24kV Pro-MEC Manual

-

Upload

0510226445 -

Category

Documents

-

view

120 -

download

8

Transcript of 24kV Pro-MEC Manual

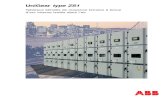

Pro-MEC VCB

Safety Instructions -------------------------------------------------------------------------------------- 1

Receiving & Unpacking, Service Conditions ----------------------------------------------------- 4

Moving, Storage and Disposal ----------------------------------------------------------------------- 5

Installation ------------------------------------------------------------------------------------------------- 6

Structure and Operation ------------------------------------------------------------------------------- 71.Front Parts----------- ------------------------------------------------------------------------------------ 72.Operating Mechanism Parts----------------------------------------------------------------------- 133.Main Circuit Parts------ ------------------------------------------------------------------------------ 164.Vacuum Interrupter ---------------------------------------------------------------------------------- 17

Withdrawal /Insertion Operation (E,F Class) --------------------------------------------------- 18

Withdrawal/Insertion Operation (G Class) ------------------------------------------------------ 201. Manual Insertion------------------------------------------------------------------------------------- 202. Manual Withdrawal------- -------------------------------------------------------------------------- 203. Interlocks for Withdrawal and Insertion-------------------------------------------------------- 214. Interlocks for Earthing Switch------------ -------------------------------------------------------- 23

Maintenance and Inspection ------------------------------------------------------------------------ 241. General ------------------------------------------------------------------------------------------------- 242. Routine inspection -----------------------------------------------------------------------------------

2 63. Periodical inspection ----------------------------------------------------------------------------------

2 64. Special inspection ----------------------------------------------------------------------------------- 285. Lubricant Points for Operating Parts ----------------------------------------------------------- 29

Ratings ---------------------------------------------------------------------------------------------------- 30

Circuit Diagrams --------------------------------------------------------------------------------------- 31

Quality Guarantee Certificate ---------------------------------------------------------------------- 33

Contents

1

Pro-MEC VCB

2

Pro-MEC VCB

DANGER

WARNING

CAUTION

DANGER

This symbol indicates the instant death orserious injury if you don’t follow instructions.

This symbol indicates the possibility ofdeath or serious injury.

This symbol indicates the possibility ofinjury or damage to property.

This is the safety alert symbol.Read and follow instructions carefully to avoid dangerous situation.

This symbol alerts the user to the presence of “dangerous voltage”inside the product that might cause harm or electric shock.

The meaning of each symbol in this manual and on your equipmentis as follows.

Do not touch charged parts electrically like conductors and connector parts of terminals, under any of energized condition.Otherwise, there is the danger of severe physical injury or electrocution is caused by electric shock.

WARNING

1. Inspection and maintenance have to be performed by a qualified electrician.Otherwise, there is the danger of malfunction, severe physical injury or electric shock.

2. When the circuit breaker is in service, don’t open the front cover.Otherwise, there is the danger of severe physical injury or electric-shock.

3. When the circuit breaker is in service, don’t insert or withdraw the circuitbreaker.Otherwise, there is the danger of severe physical injury or electric-shock.

4. Inspection and maintenance have to be performed only after shutting offthe electric power and discharging a charge current.Otherwise, there is the danger of severe physical injury or electric shock.

5. When making bolts and screw assembling, follow the instruction withrecommended torque values. Otherwise, there is the danger of over heating or fire.

6. After performing installation, maintenance or inspection, remove someforeign objects like tools, test leads or bolts, instruments.Otherwise, there is the danger of short circuit or fire.

7. When performing a maintenance, make a power-off of the circuit breaker and maintain test position.Otherwise, there is the danger of electric shock.

8. Do not move the circuit breaker by handling main circuit bus terminals.Otherwise, there is the danger of an electric accidents by temperature rise.

Safety instructionsSafety instructions

To prevent injury and property damage, follow these instructions.Incorrect operation due to ignoring instructions will cause harm ordamage, the seriousness of which is indicated by the following symbols.

Pro-MEC VCB

3

Pro-MEC VCB

Receiving & Unpacking

1. When unpacking the package, take care to handlethe main contactor, standard components and accessories and certify standard component described in this manual (Load wire for user : 18sets)

2. Certify that the instruction manual and a testreport of final testing were packed inside eachPVC envelop.

3. If damage or breakage of products are founded, immediately notify LSIS’ sales office or servicerepresentatives.

4. If damage or breakage of products by the carrier arefounded, immediately file a claim with the carrier and notify the shipping company.

