Mission d’industrialisateur Pour Unilog – A Logica CMG Company Chez La Mondiale Partenaire

25 t–35 t PLUS SERIES - WITTMANN BATTENFELD PLUS e.pdf · PLUS Series THE PLUS Compact, ......

Transcript of 25 t–35 t PLUS SERIES - WITTMANN BATTENFELD PLUS e.pdf · PLUS Series THE PLUS Compact, ......

25 t–35 tPLUS SERIESPLUS SERIES

PLASTICS TECHNOLOGY

INJECTION MOLDING TECHNOLOGY

PLUS 25 t – 35 t

22

BATTENFELD Injection Molding Machines

INJECTION MOLDING MACHINESINJECTION MOLDING MACHINESPLUS Series

THE PLUS

Compact, powerful, profitable!

The keyword is lean production. Lean production in more than one sense. Ultra-modern hydraulics and control technology packed into smallest space. This combination is simply ingenious and thus highly profitable. A power package: the PLUS UNILOG B2 comes in two sizes, with 25 or 35 t clamping force.

THE PLUS V

Vertical beats horizontal. At least in the field of required space. Apart from this, the machine offers all benefits of the horizontal series. The ideal equipment for insert molding. Battenfeld: building injection molding machines and automation equipment. For decades! And shipping them to satisfied customers. Worldwide!

3

PLUS 35.

INJECTION MOLDING MACHINESINJECTION MOLDING MACHINESPLUS Series

4

SPECIAL FEATURESSPECIAL FEATURESof the PLUS range

BATTENFELD Injection Molding Machines

Maintenance-free, compact injection unit in EUROMAP 50 or 75 with slow-running hydraulic motor for screw drive

Maintenance-free hydraulic,2 tie-bar clamping system with moving platen support

Measuring system for all strokes

Energy-efficient variable displacement pump with velocity and pressure control via proportional valves

Control terminal with function keys for direct parameter setting (symbol-guided). Storage of data on floppy disk and via USB interface

5

UNIFEED A1 material loader

Convertible injection unit:The injection unit can be moved in virtually no time from its ver-tical position into a horizontal position

Pneumatic safety gate with integrated safety strip for easy access to the tool, ejector and nozzle area

Integrated control cabinet. The compact, space-saving control cabinet with an inte-grated control panel is desig-ned for easy access

Mechanical safety scotch bar

6

UNILOG B2UNILOG B2

Password system

Quality table with accepts/rejects detection, process monitoring and safety cut-off

Color display 116 x 87 mm (5.7” TFT ); symbolic input dialog on few screen pages; the status bar shows the machine status.

Machine settings stored on PC-compatible floppy disk and via USB

Printer via USB

UNILOG B2 is an advanced micro-processor control system designed to meet the requirements of injec-tion molding machine control. The system has been optimized to control all machine movements. The Unilog B2 control system comes with a 116 x 87 mm (5.7” TFT) color monitor. Its operation is straight-forward. Data is entered in a concise entry form displayed on a graphical user interface. The concise dialog box with icons facilitates data input. Selec-tion of individual functions is fast and easy. Only few screen pages are required for symbolic display of the injection molding process, these can be selected by

pressing the function keys. A status bar facilitates diagnostics and provides a precise machine status report. Error identification texts can be displayed in several languages. Access via a password system ensures operation of the equipment according to the skills of the operator. A quality table with accepts / rejects analysis, process monitoring and automatic safety cut-off functions controls the production pro-cess. Values that exceed tolerance are clearly marked in red. All parameter settings can be stored on a 3.5” floppy disk or via USB interface. Physical units can be displayed either in metric units or as SPI units.

BATTENFELD Injection Molding Machines

7

Symbolic input and display ensures a quick overview of the process and reduces the number of screen pages. The positioning and alignment of symbols allows intuitive operation. Only 3 graphic elements are required for input and display.

In the rectangular boxes the actual values are shown, the rectangles with pointed tops contain set value entries. Parameter settings are shown in the rectangles with solid arrows.

