4. Mining Machinery - Mine Trucks

-

Upload

tessfaye-wolde-gebretsadik -

Category

Documents

-

view

237 -

download

1

Transcript of 4. Mining Machinery - Mine Trucks

-

8/9/2019 4. Mining Machinery - Mine Trucks

1/22

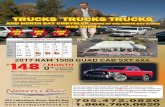

MINING MACHINERYTrucks

-

8/9/2019 4. Mining Machinery - Mine Trucks

2/22

MINE TRUCK

A truck is a machine for hauling material.It is used for transport of ore from the face to

processing or stockpile or for transport overburden to

the dump area.

Broader application and the growth of surface mininghave led to the development of off-highway units of

very high power and capacity.

Caterpillar made miningtruck in operation

http://www.cat.com

-

8/9/2019 4. Mining Machinery - Mine Trucks

3/22

MINE TRUCK

-

8/9/2019 4. Mining Machinery - Mine Trucks

4/22

-

8/9/2019 4. Mining Machinery - Mine Trucks

5/22

TYPES OF MINE TRUCKS

Rear dump and bottom dump

The rear dump

discharges material by tilting the body and spilling the

content out the rear by gravityRear dump trucks are used when:

The material hauled is free flowing, or has bulky

components

The hauling must dump into a specific point or over

the edge of a bunk or a bank fill

Maximum maneuverability in the loading and

dumping are is required

-

8/9/2019 4. Mining Machinery - Mine Trucks

6/22

TYPES OF MINE TRUCKS

Rear Dump trucks featureGenerally 2 axle units (one steering, one driving)

three axle on very large sizes or on smaller

articulated units (one steering, two driving)

Rigid frame with heavy duty body

Single wheels in front axle, dual wheels in rear axle

Articulated frame with four to six wheel drive

-

8/9/2019 4. Mining Machinery - Mine Trucks

7/22

TYPES OF

MINE TRUCKS

Bottom dump

The bottom dump discharges material by opening thebottom of the body spilling the content out the rear by

gravity.

Bottom dump trucks are used when:

When the material to be hauled is free flowing

There are unrestricted loading and dumping sitesBottom Dump trucks featureTractor-trailer 3 axle units (one steering, one driving,

one trailing or rigid frame 2 axle units (one steering

one driving.

-

8/9/2019 4. Mining Machinery - Mine Trucks

8/22

RIGID AND ARTICULATED MINE HAUL TRUCKS

Rigid truckshave rigid chassis

require longer turning radius

Can have higher capacity reaching 400 tonnes

Articulated dump trucksHave articulated chassis

Require shorter turning radius

Maneuver on rough terrain

Suitable on wet groundCapacity not exceeding 60 tonnes with current

designs

Have normally three axle with four wheel or six wheel

drive

-

8/9/2019 4. Mining Machinery - Mine Trucks

9/22

MECHANICAL AND ELECTRIC DRIVE

Mechanical drive power-trainThe main components of a mechanical drive system

for a mining truck comprise: diesel engine, torque

converter, drive shaft, transmission, differential and

final drive; and featureFully automatic power-shift transmission for operator

comfort and reduction of component stress

Three to six gear ratio and one reverse

Front mounting for engine provides cleaner

environment, good cleaning system air flow and less

filter maintenance

-

8/9/2019 4. Mining Machinery - Mine Trucks

10/22

MECHANICAL AND ELECTRIC DRIVE

Mechanical drive power-trainThe main components of a mechanical drive system

for a mining truck comprise: diesel engine, torque

converter, drive shaft, transmission, differential and

final drive; and featureFully automatic power-shift transmission for operator

comfort and reduction of component stress

Three to six gear ratio and one reverse

Front mounting for engine provides cleaner

environment, good cleaning system air flow and less

filter maintenance

-

8/9/2019 4. Mining Machinery - Mine Trucks

11/22

MECHANICAL AND ELECTRIC DRIVE

Electric drive power-train

An alternate current electric-drive truck contains

a diesel engine, inverter control cabinet

(including rectifiers and inverters), resistor grid

box, alternator, drive shaft, generator and final

drive/wheel motors. Some companies also regard

the retarding system, brakes and wheels as part

of the powertrain.