4

Safety instructions

CAUTION

1. Don’t alter the control circuit at discretion.Otherwise, there is the danger of malfunction or damage to products.

2. The circuit breakers must be kept in dry condition and don’t reach water. Otherwise there is the danger of deterioration of insulation.

3. This products must be stored at the place with no corrosive gas. Otherwise there is the danger of a damage of products(discoloration).

Receiving & Unpacking, Service Conditions

Operating conditions(Indoor use)1 Normal operating condition

Design to IEC 60694( IEC 62271-1), with the following limits values : Ambient temperature * Maximum : +40 * Maximum 24 hour average : +35* Minimum : -25

Maximum site altitude : ≤ 1000 m above sea level. Humidity * 24 hour average value : ≤ 95% * One month average value : ≤ 90%

2 Special operating conditionsSpecial operating conditions are to be agreed on by the manufacturer and user. The manufacturer must be consulted in advance about each special operating conditions using at the following cases or places : Higher level of site altitude or ambient temperature exceeding the normal conditions At place much influence by sea wind. At a wet place with high humidity usually At places with much water or oil vapors At places with an explosive, flammable or noxious gas At places with much dust At places with abnormal vibration or impact at places with much ice and snow In case of using at other special conditions besides above cases

5 6

Pro-MEC VCBPro-MEC VCB

Moving, Storage and Disposal

1. For lifting or moving the circuit breaker, a specified lifting device should be used.2. When lifting the withdraw type of circuit breakers with a cradle, it should be

raised at the state of running position.

Moving

WARNING

CAUTION

Storage

1. The circuit breakers must be stored in clean, dry, dust andcondensation- free environment.may cause a weakness of insulation.

2. The products must be stored at the place with no corrosive gas.may cause a damage of product s (discoloration)

1. When making a disposal, dispose it at a designated place withno affection to environment. may cause an environmental pollution

CAUTION

Disposal

1. According to the ISO 14000, separate all of them as metallic or non-metallic material and dispose them at a designated place after dividing e all of material as renewablematerials and other materials which may cause an environmental pollution.

2. In case of being materials whatever you want to remake please contact us.3. In case of special materials making noxious gas when destroying by fire, be sure to

dispose them at an approved place

Installation

1. When making bolts and screw assembling, follow the instructionwith recommended torque valuesmay result in over heating or burns.

2. Do not alter the control circuit at one’s discretion.may cause of malfunction or damage to products.

WARNING

<Table 1> Torque value

Steel Brass

7.3 (6.2 - 8.4) 4.3 (3.7 - 4.9)

11.2 (9.5 - 12.9) 6.6 (5.6 -7.6)

16.8 (14.2 - 19.3) 9.8 (8.4 - 11.3)

33.0 (28 - 37) 19.1 (16.2 - 22.0)

56.0 (48 - 65) 33.0 (28 - 38)

135 (115 - 156) 89 (68 - 91)

270 (230 - 310) 159 (135 - 182)

470 (410 - 540) 270 (230 - 310)

M 3

M 3.5

M 4

M 12

M 5

M 6

M 8

M 10

Size of bolt

Torque

(kgfㆍcm) (kgfㆍcm)

For safe and normal operation of circuit breaker installed in switchgear, a very careful and special installation should be followed. When installing a fixed type of circuit breaker into switchgear, fix the breaker with

same torque value by passing through mounting holes (4-Ø14) after inserting springwashers into head of bolt without high pressure or alteration. Take care not to apply pressure or permanent tension by bus bars or others to main

bus terminals. Remove dust or other foreign substances. When bolting, follow the recommended torque value specified in Table 1.

1. Do not move the circuit breaker by handling main circuit bus terminals.Otherwise, there is the danger of electric accidents by temperature increasing.

Pro-MEC VCBPro-MEC VCB

7

Structure and operation1.1 Operating method for operating mechanism

The operating mechanism is designed to be operated by manual and/or electrical motor.

1) Manual spring charginga) Manual : Insert a manual charging handle into a manual charging hole (Fig.1/No.5)

and rotate it over 20 times clockwise until it runs idle.At the same time of charging completion it sounds “clatter”

b) Motor : If the control power is provided to the control circuit of circuit breaker the charging motor with a gear box is activated and it starts to chargethe spring. After a completion of charging for the closing spring, the controlpower for motor will be disconnected by the limit switch of motor.At this stage the closing spring will be recharged automatically as repeating the above sequence according to manual closing operation.

