4JX1–TC 3.0L ENGINE DRIVEABILITY AND...

Transcript of 4JX1–TC 3.0L ENGINE DRIVEABILITY AND...

6E–14JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

4JX1–TC 3.0L ENGINE DRIVEABILITY AND EMISSIONS

CONTENTS

Specification 6E–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Tightening Specifications 6E–7. . . . . . . . . . . . . . . Diagrams and Schematics 6E–8. . . . . . . . . . . . . . . .

ECM Wiring Diagram (1 of 6) 6E–8. . . . . . . . . . . .

ECM Wiring Diagram (2 of 6) 6E–9. . . . . . . . . . . .

ECM Wiring Diagram (3 of 6) 6E–10. . . . . . . . . . . .

ECM Wiring Diagram (4 of 6) 6E–11. . . . . . . . . . . .

ECM Wiring Diagram (5 of 6) 6E–12. . . . . . . . . . . .

ECM Wiring Diagram (6 of 6) 6E–13. . . . . . . . . . . .

ECM Pinouts 6E–14. . . . . . . . . . . . . . . . . . . . . . . . . . .

ECM Pinout Table, 32-Way Connector – J1 RED – Upper 6E–14. . . . . . . . . . . . . . . . . . . . . . . . . ECM Pinout Table, 32-Way Connector – J1 RED – Lower 6E–15. . . . . . . . . . . . . . . . . . . . . . . . . ECM Pinout Table, 32-Way Connector – J2 BLUE – Upper 6E–16. . . . . . . . . . . . . . . . . . . . . . . . ECM Pinout Table, 32-Way Connector – J2 BLUE – Lower 6E–17. . . . . . . . . . . . . . . . . . . . . . . . ECM Pinout Table, 5-Way Connector – J3 6E–18

Component Locator 6E–19. . . . . . . . . . . . . . . . . . . . .

Sensors and Miscellaneous Component

Locators 6E–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations Charts 6E–23. . . . . . . . . . . . . . . . . . . .

Diagnosis 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–24. . . . . . . . . . . . .

Strategy-Based Diagnostics 6E–24. . . . . . . . . . . . .

DTC Stored 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . .

No DTC 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

No Matching Symptom 6E–24. . . . . . . . . . . . . . . . .

Intermittents 6E–24. . . . . . . . . . . . . . . . . . . . . . . . . .

No Trouble Found 6E–24. . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–24. . . . . . . . . . . . . . . .

General Service Information 6E–25. . . . . . . . . . . . . .

Serviceability Issues 6E–25. . . . . . . . . . . . . . . . . . .

Visual/Physical Engine Compartment

Inspection 6E–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Knowledge of Tools Required 6E–25. . . . . .

Serial Data Communications 6E–25. . . . . . . . . . . . . .

Class II Serial Data Communications 6E–25. . . . .

On-Board Diagnostic (OBD) 6E–25. . . . . . . . . . . . . .

On-Board Diagnostic Tests 6E–25. . . . . . . . . . . . .

Comprehensive Component Monitor

Diagnostic Operation 6E–25. . . . . . . . . . . . . . . . . .

Common OBD Terms 6E–26. . . . . . . . . . . . . . . . . .

The Diagnostic Executive 6E–26. . . . . . . . . . . . . . .

DTC Types 6E–26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying Vehicle Repair 6E–27. . . . . . . . . . . . . . . .

Reading Flash Diagnostic Trouble Codes 6E–27.

Reading Diagnostic Trouble Codes Using

a TECH 2 6E–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tech 2 Scan Tool 6E–29. . . . . . . . . . . . . . . . . . . . . .

Getting Started 6E–30. . . . . . . . . . . . . . . . . . . . . . . .

DTC Modes 6E–32. . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Information Mode 6E–32. . . . . . . . . . . . . . . . .

Injector Test 6E–32. . . . . . . . . . . . . . . . . . . . . . . . . .

EGR Valve Test 6E–32. . . . . . . . . . . . . . . . . . . . . . .

Rail Pressure Control Valve Test 6E–32. . . . . . . . .

Injector Balance Test 6E–32. . . . . . . . . . . . . . . . . . .

Data Programming in Case of ECM Change 6E–32

Rail Pressure Sensor Programming 6E–33. . . . . .

Injector Group Sign Programming

(Injector Change) 6E–33. . . . . . . . . . . . . . . . . . . . .

On-Board Diagnostic (OBD) System Check 6E–35.

Circuit Description 6E–37. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–37. . . . . . . . . . . . . . . . . . . . . . . .

Engine Control Module ECM Diagnosis 6E–39. . . .

Multiple ECM Information Sensor DTCS Set 6E–39

Circuit Description 6E–39. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–39. . . . . . . . . . . . . . . . . . . . . . . .

EGR (Exhaust Gas Recirculation) Diagnosis 6E–41

Tech 2 Data Definitions and Ranges 6E–41. . . . . . .

Typical Scan Data Values 6E–41. . . . . . . . . . . . . . . .

Test Conditions 6E–41. . . . . . . . . . . . . . . . . . . . . . . .

4JX1-TC Engine (Automatic and Manual Transmission) 6E–42. . . . . . . . . . . . . . . . . . . . . . . .

No Malfunction Indicator Lamp (MIL) 6E–44. . . . . . .

Circuit Description 6E–44. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–44. . . . . . . . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) “ON”

Steady 6E–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit description 6E–47. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–47. . . . . . . . . . . . . . . . . . . . . . . .

Engine Cranks But Will Not Run 6E–49. . . . . . . . . . .

Circuit Description 6E–49. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–49. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) System

Check 6E–52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–52. . . . . . . . . . . . . . . . . . . . .

ECM Diagnostic Trouble Codes 6E–54. . . . . . . . . . .

ECM Diagnostic Trouble Codes 6E–54. . . . . . . . . Diagnostic Trouble Code (DTC) P0107

(Flash DTC 34)

MAP Sensor Circuit Low Voltage 6E–56. . . . . . . . . .

6E–2 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description 6E–56. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–56. . . . . . .

Conditions for Clearing the MIL/DTC 6E–56. . . . .

Diagnostic Aids 6E–56. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0108

(Flash DTC 34)

MAP Sensor Circuit High Voltage 6E–58. . . . . . . . .

Circuit Description 6E–58. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–58. . . . . . .

Conditions for Clearing the MIL/DTC 6E–58. . . . .

Diagnostic Aids 6E–58. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0112

(Flash DTC 23) IAT Sensor Circuit Low

Voltage 6E–60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–60. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–60. . . . . . .

Conditions for Clearing the MIL/DTC 6E–60. . . . .

Diagnostic Aids 6E–60. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–61. . . . . . . . . . . . . . . . . . . . . . .

Intake Air Temperature Sensor 6E–61. . . . . . . . . .

Diagnostic Trouble Code (DTC) P0113

(Flash DTC 23) IAT Sensor Circuit High

Voltage 6E–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–62. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–62. . . . . . .

Conditions for Clearing the MIL/DTC 6E–62. . . . .

Diagnostic Aids 6E–62. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–63. . . . . . . . . . . . . . . . . . . . . . .

Manifold Air Temperature Sensor 6E–63. . . . . . . .

Diagnostic Trouble Code (DTC) P0117

(Flash DTC 14) ECT Sensor Low Voltage 6E–65.

Circuit Description 6E–65. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–65. . . . . . .

Conditions for Clearing the MIL/DTC 6E–65. . . . .

Diagnostic Aids 6E–65. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–65. . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor 6E–66. . . . .

Diagnostic Trouble Code (DTC) P0118

(Flash DTC 14) ECT Sensor High Voltage 6E–67.

Circuit Description 6E–67. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–67. . . . . . .

Conditions for Clearing the MIL/DTC 6E–67. . . . .

Diagnostic Aids 6E–67. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–68. . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature Sensor 6E–68. . . . .

Diagnostic Trouble Code (DTC) P0121

(Flash DTC 33) AP Sensor Rationality 6E–70. . . . .

