2014 Draught Beer Quality Workshop Draught System … · Draught System Design 1. System component...

Transcript of 2014 Draught Beer Quality Workshop Draught System … · Draught System Design 1. System component...

DraughtSystem Design

1. System component choices

2. Balance and design calcs

3. Making sense of it?

2014 Draught Beer Quality Workshop

Jaime [email protected]

DraughtQuality.org

Monday, October 6, 14

not today....Monday, October 6, 14

TEMPERATURE PARAMETERS

Temperature of many Keg Beers: In cooler: 36o F At faucet: 37o F - 39o F

1/2-bbl keg (36 F): if room is at 90 deg F, rise in temp of 20 deg F in 2 hours. A keg at 50 deg F delivered into a 36 deg F cold room

requires 3 days to equilbrate.

• Consistent Quality• Clean and brilliant• Full of condition• Palate - no off tastes• Good head formation• Lasting head retention

Monday, October 6, 14

Direct Draw

DraughtQuality.orgMonday, October 6, 14

cooling options

See page 26 of , “freeze tower” drawing!

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

See page 24, “Shadow Box” drawing!

Monday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

fan

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

--------------------return

-----------------supply1

2

3 4

5

6

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

FOB (Flow of Beer) Stop

100 ftof 3/8 in. lineHolds 6 beers

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

Monday, October 6, 14

DraughtQuality.orgMonday, October 6, 14

Monday, October 6, 14

Monday, October 6, 14

40 deg F44 deg F

Monday, October 6, 14

40 deg F44 deg F

Monday, October 6, 14

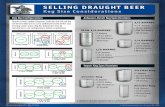

No. of glasses per 1/2-Bbl keg Glass Size 8 oz 10 oz 20 oz

Drawn Flat 248 198 99

w/20% Foam 310 248 124

…of course, no waste is considered here!

DraughtQuality.orgMonday, October 6, 14

Gases Increase SolubilityWith Lowering Temperature

FOR EXAMPLE: at 60o F - 1 gallon of CO2 gas at atmospheric pressure will

dissolve in 1 gallon of beer. at 32o F - 1.71 gallons of CO2 gas at atmospheric pressure

will dissolve in 1 gallon of beer.If we have 1 gallon of CO2 in 1 gallon of beer, we say we

have 1 volume of CO2.

DraughtQuality.orgMonday, October 6, 14

EQUILIBRIUMSee page 37, “Carbonation Dynamics” discussion!

DraughtQuality.orgMonday, October 6, 14

EQUILIBRIUMBeer now has 1 gallon of CO2 dissolved in it.The equilibrium condition is 1 volume CO2 in

solution at 0 PSI and 60o F.

See page 37, “Carbonation Dynamics” discussion!

DraughtQuality.orgMonday, October 6, 14

EQUILIBRIUMAdd more gas: CO2 is now being restrained in solution by 22

PSI pressure.The new equilibrium condition is 1 + 1.5 volume = 2.5

volume CO2 at 22 PSI and 60o F.

See page 37, “Carbonation Dynamics” discussion!

Monday, October 6, 14

HYPOTHETICAL DRAFTINSTALLATION

A

B C

D

E

F

G

HI J

B - J Length of line = 70 feet = 4.5 psiA - D Lift 1 = 6 feet = 3.0 psiG - H Lift 2 = 3 feet = 1.5psiB - C Keg coupler = = 1.0 psiD - E Bend in line #1 = = 1.0 psiF - G Bend in line #2 = = 1.0 psiH - I Bend in line #3 = = 1.0 psiJ faucet = = 4.0 psi

TOTAL = 17.0 psi

3/8 in barrier 0.06 psi/ft

See page 36, “BEER TUBING” Table!

E-F

DraughtQuality.orgMonday, October 6, 14

5

10

15

17.5

70

A

B

C

D

E

FG

H

I

J

EQUILIBRIUM2.5 vols at 39 deg F

Sensitive Beer

0

0 Distance from the keg

---11.9--------------------------------------------------------------

Monday, October 6, 14

RESTRICTION Resistance in dispense is made up of:$a) Hydrostatic head: 1 - 1.5 psi/ft of vertical lift.$b) The combined friction of the beer trunk, jumper, choker, etc.$$ Length of LLDPE trunk req’d per 1 psi resistance:$$ $ $ $ $ Horiz run: 60 feet$$ $ $ $ $ Vertical . . . 9 feet

A

B C

D

E

F

G

HI J

B - J Length of line = 70 feet = 4.5 psiA - D Lift 1 = 6 feet = 3.0 psiG - H Lift 2 = 3 feet = 1.5psiB - C Keg coupler = = 1.0 psiD - E Bend in line #1 = = 1.0 psiF - G Bend in line #2 = = 1.0 psiH - I Bend in line #3 = = 1.0 psiJ faucet = = 4.0 psi