Summary : It can be verified a completion of closing spring charging by a spring indication shown via the closing spring charging indicator(Fig.1/No.7).

The circuit breaker can not be closed, unless the closing spring is chargedcompletely.

<Figure 2.1> Charged <Figure 2.2> Discharged

2) Closing operationManual : If the closing button(Fig.1/No.2) on the front of circuit breaker is pressed

the closing operation is started and the red color of ”ON” plate is appeared by rotation of the contact position indicator(Fig.1/No.6) simultaneously.

3) Trip operationManual : If the trip button(Fig.1/No.4) is pressed until the trip latch will be released

the trip operation is performed and the green color of “OFF” plate is appeared by rotation of the contact position indicator(Fig.1/No.6).The electrical remote control for above operations is available if eachsignals is provided since this operating mechanism have electrical closing and tripping devices.

4) High speed reclosing operationThis operating mechanism is available for the high speed reclosing (O-0.3s-CO) operating duty by remote operation at the status that the main circuit is “ON”and the closing spring is “CHARGED”For this operation the auto charging of closing spring should be within 15 sec.This circuit breaker is available for auto charging of closing spring within 12 sec.

Structure and operation

⑦

①

⑤

⑥

⑨⑧

②

③

④

<Figure 1> Front part of circuit breaker

(G Class Draw-out type)

① Name plate

② Manual closing button

③ Key-Lock Device

④ Manual trip button

⑤ Manual charging hole

⑥ Contact position indicator

⑦ Closing spring charging indicator

⑧ Operation counter

⑨ Screw for Insertion & Withdrawal

1. Front Parts

8

Pro-MEC VCB Pro-MEC VCB

9

Structure and operation

1.3 The frequency of operationIt is recommended not to operate the circuit breaker unnecessarily for the bestcondition. You should keep In mind as follows:

*10 times continuous operations (Each minimum time interval for spring charging is about 8 seconds,after finishing of continuous operation, it is needed to have at least30 minutes to operate again)

*20 times operation per hour.

*100 times operation per day.

In this case constant high frequency or operate in dust,polluted condition,it will be necessary to increase maintenance and inspection.

Structure and operation

10

Pro-MEC VCB Pro-MEC VCB

-

-

Structure and operation Structure and operation

11

.. .. ....

12

.. .. ....