Circuit Description 6E–70. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–70. . . . . . .

Conditions for Clearing the MIL/DTC 6E–70. . . . .

Diagnostic Aids 6E–70. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0122

(Flash DTC 21) AP Sensor Low Voltage 6E–72. . .

Circuit Description 6E–72. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–72. . . . . . .

Conditions for Clearing the MIL/DTC 6E–72. . . . .

Diagnostic Aids 6E–72. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0123

(Flash DTC 21) AP Sensor High Voltage 6E–75. . .

Circuit Description 6E–75. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–75. . . . . . .

Conditions for Clearing the MIL/DTC 6E–75. . . . .

Diagnostic Aids 6E–75. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–75. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0182

(Flash DTC 15) FT Sensor Low Voltage 6E–78. . .

Circuit Description 6E–78. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–78. . . . . . .

Conditions for Clearing the MIL/DTC 6E–78. . . . .

Diagnostic Aids 6E–78. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–78. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0183

(Flash DTC 15) FT Sensor High Voltage 6E–80. . .

Circuit Description 6E–80. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–80. . . . . . .

Conditions for Clearing the MIL/DTC 6E–80. . . . .

Diagnostic Aids 6E–80. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–80. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0192

(Flash DTC 63) Rail Pressure Sensor Low

Voltage 6E–82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–82. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–82. . . . . . .

Conditions for Clearing the MIL/DTC 6E–82. . . . .

Diagnostic Aids 6E–82. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0193

(Flash DTC 63) Rail Pressure Sensor

High Voltage 6E–84. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–84. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–84. . . . . . .

Conditions for Clearing the MIL/DTC 6E–84. . . . .

Diagnostic Aids 6E–84. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1193

(Flash DTC 64) RPCV Circuit Open/Short 6E–86. .

Circuit Description 6E–86. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–86. . . . . . .

Conditions for Clearing the MIL/DTC 6E–86. . . . .

Diagnostic Aids 6E–86. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1194

(Flash DTC 61) Rail Pressure System

Low Voltage 6E–88. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–88. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–88. . . . . . .

Conditions for Clearing the MIL/DTC 6E–88. . . . .

Diagnostic Aids 6E–88. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1195

(Flash DTC 61) Rail Pressure System

High Voltage 6E–90. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–90. . . . . . . . . . . . . . . . . . . . .

6E–34JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Action Taken When the DTC Sets 6E–90. . . . . . .

Conditions for Clearing the MIL/DTC 6E–90. . . . .

Diagnostic Aids 6E–90. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1196

(Flash DTC 62) Rail Pressure System

High Warning 6E–92. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–93. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–93. . . . . . .

Conditions for Clearing the MIL/DTC 6E–93. . . . .

Diagnostic Aids 6E–93. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–93. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0197

(Flash DTC 16) Oil Temp Sensor Low

Voltage 6E–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–94. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–94. . . . . . .

Conditions for Clearing the MIL/DTC 6E–94. . . . .

Diagnostic Aids 6E–94. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–95. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Temperature Sensor 6E–95. . . . . . . . .

Diagnostic Trouble Code (DTC) P0198

(Flash DTC 16) Oil Temp Sensor High

Voltage 6E–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–96. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–96. . . . . . .

Conditions for Clearing the MIL/DTC 6E–96. . . . .

Diagnostic Aids 6E–96. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–97. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Temperature Sensor 6E–97. . . . . . . . .

Diagnostic Trouble Code (DTC) P0201

(Flash DTC 51) Injector # 1 Circuit Fault 6E–99. . .

Circuit Description 6E–99. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–99. . . . . . .

Conditions for Clearing the MIL/DTC 6E–99. . . . .

Diagnostic Aids 6E–99. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–99. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–99. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0202

(Flash DTC 52) Injector # 2 Circuit Fault 6E–101. . .

Circuit Description 6E–101. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–101. . . . . . .

Conditions for Clearing the MIL/DTC 6E–101. . . . .

Diagnostic Aids 6E–101. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–101. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–101. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0203

(Flash DTC 52) Injector # 3 Circuit Fault 6E–103. . .

Circuit Description 6E–103. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–103. . . . . . .

Conditions for Clearing the MIL/DTC 6E–103. . . . .

Diagnostic Aids 6E–103. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–103. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–103. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0204

(Flash DTC 54) Injector # 4 Circuit Fault 6E–105. . .

Circuit Description 6E–105. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–105. . . . . . .

Conditions for Clearing the MIL/DTC 6E–105. . . . .

Diagnostic Aids 6E–105. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–105. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–105. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0217

(Flash DTC 22) High Coolant Temp Waring 6E–107

Circuit Description 6E–107. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–107. . . . . . .

Conditions for Clearing the MIL/DTC 6E–107. . . . .

Diagnostic Aids 6E–107. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–107. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1217

(Flash DTC 36) High Oil Temp Warning 6E–109. . . .

Circuit Description 6E–109. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–109. . . . . . .

Conditions for Clearing the MIL/DTC 6E–109. . . . .

Diagnostic Aids 6E–109. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0219

(Flash DTC 11) Engine Over Speed Warning 6E–111

Circuit Description 6E–111. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–111. . . . . . .

Conditions for Clearing the MIL/DTC 6E–111. . . . .

Diagnostic Aids 6E–111. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0336

(Flash DTC 43) CKP (Crank Position)

Sensor Out of Synchro 6E–114. . . . . . . . . . . . . . . . . .

Circuit Description 6E–114. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–114. . . . . . .

Conditions for Clearing the MIL/DTC 6E–114. . . . .

Diagnostic Aids 6E–114. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0337

(Flash DTC 43) CKP (Crank Position)

Sensor No Signal 6E–116. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–116. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–116. . . . . . .

Conditions for Clearing the MIL/DTC 6E–116. . . . .

Diagnostic Aids 6E–116. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0341

(Flash DTC 41) CMP (Cam Position)

Sensor Out of Synchro 6E–119. . . . . . . . . . . . . . . . . .

Circuit Description 6E–119. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–119. . . . . . .

Conditions for Clearing the MIL/DTC 6E–119. . . . .

Diagnostic Aids 6E–119. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–119. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0342

(Flash DTC 41) CMP (Cam Position)

Sensor No Signal 6E–122. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–122. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–122. . . . . . .

Conditions for Clearing the MIL/DTC 6E–122. . . . .

6E–4 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Aids 6E–122. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–122. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0380

(Flash DTC 66) Glow Relay Circuit

Open/Short 6E–126. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–126. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–126. . . . . . .

Conditions for Clearing the MIL/DTC 6E–126. . . . .

Diagnostic Aids 6E–126. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0381

(Flash DTC 67) Glow Lamp Circuit

Open/Short 6E–128. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–128. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–128. . . . . . .

Conditions for Clearing the MIL/DTC 6E–128. . . . .

Diagnostic Aids 6E–128. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1403

(Flash DTC 32) EGR EVRV Fault 6E–130. . . . . . . . .

Circuit Description 6E–130. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–130. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–130. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1404

(Flash DTC 31) EGR VSV Circuit 6E–132. . . . . . . . .

Circuit Description 6E–132. . . . . . . . . . . . . . . . . . . . .

Diagnostic Aids 6E–132. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0405

(Flash DTC 26) EGR Pressure Sensor

Low Voltage 6E–134. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–134. . . . . . .

Conditions for Clearing the MIL/DTC 6E–134. . . . .

Diagnostic Aids 6E–134. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1405

(Flash DTC 37) EGR EVRV Circuit

Open/Short 6E–136. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–136. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–136. . . . . . .

Conditions for Clearing the MIL/DTC 6E–136. . . . .

Diagnostic Aids 6E–136. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0406

(Flash DTC 26) EGR Pressure Sensor

High Voltage 6E–138. . . . . . . . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–138. . . . . . .

Conditions for Clearing the MIL/DTC 6E–138. . . . .

