3 4 FB 250 5 Function Block for the ASM 400 6 7 ... - Siemens · which have been approved or...

Transcript of 3 4 FB 250 5 Function Block for the ASM 400 6 7 ... - Siemens · which have been approved or...

Table of Contents

Overview 1

Block Specifications 2

Command Chain 3

Application Example 4

Control and Inquiry for “Data Storage MDSs in the Field” 5

Commissioning the ASM 400 with FB 250 6

The ECC Driver 7

Error searching with the ASM 400and FB 250 8

Contents of the FB 250Project Provided 9

Warnings 10

Published in September 2002

6GT2 097-3AA00-0DA2

FB 250Function Block for the ASM 400

Technical Description

MOBY I�

Safety Guidelines

This manual contains notices which you should observe to ensure your own personal safety, as well to protect theproduct and connected equipment. These notices are highlighted in the manual by a warning triangle and are mar-ked as follows to the level of danger.

!Danger

indicates that death, severe personal injury or substantial property damage will result if proper pre-cautions are not taken.

!Warning

indicates that death, severe personal injury or substantial property damage can result if proper pre-cautions are not taken.

!Caution

indicates that minor personal injury or property damage can result if proper precautions are nottaken.

Caution

indicates that property damage can result if proper precautions are not taken.

Note

draws your attention to particularly important information on the product, handling the product, or toa particular part of the documentation.

Qualified Personnel

Only qualified personnel should be allowed to install and work on this equipment. Qualified persons are definedas persons who are authorized to commission, to ground, and to tag circuits, equipment, and systems in accor-dance with established safety practices and standards.

Correct Usage

Note the following:

!Warning

This device and its components may only be used for the applications described in the catalog ortechnical description, and only in connection with devices or components from other manufactorerswhich have been approved or recommended by Siemens.

This product can only function correctly and savely if it is transported, stored, set up, and installedcorrectly, and operated and maintained as recommended.

Trademarks

SIMATIC� and MOBY� are registered trademarks of SIEMENS AG.Some of the other designations used in these documents are also registered trademarks; the owner’s rights maybe violated if they are used by third parties for their own purposes.

We have checked the contents of this manual for agreement with the hard-ware and software described. Since deviations cannot be precluded entirely,we cannot guarantee full agreement. However, the data in this manual arereviewed regularly and any necessary corrections included in subsequenteditions. Suggestions for improvement are welcomed.

Disclaimer of LiabilityCopyright � Siemens AG 1995, 2002 All rights reserved

The reproduction, transmission or use of this document or its contents is notpermitted without express written authority. Offenders will be liable fordamages. All rights, including rights created by patent grant or registration ofa utility model or design, are reserved.

Siemens AGAutomation & Drives (A&D)Systems Engineering (A&D SE)P.O. Box 23 55, D-90713 Fuerth

� Siemens AG 2002Technical data subject to change.

Siemens Aktiengesellschaft Order No. 6GT2 097-3AA00-0DA2

FB 250 Description 6GT2097–3AA00–0DA2

– 1 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

ContentsPage

1 Overview 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Block Specifications 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 Technical Data 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 User Interface (Parameterization) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.1 System Overview 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.2 FB 250 Parameters 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.3 Instruction and Status Word “BEST” 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.4 Flag Word “ANZ” (see chapter 8) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.5 Address Reference List (DW 6 = ZUW) 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3 Data Organization 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4 Start Up 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 Addressing the Module 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6 Indicator Lamps 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Command Chain 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1 MOBY Command Construction 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2 Table of Possible MOBY Commands 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3 Maximum Chain Parameters 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.4 Example of a Command Chain 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5 Special Commands 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Application Example 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1 Flow Chart: FB 250 Request by the User 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.2 Processing the MDS Data Storage 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 Initializing the MDS 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4 Cyclic Call of FB 250 (e.g., in OB1) 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 Programming from New Start and Restart 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6 Configuration of a Reference List 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6.1 User Data, Commands and Control Data in One DB 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6.2 Different DBs for FBDB, ZUWDB and DATDB 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7 Setup of a Dialog Transmission with ASM 400 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7.1 How Is the MOBY I Dialog Set Up ? 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7.2 How does the User Work with MOBY I Dialog? 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Control and Inquiry for “Data Storage MDSs in the Field” 39. . . . . . . . . . . . . . . . . . . . . .

6 Commissioning the ASM 400 with FB 250 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 Module Ports 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2 Loading FB 250 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.3 Presetting the Organization Blocks 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4 Setting Up the Data Block 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5 Calling FB 250 in the Application Program 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6 Program Processing 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 Function Monitoring 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7.1 Program processing running: No command is being processed. 42. . . . . . . . . . . . . . . . . . . . 6.7.2 Command Input 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7.3 Command Executed 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 The ECC Driver 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Error Searching with the ASM 400 and FB 250 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Contents of the FB 250 Project Provided 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 Warnings 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FB 250 Description6GT2097–3AA00–0DA2

– 2 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

1 Overview

This description of the function block concerns the data transfer between the STEP–5 program and theASM 400 interface module.

The FB 250 can be installed in the following programmable logic controllers without modification:115U/941/942/943/944/945/115F135U–R/S/CPU928B155U/155H

FB 250 can be used equally for all MOBY systems (MOBY I/E/F/V/L/U).

This is possible when the FB 250 does not use any system commands.All data storage memories can also be processed with FB 250.

Essential functions of the FB 250 are:– Conditioning of the data structure from the user parameters to an ASM

data structure– Complete data communication with ASM using commands and data exchange– Error handling:

Repetition of commands: conditioning of errors for the user

Chaining of several part commands into a complete command:– Read and write are possible with one user command.– Any number of address areas of an MDS can be processed with one command.– Control of the PLC cycle load by the user

Data transfer between the FB and the MDS can be divided into three parts:– Provision of the interface card with the necessary command and the parameters

or data– Transfer of the data between the interface and the data memory– Provision of the S5 with the data and parameters from the interface card

An additional function block with the designation FB 252 has been added to the “MOBY Software” CD.As seen by the user, the FB 252 works with the same interface as the FB 250. The only difference be-tween the two FBs is the addressing of the ASM 400 MOBY interface module in the SIMATIC.

FB 250: P–area; Max of 32 channels or 8 interface modulesFB 252: Q–area; Max of 64 channels or 16 interface modules

This increases the maximum number of channels from 32 to 96.

The ASM 400 can also be parameterized as a dialog station so that data can be transferred from one SLGto another.

Caution:The Q-area is only available in PLCs S5-135U, S5-155U, and S5-115U with CPU 945.

FB 250 Description 6GT2097–3AA00–0DA2

– 3 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

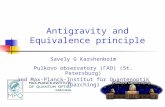

Program Schematic

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

FBDB DATDBZUWDB

User Program

SIMATIC S5

ASM 400

MDS

SLG

FB 250

”FBDB” ”ZUW”

”ADR”

Electromagneticinduction field

Serialinterface

BESTANZZUW

“KAN”

VMDS (only set up for dialogue)

FB 250 Description6GT2097–3AA00–0DA2

– 4 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2 Block Specifications

2.1 Technical Data

For P–Area For Q–Area

Block number: FB 250 FB 252(Can be changedby the user)Block name: MOBY:KET MOBY:250Library number: E88530–B6082–B–5 E88530–B6082–B–5Block length: 895 wordsBlocks called: NoneData blocks used: FBDB through parameterization � 25 data wordsFlags used: FY 240 to 255Counters used: NoneSystem commands used: NoneCall: Cyclic call

Typical FB 250 Run Times (PLC Cycle Load in msec)

Idle ProgrammingASM

Waitingfor MDS

Fetch Resultfrom ASMCyclePLC–CPU

115U– 943B

135U – 922

155U/155H– 946/947

135U – 928

115U– 943B

135U – 922

155U/155H– 946/947

135U – 928

0.3 8.55 + n*0.45 0.9 2.5

0.3 5 0.9 5 + n*0.5

0.10 0.43

0.7 0.66 + n*0.05

0.074

0.074 0.10

0.7 + n*0.05

0.9 1.28.1 + n*0.5 5.7

7.3 8.0 + n*0.60.9 1.2

0.52 0.74.7 + n*0.37 3.2

4.5 4.8 + n*0.420.52 0.7

115U– 944B 0.06 0.7 + n*0.05 0.4 0.4

135U – 928B 0.04 0.060.6 + n*0.05 0.34

115U– 944B 0.06 0.40.7 0.55 + n*0.05

135U – 928B 0.58 0.6 + n*0.050.04 0.06

115U– 941B 8.55 + n*0.81 5.840.89 1.54

115U– 942B 5.840.89 1.54

115U– 945 0.02 0.4 + n*0.04 0.02 0.26

155U/155H– 948 0.05 0.230.03 0.4 + n*0.04

115U– 941B 1.548.63 8.75 + n*0.850.89

115U– 942B 1.548.63 8.75 + n*0.850.89

115U– 945 0.02 0.020.4 0.4 + n*0.04

155U/155H– 948 0.4 0.4 + n*0.040.03 0.05

WR

ITE

TO

MD

SR

EA

D F

RO

M M

DS

8.55 + n*0.81

n = Quantity of user data to be processed (per command or part command)

With command chains the values in the “programming” column and “result” column are to be added and used for each partcommand.