1.4 Electrical operation

Main circuit contact status

Input a control powerElectrical charging Tripped Closing-Trip

CB Closing Closed Trip

Auto Recharging Closed Trip-Closing-Trip

CB Trip Tripped Closing-Trip

CB Closing Closed Trip

Auto Recharging Closed Trip-Closing-Trip

High-speed Reclosing

Tripped

Closed Auto Recharging Starting

Tripped

Auto Charging Completed Tripped Closing-Trip

CB Closing Closed Trip

Auto Recharging Closed Trip-Closing-Trip

Operating sequence

Operating resultsPossible subsequent operationClosing spring status

1.5 Manual operation

Manual Charging Tripped Closing-Trip

CB Closing Closed Trip

CB Trip Tripped

Spring Charging Tripped Closing-Trip

CB Closing Closed Trip

Manual Recharging Closed Trip-Closing-Trip

High-speed Reclosing

Tripped

Closed

Tripped

Manual Charging Tripped Closing-Trip

CB Closing Closed Trip

Manual Recahrging Closed Trip-Closing-Trip

CB Closing Closed Trip

Operating sequence Main circuit contact

statusClosing spring status

Operating resultsPossible subsequent operation

Pro-MEC VCBPro-MEC VCB

③

④

⑤

⑦

⑥

⑩

⑧

⑪

⑨

①

②

Structure and operation

③

⑤

16

11

15

7

6

⑫

②

⑬⑭

2 Closing spring 12 Gear cam

3 Opening spring 13 Crank shaft

5 Manual charging shaft 14 Close latch and roller

6 Driving shaft 15 Linkage

7 Driven shaft 16 Roller

11 Trip latch

Structure and operation

① Switching shaft

② Closing spring

③ Opening spring

④ Motor

⑤ Manual charging shaft

⑥ Driving shaft

⑦ Driven shaft

⑧ Closing coil

⑨ Trip coil

⑩ Auxiliary switch

⑪ Trip latch

<Figure 4> Structure of operation mechanism

2. Operating mechanism parts

<Figure 5.1>1) Main circuit is is open

The closing and opening spring are discharged

<Figure 5.2>2) Main circuit is open

The closing spring is charged The opening spring is discharged

<Figure 5.3>3) Main circuit is closed

The closing spring is discharged The opening spring is charged

<Figure 5.4>4) Main circuit is closed

The closing and opening spring are charged

1413

Pro-MEC VCBPro-MEC VCB

① Insulation rod② Lower terminal③ Shunt④ Vacuum interrupter⑤ Upper terminal⑥ Heat sink⑦ Tulip contactor

⑦

⑥

⑤

④

③

②

①

1) Open position 1Figure 5.1 shows the main circuit is open status, the closing spring(2) and the opening spring(3) are discharged status. If the gear cam(12) is rotated clockwise by manual or electrical motor, then the closing spring(2) will be charged.

4) Closing position 2According that the main circuit is transferring to the closed status, the motor(4) is operatedagain and the discharged closing spring (2) will be recharged.Figure 5.4 shows the main circuit is the closed status and the closing spring is rechargedstatus.If the trip latch(11) release the roller (16) by a trip signal, the main circuit will be tripped bythe driven shaft(7) is rotated counter-clockwise.At this time it becomes the status as Figure 5.2 that the opening spring(3) is discharged

and the closing spring(2) is charged status.

2.1 Description of operation for each position

2) Open position 2Figure 5.2 shows the main circuit is open status and the closing spring(2) is charged.In this situation, the crank shaft (13) connected with the closing spring (2) is located passing through the Death Point and is getting a rotation force of clockwise, but it maintains the current situation since the roller of closing latch (14) is engaging this rotation. At this time the motor will be stopped when the closing spring is charged completely.

3) Closing position 1Figure 5.3 shows the main circuit is closed status and the opening spring is only charged.If the roller(14) is released from the cam of crank shaft (13) by a closing signal, the crankshaft will be rotated clockwise. At the same time the driving shaft(6) connected with linkages and the driven shaft(7) are rotating mutually and the closing operation will be completed. At this time the opening spring is charged and tit maintains the closed statussince the trip latch(11) is engaging the roller(17) connected with the driven shaft(7)even if the driven shaft(7) is getting a force counter-clockwise by the opening spring.

Structure and operation

<Figure 6> Structure of main circuit parts

Structure and operation

3. Main circuit parts

1615

Pro-MEC VCB Pro-MEC VCB

Bellows shield

Ceramic

Arc shield

Splash shield

Fixed end header

Bellows

Contact

Fixed electrode

< Figure 7> Structure of vacuum interrupter

4. Vacuum Interrupter (V.I.)

-5 The vacuum interrupter has high insulation level with high vacuum integrity

(approx. 5x10 Torr) and the gaps of between a stationary contact and moving moving contact are 6~20mm according to the rated voltage.Both contacts are designed to eliminate the arc easily and are made of special alloy in order to reduce the contact wearing by short circuit interruption and overload,or arc energy when switching.And the complete insulation of internal part prevents from the deterioration ofvacuum integrity.

Structure and operation Insertion/Withdrawal Operation (E,F Class)

The withdrawable circuit breaker can be positioned at two following positions in a cradle.

· Test Position (TEST)· Run Position (RUN)

1. Method of insertion

1) Verify that the contact position indicator is at “OFF” by pressing the trip button on

the front of circuit breaker.

2) Insert both wheel of a circuit-breaker inside both guide rail of a cradle, then push and insert a circuit breaker to the Test Position (TEST).

3) Hold the interlocking lever up on the front of circuit breaker with enough, then the interlocking bar will be pull out of from a rectangular hole of interlocking plate in a

cradle.

4) At the condition of holding the interlocking lever up, hold the handle of circuitbreaker and insert a circuit breaker into a cradle. It is not necessary to hold the interlocking lever after moving it in variable distance(about 10mm)

5) Insert the withdrawal lever into the withdrawal plate, then push and insert the interlocking lever to the arrow direction in Figure 8 to insert the interlocking leverinside a rectangular hole of the Run Position (RUN) in a cradle.