Diagnostic Aids 6E–138. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0475

(Flash DTC 71) EXH #1 VSV Circuit 6E–140. . . . . . .

Circuit Description 6E–140. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–140. . . . . . .

Conditions for Clearing the MIL/DTC 6E–140. . . . .

Diagnostic Aids 6E–140. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1475

(Flash DTC 71) EXH #2 VSV Circuit

Open/Short 6E–142. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–142. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–142. . . . . . .

Conditions for Clearing the MIL/DTC 6E–142. . . . .

Diagnostic Aids 6E–142. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1485

(Flash DTC 74) ITP (Intake Thorottle Position)

Sensor Low Voltage 6E–144. . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–144. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–144. . . . . . .

Conditions for Clearing the MIL/DTC 6E–144. . . . .

Diagnostic Aids 6E–144. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1486

(Flash DTC 74) ITP (Intake Throttle Position)

Sensor High Voltage 6E–146. . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–146. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–146. . . . . . .

Conditions for Clearing the MIL/DTC 6E–146. . . . .

Diagnostic Aids 6E–146. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1487

(Flash DTC 73) Intake Throttle System

Circuit Open/Start 6E–148. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–148. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–148. . . . . . .

Conditions for Clearing the MIL/DTC 6E–148. . . . .

Diagnostic Aids 6E–148. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1488

(Flash DTC 72) Intake Throttle Motor Control

Circuit Signal Gap 6E–150. . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–150. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–150. . . . . . .

Conditions for Clearing the MIL/DTC 6E–150. . . . .

Diagnostic Aids 6E–150. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0502

(Flash DTC 24) VSS (Vehicle Speed Sensor)

No Signal 6E–152. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–152. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–152. . . . . . .

Conditions for Clearing the MIL/DTC 6E–152. . . . .

Test Description 6E–153. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0510

(Flash DTC 75) Idle SW Malfunction, Open

Circuit 6E–155. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–155. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–155. . . . . . .

Conditions for Clearing the MIL/DTC 6E–155. . . . .

Diagnostic Aids 6E–155. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1510

(Flash DTC 75) Idle SW Malfunction

Short Circuit 6E–157. . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–157. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–157. . . . . . .

Conditions for Clearing the MIL/DTC 6E–157. . . . .

Diagnostic Aids 6E–157. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0562

(Flash DTC 35) System Voltage Too Low 6E–159. .

Circuit Description 6E–159. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–159. . . . . . .

6E–54JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Conditions for Clearing the MIL/DTC 6E–159. . . . .

Diagnostic Aids 6E–159. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1562

(Flash DTC 35) System Voltage Too Low

at Cranking 6E–160. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–160. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–160. . . . . . .

Conditions for Clearing the MIL/DTC 6E–160. . . . .

Diagnostic Aids 6E–160. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1587

(Flash DTC 25) Brake SW Malfunction 6E–161. . . .

Circuit Description 6E–161. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–161. . . . . . .

Conditions for Clearing the MIL/DTC 6E–161. . . . .

Diagnostic Aids 6E–161. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1588

(Flash DTC 25) Brake SW Malfunction 6E–163. . . .

Circuit Description 6E–163. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–163. . . . . . .

Conditions for Clearing the MIL/DTC 6E–163. . . . .

Diagnostic Aids 6E–163. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0601

(Flash DTC 55) ECM Checksum Error 6E–165. . . . .

Action Taken When the DTC Sets 6E–165. . . . . . .

Conditions for Clearing the MIL/DTC 6E–165. . . . .

Diagnostic Aids 6E–165. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0650

(Flash DTC 77) Check Engine Lam Circuit

Open/Short 6E–166. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–166. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–166. . . . . . .

Conditions for Clearing the MIL/DTC 6E–166. . . . .

Diagnostic Aids 6E–166. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0654

(Flash DTC 27) Tachometer Circuit

Open/Short 6E–168. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–168. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–168. . . . . . .

Conditions for Clearing the MIL/DTC 6E–168. . . . .

Diagnostic Aids 6E–168. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1655

(Flash DTC 17) Thermo Relay Circuit

Open/Short 6E–170. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–170. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–170. . . . . . .

Conditions for Clearing the MIL/DTC 6E–170. . . . .

Diagnostic Aids 6E–170. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1657

(Flash DTC 76) ECM Main Relay Circuit

Open/Short 6E–172. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–172. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–172. . . . . . .

Conditions for Clearing the MIL/DTC 6E–172. . . . .

Diagnostic Aids 6E–172. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1589

(Flash DTC 47) Transmission SW Circuit

Open/Short 6E–174. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–174. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–174. . . . . . .

Conditions for Clearing the MIL/DTC 6E–174. . . . .

Diagnostic Aids 6E–174. . . . . . . . . . . . . . . . . . . . . . . .

Symptom Diagnosis 6E–176. . . . . . . . . . . . . . . . . . . . .

Default Matrix Table 6E–199. . . . . . . . . . . . . . . . . . . . .

On–Vehicle Service Camshaft Position

(CMP) Sensor 6E–201. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–201. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–201. . . . . . . . . . . . . . . . . .

Installation Procedure 6E–201. . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–202. . . . . . . . .

Removal Procedure 6E–202. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–202. . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–203.

Removal Procedure 6E–203. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–203. . . . . . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–203. . . . . . .

Removal Procedure 6E–203. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–204. . . . . . . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–204.

Removal Procedure 6E–204. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–205. . . . . . . . . . . . . . . . . .

Oil Temperature (OT) Sensor 6E–205. . . . . . . . . . . . .

Removal Procedure 6E–205. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–206. . . . . . . . . . . . . . . . . .

Malfunction Indicator Lamp (MIL) 6E–206. . . . . . . . . .

Removal and Installation Procedure 6E–206. . . . . .

Engine Control Module (ECM) 6E–206. . . . . . . . . . . .

Service Precaution 6E–206. . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge (ESD) Damage 6E–206. . .

Removal Procedure 6E–207. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–208. . . . . . . . . . . . . . . . . .

EEPROM 6E–208. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–208. . . . . . . . . . . . . . . . . . . .

Functional Check 6E–208. . . . . . . . . . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–208. . . . . . .

Removal Procedure 6E–208. . . . . . . . . . . . . . . . . . . .

Function Check 6E–209. . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–209. . . . . . . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–210. . . . . . . . . . . . .

Removal Procedure 6E–210. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–210. . . . . . . . . . . . . . . . . .

Installation Procedure 6E–210. . . . . . . . . . . . . . . . . .

Air Cleaner/Air Filter 6E–211. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–211. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–211. . . . . . . . . . . . . . . . . .

Accel Position (AP) Sensor 6E–211. . . . . . . . . . . . . . .

Removal Procedure 6E–211. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Accelerator Pedal Replacement 6E–212. . . . . . . . . . .

6E–6 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Removal Procedure 6E–212. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–212. . . . . . . . . . . . . . . . . .

Fuel Filter Cap 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–213. . . . . . . . . . . . . . . . . . . .

Inspection Procedure 6E–213. . . . . . . . . . . . . . . . . .

Fuel Filter 6E–213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–213. . . . . .

Fuel Gauge Unit 6E–213. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–213. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–214. . . . . . . . . . . . . . . . . .

Fuel Injectors 6E–214. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedure 6E–214. . . . . .

Fuel Temperature Sensor 6E–214. . . . . . . . . . . . . . . .

Removal Procedure 6E–214. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–215. . . . . . . . . . . . . . . . . .

Rail Pressure (RP) Sensor 6E–216. . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–216. . . . . . . . . . . . . . . . . .

Fuel Tank 6E–216. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–216. . . . . . . . . . . . . . . . . . . .

Throttle Body (TB) 6E–217. . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Air Conditioning (A/C) Relay 6E–217. . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–217. . . . . . . . . . . . . . . . . .

Exhaust Gas Recirculation (EGR) Vacuum

Switch Valve (VSV) 6E–217. . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–217. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–218. . . . . . . . . . . . . . . . . .

