862 En 4ed. 06.06 new controller - EuroClean.sk...FIRST COMMISSIONING AND ROUTINE START - UP FIRST...

Transcript of 862 En 4ed. 06.06 new controller - EuroClean.sk...FIRST COMMISSIONING AND ROUTINE START - UP FIRST...

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OOOdddiiisssMMMaaatttiiiccc®®® EEEllleeeccctttrrriiiccc FFFiiilllttteeerrr

SSeerriieess 886622

Operator's Manual

Models

86212 (12”)

86214 (14”)

86216 (16”)

Board No. 86302

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

CONTENTS

Page

Technical Specification ……………………………………... 3

Filtration Screens ……………………………………………. 3

Materials ……………………………………………………… 4

Construction ………………………………………………….. 4

Operational Principles ………………………………………. 5

Operational Modes ………………………………………….. 6

Installation ……………………………………………………. 7

First Commissioning and Routine Start-up ……………….. 8

Automatic Operation ………………………………………… 9

Continuous Operation ………………………………………. 9

Changing Parameters On The PLC ……………………… 10

Control Box …………………………………………………… 14

Maintenance …………………………………………………. 14

Trouble Shooting Table …………………………………….. 15

Parts Breakdown …………………………………………….. 17

Parts List ……………………………………………………… 18

Hydraulic Scheme …………………………………………… 20

Head Loss/ Flow Rate Diagram ……………………………. 21

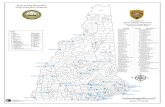

General Dimensions ………………………………………… 22

Electric Drawings ………………………………………… 23

ODIS takes all possible precautions in packing each equipment

item to prevent damage during shipment. Carefully inspect each

item, and if damage occurred, please report ODIS immediately.

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

General Data

Min. Working Pressure 2 bar 30 psi

Max. Working Pressure 10 bar 150 psi

For other pressure consult ODIS representative

Screen area & Maximum Flow Rates

In/Out – dia. Max. Flow Rate Flush Flow Rate Screen Area

Model Inch mm m3/h gpm m3/h gpm Sq.cm Sq.inch

86212 12” 300 600 2630 35 155 10050 1560

86214 14” 350 800 3520 35 155 10050 1560

86216 16” 400 1000 4400 35 155 10050 1560

The max. flow rate refers to screens over 200 microns/ less than 80 mesh

For a finer filtration degrees consult our representative.

Screen Grades

mesh 500 300 200 150 100 80 40

micron 30 50 80 100 150 200 400

* Other screen grades’ are available.

Electrical Data

Mains 3 Phase 380V – 50 Hz, 220V/440V – 60 Hz

Drive Assembly 1/3 HP, 1/4 KW

Control PLC operating at 24V DC

For other power supply consult ODIS representative

TECHNICAL SPECIFICATION

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

Filter housing : Carbon Steel , electrostatic powder coating

Optional - Stainless Steel .

Filtration Screens :Stainless Steel 316

Gaskets : Natural Rubber

Optional - other materials

The standard housing of the filter is constructed of carbon steel, which has a 100

micron protective coating of extra durable polyester, applied electrostatically and oven

cured on a zinc-phosphate layer, for maximal anti-corrosion protection both internally

and externally

Access to the internal of the filter is through a removable bolted cover.

This allows for easy access for servicing and maintenance purposes. All immersed

parts are constructed of either plastic or non-corrosive metals, allowing for extended

service life.

Optional materials are available for special applications ; contact our representative for more information.

On the end of the filter housing the electric worm-gear motor is mounted, performing

simultaneously two movements during the flushing cycle:

a. Rotation of the collector assembly with all the suction nozzles to clean the

screen on all it’s perimeter.

b. Longitudinal motion of the collector assembly with all the nozzles to clean the

screen on all it’s length.

Both actions clean all the surface of the filtering screen in a helical movement . The

rotation is transmitted from the worm-gear motor to the collector assembly by a sliding

key, while the longitudinal motion is transmitted by a square, double thread screw.

MATERIALS

CONSTRUCTION

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

1. INLET 5. OUTLET 9. WORM GEAR MOTOR

2. COARSE SCREEN 6. FLUSHING VALVE 10. CONTROLLER

3. FINE SINTERED SCREEN 7. FLUSHING CHAMBER

4. SUCTION NOZZLE 8. COLLECTOR

A. Normal flow pattern

The raw water enters the filter inlet and passes through the coarse

screen , the first stage of filtration . This prevents passage of large

particles which may damage the filter internals.