Note: The data exchange times for the ASM and the data memories are described in the catalogue.

FB 250 Description 6GT2097–3AA00–0DA2

– 5 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.2 User Interface (Parameterization)

2.2.1 System Overview

FB 250

ADR

KAN

TYP

FBDB

MOBY:250

ANW

AG

Explanation of the Input and Output Parameters

ParameterName

Description Kind Type PermissableValues/Characters

Note

ADR

KAN

TYP

FBDB

Peripheraladdress

Channel no.

Command type

Process data

D

D

D

B

KF

KF

KF

128, 144 .... 240**

1, 2, 3, 4**

DB 1 to 255

See chapter 2.5.

3, 5, 6 *

ANW Availability D KF 0, 1 See chapter 5.

AG PLC type D KF 0 .... 20 See table onnext page.

� 25 DW

Only FB 250

QADRexpanded I/O area

D KF 0, 16, 32, ... 240 Only FB 250Address in

Starting withrelease –B–5 of the FB

* Earlier method of parameterization for the initialisation with 0 and 1 can still be used.

** FB parameterization after release -B-4 of the FB can still be used.

FB 250 Description6GT2097–3AA00–0DA2

– 6 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.2.2 FB 250 Parameters

ADR / Physical addressing of interface module. See chapter 2.5.QADR /KAN

TYP Command type:3 = Special commands (See chapter 3.5.)

� Set MDS 507/407E operation� MDS initialization� Switch on MOBY I dialog operation� Set MOBY F/U operation

5 = Process any data storage memoryECC* driver is switched on (see chapter 7). (MOBY I only.)

6 = Read and write any data storage memory

* Error Correction Code (see chapter 7).

FBDB Data block for internal FB useThe FBDB must be set up for every channel by the user.Length: 25 words. Starting at DW 25 free for the user:

(e.g., ZUW list and/or user data)DW 4 Command or status word (BEST)DW 5 Error and flag word (ANZ)DW 6 Reference list address (ZUW)

ANW Test for availability (proximity) of an MDS in the SLG area (See chapter 5.)0 = Availability will not be checked.1 = Availability of an MDS in the SLG field is checked and stored in BEST bit 12.

AG Parameterization of the type of PLC. This value is required for an internal FB timeout times.A value that is too small may cause a timeout error. A value that is too large will put the PLCinto STOP when an error occurs.

115U941B/942B/943B

4

115U945

20

PLC type

Value fromPLC

135U928

1

115U944B

5

928B

5

135U922

1 10

946/947

5

155U/H948

155U/H135U

FB 250 Description 6GT2097–3AA00–0DA2

– 7 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.2.3 Instruction and Status Word �BEST”

BEST is also found in FW 254 when you exit the FB.DW 4 = BEST = FW 254*

BEST is always valid and can always be accessed by the user.

FY 254* FY 255*

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RESET**)

Start command

New start (RESET)**)

In reserve

In reserve

RESET active/ready

Command active/ready

STG active; ASM Test

FB 250 active

Battery check

Error (exact error is found in ANZ)

READY for next command

Availability

NOTE:The BEST parameters in the cold and warm start modes are to be preset with 0004H in the respective OB(see catalogue).The following are valid for the S5–150U:

– OB 20 for new start – OB 21 for manual restart– OB 22 for automatic restart

* The BEST parameter is only valid in FW 254 as long as the scratchpad flag is not overwritten by the user or a second FB 250 call.

** When MOBY U is used, it may take up to 20 seconds to execute this command. The delay of the command is indicated with BEST bit 6 = 1.

FB 250 Description6GT2097–3AA00–0DA2

– 8 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Permitted Modifications of Control Bits in the BEST

BEST Bit 0123456789101112131415

F

UF/U

F F F

F F

F/U

F/U

F/U F/U F/U

0

0

0

0

0

0

0

0

0

F

F

F

F

F/U

F

F

F/U

F

F

U

F/U

F/U

F

U

F/U

F

U

F/U

F

U

F/U

F

F

F

U

U = User F = FB 0 = Always 0

Set

Reset

Inquiry

Description of the Control Bits in BEST:

BIT 0 RESET Reset of a read or write commandAfter the first commissioning and every subsequent change to the ADR,KAN, TYP, FBDB and ANW parameters, the user should initiate a RESETso that a parameter check, and construction of the command in FBDB, canbe carried out new.

BIT 1 Read/write Start signal for the FB: Execution of the command in the reference list.start After starting the execution of the command the bit will be reset by the

FB.

BIT 2 New start Set by the user after new start and after return of power.The function is the same as RESET. The bit is also accessed during the processing of the command.

BIT 4 RESET Positive acknowledgment of the RESET command (BIT 0)active/ready This bit is set when a command from the ASM is processed by the STG.

BIT 5 Command Positive acknowledgment of read/write (BIT 1)active/ready

BIT 6 STG active When this bit is set by the FB this delays the execution of a MOBY ASM test command for a short period. This bit can be set for several reasons.

a) The ASM has received a command from the STG (service and test device) and is just carrying it out.

b) After switching on the SIMATIC S5 the ASM 400 carries out an extensive self–test. During this time (about 3 seconds) the module cannot be accessed. The bit is automatically reset after the self–test. The module reports with READY in BEST.

c) A RESET/new start is active on the ASM (MOBY U).

BIT 7 FB active The FB is active with the execution of a command.When bit 7 is set, bit 15 is reset.

BIT 8 to11 In reserve

BIT 12 Availability This bit is only set when the “ANW” parameter is set at “1” during the parameterization of the FB call (see chapter 5).0 = No MDS is in the SLG field.1 = MDS is now in the SLG field.

BIT 13 BATT The MDS battery check has been triggered (only for RAM MDSs).The remaining battery capacity can only hold for a few months at room tem-perature. It is recommended to immediately change the battery anyway –or the MDS if it is not a battery–replaceable MDS.

BIT 14 Error “ERROR” is set by the FB when a problem occurs with the reset, read or write commands. The exact cause of the error is located in data word “ANZ” (= DW 5). A RESET is required after an error. The start of a read/write command resets the ERROR bit.

BIT 15 READY – The last command (reset, read, write) has ended.– The user can start a new (reset, read, write) command.Note: READY does not need to be set to start a new RESET command.

FB 250 Description 6GT2097–3AA00–0DA2

– 9 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.2.4 Flag Word “ANZ” (see chapter 8)

DW 5 = ANZ

ANZ is always valid when the READY bit is set in BEST or when the READY and ERROR bit are set.

–> Address error0D

14

1B

1E

–> Checksum error

Synch

In reserve

Parameter error

ASM error

Timing error

Repeat error

ECC–correction was executed (the data in DATDB is OK).

Battery voltage of the MDS lower than required (same meaning as DW 4, bit 13)

In

Synchronisa-tion error

Setting:Resetting:Request:

FBFBUSER

Generally the following is valid for ANZ:

030405060708090A0B0C

–> Error in the connection to the SLG–> Error in the MDS memory (not initialized)–> Command from ASM not interpretable–> Field disturbance in the SLG–> Too many send errors–> CRC send error–> INIT: CRC error–> INIT: MDS cannot be initialized.–> INIT: Timeout when initializing–> INIT: Write error when initializing

–> Firmware error

(no error)1 –> The FB is

–> Error when processing the function block

–> ECC mode: Data on the MDS are wrong.0E

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

ASM ERROR

Only for MDS 507/407E: Status of the MDS dialog battery.1 = battery under threshold value. The bit may be 0 or 1 with other MDSs.

initialized.

