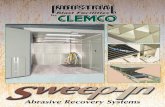

Abrasive grit material recovery system

Transcript of Abrasive grit material recovery system

and second processes; and wherein a pe- ripheral speed of the bell-shaped atomizing head during the first process is higher than that during the second process. and a re- duction rate of a nonvolatile value is main- tained at least 3%.

Binders for Powder Coatings U.S. Patent 5.620,751. Apr. 15, 1997 G. Brindoepke et al., assignors to Hoe&t AG, Germany

A method of forming a powder coating on a substrate by applying a coating of powder to a substrate and curing the same thermally or with electron beams or by high energy radiation or by irradiation with IN light, the improvement comprising us- ing a binder in the powder, which binder consists at solid unsaturated polyester and a polyurethane comprising (meth)acrylo:yl groups wherein the polyurethane is ob- tained by reacting a polyisocyanate corn- ponent comprising at least one organic polyisocyanate, an alcohol component con- taining (meth)acryloyl groups, and corn prising at least one mono- or polyhydrtc alcohol, and a further structural component comprising at least one compound free

from (meth)acryloyl groups and having groups reactive towards isocyanate groups selected from the group consisting of ethyl- ene glycol, 1.2. and 1,3-propane diol, neo pentyl glycol, glycerol, trimethylol propane. tris hydroxyethyl isocyanurate, pentaerythri- to1 and diethanolamine, polyamines, and amines containing hydroxyl groups in addi- tion to secondary and primary ammo groups.

Abrasive Grit Material Recovery System U.S. Patent 5,622,265. Apr. 22. 1997 J.C. &enter et a/, assignors to PCT Inc., Davenport, lowa

A method useful in connection with the separation and recovery of abrasive grit material from blasting material containing waste material. contaminants, and abrasive grit material.

Powder Spray Gun U.S. Patent 5,622.313. Apr. ;?2 1997 H.J. Lader ef ai, ass\gnors to Wordson Corp., Westlake, Ohio

A triboelectric powder spray gun with internal discharge electrode.

Method of Polishing U.S. Patent 5,622,525. Apr. 22, 1997 J. Haisma et al., assignors to U.S. Philips Corp., New York

A method of polishing a surface of cop- per or an alloy comprising mainly copper comprising moving a polishing means and the surface with respect to each other while exerting a polishing pressure of between 400 and 600 g/cm’, the polishing means comprising a colloidal suspension of SiOZ particles, demineralized water, and a chem- ical activator.

Polishing Apparatus U.S. Pafent 5.622526. Apr. 22, 1997 J.D. Phrllips, assignor to J.D. Phillips Corp., Aipena, Mich.

An apparatus for trueing CBN abrasive belts and grinding wheels.

Abrasive Article U.S. Patent 5,622.535. Apr. 22, 1997 R. L. Bradshaw. assignor to IBM Corp., Armonk, N. Y

An abrasive article comprtsing an inor- ganic filler having absorption sites selected from the group consisting of unhydrated

ELECTROPLATING KNOW HOW BASICS” A TWO DAWRA/MMGMOGRAM

ON THE BASIC PMfWPLES OF ELEC7ROPLA77No

San Jose, CA March 9 & ‘IO, 1998

Phoenix, AZ March 12& 13, 1998

Tulsa, OK April 2 & 3, 1998

Providence, RI April 13 & ‘14, 1998

Cincinnati, OH April 16 & ‘I 7, 1998

Greenville, SC April 20 & 21, 1998

Detroit, MI April 23 & :24, 1998

CALL OR FAX FOR A BROCHURE!!

“Training Electroplaters Since 1947”

732 Clencoe Court, Sunnyvale, Callifurnia 94087

(408) 749-8652 l FAX: (408) 749-0176

Circle 078 on reader information card Circle 037 on reader information card

METAL FINISHING l JANUARY 1998 87