6) If it is connected completely the interlocking lever is inserted inside a rectangular holeof a cradle. It is Run Position (RUN)

2. Method of withdrawal

1) Verify that the contact position indicator is at “OFF” by pressing the trip button on the front of circuit breaker.

2) Insert the interlocking lever into the withdrawal plate and pull the withdrawal lever out to the arrow direction in Figure 8 at the condition of holding the interlocking lever up.

3) When the main contacts of circuit-breaker are away from the terminals of cradle, remove the withdrawal lever and withdraw a circuit breaker to the Test Position(TEST)by holding the handle of circuit breaker.

4) At this position the interlocking bar will be inserted into a rectangular hole of cradle.It is Test Position (TEST)

Movable terminal

Movable end plate

17 18

Pro-MEC VCB Pro-MEC VCB

Insertion/Withdrawal Operation (G Class)Insertion/Withdrawal Operation (E,F Class)

<Figure 8> Operation drawing of circuit breaker’s insertion/withdrawal

Keep the VCB only at “TEST” or “RUN” position, don’t keep the

VCB other place except “TEST’ or “RUN” position.

CAUTION

For insertion

For withdrawal

Withdrawal Lever

Interlock plate

Interlock Lever

Interlock bar

For the completion of withdrawal and insertion operation, you should insert wheel(Figure 9.1/No.3) of withdrawal device into square hole which is located inboth right and left of cradle or switchgear.

1. Manual insertion (TEST position → RUN position)1) The connect of control circuit should be connected with circuit breaker.2) Check the position of indicator. circuit breaker indicate “open”.3) The withdrawal handle should be inserted completely to the withdrawal screw.

(Figure 9.1/No.1)4) When the withdrawal handle is rotated about 40 times on CW, circuit breaker is

inserted into RUN position and conflicts sound is happened due to the idling.5) If you hear the sound of continuous bumps, the circuit breaker doesn’t proceed

furthermore, therefore you can get rid of draw-out handle.6) You should check the name plate of “RUN”.

2. Manual withdrawal (RUN position→TEST position)1) Check if the circuit breaker is in the open position through position indicator of

VCB.2) You should do the withdrawal operation in the reverse order of the insertion

operation.3) You should check the name plate of “TEST” indicated in this position.

①Withdrawal screw② Handle③Wheel

<Figure 9.1> Test position of withdrawal device

③

②①

Keep the VCB only at “TEST” or “RUN” position, don’t keep the

VCB other place except “TEST’ or “RUN” position.

CAUTION

19 20

Pro-MEC VCBPro-MEC VCB

<Figure 9.2>Run Position of withdrawal assembly

Withdrawal Stroke :310 mm (24kV)

<Figure 10.1> CB is at Closed Position <Figure 10.2> CB is at OPEN position

Insertion/Withdrawal Operation (G Class)

3. Interlocks for withdrawal/insertion of circuit breaker

1) Preventing a withdrawal/insertion during a circuit breaker closing operation

① Withdrawal Screw ⑤ Interlock bar② Lock pin ⑥ Plate③ Nut ⑦ Bearing④ Nut Assembly

Insertion/Withdrawal Operation

2) Closing prevention during a withdrawal/insertion of circuit breaker

<Figure 11> Structure of closing prevention duringwithdrawal/insertion of circuit breaker

When making a withdrawal/insertion of circuit breaker it prevents from the closing electrically so that the interlock bar(Fig11/No.3) operates a micro switch(Fig.11/No.2)and the closing coil can not be energized. It also makes mechanical closing prevention by means of not operating a push button.

If the circuit breaker is inserted, the Lock Pin(Fig.10.1/No.2) is disconnected from the Nut(Fig.10.1/No.3) according that the interlock bar(Fig.10.1/No.5) move the Plate(Fig.10.1No.6) to left-hand position.At this condition the Nut Assembly(Fig.10.1/No.4) can not be moved even if rotating the withdrawal screw(Fig.10.1/No.1) and the withdrawal screw(Fig.10.1/No.1) and the Nut(Fig.10.1/No.3) are to be run-idle.For this reason it is not possible to operate the circuit breaker for withdrawal and/or insertion at the status of running idle –i.e. at the closed status of circuit breaker.But it may be possible to be withdrawn or inserted so that the Nut Assembly(Fig.10.1/No4)can be moved before and behind.