The bit is used for internal FB purposes during command processing (READY = 0).

–> ASM unclear0F

15 –> Parameterization error18 –> RESET/new start required19 –> Previous command is active.

1C –> Antenna is off.1D –> Not enough RAM is available on the ASM.

More than 1 MDS in the field.

1F –> Running command terminated

reserve

FB 250 Description6GT2097–3AA00–0DA2

– 10 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.2.5 Address Reference List (DW 6 = ZUW)

The �ZUW” parameter shows the next command to be carried out.

Number of the ZUWDBs Start address of the command in ZUWDB:3 to 253

If ZUWDB and FBDB are identical:start address = 25 to 253

(1 to 255)

ZUWDB ZUWDW

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

The �ZUW” pointer can only be modified by the user if the FB is not processing a command (i.e., READYmust be set in BEST).

Generally the following is valid for ZUW :

Setting:

Request:

USER

FB

FB 250 Description 6GT2097–3AA00–0DA2

– 11 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.3 Data Organization

FB 250 works with 3 data blocks.

FBDB:

ZUWDB:

DATDB:

Includes the requirements of FB 250

The user must set up an FBDB with a minimum of 25 DWs for eachchannel module of an ASM 400. The FBDB is determined during parameteriza-

(See also chapter 2.2.2 for parameters to be supplied.)

This data block includes the command(s) with which an MDS willbe processed. Several FBDBs can work with the same commands in one

Minimum length of the DB for a command = 6

Data block with user data for reading and writingSeveral commands in ZUWDB can refer to the same DATDB.Minimum length for a data byte = 4

Name Description:

Note: The first data byte from each command isleft justified in the data word (DL).If several single byte commands are chained the data is stillleft justified. The right data word is not affected.

tion of FB 250.

ZUWDB.

FBDB, ZUWDB and DATDB can be combined through appropriate configuration in a data block (see chapter 4.6.1).

Note: ZUWDB and DATDB in a combined data block may not be used by another FBDB.

FB 250 Description6GT2097–3AA00–0DA2

– 12 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Principal Construction of the DBs

DW0

DW4

DW5

DW6

DW24

DW0

DW3

DW4

DW5

DW6

DW7

DW8

DW255

FBDB

ZUWDB

BEST

ANZ

ZUWDB ZUWDW

Command Length

Start address on the MDS

DATDB DATDW

1st command

2nd command

See chapter 2.2.3.

Command

Length

Start addr.

DATDB:

DATDW:

See chapter 3.

Data block sizein bytes = 1 – 250Start address on thedata storage unitEnd address of MDS

Ref. to data blockin the S5 with which thecommand will beprocessedStart of the user datain DATDB

FB–internal

.

.

.

.

.

.

.

.

.

.

.

.

See chapter 2.2.4.

See chapter 2.2.5.

(”start address +length”) may not beexceeded. See chap. 4.2.

Note: The first 3 data words in ZUWDB (DW 0 to 2) are reserved for internal FB operations.

DW0

DW3

DW4

DW255

DATDB

1st data byte 2nd data byte

3rd data byte 4th data byte

FB–internal

.

.

.

.

.

.

.

..

.

.

.

..

.

Note: The first 3 data words in DATDB (DW 0 to 2) are reserved for internal FB operations.

FB 250 Description 6GT2097–3AA00–0DA2

– 13 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Branching of the FBDB, ZUWDB and DATDB Data Blocks (Example)

ZUWDB=250 ZUWDW=25

DW25

DW26

DW27 DATDB=250 DATDW=50

DW50

FBDB = DB250

ZUWDB=DB250

DATDB=DB250

DW51.....

.

.

.

.

.

DW 6

User data

1st command

Further MOBY

Command Length

Address

commands

FB 250 Description6GT2097–3AA00–0DA2

– 14 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Representation of Different Data Structures

Separate Data Blocks for Function Blocks, Commands and Data

FBDB1 FBDB2 FBDB3 FBDB4

DATDB1

DATBD2

DATBD3

ZUWDB

Each MOBY station (channel) has its own exclusive combined data block.

FBDB1

ZUWDB1

DATDB1

FBDB2

ZUWDB2

DATDB2

FBDB3

ZUWDB3

DATDB3

FB 250 Description 6GT2097–3AA00–0DA2

– 15 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Each SLG station is allocated to a data block (FBDB + DATDB) while the commands are located ina common ZUWDB.

FBDB1 FBDB2 FBDB3

DATDB1 DATDB2 DATDB3

ZUWDB

Note:FB 250 works at the same speed for every implemented data structure. It is up to the user which datastructure he prefers.

Example of a Non–Permissable Data Structure:

FBDB1 FBDB2 FBDB3

DATDB

ZUWDB

FB 250 Description6GT2097–3AA00–0DA2

– 16 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

2.4 Start Up

Special steps are needed to correctly start up the ASM and FB when performing a new start or restart.The FB 250 must be supplied with the “new start = 1” parameter in the new start and restart OB (seechapter 4.5).

Special features of startup of high-speed SIMATIC CPUs:When MOBY is used in an S5-115U/CPU 945 or S5-155U/CPU 948, the presence check (ANW = 1) to beenabled may not be accepted by the ASM 400. Use the following programming strategy for new start andrestart.Wait for READY after the RESET command is started (call FB 250). Then wait at least another 10 msecbefore starting FB 250 with a MOBY command.

2.5 Addressing the Module

ADR and KAN parameters are used to set the physical address of the modules. One ASM 400 occupies16 peripheral bytes in the address area between 128 and 255. The P-area or Q-area setting must beperformed in the expansion device interface in the SIMATIC S5.These are the relevant allocations.

ASM 400 Switch Setting FB 250Parameterization

FB 252Parameterization

Start Address ofthe ASM

Switch S3

4 3 2 1

Switch S4

2 1ADR KAN* QADR KAN*

0 0 0 0 0 0 1 0 1 – 4

16 0 0 0 1 16 (Corre-32 0 0 1 0 This S4

it h t32

(Corre-sponds toh l48 0 0 1 1 switch set-

ting must al- Not48 channel mo-

dule 1 – 4)64 0 1 0 0

ting must al-ways be

d h

Not available 64

dule 1 – 4)

80 0 1 0 1

yused whenthe module

80

96 0 1 1 0the moduleis to be op-

d i96

112 0 1 1 1 erated instandard

112

128 1 0 0 0standardmode. 128 1 – 4 128

144 1 0 0 1mode.

144 (Corre- 144

160 1 0 1 0 160(Corre-

sponds toh l

160

176 1 0 1 1 176 channel mo-dule 1 to 4)

176

192 1 1 0 0 192dule 1 to 4)

192

208 1 1 0 1 208 208

224 1 1 1 0 224 224

240 1 1 1 1 240 240

* Parameterization of KAN and ADR can still be used for older releases of the function blocks.

1 = Switch to ON

Other combinations of switch 3 and ADR are not permitted !

Note: One ASM 400 always uses 16 peripheral bytes (i.e., if not all the ASM 400 channel modules are occupied, the unused address area is still NOT available for other modules).

2.6 Indicator Lamps

For the explanation see the ASM 400 Hardware Description.

FB 250 Description 6GT2097–3AA00–0DA2

– 17 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

3 Command Chain

General Performance Notes:

– One data storage operation consisting of several commands can be combined into a command with several part commands.

– The user can read and write to an MDS with one command.– Any number of address areas of an MDS can be processed with a chained command.– The data transfer of a chained command can be programmed by the user and distributed over

several cycles.

3.1 MOBY Command Construction

01234567

0RDWRPause000Chain

Command is to read.

Command is to write.

Change cycle after data transfer

Command in ZUWDB

Write:

Read:

Change cycle after command transferto the ASM. No cycle change occurswhen status data is received.

No cycle change after command transferto the ASM. Cycle change after the takeover of the result telegram with the readdata

Bit:

1 � The next ZUWDB command follows.0 � Single MOBY command or

last command in a chain of commands

FB 250 Description6GT2097–3AA00–0DA2

– 18 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

3.2 Table of Possible MOBY Commands

02

04

0A

0C

82

84

8A

8C

Read or last read command in a command chain

Write or last write command in a command chain

Read with cycle change orlast read command in a command chain with cycle change

Write with cycle change orlast write command in a command chain with cycle change

Read; a further ZUWDB command follows.

Write; a further ZUWDB command follows.

