870 y 871 Destaco

-

Upload

marco-antonio-ortiz -

Category

Documents

-

view

31 -

download

6

Transcript of 870 y 871 Destaco

11.25 Subject to technical modifications without notice DE-STA-CO

Sta

nd

ard

Pn

eum

atic

Cla

mp

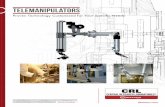

s Models 870, 871Power clamps with the roller and cam principle

Roller and cam mechanism of the Models 870 and 871

These models use a roller and cam principle and provide the following benefits:

n Able to clamp work of inconsistent thickness and still maintain a locked condition.n Modular units 2-1/8" square can stack together for minimum distance between

clamping points.n Four-way mounting surface for full mounting flexibility.n Built-in pre-stop eliminates need to bottom out cylinder. Gives extra travel to

automatically compensate for wear. Also permits arm to be machined accurately relative to mounting surface.

n Clamp arms can be altered by welding, drilling, or machining to suit the application.n Standard mounting plate included.

Application Note: Clamping range at end of arm in fully closed position: Model 870 – 0.18" Model 871 – 0.14"

Sensors

Model 870

(clamping arm vertical

when in clamped position)

Model 871

(clamping arm

horizontal when in

clamped position)

Standard equipment:1 assembly plate, part no. 870116

Power clamp models 871 and 803 on a pressure test fixture for vehicle gearbox lids

Order separately:sensors for -MR versions(2 pieces required to sense both the open and closed positions of the cylinder)

ALSO AVAILABLE

With Magnetic Ring Model 870-MRModel 871-MR

Switch Options Page 13.5

See accessories beginning on page 13.1.

Maximum Holding Capacity Exerting Force

@ 80 PSI

Max. Operating Pressure Clamping range at

end of arm in fully closed position

Cylinder Area

Mechanical advantage

Port SizeModel no. [lbs.] [PSI] Weight

870

871

2,000

2,000

170 / 350

170 / 350

250

250

0.18

0.14

1.767 sq. in.

1.767 sq. in.

1.2 to 2.5:1

1.2 to 2.5:1

7.00

7.00

1/4 NPT

1/4 NPT

DE-STA-CO Subject to technical modifications without notice 11.26

Sta

nd

ard

Pn

eum

atic

Cla

mp

sModels 870-2, 871-2Power clamps with the roller and cam principle

Assembly plate (870116)(standard)

L1

L13

S max.(max. tolerance compensation at the clamp arm´s end)

Opening- ~112°

Opening- ~126°

Model no. a a1 A1 b b1 B1 B2 B2a B7 B7a øD D1 L1 L3 L4 L4a L5 L5a L8 L8a L9 L9a L10 L12 L13

870

871

1.75

1.75

2.19

2.19

2.13

2.13

1.00

1.00

1.75

1.75

2.13

2.13

4.25

–

–

3.31

1.75

1.75

1.75

1.75

0.25

0.25

0.28

0.28

9.58

9.96

3.38

3.38

1.00

–

–

1.00

0.62

–

–

0.76

1.50

1.50

1.00

1.00

1.00

1.00

1.00

1.00

0.78

0.78

1.00

1.00

4.50

4.88

L8a

B7a

L9a

b b1

a1

a

øD

B2a

L9

L8

D1

L12

L5a

L4a

B2

S max.L4

870

L5

871

870

871

B7

L10

A1

B1

L3

![[テキストPDF]保土ケ谷区ガイドマップ B 地図面 2020 - …...2020/03/30 · 124 181 145 151 100 15 14 11 28 888 900 876 876 871 876 1 5 889 861 871 870 865 864 863](https://static.fdocuments.net/doc/165x107/609252c309b292286c3af177/ffpdfoeeoefffff-b-oee-2020-20200330.jpg)