Acoustical BoardsFalse CeilingsThermoplastics An acoustic board is a special kind of board made of sound absorbing materials.

Its job is to provide sound insulation.

Between two outer walls sound absorbing material is inserted and the wall is porous. Thus, when sound passes through an acoustic board, the intensity of sound is decreased. The loss of sound energy is balanced by producing heat energy. They are used in auditoriums, halls, seminar rooms, libraries, studio, courts and wherever Sound insulation is needed. Acoustic boards are also used in speaker boxes.

Acoustical BoardsUses :-Acoustic foam Panels Acoustic foam Panels are used for acoustic treatment. They are typically open-celled.

They attenuate airborne sound waves by increasing air resistance, thus reducing the amplitude of the waves.

The energy is dissipated as heat.

There are different types of panels available in market namely:

Anechoic foam wedgesCutting wedge foamPolyurethane acoustic foamfire flex acoustical foamFabrics and CurtainsFabrics and curtains are also used for sound buffering.

Acoustical fabrics are typically used to either absorb sound or as a cover for acoustical panels.

Some fabrics can also be used as a speaker grill cloth or as a finish on other types of materials.

Many other fabrics are available for use as panel coverings, grill cloths, speaker covers, cabinetry work, etc.

Fabrics and Curtains4TRADITIONAL ACOUSTICAL MATERIALS AND TECHNIQUIES Wood Wool Cement boards Wood Wool Cement Board is a versatile building material made from long wood fibers and cement.The fibers are 1-5 mm wide and 0.2 to 0.5 mm thick. From one cubic meter of second-class wood, three cubic meters of wood wool cement boards can be produced with a density of about 400-kg per cubic meter.The worldwide acceptance of Wood Wool Cement Board proves its versatility and its durability in any climatic condition. The main characteristics are: Fire resistance

Wet and dry rot resistance

Termite and vermin resistance

High thermal insulation

Acoustic performance- sound absorption

Acceptance of a wide range of finishes

WOOD WOOL CEMENT BOARDS Acceptance of a wide range of finishes:-

WWCB accepts all kinds of conventional rendering, plastering, decorative material and mastics. Acoustic ceilings can be sprayed or roll-painted to retain the acoustic properties of the board.

Fire resistance:-

Wood Wool Cement Board has been tested and classified B1 (non readily ignitable) according to the German DIN 4102 standard.

Wet and dry rot resistance:-

Because the wood wool has been dematerialized, moisture loses its effect on the board. The boards can even be applied in moist conditions like ceilings in indoor swimming pools. Termite and vermin resistance:-

Tests have proven that Wood Wool Cement Board is not vulnerable to attack by termites or vermin, nor is Wood Wool Cement Board subject to any biological decay. Thermal insulation:-

Because of its relatively low density, Wood Wool Cement Board has good thermal properties.

Acoustic performance:-

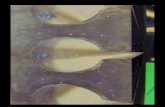

The unfinished Wood Wool Cement Board has very good acoustic properties since the open surface structure allows for a high level of acoustic absorption. REVERBERATION ROOMS

REVERBERATION ROOMS Areverberationchamber or room is a room designed to create adiffuseor random incidence sound field.

Reverberation chambers tend to be large rooms and have very hard exposed surfaces.

The change ofimpedance(compared to the air) these surfaces present to incident sound is so large that virtually all of the acoustic energy that hits a surface is reflected back into the room.

Arranging the room surfaces (including the ceiling) to be non-parallel helps inhibit the formation ofstanding waves- additional acousticdiffusersare often used to create more reflecting surfaces and further encourage even distribution of any particular sound field.

Application :-The main uses for a reverberation chamber are measurement microphone calibration, measurement of the sound powerof a source, and measurement of theabsorption coefficientof a material.

All these techniques assume the sound field in the chamber to be diffuse, and will normally use a broadband sound source. So, that the resulting sound field contains acoustic energy across the whole audible range.

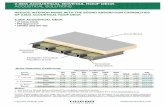

ROCKWOOL BLOWN LOFT INSULATION

The quicker to install loft insulation for new and existing loftsAdvantages :-

Excellent thermal insulation.Ideal for new and existing lofts (topping up).Quicker to install than conventional double layering of roll Improved sound insulation.Approved Rockwool installers Rockwool Blown Attic Insulation is todays solution to meet the thermal regulations for both new-build and existing loft spaces.Installation is quicker than laying conventional roll insulation and creates minimum disturbance.Description, performance and properties :-Density :-The nominal blown density of the product is 30kg/m3

Thermal Conductivity :-Rockwool will not react with any metal components in the loft, nor will it cause loss of plasticizer from PVC cables and pipes Durability :-Rockwool Blown Loft Insulation is a durable material. When installed, it will not be affected by normal ventilation within the loft space and will remain as an effective loft insulation for the life of the building.

Loft Hatches :-Covers to loft hatches should be insulated with a minimum thickness of 100mm Rockwool Roll. To prevent disturbance of the blown insulation when gaining access and leaving loft space, a Rockwool cardboard hatch box is fitted around the joist/trimmers.Acoustic Performance :-Rockwool Blown Loft Insulation can improve the sound insulation of a building. 250mm of Rockwool Blown Loft Insulation, with an isolated 12.5mm plasterboard ceiling, achieved > 50dB reduction in a tiled roof construction.

BY MIXING ASBESTOS AND CELLULOSE FIBER WITH BINDERS AND PRESERVING CHEMICALSAVAILABLE IN DRY FORMMIXED WITH WATER THICKNESS OF COAT IS OR 3/4CAN BE PAINTED LATER.ALSO AVAILABLE IN DIFFERENT COLORSACCOUSTICAL PULP

APPLIED IN TWO COATSTHICKNESS PROVIDES A MONOLITHIC SURFACE FIRE RESISTANTOTHER PLASTERS: SABINITELIMPET ASBESTOSTHERMACOUSTICS:MINERAL WOOL.CAN BE APPLIED ON WOOD,METAL,MASONRY OR GLASS.WITH PRIOR COATING OF ASPHALT EMULTION. VERSATILE,FIRE PROOF, HIGH EFFICIENCY.ACOUSTICAL plaster

Mineral wool

SOUND PROOFING MATS

SOUND PROOF BOARDS

Acoustical doors

CORK FLOORINGHERA KLITH