The water then enters the second stage of filtration, where the fine sintered screen

is located. This screen consists of a multi-layer sintered screen of stainless steel

woven mesh sintered together.

As the water passes through this screen, the solids accumulate creating a “cake” of

dirt on the surface of the screen. This cake performs finer filtration than the screen

itself, resulting in increased filter efficiency. The cake creates also a pressure

differential across the screen.

This differential is monitored by the control system, and a flushing cycle is

activated once the predetermined differential is achieved.

OPERATING PRINCIPLES

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

B. Flushing cycle

When the predetermined differential pressure is reached (as preset on the D.P.

switch gage) the controller activates the flushing valve (opens it) and the gear

motor.

The pressure differential between the pressure inside the filter and at the open valve

to the atmosphere, produces a back-flushing effect at the nozzles removing

accumulated solids from the screen to the drain . The helical motion of the nozzles

as mentioned above cleans all the area of the screen.

The same Flushing cycle may be activated by the controller - by the Preset Timer or

by the Manual Flushing button (Test).

C. Continuous flushing

Means the flushing of the fine sintered screen continuously, through the suction

nozzles. The flushing valve and the worm-gear motor are activated continuously.

The “Continuous Flushing” is selected manually by the operator.

This efficient filter is automatic and easy to operate.

Its operating modes are as follows:

1) Filtration - The normal function of the filter, until a flushing mode is activated.

2) Automatic Flushing – Back flushing of the screen through the suction nozzles,

when activated by time or DP. The gear-motor and the flushing valve are activated

simultaneously by the controller. The Yellow Flushing light (on the control board)

is ON.

The timer activates the flushing cycle, if the D.P. is not activated.

3) Continuous Flushing -

Back flushing of the screen through the suction nozzles. The gear motor and the

flushing valve, are activated continuously and the Yellow Flushing light is ON.

This manual mode is selected by the operator.

4) Malfunction mode – This mode takes place

a. When the overload is tripped.

b. When both micro-switches are pressed down at the same time, or when

both micro-switches are short-circuited.

c. The motor works for more than T2 (= 60 secs) between microswitches.

Then the RED Fault Light (on the control board) is ON.

OPERATING MODES

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

WARNING : Maximal pressure 10 bar (150 psi).

If the pressure is not controlled effectively, a pressure relief valve must be installed

before the filter.

Prevent back-pressure or reverse flow - install a mechanical non-return valve on each

filter outlet.

NOTE: Install isolation valves at inlet & outlet. These valves would service the filter

whenever needed, and in addition the outlet valve can be used to adjust the flow rate

whenever needed.

Install the filter in any position with enough space for servicing and dismantling, but

horizontally is recommended.

Water inlet and outlet directions are clearly marked by an arrow.

Install a mechanical non-return valve at outlet.

Connect a drain pipe with no appreciable resistance.

Check for leaks.

INSTALLATION

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

NOTE : The differential pressure switch and timers have been preset to the proper

settings . Do not adjust prior to start-up.

1. Check that the line pressure will always be at least 2 bar (30 psi) at the filter

inlet during the flushing cycle.

2. Check that there are no upstream pipeline restrictions.

3. Check that the filter is mounted in the correct flow orientation as indicated

by the arrows on the body.

4. Check that the flushing valve is mounted properly.

5. Check that the tubing connections are completed.

6. Check that power is available to the Electrical Control Box and that the main

switch on the control box is in the “OFF” position .

7. Check that the flushing valve drain lines are installed.

8. Check that the upstream and downstream isolation valves are closed.

9. Check that adequate space is available around the filter for maintenance as

indicated on drawing no. 007049-E included in this manual.

1. Slowly open the inlet valve to the filter allowing the filter to pressurize.

2. Check for any external leakage and eliminate.

3. Slowly open the outlet valve of the filter (if installed).

4. Turn the main switch ON.

NOTE: An automatic procedure will find the right moving direction.

5. Verify that all power supply and all machine elements are connected.

6. Verify input voltage is correct.

7. Turn on main switch wait 5 sec.

8. Push the TEST push button for two seconds. See the movement of the screw.

NOTE: The filter will perform its first flush and will stop, (between the limit

switches). During flushing ensure that the filter inlet pressure is higher than

2 bar (20mWC).

After this first operation the filter passes into automatic mode (command

switch: on "AUTO" position), at any given time pressing the TEST button

will cause one flush cycle.