Electronic Vacuum Regurating Valve (EVRV) 6E–219

Removal Procedure 6E–219. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–220. . . . . . . . . . . . . . . . . .

Wiring and Connectors 6E–220. . . . . . . . . . . . . . . . . . .

Wiring Harness Service 6E–220. . . . . . . . . . . . . . . .

Connectors and Terminals 6E–220. . . . . . . . . . . . . .

Wire Harness Repair: Twisted Shielded

Cable 6E–220. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–220. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–221. . . . . . . . . . . . . . . . . .

Twisted Leads 6E–221. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–221. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–222. . . . . . . . . . . . . . . . . .

Weather-Pack Connector 6E–223. . . . . . . . . . . . . . . . .

Tools Required 6E–223. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–223. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–223. . . . . . . . . . . . . . . . . .

Com-Pack III 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 6E–224. . . . . . . . . . . . . . . . . . . .

Metri-Pack 6E–224. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 6E–224. . . . . . . . . . . . . . . . . . . . . . . .

Removal Procedure 6E–224. . . . . . . . . . . . . . . . . . . .

Installation Procedure 6E–224. . . . . . . . . . . . . . . . . .

General Description

(ECM and Sensors) 6E–225. . . . . . . . . . . . . . . . . . . . .

57X Reference ECM Input 6E–225. . . . . . . . . . . . . .

A/C Request Signal 6E–225. . . . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–225. . . . . . .

Camshaft Position (CMP) Sensor and

Signal 6E–225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–225

Electrically Erasable Programmable Read

Only Memory (EEPROM) 6E–225. . . . . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–225. . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–226

Engine Control Module (ECM) 6E–226. . . . . . . . . . .

ECM Function 6E–226. . . . . . . . . . . . . . . . . . . . . . . . .

ECM Components 6E–226. . . . . . . . . . . . . . . . . . . . .

ECM Voltage Description 6E–226. . . . . . . . . . . . . . .

ECM Input/Outputs 6E–226. . . . . . . . . . . . . . . . . . . .

ECM Service Precautions 6E–227. . . . . . . . . . . . . .

Intake Throttle Position (ITP) Sensor 6E–227. . . . .

Transmission Range Switch 6E–227. . . . . . . . . . . . .

Accelerator Position Sensor (AP) 6E–227. . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–227. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–227. . . . . . . . .

General Description (Air Induction) 6E–228. . . . . . . .

Air Induction System 6E–228. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–228. . . . . . .

Deceleration Mode 6E–228. . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–228. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–228. . . . . .

A/C Clutch Diagnosis 6E–228. . . . . . . . . . . . . . . . . . . .

A/C Request Signal 6E–228. . . . . . . . . . . . . . . . . . . .

General Description Exhaust Gas

Recirculation (EGR) System 6E–228. . . . . . . . . . . . .

EGR Purpose 6E–228. . . . . . . . . . . . . . . . . . . . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) RHD 6E–229. . . . . . .

Fuse and Relay Panel

(Underhood Electrical Center) LHD 6E–230. . . . . . .

6E–74JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

SpecificationTightening Specifications

Application N·m Kg·m Lb Ft. Lb In.

Camshaft Position Sensor Retaining Screw 9 0.9 — 78

Crankshaft Position Sensor Mounting Bolt 9 0.9 — 78

Engine Coolant Temperature Sensor 19 1.9 14 —

Throttle Body Mounting Nuts 20 2.0 14 —

VSS Retaining Bolt 16 1.6 12 —

MAP Sensor Screw 4 0.4 — 35

EGR VSV Bolts 8 0.8 — 69

Fuel Temp Sensor 19 1.9 14 —

Oil Temp Sensor Bolt 19 1.9 14 —

Rail Pressure Sensor Bolt 20 2.0 14 —

6E–8 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagrams and Schematics

ECM Wiring Diagram (1 of 6)

060RW127

6E–94JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Wiring Diagram (2 of 6)

060RW125

6E–10 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Wiring Diagram (3 of 6)

060RW126

6E–114JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Wiring Diagram (4 of 6)

060RW128

6E–12 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Wiring Diagram (5 of 6)

060RW123

6E–134JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Wiring Diagram (6 of 6)

060RW124

6E–14 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Pinouts

ECM Pinout Table, 32-Way Connector – J1 RED – Upper

060RW138

J1 – RED

PIN SIGNAL

1 FUEL TEMPERATURE

2 SPARE ANALOG 1

3 +5VB1

4 +5VB2

5 SPARE ANALOG 3

6 ACCEL POS OUT 1

7 NOT USED

8 SPARE OUT 2 (TCC)

9 EVRV (EGR)

10 IGN RELAY

11 GLOW PLUG LAMP

12 DIAGNOSTIC LAMP

13 VSV (EXHAUST #2)

14 RAIL PRESS CNTRL VALVE

15 GLOW PLUG RELAY

16 VSV (EXHAUST #1)

6E–154JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Pinout Table, 32-Way Connector – J1 RED – Lower

060RW137

J1 – RED

PIN SIGNAL

17 SPARE ANALOG 4

18 INTAKE SM POSITION

19 VEHICLE SPEED

20 MT NEUTRAL

21 REVERSE SW

22 ACCEL POS OUT 2

23 THERMO SW RELAY

24 SPARE OUT 3 (TURBO)

25 VSV (EGR)

26 TACHOMETER 1

27 BRAKE SW 1

28 NOT USED (BRAKE 2)

29 A/T NEUTRAL SW

30 NO CONNECTION

31 AC REQUEST SW

32 AT SOLENOID

6E–16 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Pinout Table, 32-Way Connector – J2 BLUE – Upper

060RW138

J2 – BLUE

PIN SIGNAL

1 INJECTOR A RTN

2 INJECTOR B RTN

3 INJECTOR C RTN

4 INJECTOR D RTN

5 CLASS 2

6 SDATA

7 RAIL OIL PRESSURE

8 IDLE SW

9 IGN SW

10 BATTERY

11 QUICK WARM REQ. SW

12 PARTIAL IDLE SW

13 CERAMIC HTR REQUEST SW

14 INTAKE SW S2B

15 INTAKE SW S1T

16 INTAKE SW S1B

6E–174JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Pinout Table, 32-Way Connector – J2 BLUE – Lower

060RW137

J2 – BLUE

PIN SIGNAL

17 COOLANT TEMP OUT

18 OIL TEMPERATURE

19 TDC/CAM

20 SPARE ANALOG 2

21 INTAKE AIR TEMPERATURE

22 +5VRTN2

23 BOOST/INLET PRESSURE

24 +5VRTN3

25 ACCELERATOR POSITION

26 +5VRTN1

27 EGR VACUUM PRESSURE

28 INTAKE SM S2T

29 DIAGNOSTIC REQUEST SW

30 COOLANT TEMPERATURE

31 A/T PARK SW

32 CRANKSHAFT

6E–18 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Pinout Table, 5-Way Connector – J3