Read; a further command follows; change cycleafter fetching the results

Write; a further command follows; change cycleafter outputting the command

Command CodeKH(hex.)

DescriptionKY(dec.)

2

4

10

12

130

132

138

140

Other command codes will be rejected by the FB with a parameterization error.

3.3 Maximum Chain Parameters

The chaining of commands is limited through:a) Max. number of commands in a ZUWDBb) The available RAM on the ASMc) Cycle time

to a) Since the first 3 data words are reserved in ZUWDB, up to 253 data words are available to the user for his commands. This means that a maximum of 84 commands (= 253/3) are available.

to b) 12 Kbytes of RAM on the ASM are available to the user. A byte quantity of “data length + 8” is needed on the ASM for each chained part command. Error “1D” is reported if the RAM area on the ASM is too small.Example: 8453 bytes (i.e., 8189+33x8) are reserved on the ASM for read–accessing an

entire 8–K MDS with a chained command.33 commands each are stored in ZUWDB for read and write–accesses to the MDS.

to c) In order not to exceed a given cycle load by the FB 250 the user can program one or several cycle changes in one chained command (see table in chapter 2.1).

Note: When reading: A programmed cycle change will only be carried out in the resultsphase. When writing: The programmed cycle change will only be carried out during the command transfer phase.

FB 250 Description 6GT2097–3AA00–0DA2

– 19 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

3.4 Example of a Command Chain

82 80XXXX

82 80XXXX

8A 80XXXX

82 80XXXX

84 80XXXX

8C 80XXXX

84 80XXXX

04 80XXXX

ZUWDB:

1st

3rd

4th

5th

6th

7th

8th

part command

part command

part command

part command

part command

part command

part command

Read 128 bytes w/o

with

cycle change

Write

Read 128 bytes cycle change

128 bytes w/o cycle change

Write

with

128 bytes cycle change

Read 128 bytes w/o cycle change

Read 128 bytes w/o cycle change

Write 128 bytes

w/o

cycle change

Write 128 bytes w/o cycle change

w/o = without

2nd part command

The processing of this command in the PLC is shown on the next page.

FB 250 Description6GT2097–3AA00–0DA2

– 20 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Processing the Chaining of MOBY Commands in the PLC

Cycle change

Idle time of the FB

Start of a MOBY commandUser sets Bit 1 in BEST

Command transfer of1st,2nd,3rd,4th

5th,6th

4 read commands

2 write commands with128 data bytes each

Command transfer of 7th,8th Part command

Wait for data

Fetch result for 1st,2nd,3rd part command3 read commands with 128 data bytes each

Result for 4th part command

5th,6th,7th,8th

Read command with

Acknowledgements

Idle time

ÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

Commandtransfer

Time axis

1 cycle

ÉÉÉÉÉÉ

ÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉ

ÉÉÉÉÉÉÉÉÉ

Result ofthe 4readcommands

Statusof the 4writecommands

’ ’

’ ’*)

Cycle Loading in PLC

READY in BEST is set.

Part com.

Part com.

2 write commands with

part command

the 4 write commands

128 data bytes

0,074

0.7

0.7+128x0.05

17.00

14.20

0.1

0.1

21.30

0.43

8.82

0.07

msec

0.074

Time for eachPart command

Total timeper cycle

e.g. 155U (see chapter 2.1)

(until the start of the next command)

0.43

0.43

0.43

128 data bytes each

0.7

0.7

0.7

0.7+128x0.05

0.7+128x0.05

0.7+128x0.05

0.7+128x0.05

0.7+128x0.05

0.7+128x0.05

0.7+128x0.05

FB 250 Description 6GT2097–3AA00–0DA2

– 21 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

ÉÉÉÉ

KEY:

Cycle change in PLC

Run time of FB 250 in PLC (cycle load by the FB)

Run time of the other user program in the PLC

* The actual distribution of the cycles in the result phase can differ from the programmed distribution.The ASM processes the part commands in order in which they were transferred.The ASM provides the first partial result as soon as the first part command is processed.The PLC fetches the queued results from the ASM during the next cycle but never later than theprogrammed cycle change. This means:The user programmed maximum cycle load is never exceeded.

Note:The processing of single part commands by the ASM to MDS occurs exactly in the sequence in which thepart commands are programmed in the ZUWDB.

FB 250 Description6GT2097–3AA00–0DA2

– 22 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

3.5 Special Commands

Special commands are used to parameterize new MDS types correctly. A special command is calledwhen FB 250 is called with the following parameterization.

TYP = 3

FB 250 must be switched back to normal operation (typ = 5, 6) after a special command has beenprocessed. It is absolutely necessary that a reset be performed after the switchover.

Processing of a special command is divided into several stages.

� Parameterize FB 250 call with TYP=3.

� Start RESET command.

� Start special command(s).

� Parameterize FB 250 call with TYP=5, 6.

� Start RESET command.

� FB 205 is ready for normal commands.

Data Organization for Special Commands (See chapter 2.3.)

DW0

DW3

DW4

DW0

DW3

DW4

DW5

DW6

DW7

DW8

DATDB

ZUWDB

1st data byte

Code Length

Subcode

DATDB DATDW

1st command

2nd command

For internal Code: 04 = Data transfer to ASM

02 = Reserved (data transferfrom ASM)

3rd data byte

2nd data byte

4th data byte

FB use

FB useFor internal

FB 250 Description 6GT2097–3AA00–0DA2

– 23 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

The following special commands are available.

MOBY F MDS F4xxMOBY F MDS F2xx

2 Kbytes (MOBY I/U)

Command Code Subcode Data (DATDB)

MDS 507/407Eoperation

04 01 0000

Length

1st data byte:(tABTAST*)

7 6 5 4 3 2 1 0

Time value: 00–3F

Time factor: 00 = 0.01 sec01 = 0.1 sec10 = 1 sec11 = 10 secMDS or VMDS

initialization

Normal

With ECC

04

04

04

04

0001

0002

Bit:

Switch on MOBY Idialog operation onthe ASM 400

04 01 0003 1st data byte: 01 = Switch on dialog operation

A 16–Kbyte VMDS (virtual mobile data memory) is set up on the ASM. The VMDSis used for communication memory during dialog operation. When dialog is switchedon, the VMDS is automatically cleared to 00. Dialog operation must be switched onagain each time power is turned on.When the SIMATIC is switched off, the dataon the VMDS are lost.Note:� Dialog operation may only be

switched on on one side of the communicating ASMs. The other side operates in normal mode.

� ECC operation is not possible with the VMDS.

� Dialog operation can only be switched off by switching off the SIMATIC.

� ANW (presence) can be switched on oroff. If on, the ANW bit in DW 5 indicates the presence of another SLG.

62 bytes128 bytes

Data

1st 2nd 3rd 4th data byte

00 00 4000 00 8000 08 00

8 Kbytes00 20 00

32 Kbytes (MOBY I/U)00 80 00

The MDS iswritten with this value.

End address +1

16 Kbytes00 40 00 InitializeVMDS(virtualmobiledata car-rier)

00 00 10MOBY E00 02 F0

00 00 C0

* See the MDS 507/407E description for a detailed description and handling of tABTAST.

FB 250 Description6GT2097–3AA00–0DA2

– 24 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Command Code Length Subcode Data (DATDB)

Set MOBYdriver 1

04 01 0004 1st data byte: 00 = MOBY I default91 = MOBY F MDS F1xx92 = MOBY F MDS F4xx93 = MOBY F MDS F2xx

04 0C 0004 Set MOBY U: 3

95

1st 2nd 12th data byte3rd

00

4th 5th

05

6th

00

7th 8th/9th

0001

10th11th

00

field_ON_time_00 hex = without prox. switches01 hex to FF hex =1 to 255 sec. switch on timefor the SLG field

field_ON_control_Prox. switch mode00 hex = without prox. switches01 hex = field_ON_time_

switches the field off02 hex = 1st prox. switch turns on the field;

2nd prox. switch turns off the field.

distance_limiting_Range limitation05; 0A; 0F; 14; 19; 1E; 23 hex =0.5; 1.0; 1.5; 2.0; 2.5; 3.0; 3.5 m

scanning_time_;Standby time for the MDS00 hex = No standby operation01 hex to C8 hex = 7 msec to 1400 msec standby time

Baudrate to SLG:01 = 19.2 Kbaud;03 = 57.6 Kbaud

FFT com-mand forMOBY F 2

04 01 0005 1st data byte: 01 = Perform FFT

(EMC interference suppression filters arerecalculated by the firmware of the SLG)

Antennaon/off 4

04 04 0006 1st 2nd 3rd 4th data byte

01 = Turn on antenna

02 = Standby; turn off antenna

03 0A 00 Mode

1 The presence check must be disabled before switching to MOBY F.2 The FFT command can only be used when the presence check is disabled.3 It may take up to 20 seconds to execute this command.4 This command only applies to MOBY U. Remember: When the FB 250 call changes from TYP = 3 to TYP = 5,

6, a RESET is performed on the ASM/SLG and the antenna is turned on again automatically. This is the reasonthe FB 250 call must remain TYP = 3 until the antenna is to be turned on again.