9. Initiate a manual flushing; observe the inlet and flushing chamber pressures.

The flushing chamber pressure should be between 1.2 to1.5 bar below inlet

pressure during the flushing cycle.

FIRST COMMISSIONING AND ROUTINE START - UP

FIRST COMMISSIONING

START - UP

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

1. The filter will perform a flushing cycle after interval (T6) time in which no

flushes took place.

2. The filter will perform a flushing cycle due to the pressure differential

switch command (D.P.), and will stop near the limit switches.

3. If the pressure differential remains on, the filter will continue its flushing.

4. Counter CTMR (C2) will count the number of flushes due to TFmin time.

5. Counter CDP (C3) will count the number of flushes due to pressure differential.

6. Counter fault (C4) will count the number of faults.

AUTOMATIC OPERATION

CONTINUOUS OPERATION

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

INTERVAL CHANGING INSTRUCTIONS:

1. At normal operation the PLC displays the time, date and I/O table (FIG.1)

2. To change and read parameters press Menu/OK – the following screen will show

(FIG. 2). Use the up/down arrow to reach the PARAMETER (it will blink) and

press Menu/OK.

CHANGING PARAMETERS ON THE PLC

FIG.1

FIG.2

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

3. The following screen will show (FIG. 3)

4. Use the up (∧) arrow till the following screen will show (FIG. 4)

4. Push the left key (<), the time value will start blinking. Use the up (∧) and down

(∨) keys to change the time interval (hours: minutes).

5. Press Menu/OK to confirm changes the following screen will show (FIG. 5).

Select YES by using up (∧) and down (∨) keys and confirm by pressing Menu/OK.

FIG.3

FIG.4

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

MASTR./ SLAVE CHANGING INSTRUCTIONS:

Another change - required only on first use (installation) - is C1:

− If operated as single filter or master filter in cascade - 0001 (MSTR).

− If operated as slave filter in cascade - 0002 (SLAVE)

• On main menu (FIG 1) press Menu/OK

• On the menu shown in (FIG 2) press down arrow to reach the PARAMETER

(it will blink) and press Menu/OK.

• Press up (∧) arrow to choose C1 screen then press Menu/OK.

• Press Right (>) arrow until the value will blink, choose the last figure (1 or 2)

of the number (0001 or 0002), and change it by using the vertical buttons

• Use horizontal buttons Z2, Z4 to choose the last figure (1 or 2) of the number

(0001 or 0002), and change it by using the up (∧) or down (∨) buttons. Press

Menu/OK. to approve the changing. (C1 will blink).

GENERAL DATA

When the PLC is on the main screen (FIG 1), pressing one of the keys below the

numbers: 2, 3, 4 will show one the following data:

2 INTERVAL Time between last flushing cycle to following flushing cycle

(interval) h : m

3 FAULT Number of faults. (Counter)

CTMR Number of flushing cycles due to timer (Counter). 4

CDP Number of flushing cycle due to pressure difference (Counter).

FIG.5

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

The fault condition (RED light on) is generated in following cases:

1. If the two motor limit switches are pressed simultaneously (or both are shorted).

2. The motor works continuously for more than 60 seconds without stopping.

Turn the command switch to RESET (spring loaded) to eliminate FAULT

continuation. RED light should turn off.

Check always the reason for the FAULT.

FAULT

RESET

CONTROLS

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

EXTERNAL

Lights : YELLOW - Flushing

RED - Malfunction

Command Switch : RESET – (Exit fault mode)

AUTO – (Automatic Operation)

CONT.– Continuous Flushing

Yellow Button: TEST – Manual Flush

INTERNAL

PLC : Programmable Logic Controller, for

service personnel ONLY.

Counter : For monitoring the number of flushings

See PLC instructions.

D.P. - differential pressure switch gage

The D.P. monitors the differential pressure of the filter at

inlet/outlet, to activate the PLC for a single back-flushing cycle.

PLC - control

The PLC activates a single flushing cycle when either the DP or time is activated

DP is set to 6 psi, 0.4bar; the time is set to 3 hrs. (Normally 3-8 hours).

The PLC may be in CONTINUOUS mode - the Timer is then by-passed .

For details of control modes, see the operating modes.

NOTE: before installing bolts back to their places spread the bolts treads with

grease.

1. Every 1 month apply MOLYKOTE G-n Plus Paste to the screw of the drive

assembly (item 30 on breakdown drawing).