060RW139

J3

PIN SIGNAL

1 IGNITION

2 IGNITION

3 PWR GND

4 PWR GND

5 INJECTOR H1

6E–194JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Component Locator

Engine Component Locator Table

F06RW051

Number Name Location

1 AP (Accelerator Pedal Position) Sensor AP Bracket

2 CKP (Crankshaft Position) Sensor Inside the right front flywheel Housing

3 Oil Rail Mounted on the camshaft carrier

4 Oil (Rail) Pressure Sensor Mounted on the Oil Rail

5 OT (Oil Temperature) Sensor Mounted on the Oil Rail

6 Fuel Injector In the Cylinder Head Cover

7 Fuel Return Orifice Inside the Cylinder Head

8 FT (Fuel Temperature) Sensor Fuel Return Adaptor

9 Intercooler On the Cylinder Head Cover

10 Intake Throttle Motor Behind the Intake Manifold

11 Intake Throttle Behind the Intake Manifold

12 2 Way Check Valve Below the Intake Manifold

13 VSV (Vacuum Switching Valve) At the left Cylinder Body

14 EGR Pressure Sensor Below the Intake Manifold

15 Fuel Filter At the left Engine Room

16 CMP (Camshaft Position) Sensor On the forward of Timing Gear Case

17 IAT (Intake Air Temperature) Sensor Below the Intake Manifold

18 ECT (Engine Coolant Temperature) Thermostat Housing

19 High Pressure Oil Pump On the back Timing Gear Case

6E–20 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Number Name Location

20 Rail Pressure Control Valve In the High Pressure Oil Pump

21 Fuel Pump In the High Pressure Oil Pump

22 EVRV On the Intake Manifold

23 MAP (Manifold Absolute Pressure) Sensor On the Intake Manifold

24 EGR Valve On the Intake Manifold

25 Air Cleaner At the left Engine Room

26 ECM Behind the Air Cleaner

6E–214JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Sensors and Miscellaneous Component Locators

035RW115

035RW117

060RW179

035RW118

035RW119

035RW120

6E–22 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

035RW121

035RW122

035RW116

035RW107

6E–234JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Abbreviations Charts

List of abbreviations which may be used in this section.

Abbreviations Term Abbreviations Term

A/C Air Conditioner BLK Black

A/T Automatic Transmission BLU Blue

ACC Accessory BRN Brown

AP Accel Position GRN Green

ASM Assembly GRY Gray

CKP Crank Position LT BLU Light Blue

CMP Cam Position LT GRN Light Green

DLC Data Link Connector ORN Orange

DTC Diagnosis Trouble Code PNK Pink

DVM Digital Volt Meter RED Red

ECM Engine Control Module VIO Violet

ECT Engine Coolant Temperature WHT White

EGR Exhaust Gas Recircuration YEL Yellow

EVRV Electric Vacuum Regulating Valve

EXH Exhaust

FT Fuel Temperature

IAT Intake Air Temperature

IG Ignition

ITP Intake Throttle Position

M/T Manual Transmission

MAP Manifold Absolute Pressure

MIL Mulfunction Indicator Lamp

OBD On-Board Diagnostic

OT Oil Temperature

QOS Quick on Start System

QWS Quick Warming-Up System

RP Rail Pressure

RPCV Rail Pressure Control Valve

SRS Supplemental Restraint System

ST Start

SW Switch

TEMP Temperature

TOD Torque on Demand

VSS Vehicle Speed Sensor

VSV Vacuum Switching Valve

HEUI Hydraulically Actuated Electronically Controlled UnitInjectorInjector

6E–24 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnosis

Strategy-Based Diagnostics

Strategy-Based Diagnostics

The strategy-based diagnostic is a uniform approach torepair all Electrical/Electronic (E/E) systems. Thediagnostic flow can always be used to resolve an E/Esystem problem and is a starting point when repairs arenecessary. The following steps will instruct the technicianhow to proceed with a diagnosis:

1. Verify the customer complaint.

� To verify the customer complaint, the technicianshould know the normal operation of the system.

2. Perform preliminary checks.

� Conduct a thorough visual inspection.

� Review the service history.

� Detect unusual sounds or odors.

� Gather diagnostic trouble code information toachieve an effective repair.

3. Check bulletins and other service information.

� This includes videos, newsletters, etc.

4. Refer to service information (manual) systemcheck(s).

� “System checks” contain information on a systemthat may not be supported by one or more DTCs.System checks verify proper operation of thesystem. This will lead the technician in anorganized approach to diagnostics.

5. Refer to service diagnostics.

DTC Stored

Follow the designated DTC chart exactly to make aneffective repair.

No DTC

Select the symptom from the symptom tables. Follow thediagnostic paths or suggestions to complete the repair.You may refer to the applicable component/system checkin the system checks.

No Matching Symptom

1. Analyze the complaint.

2. Develop a plan for diagnostics.

3. Utilize the wiring diagrams and the theory ofoperation.

Call technical assistance for similar cases where repairhistory may be available. Combine technician knowledgewith efficient use of the available service information.

Intermittents

Conditions that are not always present are calledintermittents. To resolve intermittents, perform thefollowing steps:

1. Observe history DTCs, DTC modes, and freezeframedata.

2. Evaluate the symptoms and the conditions describedby the customer.

3. Use a check sheet or other method to identify thecircuit or electrical system component.

4. Follow the suggestions for intermittent diagnosisfound in the service documentation.

Most scan tools, such as the Tech 2 and the DVM, havedata-capturing capabilities that can assist in detectingintermittents.

No Trouble Found

This condition exists when the vehicle is found to operatenormally. The condition described by the customer maybe normal. Verify the customer complaint against anothervehicle that is operating normally. The condition may beintermittent. Verify the complaint under the conditionsdescribed by the customer before releasing the vehicle.

1. Re-examine the complaint.

When the complaint cannot be successfully found orisolated, a re-evaluation is necessary. The complaintshould be re-verified and could be intermittent asdefined in Intermittents, or could be normal.

2. Repair and verify.

After isolating the cause, the repairs should be made.Validate for proper operation and verify that thesymptom has been corrected. This may involve roadtesting or other methods to verify that the complainthas been resolved under the following conditions:

� Conditions noted by the customer.

� If a DTC was diagnosed, verify a repair byduplicating conditions present when the DTC wasset as noted in the Failure Records or FreezeFrame data.

Verifying Vehicle Repair

Verification of the vehicle repair will be morecomprehensive for vehicles with OBD systemdiagnostics. Following a repair, the technician shouldperform the following steps:

IMPORTANT: Follow the steps below when you verifyrepairs on OBD systems. Failure to follow these stepscould result in unnecessary repairs.

1. Review and record the Failure Records and theFreeze Frame data for the DTC which has beendiagnosed (Freeze Frame data will only be stored forthe MIL (“Check Engine” lamp) has been requested).

2. Clear the DTC(s).

3. Operate the vehicle within conditions noted in theFailure Records and Freeze Frame data.

4. Monitor the DTC status information for the specificDTC which has been diagnosed until the diagnostictest associated with that DTC runs.

6E–254JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

General Service Information

Serviceability Issues

Non-OEM Parts

All of the OBD diagnostics have been calibrated to runwith OEM parts. Accordingly, if commercially sold sensoror switch is installed, it makes a wrong diagnosis and turnon the MIL (“Check Engine” lamp).Aftermarket electronics, such as cellular phones,stereos, and anti-theft devices, may radiate EMI into thecontrol system if they are improperly installed. This maycause a false sensor reading and turn on the MIL (“CheckEngine” lamp).

Poor Vehicle Maintenance

The sensitivity of OBD diagnostics will cause the MIL(“Check Engine” lamp) to turn on if the vehicle is notmaintained properly. Restricted oil filters, fuel filters, andcrankcase deposits due to lack of oil changes or improperoil viscosity can trigger actual vehicle faults that were notpreviously monitored prior to OBD. Poor vehiclemaintenance can not be classified as a “non-vehiclefault”, but with the sensitivity of OBD diagnostics, vehiclemaintenance schedules must be more closely followed.

Related System Faults

Many of the OBD system diagnostics will not run if theECM detects a fault on a related system or component.

Visual/Physical Engine CompartmentInspection

Perform a careful visual and physical enginecompartment inspection when performing any diagnosticprocedure or diagnosing the cause of an emission testfailure. This can often lead to repairing a problem withoutfurther steps. Use the following guidelines whenperforming a visual/physical inspection:

� Inspect all vacuum hoses for punches, cuts,disconnects, and correct routing.

� Inspect hoses that are difficult to see behind othercomponents.

� Inspect all wires in the engine compartment for properconnections, burned or chafed spots, pinched wires,contact with sharp edges or contact with hot exhaustmanifolds or pipes.

