2.3.4 Compressor Bleed Air

-

Upload

elmokadem-einstein -

Category

Documents

-

view

16 -

download

0

description

Transcript of 2.3.4 Compressor Bleed Air

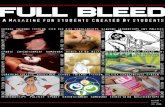

2.3.4 Engine Compressor Bleed Air System

TCB1-1 2.3.4-1

AIR INTAKE DUCT

5TH STAGE

5TH STAGE

10TH STAGE

DRAIN

AUTO TRAP

S

S

S

S

S

A40AA401

A41AA052B

A42AA051B

A41AA052C

A41AA052A

A42AA051A

A41BS002

A42BS002

A40AA201

A40AT001

A41BS003

A41BS001

A42BS001

A21AA251

A41AA051

A41AA052

A42AA051

A40BP001

A40CT203

16TH STAGE

TCB1-1BJ

GAS TURBINE COMPRESSOR BLEED AIR SYSTEM(MBA)

ACCUMULATOR

X40BB 001

2.3.4 Engine Compressor Bleed Air System

The purpose of the compressor bleed air system is to prevent compressor surge or stall during low speed (low air flow) operation of the engine's rotor. The axial flow compressor of the engine is designed to operate at 3,000 RPM. During operation, speed must remain within a defined tolerance of the design operating speed of 3,000 RPM. At speeds below the permissible range, the front of the compressor would be so highly loaded aerodynamically that air flow would separate at the compressor blading surface, due to excessive deceleration. As a result the overloaded compressor stages are no longer capable of generating the necessary increase in pressure, the compressor stalls and the air flow becomes unstable.

The break down of air flow patterns results in periodic reversal of the air flow (surge), which is characterized outwardly by pronounced, periodic fluctuations in the compressor at the final compressor stage together with severe vibration of the engine and pulsating noise synchronous with the pressure fluctuations. This endangers the compressor blades, which are subject to high alternating bending stresses and high temperatures.

Since the turbine has to be operated below the compressor's design operating speed during start up and shutdown, air must be bleed off from selected compressor stages to prevent the compressor from surging. Compressor air flow may also become unstable when the engine is operating in an under frequency condition. The compressor bleed air valves are therefore opened when the engine rotor speed drops below the allowable limits from design operating speed.

Two compressor bleed air lines are connected to the compressor stage 5 and one each to compressor stage 10 . The bleed lines open into the turbine exhaust. As a result, the exhaust silencer simultaneously functions as a silencer for the compressor bleed air. Each compressor bleed air line is provided with a bleed valve, which is opened when compressor bleed air is to be vented. These valves operate in either the full open or full closed position by dual plenum pneumatic actuators.

r Stage 5 Valve 1.1 ( A41 - AA051 )r Stage 5 Valve 1.2 ( A41- AA052 )r Stage 10 Valve 2 ( A42 A A051 )

TCB1-1 2.3.4-2

AIR INTAKE DUCT

5TH STAGE

5TH STAGE

10TH STAGE

DRAIN

AUTO TRAP

S

S

S

S

S

A40AA401

A41AA052B

A42AA051B

A41AA052C

A41AA052A

A42AA051A

A41BS002

A42BS002

A40AA201

A40AT001

A41BS003

A41BS001

A42BS001

A21AA251

A41AA051

A41AA052

A42AA051

A40BP001

A40CT203

16TH STAGE

TCB1-1BJ

GAS TURBINE COMPRESSOR BLEED AIR SYSTEM(MBA)

ACCUMULATOR

X40BB 001

2.3.4 Engine Compressor Bleed Air System ( Continued )

When the engine is started up on natural gas fuel each of the compressor bleed air valves are closed as a function of engine speed. Each one is closed as soon as permissible to maximize the amount of air that can flow through the burners and the amount of fuel that can be added. This reduces the starting time of the gas turbine generator. When the engine is in a shutdown condition all of the compressor bleed air valves are in the full open position. During start up, on gas fuel, compressor bleed air valve 2 closes at 80% of the design operating speed and compressor bleed air valve1.2 at 98%. Compressor bleed air valve 1.1 closes 5 seconds after valve 1.2.

During start up on liquid fuel, all of the compressor bleed air valves remain open until after the gas turbine engine is at 3,000 RPM and the main generator circuit breaker is closed. Valve 1.1 is closed immediately upon closing of the circuit breaker. Valve 1.2 closes 5 seconds later. Valve 2 is closed 10 seconds after breaker closure. The reason for keeping the compressor bleed valves open until after breaker closure and loading, is to improve flame stability by minimizing air flow through the combustor.

During a shutdown sequence, when operating on either liquid or gaseous fuel, all of the compressor bleed air valves are opened immediately when the emergency fuel shut off valves are de-energized closed, in preparation for a deceleration of the engine's rotor below the compressor's design operating speed. The compressor bleed air valves are pneumatically closed and held closed by air pressure, when the air supply solenoid valves are energized (A41-AA052A through A42-AA051B). When the solenoid valves are de-energized the compressor bleed air valves will be forced open by the air supply pressure.

The position of the compressor bleed air valves are each monitored for the correct position by one limit switch for the closed position and two limit switches for the open position. If the valves are in the incorrect position an alarm is initiated by the control system. All of the valves must be in the open position as a permissive to start the gas turbine generator. After an off line water wash of the compressor the gas turbine generator is started up and accelerated to synchronous speed for the purpose of drying out the engine. If the start up is on gaseous fuel, the compressor bleed air valves should be manually opened at this time, from the control operating screen to expel water that collected in the compressor bleed air piping during the off line was

None 2.3.4-3