① Closing Button② Micro Switch③ Interlock Bar④ Position Plate

21 22

Pro-MEC VCB Pro-MEC VCB

Maintenance and inspectionInsertion/Withdrawal Operation

1. General4. Interlocks for earthing switch

<Figure 12> Structure of interlocks for earthing switch andwithdrawal/insertion

①

②

③

④

⑤ ⑥ ⑦ ⑧

⑨

⑩

1) Prevention of a withdrawal/insertion during the closing circuit breaker.If the handle is inserted into the operating shaft(Fig.12/No.2) for closing the earthingswitch by opening the lever(Fig.12/No.5) right-hand, the cam plate(Fig.12/No.3) will be moved left- hand by the interlock lever(Fig.12/No.7) and the circuit breaker can not be inserted or withdrawn with a run-idle of screw.

2) Impossible of earthing switch’s closing during a withdrawal/insertion or at the Run Position(RUN)During a withdrawal/insertion or at the Run Position(RUN) the earthing switch closing handle will not be inserted so that the lever(Fig.12/No.5) can not be opened because the interlock lever 2(Fig.12/No10) can not be rotated by the truck(Fig.12/No.9).

DANGER

1. Only a qualified electrical workers with training and experiencehigh voltage circuits should perform any operation, maintenance and inspection. may result in malfunction, severe bodily injury or electric shock. .

2. When the contactor is in service, do not open the front cover.may result in bodily injury or electric-shock

3. When the contactor is in service, do not insert or withdraw thecontactor.may result in bodily injury or electric-shock

4. Before performing any inspection or maintenance on this device,disconnect all sources of electric power and take every precautions to see that all connections are de-energized andgrounded. may result in severe bodily injury or electric shock.

5. When making bolts and screw assembling, follow the instructionwith recommended torque values may result in over heating or burns..

6. After performing installation, maintenance, inspection, remove some foreign objects like tools, test leads or bolts, instruments.may result in short circuit or burn.

7. When performing a maintenance, make a power-off of contactorand maintain it at the test position.may result in electric shock.

8. Do not move the contactor by handling main circuit bus terminals.may result in an electric accidents by temperature increasing

WARNING

Do not make any touch to charged parts electrically like conductors, terminals and disconnects etc., under any of energized condition.Will result in electric shock, severe bodily injury or electrocution.NO. NAME

① Earthing S/W② Operating shaft③ Cam④ Pad lock⑤ Lever⑥ Shaft weld⑦ Interlock lever1⑧ Cam plate⑨ Truck⑩ Interlock lever2

23 24

Pro-MEC VCB Pro-MEC VCB

Maintenance and InspectionMaintenance and Inspection

1. Do not alter the control circuit at one’s discretion.may cause of malfunction or damage to products.

CAUTION

<Table 2> Period of maintenance and inspection

Item

Routine inspection

Periodical inspection

Special inspection

Maintenance and inspection interval

Normal condition Abnormal condition(dusty and wet places)

6 months

6 months after an installation. Once 3years after that

If necessary

1 month

A periodic inspection

If necessary

2. Routine inspectionMake an inspection for the contactor on service between the periodic inspection.Be careful for not getting in touch with any energized parts when opening the doorof switchgear.

Ins pection item Ins pection Method Corrective action

Switching indicator Verify ing a normal operation Vis ual Inves tigating the caus e and repair

Control circuit Verify ing a connection of conne Vis ual Inves tigating the caus e and repair

Operating counter Verify ing a time of operation Vis ual Check the contactor if exceeding 10,000 operations

Others Verify ing abnormal noise,smell Vis ual Af ter disconnecting the m ain power, inv estigat ing and repair

3. Periodical inspection

<Table 4> Items of periodic inspection (1)

Inspection item Inspection Method Corrective action Interval

Operation and Equipment parts

Check abnormal assembling parts

Check parts to be lubricated

Check dust and foreign material

Check whether C-Rings,spring pins and dividerpins are wrinkled or missed

Verify a smoothoperation by visual or manual

Clean and grease

Replace if necessary

Control circuit

Wiring

Closing,trippingdevice

Aux. Switch

Poor connection and/orloose wirings

Check component of movableparts.