Basic Knowledge of Tools Required

NOTE: Lack of basic knowledge of this powertrain whenperforming diagnostic procedures could result in anincorrect diagnosis or damage to powertraincomponents. Do not attempt to diagnose a powertrainproblem without this basic knowledge.

A basic understanding of hand tools is necessary to effec-tively use this section of the Service Manual.

Serial Data Communications

Class II Serial Data Communications

This vehicle utilizes the “Class II” communication system.Each bit of information can have one of two lengths: long

or short. This allows vehicle wiring to be reduced bytransmitting and receiving multiple signals over a singlewire. The messages carried on Class II data streams arealso prioritized. If two messages attempt to establishcommunications on the data line at the same time, onlythe message with higher priority will continue. The devicewith the lower priority message must wait.On this vehicle the Tech 2 displays the actual values forvehicle parameters. It will not be necessary to performany conversions from coded values to actual values.

On-Board Diagnostic (OBD)

On-Board Diagnostic Tests

A diagnostic test is a series of steps, the result of which isa pass or fail reported to the diagnostic executive. Whena diagnostic test reports a pass result, the diagnosticexecutive records the following data:

� The diagnostic test has been completed since the lastignition cycle.

� The diagnostic test has passed during the currentignition cycle.

� The fault identified by the diagnostic test is notcurrently active.

When a diagnostic test reports a fail result, the diagnosticexecutive records the following data:

� The diagnostic test has been completed since the lastignition cycle.

� The fault identified by the diagnostic test is currentlyactive.

� The fault has been active during this ignition cycle.

� The operating conditions at the time of the failure.

Comprehensive Component MonitorDiagnostic Operation

Comprehensive component monitoring diagnostics arerequired to operate engine properly.

Input Components:

Input components are monitored for circuit continuity andout-of-range values. This includes rationality checking.Rationality checking refers to indicating a fault when thesignal from a sensor does not seem reasonable. AccelPosition (AP) sensor that indicates high throttle positionat low engine loads or MAP voltage. Input componentsmay include, but are not limited to the following sensors:

� Intake Air Temperature (IAT) Sensor

� Crankshaft Position (CKP) Sensor

� Intake throttle Position (ITP) Sensor

� Engine Coolant Temperature (ECT) Sensor

� Camshaft Position (CMP) Sensor

� Manifold absolute Pressure (MAP) Sensor

� Accel Position Sensor

� Fuel Temp Sensor

� Rail Pressure Sensor

� Oil Temp Sensor

� EGR Pressure Sensor

� Vehicle Speed Sensor

6E–26 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Output Components:

Output components are diagnosed for proper response tocontrol module commands. Components wherefunctional monitoring is not feasible will be monitored forcircuit continuity and out-of-range values if applicable.Output components to be monitored include, but are notlimited to, the following circuit:

� EGR VSV

� EGR EVRV

� Electronic Transmission controls

� Injector

� Intake throttle

� Glow plug

� MIL control

Refer to ECM and Sensors in General Descriptions.

Passive and Active Diagnostic Tests

A passive test is a diagnostic test which simply monitors avehicle system or component. Conversely, an active test,actually takes some sort of action when performingdiagnostic functions, often in response to a failed passivetest.

Intrusive Diagnostic Tests

This is any on-board test run by the DiagnosticManagement System which may have an effect onvehicle performance or emission levels.

Warm-Up Cycle

A warm-up cycle means that engine at temperature mustreach a minimum of 70�C (160�F) and rise at least 22�C(40�F) over the course of a trip.

Freeze Frame

Freeze Frame is an element of the DiagnosticManagement System which stores various vehicleinformation at the moment an emissions-related fault isstored in memory and when the MIL is commanded on.These data can help to identify the cause of a fault. Referto Storing And Erasing Freeze Fame Data for moredetailed information.

Failure Records

Failure Records data is an enhancement of the OBDFreeze Frame feature. Failure Records store the samevehicle information as does Freeze Frame, but it will storethat information for any fault which is stored in on-boardmemory, while Freeze Frame stores information only foremission-related faults that command the MIL on.

Common OBD Terms

Diagnostic

When used as a noun, the word diagnostic refers to anyon-board test run by the vehicle’s DiagnosticManagement System. A diagnostic is simply a test run ona system or component to determine if the system orcomponent is operating according to specification. Thereare many diagnostics, shown in the following list:

� EGR

� engine speed

� vehicle speed

� ECT

� MAP

� VSV

� IAT

� ITP

� AP

� FT (Fuel Temp)

� RP (Rail Pressure)

� OT (Oil Temp)

� EGR EVRV

� Idle SW

� Brake SW

The Diagnostic Executive

The Diagnostic Executive is a unique segment ofsoftware which is designed to coordinate and prioritizethe diagnostic procedures as well as define the protocolfor recording and displaying their results. The mainresponsibilities of the Diagnostic Executive are listed asfollows:

� Commanding the MIL (“Check Engine” lamp) on andoff

� DTC logging and clearing

� Freeze Frame data for the first emission related DTCrecorded

� Current status information on each diagnostic

Diagnostic Information

The diagnostic charts and functional checks are designedto locate a faulty circuit or component through a processof logical decisions. The charts are prepared with therequirement that the vehicle functioned correctly at thetime of assembly and that there are not multiple faultspresent.There is a continuous self-diagnosis on certain controlfunctions. This diagnostic capability is complemented bythe diagnostic procedures contained in this manual. Thelanguage of communicating the source of the malfunctionis a system of diagnostic trouble codes. When amalfunction is detected by the control module, adiagnostic trouble code is set and the MalfunctionIndicator Lamp (MIL) (“Check Engine” lamp) isilluminated.

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) looks the same asthe MIL you are already familiar with “Check Engine”lamp.Basically, the MIL is turned on when the ECM detects aDTC that will impact the vehicle emissions.

� When the MIL remains “ON” while the engine isrunning, or when a malfunction is suspected due to adriveability or emissions problem, a PowertrainOn-Board Diagnostic (OBD) System Check must beperformed. The procedures for these checks aregiven in On-Board Diagnostic (OBD) System Check.These checks will expose faults which may not bedetected if other diagnostics are performed first.

DTC Types

Characteristic of Code

6E–274JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

� Non-Emissions related

� Dose not request illumination of any lamp

� Stores a History DTC on the first trip with a fail

� Stores Fail Record when test fails

� Updates the Fail Record each time the diagnostic testfails

Storing and Erasing Freeze Frame Data and FailureRecords

The data captured is called Freeze Frame data. TheFreeze Frame data is very similar to a single record ofoperating conditions. Whenever the MIL is illuminated,the corresponding record of operating conditions isrecorded to the Freeze Frame buffer.Data from these faults take precedence over dataassociated with any other fault. The Freeze Frame datawill not be erased unless the associated history DTC iscleared.Each time a diagnostic test reports a failure, the currentengine operating conditions are recorded in the FailureRecords buffer. A subsequent failure will update therecorded operating conditions. The following operatingconditions for the diagnostic test which failed typicallyinclude the following parameters:

� Engine Speed

� Engine Load

� Engine Coolant Temperature

� Vehicle Speed

� Intake Throttle Position

� MAP

� Injector Base Pulse Width

� Loop Status

Data Link Connector (DLC)

The provision for communication with the contorl moduleis the Data Link Connector (DLC). It is located at behindthe lower front instrument panel. The DLC is used toconnect to a Tech 2. Some common uses of the Tech 2are listed below:

� Identifying stored Diagnostic Trouble Codes (DTCs).

� Clearing DTCs.

� Performing out put control tests.

� Reading serial data.

060RW046

Verifying Vehicle Repair

Verification of vehicle repair will be more comprehensivefor vehicles with OBD system diagnostic. Following arepair, the technician should perform the following steps:

1. Review and record the Fail Records and/or FreezeFrame data for the DTC which has been diagnosed.

2. Clear DTC(s).

3. Operate the vehicle within conditions noted in the FailRecords and/or Freeze Frame data.

4. Monitor the DTC status information for the specificDTC which has been diagnosed until the diagnostictest associated with that DTC runs.