TOTAL = 17.0 psi

5

10

15

17.5

70

A

B

C

D

E

FG

H

I

J

EQUILIBRIUM2.5 vols at 39 deg F

Sensitive Beer

0

0 Distance from the keg

EF

Monday, October 6, 14

Pounds per Square Inch5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

30 2.23 2.36 2.48 2.60 2.70 2.82 2.93 3.0231 2.20 2.31 2.42 2.54 2.65 2.76 2.86 2.9632 2.15 2.27 2.38 2.48 2.59 2.70 2.80 2.90 3.00 3.11 3.2133 2.10 2.23 2.33 2.43 2.53 2.63 2.74 2.84 2.96 3.06 3.15 3.2534 2.06 2.18 2.28 2.38 2.48 2.58 2.69 2.79 2.90 3.00 3.09 3.1935 2.02 2.14 2.24 2.34 2.43 2.52 2.63 2.73 2.83 2.93 3.02 3.12 3.2236 1.98 2.09 2.19 2.29 2.38 2.47 2.57 2.67 2.77 2.86 2.96 3.05 3.15 3.2437 1.94 2.04 2.14 2.24 2.33 2.42 2.52 2.62 2.71 2.80 2.90 3.00 3.09 3.18 3.2738 1.90 2.00 2.10 2.20 2.29 2.38 2.48 2.57 2.66 2.75 2.85 2.94 3.03 3.12 3.2139 1.86 1.96 2.06 2.15 2.25 2.34 2.43 2.52 2.61 2.70 2.80 2.89 2.98 3.07 3.16 3.2540 1.83 1.92 2.01 2.10 2.20 2.30 2.39 2.47 2.56 2.65 2.75 2.84 2.93 3.01 3.10 3.19 3.2841 1.79 1.88 1.97 2.06 2.16 2.25 2.34 2.43 2.52 2.60 2.70 2.79 2.88 2.96 3.05 3.14 3.2342 1.75 1.85 1.94 2.02 2.12 2.21 2.30 2.39 2.48 2.56 2.65 2.74 2.83 2.91 3.00 3.09 3.18 3.2643 1.72 1.81 1.90 1.99 2.08 2.17 2.26 2.34 2.43 2.52 2.61 2.69 2.78 2.86 2.95 3.04 3.13 3.2144 1.69 1.78 1.87 1.95 2.04 2.13 2.22 2.30 2.39 2.47 2.56 2.64 2.73 2.81 2.90 2.99 3.07 3.16 3.2445 1.66 1.75 1.84 1.91 2.00 2.08 2.17 2.26 2.34 2.42 2.51 2.60 2.69 2.77 2.86 2.94 3.02 3.11 3.1946 1.62 1.71 1.80 1.88 1.96 2.04 2.13 2.22 2.30 2.38 2.47 2.55 2.64 2.72 2.81 2.89 2.98 3.06 3.15 3.2347 1.59 1.68 1.76 1.84 1.92 2.00 2.09 2.18 2.26 2.34 2.42 2.50 2.59 2.67 276 2.84 2.93 3.02 3.09 3.18

To use this chart: First find the beer temperature along the left hand vertical edge. Then read the pressureacross the top and where the two cross, read the volumes of CO2.

Sea Level See page 38, “sea level” CO2 chart!

Fo

Monday, October 6, 14

Determination of needed Mixed Gas Composition

1.Determine equilibrium absolute pressurea to maintain the proper level of CO2.

2.Determine the total absolute gas pressure to move the beer to the tap.

3.Divide the equilibrium absolute CO2 pressure by the total absolute gas pressure to obtain the CO2 portion of the gas.

aabsolute pressure = gauge pressure + atmospheric pressure (i.e. 14.7 psi @ sea level; 10.1 psi @ 10,000 ft)

Monday, October 6, 14

Absolute pressure consideration: Beer at 39 deg F in keg...2.65 vol CO2

50 in of 1/4 in vinyl*line + 3 ft 3/16 vinyl** +18 ft of 5/16 in. barrier*** beer line.

***(18 ft)(0.3 psi/ft) = 6 psi

* (4.2 ft)(0.85 psi/ft) = 3.54 psi**(3 ft)(3 psi/ft) = 9.0

jumper

choker

trunk

Monday, October 6, 14

Absolute pressure consideration: Beer at 39 deg F in keg...2.65 vol CO2

50 in of 1/4 in vinyl*line + 3 ft 3/16 vinyl** +18 ft of 5/16 in. barrier*** beer line.

(13.5 psig+14.7 psig) / (18.54 psig+14.7 psig) = 84% CO2, and 16% nitrogen...

NOT 13.5/14.13 = 96 % plus 4 %!

***(18 ft)(0.3 psi/ft) = 6 psi

* (4.2 ft)(0.85 psi/ft) = 3.54 psi**(3 ft)(3 psi/ft) = 9.0

jumper

choker

trunk

Monday, October 6, 14

Absolute pressure consideration: Beer at 39 deg F in keg...2.65 vol CO2

30 in of 3/16 in LLDPE line + 18 ft of 1/4 in. polyvinyl beer line.

Monday, October 6, 14

Absolute pressure consideration: Beer at 39 deg F in keg...2.65 vol CO2

30 in of 3/16 in LLDPE line + 18 ft of 1/4 in. polyvinyl beer line.

(13.5 psig+14.7 psig) / (24 psig+14.7 psig) = 73% CO2, and 27% nitrogen...

NOT 13.5/24 = 56 % plus 44 %!

Monday, October 6, 14

Monday, October 6, 14

MIXED GAS

CO2 = 100% CO2ie. 10 PSI = 10 PSI of CO2

60N2 / 40 CO2 = 40% CO2ie. 10 PSI = 4 PSI of CO2

N2 is sparingly soluble(n.b.: ‘gauge pressure’ simplification)

Monday, October 6, 14

Monday, October 6, 14

Mixed gas: Guinness blend ‘heel’…all other blends costlier

Monday, October 6, 14

Monday, October 6, 14

DraughtQuality.orgMonday, October 6, 14