6654744 Presentation on Bushings

-

Upload

ashok10577 -

Category

Documents

-

view

546 -

download

28

Transcript of 6654744 Presentation on Bushings

Jump to first page

PRESENTATION ON

BUSHINGS

Jump to first page

Topics to be covered

What is a bushing Types of bushings Salient design features Testing of bushings Factors affecting bushings Causes for failure of bushings Do’s and don’ts on bushings

Jump to first page

Bushing is defined as a structure carrying one or several conductors through a partition such as a wall or tank etc. and insulating it or them therefrom

A bushing has to provide

Electrical insulation to the conductor for the working voltage and for various over voltages, which occur in service.

Mechanical support against various Mechanical forces.

Bushing

Jump to first page

TYPES OF BUSHINGS

1.1 Application

i) Alternator bushing

ii) Transformer bushing

iii) Bushings for switch gear

iv) Wall bushing or roof bushing

v) Cable end and joint box bushing

1.2 Application:

i) Indoor type

ii) Outdoor type

Jump to first page

TYPES OF BUSHINGS 2.1 Type of Bushing: i) Stem type ii) Pull-through type

2.2 Type of Bushings: i) Condenser core type ii) Non-condenser core type

(Hollow Porcelain type) iii) Gas filled bushing iv) Solid Bushing

Solid Ceramic Bushing Epoxy Bushing

Jump to first page

TYPES OF BUSHINGS

3. Type of insulation used in manufacturing Condenser Bushing:

• i) Synthetic Resin Bonded Paper (SRBP)• Oil filled• Compound filled

• ii) Oil Impregnated Paper (OIP)

• iii) Resin impregnated Paper (RIP)

Jump to first page

Jump to first page

Jump to first page

800 kV OIPCondenser Bushing

Jump to first page

Top Cap

Top Porcelain

Flange

Bottom Porcelain

MAJOR PARTSOF BUSHING

Jump to first page

Major Parts of Bushing

Jump to first page

CREEPAGE DISTANCE

The shortest distance along the contour of the external insulating surface between the metal parts which normally have the operating voltage between them. Lightly polluted atmosphere Medium polluted atmosphere Heavily polluted atmosphere Very heavily polluted atmosphere

Jump to first page

Jump to first page

Nominal Specific Creepage Distance

Level I Light 16 mm/kV

Level II Medium 20 mm/kV

Level III Heavy 25 mm/kV

Level IV Very Heavy 31 mm/kV

Jump to first page

Salient Design features

Electrostatic Field Controlled design of Condenser Core by Computer

Suitable for Operation under heavily polluted atmosphere

Reliable, relatively easy erection and practically maintenance free.

Better Dielectric Strength and Partial Discharge free up to Working Voltage

Space for mounting of Ring Type Current Transformer

Jump to first page

Salient Design Features(Cont’d)

Self Earthing Test Tap for measurement of Tan Delta and Capacitance at site.

Environmental friendly.

Bushings for special applications can be designed and supplied to suit client’s specifications.

Jump to first page

Manufacturing Requriements

Dust free pressurized winding chamber

Winding Machines

Oil Treatment Plants for oil processing

Process Plants for Vacuum Impregnation at very fine Vacuum (0.005-0.001mm of Mercury)

Jump to first page

The Standard product range of BHEL Bushings is as below

Voltage(kV)

Current(Amps.) CT Length(mm)

52 1250, 2000, 3150 100, 300

72.5 800, 1250 100, 300

145 800, 1250, 2000 100, 300, 600

245 800, 1600, 2000 300, 600

420 800, 1250 400

Jump to first page

TYPE TESTS ON BUSHINGS

Sn Test details IEC Cl.No.

52 kV 72.5 kV 145 kV 245 kV 420 kV

1. Wet power frequencyvoltage withstand (kV)

7.1 95 140 275 460 NA

2. Dry lightning impulsevoltage withstand (kVp)

7.2 250 325 650 1050 1425

3. Switching impulsevoltage withstand (kVp)

7.3 NA NA NA NA 1050

4. Thermal stability test 7.4 NA NA NA NA

5. Temperature rise test 7.5

6. Verification of thermalshort time current

7.6

7. Cantilever loadwithstand

7.7 3150N 4000N 1600N 1600N 2500N

8. Tightness test 7.8

9. Seismic test Specialtest

-- --

Jump to first page

Bushing

under

Type

Test

Jump to first page

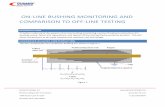

Bushing under Testing in UHV Lab.

Jump to first page

Testing Facilities (Cont’d)

Routine Tests on Bushings are conducted in a separate electro-magnetically shielded Test Laboratory which is provided with 2.0 Million-Volt, 60 kJ Impulse Generator Schering bridge Standard capacitors PD measuring equipment Facility for conducting Cantilever Load

Test

Jump to first page

ROUTINE TESTS ON BUSHINGS

Sn Test details IEC Cl.No.