Following these steps are very important in verifyingrepairs on OBD systems. Failure to follow these stepscould result in unnecessary repairs.

Reading Flash Diagnostic Trouble Codes

The provision for communicating with the Engine ControlModule (ECM) is the Data Link Connector (DLC). TheDLC is located in the front console box. It is used in theassembly plant to receive information in checking that theengine is operating properly before it leaves the plant.The diagnostic trouble code(s) (DTCs) stored in theECM’s memory can be read either through a hand-helddiagnostic scanner plugged into the DLC or by countingthe number of flashes of the “Check Engine” MalfunctionIndicator Lamp (MIL) when the diagnostic test terminal ofthe DLC is grounded. The DLC terminal “6” (diagnosticrequest) is pulled “Low” (grounded) by jumpering to DLCterminal “4”, which is a ground wire.This will signal the ECM that you want to “flash” DTC(s), ifany are present. Once terminals “4” and “6” have beenconnected, the ignition switch must be moved to the “ON”position, with the engine not running.The “Check Engine”MIL will indicate a DTC three times ifa DTC is present. If more than one DTC has been stored

6E–28 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

in the ECM’s memory, the DTC(s) will be output from thelowest to the highest, with each DTC being displayedthree times.The DTC display will continue as long as the DLC isshorted.

Reading Diagnostic Trouble Codes Usinga TECH 2

The procedure for reading diagnostic trouble code(s) is toused a diagnostic Tech 2. When reading DTC(s), followinstructions supplied by Tech 2 manufacturer.For the 1998 model year, Isuzu dealer servicedepartments will continue to use Tech 2.

Clearing Diagnostic Trouble Codes

IMPORTANT: Do not clear DTCs unless directed to doso by the service information provided for each diagnosticprocedure. When DTCs are cleared, the Freeze Frameand Failure Record data which may help diagnose anintermittent fault will also be erased from memory.

If the fault that caused the DTC to be stored into memoryhas been corrected, the Diagnostic Executive will begin tocount the “warm-up” cycles with no further faultsdetected, the DTC will automatically be cleared from theECM memory.

To clear Diagnostic Trouble Codes (DTCs), use the Tech2 “clear DTCs” or “clear information” function. Whenclearing DTCs follow instructions supplied by the Tech 2manufacturer.When a Tech 2 is not available, DTCs can also be clearedby disconnecting one of the following sources for at leastthirty (30) seconds.

NOTE: To prevent system damage, the ignition key mustbe “OFF” when disconnecting or reconnecting batterypower.

� The power source to the control module. Examples:fuse, pigtail at battery ECM connectors etc.

� The negative battery cable. (Disconnecting thenegative battery cable will result in the loss of otheron-board memory data, such as preset radio tuning).

060RW169

6E–294JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments arerecommended to use Tech 2. Please refer to Tech 2 userguide.

901RW257

Legend

(1) PCMCIA Card

(2) SAE 16/19 Adaptor

(3) DLC Cable

(4) Tech–2

6E–30 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Getting Started

� Before operating the Isuzu PCMCIA card with theTech 2, the following steps must be performed:

1. The Isuzu 98 System PCMCIA card (1) inserts intothe Tech 2 (5).

2. Connect the SAE 16/19 adapter (3) to the DLC cable(4).

3. Connect the DLC cable to the Tech 2 (5)

4. Make sure the vehicle ignition is off.

5. Connect the Tech 2 SAE 16/19 adapter to the vehicleDLC.

6. The vehicle ignition turns on.

7. Verify the Tech 2 power up display.

012RW105

NOTE: The RS232 Loop back connector is only to use fordiagnosis of Tech 2 and refer to user guide of the Tech 2.

Operating Procedure

The power up screen is displayed when you power up thetester with the Isuzu systems PCMCIA card. Follow theoperating procedure below.

060RW014

6E–314JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

060RW120

Menu

� The following table shows, which functions are usedthe available equipment versions.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Read DTC Info As Stored By ECU

F2: Clear DTC Information

F3: Freeze Frame / Failure Records

F1: Data Display

F2: Snapshot

F3: Actuator Tests

F0: Checklight

F1: Glow Time Lamp

F2: EGR Switching Valve

F3: Exhaust Switching Valve 1

F4: Exhaust Switching Valve 2

F4: Miscellaneous Tests

F0: Throttle Motor Control

F1: Rail Pressure Control

F2: EGR Regulating Valve Control

F3: Rail Pressure Control Valve

F4: Injector Balance Test

F5: Programming

F0: Injector Calibration

(F1: Rail Pressure Calibration)

6E–32 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC Modes

There are three options available in the Tech 2 DTC modeto display the enhanced information available. Adescription of the new modes, DTC Info, follows. Afterselecting DTC, the following menu appears:

� DTC Info

� Clear Info

� Read DTC Info Ordered By Priority

The following is a brief description of each of the submenus in DTC Info. The order in which they appear here isalphabetical and not necessarily the way they will appearon the Tech 2.

DTC Information Mode

Use the DTC info mode to search for a specific type ofstored DTC information.The service manual may instructthe technician to test for DTCs in a certain manner.Always follow published service procedures.

Fail This Ignition

This selection will display all DTCs that have failed duringthe present ignition cycle.

History

This selection will display only DTCs that are stored in theECM’s history memory. It will not display Type B DTCsthat have not requested the MIL (“Check Engine” lamp). Itwill display all type A and B DTCs that have requested theMIL and have failed within the last 40 warm-up cycles. Inaddition, it will display all type C and type D DTCs thathave failed within the last 40 warm-up cycles.

MIL SVC or Message Requested

This selection will display only DTCs that are requestingthe MIL. Type C and type D DTCs cannot be displayedusing this option. This selection will report type B DTCsonly after the MIL has been requested.

Test Failed Since Code Cleared

This selection will display all active and history DTCs thathave reported a test failure since the last time DTCs werecleared.

Injector Test

This test is conducted to make it sure that appropriateelectric signals are being sent to injectors Nos. 1 – 4.Tech–2 must be used for this test.

Test Procedure:

1. Connect Tech–2 to the vehicle DLC.

2. Set Ignition Switch to the “ON” position.

3. Select Control Test.

4. Select Injector Test.

5. Send instructions to each injector(Switch on), makingsure of injector working noise.

NOTE: If injector working noise (Clink) can hardly beconfirmed, remove the engine head cover noiseinsulation.

Refer to Section 6A.

6. In the injector whose working noise has beenconfirmed, its electric circuit can be regarded asnormal.

As for the injector whose working noise has not beenconfirmed, its electric circuit or the injector proper isfaulty.

EGR Valve Test

This test is conducted to check EGR valve for its working.This test needs Tech–2.

Test Procedure

1. Connect Tech–2 to vehicle DLC.

2. Switch on the engine.

3. Select “DIAGNOSIS” from the main menu.

4. Select Miscellaneous Test.

5. Select EGR Valve.

6. Instruct EGR Valve to check a data list.

7. If change in the data list shows a normal valve, theworking of EGR Valve can be judged to be normal.

Rail Pressure Control Valve Test

This test is conducted to check RPC valve for its working.This test needs Tech–2.

Test Procedure

1. Connect Tech–2 to vehicle DLC.

2. Switch on the engine.

3. Select “DIAGNOSIS” from the main menu.

4. Select Miscellaneous Test.

5. Select Rail Pressure Control Valve.

6. Instruct RPC Valve to check a data list.

7. If change in the data list shows a normal valve, theworking of RPC Valve can be judged to be normal.

Injector Balance Test

This test is conducted to make it sure that appropriateelectric signals are being sent to injectors Nos. 1-4, whenthe engine is idling.This test needs Tech–2.