Caution: MDS 507/407E processing: An MDS 507/407E must be switched on with command code 04,subcode 0000 before it can be processed.

FB 250 Description 6GT2097–3AA00–0DA2

– 25 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4 Application Example

4.1 Flow Chart: FB 250 Request by the User

New start: SetOB20, OB21, OB22 (for 155U/H)

Start command (only when ready = 1)

READY = 1

?

NY

?Y N

reportonprinter

Error = 1

Y N

Start active = 1

?

? NY

Command OK

Processdata

RESET or newstart wascarried out.

Commandnot correctlyended

Errorhandling

evaluation

Start next command if required

Possible timeoutmonitoring bythe user

RESET when timeout

Cyclical request

BATT = 1

?Y N

Reportonprinter

battery”

Status

STG 4F active

“BEST” BIT 2

“BEST” BIT 1Set

“Change

“ANZ”

“BEST” BIT 1Set

FB 250 Description6GT2097–3AA00–0DA2

– 26 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.2 Processing the MDS Data Storage

Mobile MDSs with various memories are available for the user. The following types are available:– 62 (42)* Byte RAM (e.g., MDS 115)– 128 (112)* Byte EEPROM (e.g., MDS 213E)– 2 (1.7)* Kbyte RAM (e.g., MDS 302)– 8 (7)* Kbyte EEPROM (e.g., MDS 413E)– 16 Kbyte RAM (VMDS = virtual MDS for dialog)– 32 (28)* Kbyte RAM (e.g., MDS 505)– 752 Byte EEPROM (MOBY E)– 40 Bit Fixed code (MOBY F MDS 1xx)– 16 Byte EEPROM (MOBY F MDS 2xx)– 192 Byte EEPROM (MOBY F MDS 4xx)– 2 KByte RAM (MOBY U MDS U313)

16 Byte OTP– 32 KByte RAM (MOBY U MDS U524)

16 Byte OTP

* Net capacity with ECC mode

The data memory addressing occurs linearly from the start address to the final address. The ASM auto-matically recognizes the memory capacity on the MDS. If the final address is exceeded the user receivesan error message.

The following table shows the address areas of the individual MDS models.

Adress KH KY KF

Normal With ECC Normal With ECC Normal With ECC

MOBY I: 62 Byte MDS (RAM)

Start address 0000 0000 00.00 0.0 + 0 + 0End address 003D 0029 00.61 0.41 + 61 + 41

MOBY I: 128 Byte MDS (EEPROM)

Start address 0000 0000 00.00 00.00 + 0 + 0End address 007F 006F 00.127 0.111 + 127 + 111

MOBY I: 2 KByte MDS (RAM)

Start address 0000 0000 00.00 00.00 + 0 + 0End address 07FC 06F1 07.252 06.241 + 2044 + 1777

MOBY I: 8 KByte MDS (EEPROM/FRAM)

Start address 0000 0000 00.00 00.00 + 0 + 0End address 1FFC 1BF1 31.252 27.241 + 8188 + 7153

MOBY I: 16 KByte VMDS for dialog

Start address 0000 – 00.00 – + 0 –End address 3FFF – 63.255 – + 16383 –

FB 250 Description 6GT2097–3AA00–0DA2

– 27 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Adress KFKYKH

With ECCNormalWith ECCNormalWith ECCNormal

MOBY I/V: 32 KByte MDS (RAM)

Start address 0000 0000 00.00 00.00 + 0 + 0End address 7FFC 6FF1 127.252 111.241 + 32764 + 28657

MOBY E: 752 Byte MDS with EEPROM

Start address 0000 0000 0.0 0.0 + 0 + 0End address 02EF 0291 2.239 2.145 + 751 + 657Read ID no. (can only be read completely)*Start address 1FF0 – 31.240 – 8176 –Length 4 – 0.4 – 4 –

MOBY F: MDS F1xx (5 Byte)

Start address 0000 – 0.0 – + 0 –End address 0004 – 0.4 – + 4 –

MOBY F: MDS F2xx (16 Byte)

Start address 0010 – 0.16 – + 16 –End address 001F – 0.31 – + 31 –Read ID no. (can only be read completely)Start address 0000 – 0.0 – + 0 –Length 4 – 0.4 – + 4 –

MOBY F: MDS F4xx (192 Byte)

Start address 0040 – 0.64 – + 64 –End address 00FF – 0.255 – + 255 –Read ID no. (can only be read completely)Start address 0000 – 0.0 – + 0 –Length 4 – 0.4 – + 4 –

MOBY U: 2 KByte data memory ***

Start address 0000 – 0.0 – + 0 –End address 07FF – 7.255 – + 2047 –Read OTP memory (can only be written once)**Start address FFF0 – 255.240 – – 16 –Length 10 – 0.16 – + 16 –

MOBY U: 32 KByte data memory ***

Start address 0000 – 0.0 – + 0 –End address 7FFF – 127.255 – + 32767 –Read OTP memory (can only be written once)**Start address FFF0 – 255.240 – – 16 –Length 10 – 0.16 – + 16 –

* Applies in the data presentation in DATDB: DLx = MSB, DRx+1 = LSB** The OTP memory of MOBY U can only be processed in one piece. This means that the start address must always

be FFF0 and the length must always be 10 hex.*** The ID no. of a MOBY U-MDS cannot be read with FB 250.

FB 250 Description6GT2097–3AA00–0DA2

– 28 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.3 Initializing the MDS

Function:The total MDS memory is written with “00.”Required: – When a new MDS which has never been write accessed is used

– After battery exchange or failure– When an MDS is to be used in ECC mode

The “MDS RAM error in memory” (04hex) information is deleted.The initialization cannot be executed witha “normal” write command to the MDS since a different protocol is required.The initialization command is not required during normal operation.The initialization is set by a different type of command during parameterization to avoid incorrect operatorinputs.

Parameter Example:

***** E X A M P L E: Call of FB 250 and Parameterization for Initialization *******

0000 :A DB250 FBDB call

0002 :UN –HILF If the pointer is not yet set...0004 :S D 4.0 ...then a reset...

0006 :S –HILF ...must be executed0008 :

000A :000C :JU FB250

000E NAME :MOBY:KET0010 ADR : KF+128 Module address

0012 KAN : KF+1

0014 TYP : KF+3 3 = MDS initialization*0016 FBDB : DB250

0018 ANW : KF+0001A AG : KF+1

001C :001E :

0020 :U D 4.15 If command = READY0022 :UN D 4.14 and no error

0024 :U –START and no start input0026 :S D 4.1 then start the initialization

0028 :002A :BE

Time Duration for Initialization Once the MDS Is in the SLG Field:

62 Byte MDS (RAM) : Approx. 0.1 0.2128 Byte MDS (EEPROM) : Approx. 6 122K Byte MDS (RAM) : Approx. 0.3 48K Byte MDS (EEPROM) : Approx. 25 50

32K Byte MDS (RAM/FRAM) : Approx. 2 53752 Byte MDS (MOBY E) : Approx. 0.8 –192 Byte MDS (MOBY F) : Approx. 2.2 –2K Byte MDS (MOBY U) : Approx. 1 –

32K Byte MDS (MOBY U) : Approx. 1.5 –

Type = 1 (Without ECC) [s] Type = 2 (With ECC) [s]

An error message occurs if the MDS cannot be initialized.

* Earlier method of parameterization for the initialization with type 0 and 1 can still be used.

FB 250 Description 6GT2097–3AA00–0DA2

– 29 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.4 Cyclic Call of FB 250 (e.g., in OB1)

OB1 SPRM–A LEN=48 ABS

Page 1

SEGMENT 1

********** **** E X A M P L E: CALL OF FB 250 and PARAMETERIZATION *************

If the flag is set to 0.0, the command will always be started again if it was processedwithout errors.