Control system Grid box for disipation of heat during retardation

DC motors in the hab of each drive wheel or ineach drive axle in

the largest sizes.

Motor module includs gear reduction and brake

Blowers for generators and motors.

-

8/9/2019 4. Mining Machinery - Mine Trucks

12/22

MECHANICAL AND ELECTRIC DRIVE

-

8/9/2019 4. Mining Machinery - Mine Trucks

13/22

MECHANICAL AND ELECTRIC DRIVE

Mechanical drives advantages

Require electric grid to transfer power

More flexible

Available in lower capacity trucks and higher capacity trucks

Electric drive advantages

An AC electric drive system offers several operational advantages over

mechanical drive for haul trucks:

increased efficiency (lower fuel consumption);

higher speed on ramp, reducing cycle time (productivity);

greater retard capability resulting in higher speeds going downhill,thus reducing cycle time;

increased availability (AC motors require less maintenance);

increased reliability (state-of-the-art on-board and off-board

diagnostics, reducing the chances of premature failure); and

lower maintenance costs (fewer parts to replace)

-

8/9/2019 4. Mining Machinery - Mine Trucks

14/22

TYPES OF MINE TRUCKS

Bottom dumpingThe bottom dump discharges material by opening the

bottom of the body.

Tractor-trailer 3 axle units (one steering, one driving,

one trailing) or

rigid frame 2 axle units (one steering one driving )

-

8/9/2019 4. Mining Machinery - Mine Trucks

15/22

BASIC TRUCK OPERATION

Loading

Truck bodies are filled byfront-end loaders,

hydraulic excavators,

electric shovels and / or

bucket wheel excavators,

Loading takes place while the truck is positioned so

as to optimize the operational cycle of the specific

excavating unit.

In properly matched cyclic loading machines normally

require 3 to 5 passes to fill the truck.

-

8/9/2019 4. Mining Machinery - Mine Trucks

16/22

BASIC TRUCK OPERATION

Hauling cycleLoading

Traveling loaded; periods of accelerating, deceleration

and operating in grades. Speed depends on roadconditions, traffic truck rimpull capabilities and haul

distances

Dumping with time for maneuvering

Returning to the loading area empty with time formaneuvering

Waiting time - until the truck before is loaded

-

8/9/2019 4. Mining Machinery - Mine Trucks

17/22

BASIC TRUCK OPERATION

-

8/9/2019 4. Mining Machinery - Mine Trucks

18/22

TRUCK APPLICATION

Rear dump trucks are used when:The material hauled is free flowing, or has bulky

components

The hauling must dump into a specific point or over theedge of a bunk or a bank fill

Maximum maneuverability in the loading and dumping

are is required

Bottom dump trucks are used when:When the material to be hauled is free flowing

There are unrestricted loading and dumping sites

-

8/9/2019 4. Mining Machinery - Mine Trucks

19/22

ESTIMATING SCRAPER PRODUCTION

Mine truck major specifications

-

8/9/2019 4. Mining Machinery - Mine Trucks

20/22

Thank You

-

8/9/2019 4. Mining Machinery - Mine Trucks

21/22

REVIEW QUESTIONS

1. What is a dozer or Bulldozer?

2. Name some of the mining related work.

3. What is the difference between a machine and an equipment?

4. Name the major planning stages where equipemnt selection is

studied and refined.

5. The type of equipment to be deployed depends on the type of

mining (mining method). Name the aspects that determine the

mining method to be used.

6. Ones the type of mining is selected, what aspects influence

equipment selection?

7. Describe how altitude, overburden properties, and production rate

affect equipment selection. Calculate owning and operating cost

-

8/9/2019 4. Mining Machinery - Mine Trucks

22/22

ASSIGNMENT

1. Present a description of mine trucks

2. Describe similarity between rigid and

articulated mine trucks3. Describe difference between rigid and

articulated mine trucks

4. Describe how diesel mine trucks function

5. Describe how electric driven mine trucksfunction

6. Name major difference between diesel driven

and electric driven mine trucks