INJECTION

The display of injection strokes and speeds is self-explanatory. A maximum of 4 strokes can be ente-red. The set profile is interpolated according to the characteristics of the hydraulics.

The actual values for screw stroke, injection time and pressure are shown in the rectangular boxes.

HOLDING PRESSURE

The holding pressure profile is entered in three profi-le steps. The process overview is completed by entry and display of holding pressure time and cooling time.

QUALITY TABLE

The quality table is an important tool for production monitoring and documentation. A total of 4 out of 36 parameters can be stored and monitored for the last 50 cycles. If desired, each monitoring channel can be used to control a reject gate.

8

270

60

42

127

300520 230460

ø14

ø19

255

1510

7516

75

10

1296

610900

��580510

1265

M16(3x)

11108661035

2240

50047060

465

58563

518

0

�������

���

����

���

��

�����

���

���

����� ��

���

��� ��������������

���

��

���

���

��

��� ��

��� �����

���������

�� �������

��� ���

��

������

��������

�� ���

��� ��

�

���

��

�

���

��

�

�����

���

������

���

���

�������

���

�

�

�

�

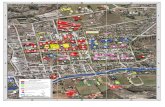

DIMENSIONS OF PLUS 25/35DIMENSIONS OF PLUS 25/35

BATTENFELD Injection Molding Machines

9

M12

(24x

)70 10

5

140

13(2x)70

105140

270330470

A 60

160

280

200

max

.250

Z

148

ø110 H7

R35

30ø110 H7

min

.200

M16

15

max

.450

A

BB

A

2015

0

100

330

155

210

120

241

R110

522535

50

200

210

B

max

.130

50

min

.75

min

.70

Z

M16(5x) 35 307 1017

1235

900

1015

770

255

410

440

510

580

���

���

�� 133

225

262

3140

1730

2710

42

1440

400

��������

DIMENSIONS OF PLUS 25V/35VDIMENSIONS OF PLUS 25V/35V

10

TECHNICAL DATATECHNICAL DATA

Clamping unit PLUS 25 PLUS 35 PLUS 25 V PLUS 35 V

Clamping force kN 250 350 250 350

Distance between tie-bars mm 270 270 270 270

Platen area mm 470 x 280 470 x 280 470 x 280 470 x 280

Max. mold hight mm 150–250 150–250 200–250 200–250

Opening stroke mm 200 200 200 200

Opening force kN 29,5 29,5 29,5 29,5

Tie bar diameter mm 60 60 60 60

Max. daylight between platens mm 450 450 450 450

Ejector force kN 26,2 26,2 26,2 26,2

Ejector stroke mm 100 100 100 100

Oil tank capacity l 125 125 125 125

Dry cycle time¹ s 1.3 1.3 1.3 1.3

¹ according to EUROMAP 6 ² according to Battenfeld Standard

Injection unit PLUS 25 PLUS 35 PLUS 25 V PLUS 35 V

International size designation 50 75 50 75

Screw diameter mm 18 22 25 18 22 25 30 18 22 25 18 22 25 30

Specific injection pressure bar 2431 1627 1260 3038 2034 1575 1094 2431 1627 1260 3038 2034 1575 1094

Theoretical shot volume cm³ 25,4 38 49 25,4 38 49 70,6 25,4 38 49 25,4 38 49 70,6

Max. shot weight (PS) g 23,1 34,5 44,6 23,1 34,5 44,6 64,2 23,1 34,5 44,6 23,1 34,5 44,6 64,2

Screw L/D ratio 21 17 15 21 17 15 13.5 21 17 15 21 17 15 13.5

Max. screw speed min¯¹ 420 420 330 420 420 330

Screw torque Nm 160 200 240 160 200 240

Plasticising rate (PS)² g/s 4,9 6,6 7,5 4,9 6,6 7,5 9,2 4,9 6,6 7,5 4,9 6,6 7,5 9,2

Nozzle stroke mm 150 150 150 150

Nozzle contact force kN 22 27,5 22 27,5

Screw stroke mm 100 100 100 100

Injection rate into the air g/s 38,4 57,3 74 38,4 57,3 74 107 38,4 57,3 74 38,4 57,3 74 107