ERROR ALREADY PROCESSED.0000 :A DB250 Call relevant FBDB

0002 : RESET: DW 4.00004 : Start: read/write DW 4.1

0006 :0008 : Report:

000A : Ready DW 4.15000C : Ready DW 4.14

000E : Error type DW 50010 :

0012 : Command list address DW 6

0014 : DB 250, DW 250016 : Command: DL 25

0018 : 2 = Read, 4 = Write001A : Quantity: DR 25

001C :JU FB250001E NAME :MOBY:KET

0020 ADR : KF+128 Module address (128 – 248)0022 KAN : KF+1 Channel 1 (1 OR 2)

0024 TYP : KF+6 Read/write the MDS0026 FBDB : DB250 FBDB = 250 (DW 0 – DW 24)

0028 ANW : KF+0 0 = Without availability check

002A AG : KF+5 1 = S5 115U–944-7UB11 (for example)002C :

002E : BEST is also stored in FW 2540030 :L DW4 These two commands can ..

0032 :T FW254 ..be left out if the user 0034 : ..has not altered FW 254 since

0036 : ..the MOBY FB call0038 :

003A :UN F 254.7 Ready ?003C :BEB ––> NO: Wait for MDS

003E :0040 :U F 254.6 Inquiry whether error occurred

0042 :BEB No automatic start of the command occurs

0044 : when there is an error0046 :

0048 :UN F 0.0 Start a new MOBY command?004A :BEB ––> NO

004C :004E :S F 255.1 Start the new MOBY command

0050 :L FW254 ..and put the start bit0052 :T DW4 ..back in the FBDB

0054 :BE

FB 250 Description6GT2097–3AA00–0DA2

– 30 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.5 Programming from New Start and Restart

OB20 SPRM–A LEN=10 ABS

Page 1

Segment 1 Cold start OB

=========================================================================Example: Cold Start Operation Block

=========================================================================This is not necessary for PLC type S5–115U!

0000 :A DB250 Call FBDB

0002 :L KH0004 ”New start” set bit ..0006 :T DW4 in BEST

0008 :BE

OB21 SPRM–A LEN=10 ABS

Page 1Segment 1 Manual warm start

=========================================================================

EXAMPLE: OPERATION BLOCK FOR MANUAL RESTART

=========================================================================REQUIRED FOR ALL PLC TYPES !!

0000 :A DB250 Select FBDB

0002 :L KH0004 Set new start bit ..0006 :T DW4 in BEST

0008 :BE

OB22 SPRM–A LEN=10 ABS

Page 1Segment 1 Automatic restart

=========================================================================

EXAMPLE: OPERATION BLOCK AFTER AUTOMATIC WARM START=========================================================================

This block is run after ”power on” and is valid for all PLC types

0000 :A DB250 Select FBDB

0002 :L KH0004 Set ”new start” bit0006 :T DW4 in BEST

0008 :BE

FB 250 Description 6GT2097–3AA00–0DA2

– 31 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Example of programming for S5-115U/CPU 945 or S5-115U/CPU 948 with ANW=1

OB20/21/22

0000 :A DB250 FBDB0002 :L KH0004 Prepare RESET in command

0004 :T DW4 and status word0006 :

0008 :UN F220.0 Auxiliary flag 1 for

000A :S F220.0 startup of high-speed000C : SIMATIC CPUs

000E :BE

OB1

Segment 10000 :U F220.0 Auxiliary flag 1 for RESET

0002 :JC FB10 call for RESET function0004 NAME :MOBYRE

0006 :U F220.0 If RESET not concluded,

0008 :BEB stop here000A :

000C :U F220.1 If auxiliary flag 2 is set,000E :L KT001.0 start time for 10 milliseconds

0010 :SI T10012 :UN F220.0 If auxiliary flag 1 is reset for

0014 := F220.1 RESET, set auxiliary flag 20016 :

0018 :U F220.1001A :U T1

001C :BEB Wait till startup timer001E : has expired

0020 :

0022 :A DB250 Normal MOBY processing0024 :JU FB250 with presence of MDS

PLC type for SIMATIC S5-115U/CPU 945or SIMATIC S5-115/135U/CPU 948

FB100000 :JU FB250 With presence of MDS

0002 NAME :MOBY:KET PLC type for SIMATIC S5

0004 ADR : KF+128 Modul address (128 - 248)0006 KAN : KF+1 channel 1 (1 or 2)

0008 TYP : KF+6 Read / write MDS000A FBDB : DB250 FBDB = 250 (DW0 - DW24)

000C ANW : KF+1 0 = No presence check000E AG : KF+5 1 = Example: S5 115U-944-7UB11

0010 :UN M254.70012 :BEB

0014 :0016 :U M254.6

0018 :BEB

001A :001C :R M220.0 If RESET concluded, reset

001E : auxiliary flag 10020 :

0022 :BE

FB 250 Description6GT2097–3AA00–0DA2

– 32 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.6 Configuration of a Reference List

4.6.1 User Data, Commands and Control Data in One DB

DB250 SPRM–A LEN=88 ABS

Page 1==========================================================================

FBDB, ZUWDB and DATDB are combined in one data block.==========================================================================

DW4 BEST: RESET BIT IS SET so that the parameterizationis checked on the first run through

DW5 ANZ: Error evaluation; need not be preset

DW6 ZUW: Pointer to reference DB : Here: FBDB = ZUWDB; START ADDR. of the reference list = 25

DW25..27 1st command in ZUWDB: WRITE 64 BYTES From ADDR. 0000 on the MDSDW28..30 2nd command in ZUWDB: READ 6 BYTES (ADDR. 0000 to 0005) from the MDS

DW31..36 3rd command in ZUWDB: DW31–33 1st part command read 6 BYTES (ADR13–18) from MDS : DW34–36 2nd part command write 1 BYTE (ADR50) on the MDS

DW37..45 4th command in ZUWDB: DW37–39 1st part command write 10 BYTES on MDSDW40–42 2nd part command write 10 BYTES on MDS

DW43–45 3rd part command write 10 BYTES on MDSThe fourth command is a write command of 30 bytes from address 0 on

the MDS. It is made up of 3 part commands in order to keep the cycle load on the PLC below 1/3 of the normal duration.

DW50 1st + 2nd DATA BYTE IN DATDBDW51 3rd + 4th DATA BYTE IN DATDB

:DW83 LAST DATA BYTE IN DATDB

0: KH= 0000; 1: KH= 0000;

2: KH= 0000; 3: KH= 0000;

4: KM= 0000000000000001; 5: KM= 0000000000000000;

6: KY= 250,025;

7: KH= 0000; :

24: KH= 0000; 25: KY= 004,064;

26: KF= +00000; 27: KY= 250,050;

28: KY= 002,006; 29: KF= +00000;

30: KY= 250,050; 31: KH= 8206;

32: KF= +00013; 33: KY= 250,115;

34: KH= 0401;

35: KF= +00050; 36: KY= 250,050;

37: KH= 8C0A; 38: KF= +000000;

39: KY= 250,050; 40: KH= 8C0A;

41: KF= +000010; 42: KY= 250,055;

43: KH= 040A; 44: KF= +000020;

45: KY= 250,060;

: 50: KS= MOBY I – The System From

77: KS= a Single Supplier 123

FB 250 Description 6GT2097–3AA00–0DA2

– 33 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.6.2 Different DBs for FBDB, ZUWDB and DATDB

DB210 SPRM–A LEN=30 ABS

Page 1

=========================================================================EXAMPLE: FBDB (ZUWDB AND DATDB ARE SEPARATE DATA BLOCKS)

=========================================================================

DW4 BEST: RESET BIT IS SET so that the parameterization

will be checked on the first run throughDW5 ANZ: Does not need to be preset by the user

DW6 ZUW: Pointer on ZUWDB (here DB 220 and data word DW 3)

0: KH= 0000; 1: KH= 0000;

2: KH= 0000; 3: KH= 0000;

4: KM= 0000000000000001;

5: KM= 0000000000000000; 6: KY= 220,003;

7: KH= 0000; 8: KH= 0000;

9: KH= 0000; 10: KH= 0000;

11: KH= 0000; 12: KH= 0000;

13: KH= 0000; 14: KH= 0000;

15: KH= 0000; 16: KH= 0000;

17: KH= 0000;

18: KH= 0000; 19: KH= 0000;