2. Every 1 month apply “DOW CORNING 4” or EQUAL grease to the shaft

extension (item 28 on breakdown drawing).

3. Repair any damage to the protective coating of the filter without delay. Prior to

application of protective paint, thoroughly clean the damaged spot with wire

brush.

4. In case that there is needs to take out the screen for maintenance, prior to

installation lubricate the screen seals and the cover gasket with “DOW

CORNING 4” or EQUAL grease.

CONTROL BOX

MAINTENANACE

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

Item Problem Check If Solution

1 System

does

not work

Power

Main switch OFF Check Main Switch is ON

Check Power supply is available

(electricity).

Check Fuses/overload

2 Fault Lamp ON Check for possible reason - remedy

then press RESET

3 No water

flowing

Isolation

Valve

not open Open then press RESET

Manual

Valves

those required to

be open are not

open

Open them

4 Flow rate

is low or

Outlet

pressure is

low.

Water

pressure

(inlet) or

Line pressure

Pressure is Low

(usually below

35psi),

Press Manual Flush button: TEST

(when all required valves are open).

Increase pressure to normal:

�Water company

�Pumps

�Remote valves

�Main Line blocking

Normal

Go to next line

5 Pressure

drop too

high

Pressure drop

on filter -

difference in

readings of

pressure gage

D.P. is high,

over 0.5 bar, (7

psi).

Press TEST: Manual Flush button.

(on panel).

6 D.P. remains high Check flow rate - if not excessive

(higher than design flow rate).

TROUBLE SHOOTING

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

Item Problem Check If Solution

7 Repeat the above mentioned (Manual

Flush) and if D.P. is high:

a - Check for any

- disconnected or leaking control

tubes.

� disconnected wires

b – Unusually high dirt load

beyond design- call service

meanwhile reduce flow rate.

c – Unusual Blocking of filter

(close isolation valves)

dismantle filter and clean

screens .

8 Flush

valve does

not close

dirt on the

valve’s seat

Dirty Close water entry - release pressure

and clean.

9 Flush

valve does

not open

Solenoid

valve lamp

light not ON

Wiring problem

Replace solenoid if Faulty.

10 Gear

motor

rotating

but Drive

Shaft not

advancing

At extremity of

travel (left or

right) and drive

pin is in place

Check that the Limit Switches are

operating:

a) they are properly positioned

b) wiring problem

c) press on Limit Switch and see if

activated.

Replace Limit Switch if faulty .

Drive nut drive pin is not in

place

Install pin in its place and fit split pin

11 Flush

cycles are

too

frequent

Raw water Dirt load is high

or very soft and

“sticky”

Go to CONTINUOUS MODE

(Command Switch: CONT.).

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

Parts breakdown- 862 - ®OdisMatic

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OdisMatic® Electric 862 Parts list (refer to drawing D-C862-004-01 issue 3)

NO DESCRIPTION 86212 86214 86216

1 Filter Body A86212-12” A86214-14” A86216-16”

2 Dirt Collector assembly E8621201 E8621201 E8621201

2/1 Suction Nozzle ER8521602 E8521602 E8521602

2/2 Collector Body E8621602 E8621602 E8621602

2/3 Collector shaft RR8521617 RR8521617 RR8521617

3 Fine Screen assembly E8521609 E8521609 E8521609

3/1 Guide Base E8521613 E8521613 E8521613

3/2 Collector lower guide E8521614 E8521614 E8521614

3/3 Fine screen seal E8521615 E8521615 E8521615

3/4 Fine screen E8521605 E8521605 E8521605

4 Coarse Screen assembly E8521611 E8521611 E8521611

4/1 Collector Upper Bearing ER8521601 ER8521601 ER8521601

4/2 Coarse Screen E8521612 E8521612 E8521612

4/3 Guide Bearing E 8521616 E 8521616 E 8521616

5 Cover E8521619 E8521619 E8521619

6 Cover Gasket ER14022 ER14022 ER14022

7 Air Release Valve N131120 N131120 N131120

8 Rinse valve NB470863030T NB470863030T NB470863030T

9 Service Cover Gasket E004365 E004365 E004365

10 Service Port Cover E400260-SFR E400260-SFR E400260-SFR

11 Pressure Gauge N6111025 N6111025 N6111025

12 D.P switch N6040 N6040 N6040

13 3 way selector valve PM202500 PM202500 PM202500

14 Solenoid Valve – N.O N512009 N512009 N512009

15 Electric Board E86336060 E86336060 E86336060

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OdisMatic® Electric 862 Parts list (refer to drawing D-C862-004-01 issue 3)