Check a discoloration of coil

Check links and contacts

Visual

Retighten any loose parts

Replace if necessary

Every a periodicinspection,

Every 5000operations

Every periodic inspection

25 26

Pro-MEC VCBPro-MEC VCB

Maintenance and Inspection

4. Special inspection

Make a special inspection in case of situation as Table 6

1When interrupting short-circuit(fault) current several times

Check wearing contacts of vacuum interrupter

Inspection item Inspection methodNO

2 In case of appearing a abnormal situation at service operation

Check defective parts

<Table 6> Special inspection

Maintenance and Inspection

Common components of the contactor

Insulated frameInsulated tubeHeat shrinkable tube

Check condensation, humidity, stain, discoloration and damage

Visual

Clean it, then measure the insulation resistance

Inspection item Inspection Method Corrective action

<Table 5> Items of periodic inspection (2)

Wipe it clearly with a dry cloth

27

Inspection item Inspection Method Corrective action Interval

Main circuit terminals

Check all connections Visual

Check the torque,Replace ifnecessary

V.I

Every aperiodic inspection

Aux.Device

Vacuumintegrity

SwitchingIndictor

Check the vacuum density

Check the normal operation

Vacuum integrityTesting method.Check withstand test

Visual

Replace V.I. if necessary

Check fixed bolts.Replace if necessary

Everyperiodicinspection,

Every 5000 operations

InsulationResistance

Main circuit: Over 500MΩ1000V Megger

500V Megger

Clean it afterfinding the cause.

Replace if necessary

Everyperiodicinspection

Withstand voltagetest

Test and checkwith a withstandvoltage tester

Operating characteristicstest

Testing for trip/closeTesting for trip-freeCheck the minimum of operating voltage

Perform the electrical testing after a manual operation test

Inspect and repairif finding a matter.Replace if necessary

Every periodic inspection,every5000 operations

Check the corrosion, discoloration

Control circuit: Over 2MΩ

Clean and replace if necessary

Every periodic inspection, Every 1,2 years

Main circuit: 1.5 x R.Voltagefor 10 min.

28

30

630 1250 630 1250 2000

41

3

0.47

Rating LVB – 20 - 13D,E/06,12 LVB – 20 - 25D,E/06,12,20

24

50/60

12.5

520

12.5/3sec

32.5

25

1000

25/3sec

65

125

50/1min

O-0.3s-CO-3min-CO

≤ 0.06

4a4b

≤ 0.04

P,E,F,G,M

IEC 62271-100

160140

≤ 7 (at 24Vdc ≤15)

210 / 265

≤ 5 (at 24Vdc ≤10)

≤ 12 (at 24Vdc ≤15)

DC 24,48,110,125,220V

DC 24,48,110,125,220V

Pro-MEC VCBPro-MEC VCB

①

④

③

②

⑤

⑥

5. Lubricant Points for Operating Parts

Maintenance and Inspection

When using the circuit breaker for long period, lubricate the grease for mechanicaldevice on the surface of operating parts and frictional parts so that the operating mechanism parts have been operated with high-speed. The important parts are indicated by the mark of in the following figure.When lubricating clean the points to be lubricated and check the condition of wear,then lubricate the grease not to be covered on wiring connection part of control circuit.

<Figure 13> The charging status of opening/closing spring of main circuit

NO LubricantPoint

1 Fixing part of opening spring

2 Fixing part of closing spring

3

4

5

Connecting pin of linkage

6

Closing latch roller and crank arm

Trip latch and roller

Guide pin for O.D.P

Rating

Frequency (kV)

TRV Max. Value (kV)

Pole distance (mm)

Rated opening time (s)

Standard aux. contacts

Control voltage for tripping (V)

Current of motor operation (A)

Control current for closing (A)

Control current for tripping (A)

TRV increasing rate (kV/)

Rated voltage (kV)

Rated current (A)

Rated frequency (Hz)

Rated short -circuit current (kA)

Rated interrupting capacity(MVA)

Rated short-time current (kA)

Rated making current (kA)

Rated interrupting time (Cycle)

Control voltage for closing (V)

Operating duty

No-load closing time (s)

Applicable standard

Weight (kg)

Motor charging time (s)

Installation type

Withstand voltage Lightning Impulse

(kV/1.2x50)

<Table 7> Ratings Table

≤ 5 (at 24Vdc ≤10)

29

Pro-MEC VCB

Circuit diagram

1. AMP jack

31

Pro-MEC VCB

Circuit diagram

2. Phoenix jack

32

Pro-MEC VCB

Circuit diagram

3. AMP jack – AC110V(Motor,Closing Coil), DC110V(Tripping Coil)

33