20: KH= 0000; 21: KH= 0000;

22: KH= 0000; 23: KH= 0000;

24: KH= 0000; 25:

FB 250 Description6GT2097–3AA00–0DA2

– 34 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

DB220 SPRM–A LEN=20 ABS

Page 1=========================================================================

EXAMPLE: ZUWDB (Reference Data Block)

=========================================================================DW0..2 To be kept free for internal FB use

DW3..5 1st reference list command: Write 64 bytes from address 0 on the MDSDW6..8 2nd reference list command: Read 10 bytes from address 15 from MDS

DW9..14 3rd reference list command: 1st part commandWrite 12 bytes from address 50 on MDS

2nd part commandRead 1 byte from address 0 on MDS

0: KH= 0000;

1: KH= 0000; 2: KH= 0000;

3: KY= 004,064;

4: KY= 000,000; 5: KY= 230,010;

6: KY= 002,010; 7: KY= 000,015;

8: KY= 230,030; 9: KH= 840C;

10: KF= +00050; 11: KY= 230,010;

12: KH= 0201; 13: KF= +00000;

14: KY= 230,003;

15:

DB230 SPRM–A LEN=48 ABS

Page 1

=========================================================================EXAMPLE: DATDB (Data Block with User Data)

=========================================================================DW0..2 To be kept free for internal FB use

DW3 1st + 2nd DATA WORD : The first byte is always in the left data byte (= DL)

:

DW42 LAST DATA BYTE

0: KH= 0000; 1: KH= 0000;

2: KH= 0000; 3: KS=

9: C = 10: KS= MOBY I – The System From a

37: KS= Single Supplier 123

FB 250 Description 6GT2097–3AA00–0DA2

– 35 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.7 Setup of a Dialog Transmission with ASM 400

The dialog function of MOBY I can be used to transfer data from one interface module to another interfacemodule.

To activate dialog operation on the ASM 400, the user must send a special command to the ASM (cf.chapter 3.5), and then switch to normal operation again.

Note:An activated dialog operation can only be reset by switching off the module.

4.7.1 How Is the MOBY I Dialog Set Up ?

The following figure shows the setup of dialog communication for MOBY I.

ÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇÇ

Station_N reads/writes the VMDS

SLG_N

ÂÂÂÂÂ

MOBY�I�interfacein normal operatione.g., ASM 400 in SIMATIC S5)

Read or writethe VMDS with FB 250

Station_N

over clearance in air.

SLG_D

MOBY�I�interface in dialog operation(e.g., ASM 400 in SIMATIC S5)

Station_D

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

VMDSRead/write/Initialize theVMDS withFB 250

FB 250 Description6GT2097–3AA00–0DA2

– 36 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Station_N Normal ASM of MOBY I (ASM 400, ASM 410, ASM 420, ASM 440, ASM 470,SIM4x)The user operates station_N as usual (i.e., as if he/she wanted to exchange data with an MDS).

SLG_N An SLG (SLG 41, SLG 42, SLG 43, SLG 44) which is connected to station_N

Station_D Dialog ASM of MOBY I (ASM 400, ASM 410, ASM 470)When turned on, station_D is parameterized as dialog ASM with a usercommand. A 16-Kbyte memory area is defined in station_D during parameterassignment. This memory area is called VMDS (i.e., virtual MDS). It is used as communication memory. Processing of station_D by the user is identical to the program in station_N. Station_D uses the same tools as station_N (e.g., FB 47).

SLG_D An SLG (SLG 41, SLG 42, SLG 43, SLG 44) which is connected to station_D

VMDS Virtual mobile data memory. The VMDS is a 16-Kbyte area of memory on station_D. This VMDS is defined and cleared when station_D is turned on and parameterized.

Term Explanation

FB 250 Description 6GT2097–3AA00–0DA2

– 37 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

4.7.2 How does the User Work with MOBY I Dialog?

ExampleThe user program in station_D issues a write command with the data to be transferred. The command isexecuted immediately. The data are now located in the VMDS. This concludes work in station_D. Theuser program in station_N issues a read command. SLG_N and SLG_D do not yet have to be positionedopposite each other in the transmission window. Reading of the desired data starts as soon as SLG_Dmoves into the transmission window of SLG_N. The data are read from the VMDS and transferred to theuser on station_N.

Communication time during dialogThe same times as described in the MOBY catalog apply for configuration of the communication time.

tk = 16 msec + 0,8 ms * n Bytes

Transmission window during dialogThe transmission window from SLG_D to SLG_N has a polarization direction (i.e., SLG_D and SLG_Nmust be directed toward each other at a certain angle). The following figure shows the transmission win-dow during dialog.

Sa

Sg

Side view

View of top

L

B

SLG_D

SLG_N

Direction of movementof SLG_D to SLG_N

Positioning of SLG_D

Transmission window

Enlarged view of the transmission win�dow when SLG_D and SLG_N are opera�ting with minimum working distance

Sa = Working distanceSg = Limit distanceL = Length of transmission windowB = Width of transmission window

FB 250 Description6GT2097–3AA00–0DA2

– 38 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Field data during dialog operationThe following table shows the field data during dialog operation. Dimensions are specified in mm.

Length of the trans- 60 230 600 3000mission window (L)

Width of the trans- 30 80 280 1300mission window (B)

Working 0 to 15 0 to 70 20 to 250 200 to 1000distance (Sa)

Limit distance (Sg) 30 130 450 2500

Distance from > 200 > 800 > 2000 > 10000SLG to SLG (D)

all dimensionsin mm

SLG 41-SLG 41

SLG 42-SLG 42

SLG 44-SLG 44

SLG 43-SLG 43

Dialog with ECCECC operation must always be deactivated during dialog operation.

New start of an ASM 400 as station_DWhen dialog operation is activated, the ASM 400 checks to determine whether the SLG is connected cor-rectly and supplied with power. If not, the red LED on the channel module continuously indicates a tripleflashing pattern. FB 250 does not give the user an error message.

FB 250 Description 6GT2097–3AA00–0DA2

– 39 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

5 Control and Inquiry for “Data Storage MDSs in the Field”

The “ANW” parameter can be set to 2 operating modes of the SLG using FB 250.

ANW = 0

The magnetic field of the SLG is only switched on when a valid command is started. After recognizing theMDS and the completion of a command, the SLG is turned off again.In this way projects can be implemented in which the specified distance between SLGs can be passedbelow as desired. The prerequisite is that the SLGs that are close to each other are addressed inmultiplexer mode. This can be necessary when large amounts of data need to be dynamically transferred.You can avoid stopping the transport conveyor by dividing up the data and distributing it over severalconsecutive SLGs.

ANW = 1

After a new start or restart of the PLC, or after a new start or RESET command of the FB 250, the SLG isswitched on and remains active until the PLC is switched off. The ASM scans continually to see if an MDS is in the field of the SLG. When the ASM recognizes an MDS,the user receives “availability bit” = 1 (= BEST bit 12) with the next FB call. Similarly, BEST bit = 0 when theMDS leaves the SLG field.If the MDS stays exactly on the edge of the SLG field, the system ensures that there is no constant switch-ing of this bit. The processor on the ASM handles this hysteresis function.Read/write commands can be sent completely transparently to FB 250 for the “availability” check. Simi-larly, the “availability bit” retains its unrestricted validity after the start of a command.

Note: When working with ANW = 1, it is absolutely essential that the distance between two SLGs specified in the configuration guidelines be adhered to.

Remark: The FB 250 cycle load will not be altered by the setting of the “ANW” parameter. The values in the table in chapter 2.1 are applicable in every case.

FB 250 Description6GT2097–3AA00–0DA2

– 40 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Switching “Availability” Monitoring On and Off

This occurs with the switching on and off of the PLC. By calling the FB 250 with different parameters andcarrying out a RESET command, the “availability” monitor can also be switched.

EXAMPLE: The availability control can be controlled with the input bit I 0.0.U I 0.0 Should the availability ...U F 0.0O( ...monitor be ...UN I 0.0UN F 0.0 ...switched ?) BEB ––> No ; no switchingA DB250 ––> Yes ; select FBDBS –RESET ... and give a reset commandU I 0.0= F 0.0 (Pointer for availability switch)JC FB250 ––> I 0.0 = 1: carry out reset, ...