Barrel heating performance kW 2,76 2,76 2,76 2,76

Number of heating zones 1+2 1+2 1+2 1+2

Drive performance kW 7,5 7,5 7,5 7,5

Weight kg 1.100 1.100 1.300 1.300

BATTENFELD Injection Molding Machines

11

Standard equipment UNILOG B2

Screen 5.7” colour TFT

3.5” floppy disk drive for data storage

USB data storage

USB printer port

Quality table

Parts counter with good/bad part detection

Pre-selection shot counter

Error signal lamp

Thermocouple failure monitoring

Barrel heating with solid state relays

Nozzle pyrometer

Electrically and hydraulically secured safety gate

Mechanical closing drop bar (PLUS V)

Oil pre-heating

Oil temperature monitoring

Oil level monitoring

Electrical oil filter monitoring

Operating hours counter

Shot counter

Material loader UNIFEED A1 (PLUS V)

Pneumatic safety gate including safety strip (PLUS V)

Cooling water manifold with four cooling circuits

Stainless steel material hopper

Linear stroke transducers

Temperature readout in F°

Start-up waste program

Seven day timer

Conversion kit for parting line injection – horizontal (PLUS V)

Painting: Machine RAL 9002 greywhite Operating column RAL 5002 ultramarine blue

Additional equipment UNILOG B2

Hydraulics

Hydraulic or pneumatic core pull

Larger oil cooler

Injection unit

Ceramic heater bands

Wear-resistant barrel BATTalloy AK+

Thermoset kit (not possible with PLUS V)

Rubber kit

Liquid silicon rubber kit including shut-off nozzle

Material loader UNIFEED A1 (PLUS)

Injection unit UNILOG B2

Material hopper in lieu of material loader UNIFEED A1 (PLUS V)

Spring loaded shut-off nozzle

Pneumatically operated shut-off nozzle

Defined nozzle contact pressure

Digitally adjustable back pressure

High torque screw motor

Clamping unit

Ejector platen safety

Mechanical safety scotch-bar (PLUS)

Unscrewing device with hydraulic motor in lieu of ejector (not possible with PLUS V)

Parts chute hopper (not possible with PLUS V)

Parts chute slide with photo electric ejection monitoring (not possible with PLUS V)

Parts chute slide for accepts/rejects separation(not possible with PLUS V)

Air valve with timer

Cooling and temperature control

Four additional cooling circuits

Shut-off valve for cooling water manifold

Closed loop feed throat temperature control

Control and electrical system

Hot runner control zones

EUROMAP 67/SPI robot interface

Initiate next cycle with closing safety gate (Gate Start)

Screw speed indicator

Audible alarm

Potential-free contact parallel to metering

Single phase socket

CEE socket

Interface for conveyor belt

Interface for vacuum pump

Potential-free contact in the event of machine fault

Hydraulic pressure-dependent switchover to holding pressure

Temperature control zone for hot runner

Additional power sockets including safety cut-off

Mobile Airmould interface

Manual parts removal (not possible with PLUS V)

Accessories

Leveling pads

Tool kit We have taken great care to collect the data and technical information in this publication. However, this publication could contain techical inac-curacies or typographical errors. We reserve the right to make improve-ments or changes to this publication and to the products at any time. ● Standard; Option

STANDARD- ANDOPTIONAL FEATURES PLUS/PLUS VSTANDARD- ANDOPTIONAL FEATURES PLUS/PLUS V

THE POWER to SUCCEED

M/3

/

/P

LUS

2500

/03

/05

(TS

/03

/05)

· A

R/k

y · P

rinte

d in

Ger

man

y

Sub

ject

to

chan

geG

B

Battenfeld Injection Molding GmbHWiener Neustädter Straße 81 · 2542 Kottingbrunn · AustriaTel. +43 2252 404-0 · Fax +43 2252 404-8202 [email protected]

www.battenfeld.com