Test Procedure

1. Connect Tech–2 to vehicle DLC.

2. The engine is running at idling condition.

3. Select “DIAGNOSIS” from the main menu.

4. Select Miscellaneous Test.

5. Select the injector Balance Test.

6. Send instructions to each injector(Switch On),making sure change of the engine vibration.

7. In the injector whose change of the vibration has beenconfirmed, it’s electric circuit can be regarded asnormal.

Data Programming in Case of ECM Change

When replacing ECM, it is necessary to confirm andrecord the group sign of injector beforehand. For thisconfirmation.

6E–334JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Tech–2 must be used. After ECM change, the recordedgroup sign should be programmed. Oil pressure sensordata also should be programmed.

� Group Sign Confirmation Procedure

1 Connect Tech–2 to vehicle DLC.

2 Turn Ignition Switch to the “ON” position.

3 Select “DIAGNOSIS” from the main menu.

4 Select programming.

5 Select Read/store Trim Data.

6 Confirm and record the group sign of injector.

� ECM Change

� Programming Procedure for Injector Group Sign

1 Connect Tech–2 to vehicle DLC.

2 Turn Ignition Switch to the “ON” position.

3 Select “DIAGNOSIS” from the main menu.

4 Select programming.

5 Select ECM change.

6 Select cylinder.

7 Program Injector Group Sign.

8 Confirm the completion of Injector programming.

� Programming Procedure for Oil Pressure Sensor

1 Connect Tech–2 to vehicle DLC.

2 Turn Ignition Switch to the “ON” position.

3 Select “DIAGNOSIS” from the main menu.

4 Select programming.

Rail Pressure Sensor Programming

Rail pressure sensor replacement must be programmed.This programming needs Tech–2.

Programing Procedure

1. Connect Tech–2 to vehicle DLC.

2. Turn Ignition Switch to the “ON” position.

3. Select “DIAGNOSIS” from the main menu.

4. Select Programming.

5. Select Oil Pressure Sensor change.

6. Execute Oil Pressure Sensor Program.

7. Confirm the completion of Oil Pressure SensorProgram.

Injector Group Sign Programming (InjectorChange)

In case of Injector change, injector group sign must beprogrammed.This programming needs Tech–2.

Programing Procedure

1. Connect Tech–2 to vehicle DLC.

2. Turn Ignition Switch to the “ON” position.

3. Select “DIAGNOSIS” from the main menu.

4. Select Programming.

5. Select Injector change.

6. Select the cylinder changed.

7. Appoint and select Injector Group Sign.

8. Confirm the completion of Injector programming.

6E–34 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

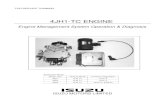

Fuel Injection System

060RW178

Legend

(1) ECM

(2) Meter Panel

(3) Battery

(4) Oil Temp Sensor

(5) Rail Pressure Sensor

(6) Glow Relay

(7) Oil Rail

(8) Tech–2

(9) A/C Comp Relay

(10) RPCV

(11) Intake Air Temp Sensor

(12) Engine Coolant Temp Sensor

(13) MAP Sensor

(14) EGR Valve

(15) EGR Pressure Sensor

(16) High Pressure Oil Pump

(17) Fuel Pump

(18) VSV

(19) EXH Throttle VSV1

(20) EXH Throttle VSV2

(21) EVRV

(22) Engine Harness Connector

(23) QWS Relay

(24) APS

(25) T.O.D

(26) ECT

(27) OBD

(28) TDC

(29) Injector

(30) Edge Filter

6E–354JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Guid to the System

� Fuel Injection system is an HEUI (HydraulicallyActuated, Electronically Controlled, Unit, Injector)type. In this type of injector system, the oilpressurized by means of High Pressure Oil Pump(16) is fed through Rail Pressure Control Valve (10)and Oil Rail (7) to Injector (29) from which fuel isinjected under this oil pressure.

For diagnosis, therefore, the Rail Pressure as well asthe Electric Circuit must be inspected.

On-Board Diagnostic (OBD) System CheckA Group

060RW135

6E–36 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

B Group

060RW133

C Group

060RW129

6E–374JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

D Group

060RW134

Circuit Description

The on-board diagnostic system check is the startingpoint for any driveability complaint diagnosis. Beforeusing this procedure, perform a careful visual/physicalcheck of the ECM and engine grounds for cleanliness andtightness.The on-board diagnostic system check is an organizedapproach to identifying a problem created by anelectronic engine control system malfunction.

Diagnostic Aids

An intermittent may be caused by a poor connection,rubbed-through wire insulation or a wire broken inside theinsulation. Check for poor connections or a damagedharness. Inspect the ECM harness and connector forimproper mating, broken locks, improperly formed ordamaged terminals, poor terminal-to-wire connection,and damaged harness.

Test DescriptionNumber(s) below refer to the step number(s) on theDiagnostic Chart:

1. The MIL (“Check Engine” lamp) should be “ON”steady with the ignition “ON”/engine “OFF.” If not,Chart A-1 should be used to isolate the malfunction.

2. Checks the Class 2 data circuit and ensures that theECM is able to transmit serial data.

3. This test ensures that the ECM is capable ofcontrolling the MIL (“Check Engine” lamp) and theMIL (“Check Engine” lamp) driver circuit is notshorted to ground.

4. If the engine will not start, the Cranks But Will NotRun chart should be used to diagnose the condition.

7. A Tech 2 parameter which is not within the typicalrange may help to isolate the area which is causingthe problem.

9. When the ECM is replaced, the characteristic data ofinjector and rail pressure sensor should be inputted.

6E–38 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

On- Board Diagnostic (OBD) System Check�

Step Action Value(s) Yes No

1 1. Ignition “ON,” engine “OFF.”

2. Observe the malfunction indicator lamp (MIL or“Check Engine” lamp).

Is the MIL (“Check Engine” lamp)“ON?” — Go to Step 2

Go to No MIL(“Check

Engine” lamp)

2 1. Ignition “OFF.”

2. Install a Tech 2.

3. Ignition “ON.”

4. Attempt to display ECM engine data with the Tech 2.

Does the Tech 2 display ECM data? — Go to Step 3 Go to Step 8

3 1. Using the Tech 2 output tests function, select MIL(“Check Engine” lamp) dash lamp control andcommand the MIL (“Check Engine” lamp) “OFF.”

2. Observe the MIL (“Check Engine” lamp).

Did the MIL (“Check Engine” lamp) turn “OFF?” — Go to Step 4

Go to MIL(“Check

Engine” lamp)On Steady

4 Attempt to start the engine.

Did the engine start and continue to run?— Go to Step 5

Go to CranksBut Will Not

Run

5 Select “Display DTCs” with the Tech 2.

Are any DTCs stored? — Go to Step 6 Go to Step 7

6 Are two or more of the following DTCs stored? A Group; P0337, P0342, P1193, P1404, P1405,P1488 B Group; P0337, P0342 C Group; P0112, P0117, P0182, P0197 D Group; P0107, P0405, P1194, P1485 —

Go to Chart,“Multiple

ECMInformation

Sensor DTCsSet”

Go toapplicableDTC table

7 Compare ECM data values displayed on the Tech 2 tothe typical engine scan data values.

Are the displayed values normal or close to the typicalvalues?

— Go to Step 8

Refer toindicated

ComponentSystemChecks

8 1. Ignition “OFF,” disconnect the ECM.

2. Ignition “ON,” engine “OFF.”

3. Check the Class 2 data circuit for an open, short toground, or short to voltage. Also, check the DLCignition feed circuit for an open or short to groundand the DLC ground circuit for an open.

4. If a problem is found, repair as necessary.

Was a problem found? — Go to Step 2 Go to Step 9

9 Check the Tech 2 on other vehicle.

Was Tech 2 abnormal? — Go to Step 11 Go to Step 10

10 Replace the ECM (Refer to the Data Programming inCase of ECM change).

Is the action complete? — Go to Step 2 —

11 Repair the Tech 2 or prepare another Tech 2.

Is the action complete? — Go to Step 2 —

6E–394JX1–TC ENGINE DRIVEABILITY AND EMISSIONS