NAME :MOBY:KET ... in this way the availability...ADR : KF+128 ... monitor is switched on (ANW = 1)KAN : KF+1TYP : KF+6FBDB : DB250ANW : KF+1AG : KF+5

UN I 0.0JC FB250 ––> I 0.0 = 0: carry out reset, ...

NAME : MOBY:KET ... in this way the availability...ADR : KF+128 ... monitor is switched off (ANW = 0)KAN : KF+1TYP : KF+6FBDB : DB250ANW : KF+0AG : KF+5

FB 250 Description 6GT2097–3AA00–0DA2

– 41 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

6 Commissioning the ASM 400 with FB 250

6.1 Module Ports

– Set free address in the SIMATIC S5 on the S3 address switch (see chapter 2.5).

– Plug in the module.

Note: Plugging in or extracting the module or a channel module may only occur when the powerhas been switched off.

6.2 Loading FB 250

– Load the FB into the user program.

6.3 Presetting the Organization Blocks

– Preset the “BEST” parameters in the OB for new start and restart as follows:For restart 0004hexFor new start 0004hex

Tip: The corresponding OBs are to be found in the relevant SIMATIC catalogue(see also chapter 4.5).

Example: S5–155U OB20 for new startOB21 and OB22 for restart

Note: The “BEST” must be preset in every FBDB if several SLGs are to be used with one PLC.

6.4 Setting Up the Data Block

– Set up data block for FBDB parameter (minimum length: 25 DW).A separate FBDB must be set up for each channel.

– Set up data block for “ZUW” parameter (see chapter 2.2.5).

– Set up the DATDB specified in the ZUWDB.

6.5 Calling FB 250 in the Application Program

– The FB 250 must always be called absolutely.

– The parameters – “ADR,” “KAN,” “TYP,” “FBDB” and “ANW” are to be established(see parameterization in chapter 2.2).

6.6 Program Processing

– Call the user program (e.g., in OB1, cyclic call).

FB 250 Description6GT2097–3AA00–0DA2

– 42 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

6.7 Function Monitoring

With the help of the “BEST” and “ANZ” (= DW4 and DW5 in FBDB), a function monitor can be carriedout.

6.7.1 Program processing running: No command is being processed.

Synchro: (general communication possible)

”BEST”: 10000000 00010000

RESET was last processed.

READY (New command is possible.)”ANZ”: 00000000 00000100

”BEST”: 10000000 00100000

Read or write command was last processed.

or

A reset command is required if the above parameter states are not kept. If both parameters still haveother values, continue with the error description.

6.7.2 Command Input

”BEST”: 00000000 00000010

Command in ZUWDB to be processed (read/write)

”ANZ” : 00100000 00000100Synchro (general communication possible)(Reserved)

(with Control VAR on the PG) and:”BEST”: 00000000 10100000

Command (read or write) is active.FB is running.

The states of these two parameters are retained until an MDS enters the field of the SLG and thecommand is correctly processed with the MDS.

6.7.3 Command Executed

”BEST”: 10000000 00100000Read/write finished

”ANZ” : 00000000 00000100Synchro

No error with the command executionREADY

The “BEST” and “ANZ” values have the same states for read and write.

After carrying out the commands both parameters go back to their basic state (6.7.1) (and a read orwrite ready message). If an error is detected and one of the parameters deviates from the above figure, continue with theerror description.

FB 250 Description 6GT2097–3AA00–0DA2

– 43 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

7 The ECC Driver

The ECC driver (Error Correction Code) can be started using an option in the ASM 400 firmware.The operating mode is switched on with the “typ” parameter during parameterization. The ECC driver canonly be used by MOBY I.

Application:

The ECC driver provides extra security for the correct data being on the MDS. For EEPROM MDSs, only awrite frequency of 10,000 operations is guaranteed by the manufacturer. Using the ECC driver providesthe same data security right up to the actual end of the chip’s life.The ECC driver can also be used for security reasons with RAM MDSs for instance where extreme distur-bance fields can affect communication.

Call Up:

The programmer must only consider the correct “TYP” parameter when installing the system.

TYP = 3 � Initialize the MDS with ECC (subcode 0002)TYP = 5 � Write and read the MDS with ECC

All other parameters such as, for example,

– Construction of the MDS data structure– Start address and length in the command– Construction of ZUWDB or DATDB

do not need to be altered.Chapters 1 to 6 of this description also apply when the ECC driver is switched on.

Function:

The ECC driver divides the MDS memory into 16–byte blocks. 14 bytes are for user information and 2 by-tes for ECC information. With every access to the MDS at least one block is read or written to (even whenthe programmer has only programmed 1 byte in ZUWDB). Therefore, the access time is lengthened to theMDS data (see the table in the catalog). When an ECC MDS is read without the ECC driver (e.g., with“TYP” = 6 or with the STG), the ECC bytes can be distinguished from among the user data. When an ECCMDS is overwritten without the ECC driver, the MDS’s data structure is destroyed. The MDS (or the de-stroyed data block) can no longer be read with the ECC driver.

Data Correction:

If one bit of data in the MDS’s memory is lost at some time (e.g., EEPROM MDS which has been writeaccessed very frequently), the ECC driver is able to reconstruct the lost bit. The user is guaranteed to gethis correct data back. The user can use a status bit in the indication word (ANZ Bit 13) to request andevaluate the corrected data (e.g., to decide whether the MDS should be replaced soon).

FB 250 Description6GT2097–3AA00–0DA2

– 44 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Example:

Data structure of a 62–byte MDS. (The figure below is for explanatory purposes only. The programmer oruser is not aware of this process and does not need to take it into consideration.)

MDS Address fromUser’s Viewpoint

Address on MDS Meaning

0

1617

293031

3233

454647

48

61

1415

27

2829

41

ECCECC

ECCECC

1

131415

ECCECC

01

13

14 bytes of user data

An incomplete block at the end of theMDS memory is not available for user data.

1st block

2nd block

3rd block

14 bytes of user data

14 bytes of user data

Please Note:

– The access times on the MDS are lengthened since less data can be processed in dynamic mode.

– The net capacity of the MDS is smaller (see chapter 4.2).

– The result can be delayed by up to one second when data correction takes place.

– A “normal” MDS must be initialized with the ECC driver switched on (e.g., with the STG) before being commissioned.

– During dialog mode, the VMDS cannot operate with ECC.

FB 250 Description 6GT2097–3AA00–0DA2

– 45 –RD: 09/02

6GT2080–2AA10 ”MOBY Software” Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

8 Error Searching with the ASM 400 and FB 250

Error: The program does not run after new start or restart.

Cause: –> The organization block for new start and restart was not preset according to the relevant FB description.

–> The synchro bit in ANZ (DW 5) has been reset.

Error : The PLC goes into STOP status after the MOBY blocks are loaded.

Cause: The parameterized FBDB is not available or is too short.

– Exact error analysis in the ISTACK output of the programming unit

Error: The PLC goes into STOP status after starting or carrying out a command.

Cause: – ZUWDB or DATDB is not available in the PLC.

– The accessed data word in ZUWDB or DATDB is not available(ZUWDB or DATDB are set up too small).

– After loading the FBDB, no reset was carried out.– The ZUW parameter (= DW6 in FBDB) was not supplied.– Too much data was transferred between the ASM and the FB with a chained command so that the maximum cycle time of the PLC was exceeded. (The ISTACK of the PLC

indicates “ZYK” as the cause.)Remedy: Program a chained command with a cycle change (see chapter 3.2).

– The user program has changed the data in the FBDB (particularly DW 0/1).

If FB 250 does not work correctly, further errors can be analysed by checking the “ANZ” parameter. “ANZ”contains the following contents when no command is active.

1 = Timing error1 = Repeat errorASM status byte

1 = Parameterization error1 = ASM error

1 = Synchronization error

0000 0000 0000 0001

0 = The FB is not operating (output RESET).

“ANZ”

The left byte in the “ANZ” parameter contains the ASM status. Evaluation with the bit pattern is describedon pages 40 and 41.

FB 250 Description6GT2097–3AA00–0DA2

– 46 –6GT2080–2AA10 ”MOBY Software”

RD: 09/02

Subject to change without notice!

(4)J31069-D0120-U001-A2-7618

Bit 1: = “1”: Synchronization error

Cause: – The FB 250 receives a result for a command that is not in the ZUWDB (not at this location). Possibly the pointer (ZUW) to ZUWDB was altered while the command was active.

– EMC conditions caused the ASM to process another command than the one programmed by the user.� Check the entire SIMATIC system. Check grounding concept.