2012 April Downer - BRP Road Patch Presentation

-

Upload

skelleyreskic -

Category

Documents

-

view

146 -

download

2

Transcript of 2012 April Downer - BRP Road Patch Presentation

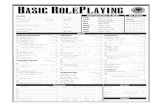

What is the BRP Road Patch?

• Prefabricated sheets (1.00m x 0.75m)

• High quality flexible rubber bitumen spray

seal (22% natural rubber)

• Has the option of 5 varying aggregate

• Requires no plant or capital equipment for

installation

• secured to surface with emulsion

Innovative & Proven

The BRP Road Patches prefabricated sheet

format is true innovation providing an easily

installed cost effective durable solution for

Pavement Sealing, Pavement Maintenance &

Traffic Calming

Launched in Sth Africa in 1986 and used by

Downer in NZ since 2008, the BRP Road Patch

“adds another tool to the toolbox”, expanding &

enhancing the options for maintenance and

safety programs.

Product Versatility

• Pavement Maintenance • Pothole repairs • Crocodile Cracking• Edge-break repairs• Rut Filling

• Pavement Sealing• Crack seal repairs (cut strips as necessary) • Restoration of waterproof seal coat

• Traffic Calming & Management• Speed Humps• Rumble Strips• Kerb Extensions

• Other

• Skid resistance

• Sealing construction joints

• Holding/Temporary repairs

• Waterproofing wooden bridge

& decks

• Ramp traction for Boat

Ramps, foot bridges etc

• Water Diversion

• Road Marking Obliteration

• plus more

Product has been used

Surfaces it can be used on

It has proven performance adhering to the following surfaces

• Bitumen

• Concrete

• Wood

• Steel

• Iron

• Aluminium

• Stainless Steel

The key: Restoration of a Waterproof Surface

BRP Road Patch

Defect or TrenchHidden

structural damage

Restore the pavement defect as normal and then overlay the repair with a BRP Road Patch extending past repair edges by 100mm to seal

hidden structural damage and provide a truly waterproof surface

100mm

Does it cause a Bump?

NoYes

A bump (rumble strip, speed hump) can be created by applying larger Aggregate Patches to the surface.

Match the surface aggregate and the patch will integrate with the surface matrix becoming unnoticeable to road users

5 Step Application Procedure

Ensure surface is ≥10 degrees Celsius and rising.

Sweep area free of loose material.

Mark out the area to be sealed (defect area plus 100mm in all directions)

Cut the BRP Road Patch to the required size / shape.

Step 1 - Prep

Evenly apply cationic 60% (or similar) emulsion to the road surface and the back of the BRP Road Patch. Apply as if painting, no puddles and no dry areas.

When the emulsion turns black and is very sticky place BRP Road Patch over the prepared area.

Step 2 - Adhesion

Step 3 - Position

5 Step Application Procedure

Roll with rubber tyred vehicle, (no steel) In high stress turning or breaking areas, cold or if rain is imminent additional rolling is recommended.

Sand seal the edges and joints with a small quantity of emulsion and sand.

Step 4 - Seal Step 5 - Roll

5 Step Application Procedure

In 5 simple steps the issue has been quickly resolved, protected against further water damage, leaving a neat appearance with minimal financial & social costs.

Prep RollSealPositionAdhesion

5 Step Application Procedure

Installation Instructions are also included on the label found on every pack

Flexibility

Down-size

Up-sizeShaping

Standard size1.000m x 0.750m

Ability to use every piece of the patch means No Wastage

Trafficable Immediately

Straight after installation these patches where driven on by a Lumber and a Garbage truck at 100kph

Proactive 0.75m2 Crocodile cracking

1 site visit by the maintenance crew

Approx $75 cost

Reactive6 potholes

2m2 AC leveling24m2 dig-out

7 site visits by the maintenance crew

Approx $750 cost

BRP Road Patch

Proactive Maintenance

Pothole Repairs

“Reactive strategies” have their limitations.

“Proactive strategies” are cost and operationally

efficient.