NO DESCRIPTION 86212 86214 86216

16 Drive shaft cover E86026060 E86026060 E86026060

17 Worm gear motor E86035060 E86035060 E86035060

18 Drive base E86021060 E86021060 E86021060

19 Drive nut E86020060 E86020060 E86020060

20 Shaft guide E86302041 E86302041 E86302041

21 Guide seal E86302043 E86302043 E86302043

22 Shaft Seal (set) E86302162 E86302162 E86302162

23 Limit switch N598605 N598605 N598605

24 Drive base support E8621226 E8621226 E8621226

25 Drive key E86025060 E86025060 E86025060

26 Drive pin E86023060 E86023060 E86023060

27 Disk positioning nut E86011060 E86011060 E86011060

28 Shaft Extension E86022060 E86022060 E86022060

29 Limit switch disk E86024060 E86024060 E86024060

30 Drive shaft E86012060 E86012060 E86012060

31 Drive protection cover E86010060 E86010060 E86010060

32 Drain Valve 1" PM 1100010 PM 1100010 PM 1100010

33 Pressure Control Box Y8510201 Y8510201 Y8510201

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OdisMatic-862

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OdisMatic-862

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OdisMatic-862

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

OdisMatic-862

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

)ctric or Hydraulic FilterEle ( OdisMatic

WARRANTY

1. During a period of Four (4) years (“the

Warranty Period”) which commences on the

delivery date (F.O.B. – Israeli Port) - or up to

two (2) years commences on the installation

date, but in any case not more than the

warranty period mentioned above, and subject

to the provisions of this warranty, Odis shall

remedy in the manner described below any

defect in the equipment which results directly

from Odis faulty materials or workmanship.

2. During the Warranty Period, Odis shall repair

or replace any part of the Equipment found to

be defective in manufacture, or, at its option,

refund the portion of the purchase price

attributable thereto. Such repair, replacement

or refund is purchaser’s sole and exclusive

remedy for defective Equipment. Without

derogating from the generality of the

foregoing, Odis liability shall be limited to the

cost of materials and labor required for the

repair or replacement or refund of the defective

part.

3. Purchaser must notify Odis in writing of the

claimed defect, including a detailed description

of the defect. Such notice shall be submitted to

Odis promptly and without any delay after the

discovery of the defect.

4. Purchaser shall not attempt any repair or

replacement of the Equipment other than in

cases of emergency. In no case shall Odis be

liable for the cost of such repairs or

replacement carried out by the Purchaser.

5. Odis shall have no responsibility for defects in

the Equipment to the extent caused by use

other than as stated in Odis’ Operating Manual,

misuse, abuse, or installation, maintenance,

operation or repairs by the purchaser or by

persons not under the supervision of Odis.

6. When a defect in a part of the Equipment has

been remedied, the repaired or replaced parts

shall be deemed to be part of the Equipment

and Odis shall be liable for defects therein

until the end of the Warranty Period. Any

defective part which is replaced by Odis

shall thereupon become Odis’ sole property.

7. Odis liability to defects in components of the

Equipment which are not manufactured by

Odis (including, but not limited to,

computers, electrical boards, gaskets,

gauges, valves, flow and turbidity meters) is

limited to defects which results directly from

faulty materials or workmanship, that are

discovered within a period of 1 (one) year

from the installation date, but in any case not

more than the warranty period mentioned

above.

8. The foregoing warranty is in lieu of all other

warranties, expressed or implied, including,

but not limited to any implied warranties of

merchantability or fitness for a particular

purpose.

9. In no event shall Odis be liable for any other

damages whatsoever (including, without

limitation damages for loss of business

profit, business interruption, or other

pecuniary loss) arising out of the use of or

inability to use the equipment, even if Odis

has been advised of the possibility of such

damages .

10. In any case, Odis entire liability under

any provision of this warranty shall be

limited to the amount actually paid by the

purchaser for the equipment .

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz

User’s Notes

EuroClean s.r.o. Podbabská 81 /17, Praha 6 , PSČ: 160 00 IČO: 26141477, DIČ: CZ26141477

Tel.: 224 811 900, Fax: 224 810 597, e-mail: [email protected], web: www.euroclean.cz