52 kV 72.5 kV 145 kV 245 kV 420 kV

1 Measurement of Dielectricloss and Capacitance

8.1

2 Dry lightning ImpulseVoltage withstand test

8.2 NA NA NA NA 1425

3 Dry Power FrequencyVoltage withstand test(kV)

8.3 95 140 275 460 630

4 Measurement of Partialdischarge

8.4

5 Test on test tap 8.5

6 Leakage test 8.7

7 Tightness test at theFlange or other fixingdevice

8.9

Jump to first page

Bushing

under

Routine

Test

Jump to first page

Factors affecting performance of Bushing Atmospheric condition like pollution, humidity, and

ambient temperature. Temperature rise of joints. Internal Corona Thermal instability Loss of oil Altitude

Jump to first page

Causes of failure in Bushings

Insulation failure Ingress of moisture Leakage of oil Internal discharges Disconnection of earthing link of test tap Hair crack in porcelain Looseness of joint in the current carrying path Failure due to high voltage such as lightning,

switching etc.

Jump to first page

Tan Delta Measurement

Tan Delta is the dielectric loss angle.

Limiting Value for OIP Bushing = 0.007(Max.)

For measuring tan delta at site Schering Bridge is required.New Bushing yet to be installedBushing already in service

Jump to first page

Significance of Tan Delta Measurement

It reveals increased dielectric losses (I2R) with other source of heating may eventually lead to thermal runaway

High level of partial discharges are reflected in tan delta

Source of heating include dielectric losses, ambient temperature and load fluctuations

Jump to first page

Factors affecting Tan Delta Measurement

Ambient conditions Temperature of transformer oil around the lower

end of bushing Pollution level at site Induction effect of the neighboring lines

Jump to first page

Guidelines for measurement of Tan Delta at site

Position of bushing should be vertical If mounted on transformer, remove top terminal

connections Clean the porcelain with a non-fluffy cloth Check for oil level and any leakage Short the bushings of other phases which are not

under test Avoid measurement on a rainy season or when

humidity is more than 70%

Jump to first page

Guidelines for measurement of Tan Delta at site

Note temperature and correct it at 20ºC The bushing should be tested in Ungrounded

Specimen Test (UST)mode. The bridge should be placed on a vibration free

base. Test tap should be clean and dry Connecting leads should be shielded Make sure the bare connector on the HV lead

extends away from the bushing porcelain

Jump to first page

Analysis of Results

1) High Tan delta (between0.007 and 0.01)

Ingress of moisture in bushing insulation

2)Very High Tan delta (Beyond 0.01)

High humidity, Strong ageing of insulation

3) Low Tan delta

Weak Potential connection

4) High Capacitance

This indicates Partial Breakdown.

Jump to first page

Analysis of Results

Variation in Capacitance With in 5% - Bushing Acceptable With in 5% to 10% - Monitor Bushing closely More than 10% - Inform BHARAT HEAVY

ELECTRICALS LIMITED or Replace Bushing

Jump to first page

DOs AND DO NOTs FOR BUSHINGS

DOs

1. Check the packing externally for possible damage before un packing.

2. Unpack with care to avoid any direct blow on the bushing or porcelain insulator.

3. Store the bushing in a shed or covered with tarpoline to protect it from moisture and rains. If removed from

the crate keep it indoors with lower end protective intact.

4. Handle the bushing with manila rope slings without any undue force on porcelain insulators.

Jump to first page

DOs AND DO NOTs FOR BUSHINGS

DOs

5. Clean the porcelain insulator thoroughly before taking any measurement or mounting the bushing on the transformer. Check for any foreign body adhered to

the bottom porcelain.

6. Check the oil level by making the bushing vertical

7. Check for leakage of oil from any of the gasket joints. Each bushing is tested with the oil immersed in oil tank and so some traces of oil can be found which is actually not

leakage.

8. Check tan delta and capacitance ( if possible on mounted bushing without making any connections ).

9. Maintain the log book of records of periodical checks.

Jump to first page

DOs AND DO NOTs FOR BUSHINGS

DO NOTs

1. DO NOT unpack the bushing from crate unless required to be mounted on the transformer.

2. DO NOT use metal slings on porcelain and avoid un due jerks while handling.

3. DO NOT store the bushing outdoors with out any protective covering

4. DO NOT measure IR value and tan delta with out thoroughly cleaning the porcelain and oil end portion.

Jump to first page

DOs AND DO NOTs FOR BUSHINGS

DO NOTs.......

5. DO NOT fill oil in the bushing without specific instructions from BHEL .

6. DO NOT climb the porcelain to tighten the top terminal.

Use elevators or seperate ladder for this purpose.

7. DO NOT dismantle or attempt to repair the bushing in

case the defect or mechanism is not clear.

Jump to first page

Testing Facilities

Type Tests Type tests are done in Ultra High Voltage (UHV)

Laboratory which is one of the largest electro-magnetically shielded laboratories in the world.

The Laboratory offers very low background level during PD and RIV measurements.

It is equipped with following facilities 4 Million Volt Impulse Generator 1.5 Million Volt Cascade Test Transformer 1.2 Million Volts DC Generator

Jump to first page

Testing Facilities (Cont’d)

40 MVA 3-phase Motor-Generator set Standard capacitors Calibration and Recording Equipment

A pollution test chamber is also attached to this for conducting Wet and Pollution Tests

With these facilities all Type Tests to IEC 137, IS 2099, BS 223 and ANSI can be done within BHEL

Jump to first page

Thank You

Jump to first page

Jump to first page

Jump to first page

Equipotentialcondensers