Improved Repair Presentation

loose sealing chip

loose base-course

AC in a chip seal road

Same day finishmatching texture

BRP Road P

atch Repair

Cracking Repairs

Feb 2012 City of Kingston, Southern Rd Mentone VIC – Crocodile Cracking with pumping fines would normally require a dig out but was instead overlaid with BRP Road Patch which restored a waterproof surface, preventing further pavement decline

Cracking Repairs

City of Mandurah WA – Has successfully used the BRP Road Patch to address longitudinal and crocodile cracking in high traffic areas ensuring the pavement remains intact until schedule works

Old Traffic Bridge Mandurah WA July 09

Pinjarra Rd Mandurah WA – Dec 2010

Micro surfacing Pre Treatment

Feb 2012 Kingston City Council VIC – Severe Crocodile Cracked Macadam Pavement overlaid with BRP Road

Patch to provide a protective pretreatment for a Downer Flexitex

Micro surfacing wearing course

Cracking Repairs

Entrance to Koo Canning Factory South Africa a 24hr/6.5 Day per week operation meant repairs to road cracking could only be done Sunday morning

whilst workers attended church. Work was completed during this period and opened to traffic

immediate upon completion

Driver Alert

Vic Roads Rumble Strip Project Princes Hwy between

Stratford & Bairnsdale VIC

Rumble Strips provide an audible and felt alert to drivers without affecting the handling performance of

the vehicle

Driver AlertVic Roads Rumble Strip Project Princes Hwy

between Stratford & Bairnsdale VIC

Rumble Strips provide an audible and felt alert to drivers without affecting the handling performance of the vehicle

Traffic Calming

Extension of kerb enables truck and trailer units to utilise sealed area

Nelson City using BRP Rumble Strips to deter Car Hoons

Trench Sealing

Clean stony surface

Single man compacted and sealed the

pavement after a trench repair

Line Marking Obliteration

Bitumen depletion in asphalt due To water blasting

BRP Road Patch can be used to cover unwanted road markings without damaging the road seal

Extreme case

Bridges

2011 - The single lane timber bridge on SH 8 (Beaumont Bridge) from Balclutha to

Alexandra NZ was sealed by Downer using the BRP Road

Patch and holds the record for the largest job sealed (520m2)

with the BRP Road Patch in New Zealand.

Tokomairiro Bridge SH 8, Joint construction

Product Storage & Handling

• Storage and

Handling Instructions

are included on the

label found on every

pack

•Additionally separate

Storage and Handling

info sheets are

available with Visual &

Written instructions to

support product users.

Warehousing & Transportation

• Treat with care

• Store undercover out

of direct sunlight

• Single stack pallet

only

• Protect packs when

securing load with

corner covers

If correct pallet storage and handling

procedures are followed it will make onsite

handling easier and provide a >10yr storage

life

Job Site Transportation & Storage

For ease of handling

• Treat product with care

• Store Undercover

• Keep product flat

• Do not roll or fold products when handling

• Keep patch out of heated beds

• Do not top load on patches

• When tying/securing, protect edges

• In elevated temperatures the product

should be left face down to the road surface

for the shortest possible time

Key Benefits

FeatureNew Treatment Option

Simple Installation

Waterproofs pavement

No Capital Equipment required

Non Skilled Labour

No historical constraints

Quick Install

Consumes less fossil fuel.

No Wastage

BenefitExpands current treatment options

Reduces costs.

Reduces rework = Reduces Cost

Reduces Cost = Stretches Budget

Better utilisation of employee time

24/7 availability

Safer for road repairer & user safety

Better for the environment

No landfill use & maximises spend

The BRP Rumble Strips used in a parking area in Nelson, frequented by hoons at night and over the weekends, were a cost effective method of changing driver behaviour. The Council and residents were very pleased with the outcome.Alec Louverdis, Senior Executive Technical services, Nelson City Council. New Zealand

With BRP Road Patches we have been able to complete our reinstatement immediately, to the standard required and at a significant cost advantage to traditional seal repair methods. It's great to have this advantage on demand.Cliff Olsen, Contract Manager – Thames, United Water Ltd. New Zealand

The BRP Road Patch makes small road maintenance or surfacing repairs a breeze for our teams when working in the dense urban high traffic volume areas of Auckland City. It is a very simple road maintenance repair or surfacing method that delivers immediate benefits to our clients. Jim Matangi, General Manager , Blacktop Construction Limited. New Zealand

References

NationalJason Eggleton – Manager Emulsion SalesPH: 03 8645 0812 – Mob: 0411 228 427 Email: [email protected]

Victoria, South Australia David Reinecke - Territory Representative PH: 03 8645 0883 - Mob: 0407 213 794 Email: [email protected]

New South Wales & QueenslandPat Capaan - Territory Representative – NSW & QLDMob: 0457 980 710 Email: [email protected]

New South Wales, Victoria, Queensland, South Australia, Australian Capital Territory and Northern Territory orders can be placed on Toll Free # 1800 655 951

TasmaniaScott Lello - Emulsion Supervisor – Tasmania Ph: 03 6334 1522 - Mob: 0400 523 505 Email: [email protected]

Western AustraliaJason Eggleton – Manager Emulsion SalesPH: 03 8645 0812 – Mob: 0411 228 427 Email: [email protected]

Downer Contacts