2011 QbD and More

-

Upload

alainponcin -

Category

Business

-

view

1.483 -

download

12

description

Transcript of 2011 QbD and More

Quality by Design

ProtAffin Biotechnologie AG

www.protaffin.com

2PROTAFFIN

Quality in Pharmaceutical Industry

20th Century : mostly reactive - validation

– 1950, US : wrong dosage in children syrup– 1960, Europe : thalidomide– Modern drugs are highly active, but also in a wrong way

• Initiation of regulation (EMA, FDA,…)– Acceleration of publications (1960-1980)– Rationalisation (1980-1990) Release of GMP guidelines

• Harmonisation (199O, birth of ICH : Europe, US and Japan)

• Still one of the most unsuccessfull industry

– Only 10 % in preclinical trial reach Market

3PROTAFFIN

But we are in 21th century

• Bill Clinton‘s hobby horse– Safe, effective and accessible drugs for all US citizen– Complete reorganisation of FDA– 2002 : Pharmaceutical Industry for the 21th century

• PAT, 2004

• Quality system, September 2006

• OOS, October 2006

• Process Validation : General Principle and Practices (draft 2008)

• ICH : Quality by Design (QbD) ICH Q8 : Pharmaceutical Development (2005), annex (2007), R1 (2007), R2 (2009) ICH Q9 : Quality Risk Management (2005) ICH Q10 : Pharmaceutical Quality System (2008) ICH Q11 : Development and Manufacture of Drug Substance (concept paper, 2008, draft

expected in 2010)

4PROTAFFIN

A lot of questions from industry

• Authorities :– ICH : Quality Implementation Working Group on Q8, Q9 and Q10

Questions & Answers, last update May 2010 Meetings

• Associations (PDA, EFPIA,...) Meetings, Workshops, training,...

• Meetings (Bioprocess, Bioproduction,...) Meetings, Workshops, training,...

• Industry (GSK,Amgen..) Publication of Mock examples (A mAb, a case study)

5PROTAFFIN

Quality by Design

• Science based– Prior knowledge, platform technology,... Product understanding

Target Quality Product Profile Critical Quality Attributes Control Strategy

Process understanding : Design Space Design of Experiment, multivariate statistics, Baysian statistics,...

• Risk Assessment based Product Risk Assessment Process Risk Assessment (FMEA,...)

• During the entire lifecycle of the product

6PROTAFFIN

Holistic effect of Risk Assessment and Statistics

Product/Process Risk assessment

Critical questions to be solved

DoE and multivariate statistical analysis

What is really critical ? How to master the criticality ?

7PROTAFFIN

Minimal Product Risk Assessment

ICH Q8(R2) : Pharmaceutical development should include, at a minimum, the following elements:

• Defining the quality target product profile (QTPP) as it relates to quality, safety and efficacy, considering e.g., the route of administration, dosage form, bioavailability, strength, and stability

• Identifying potential critical quality attributes (CQAs) of the drug product, so that those product characteristics having an impact on product quality can be studied and controlled;

• Determining the critical quality attributes of the drug substance, excipients etc., and selecting the type and amount of excipients to deliver drug product of the desired quality;

• Selecting an appropriate manufacturing process ;

• Defining a control strategy.

8PROTAFFIN

Enhanced Product Risk Assessment

An enhanced, quality by design approach to product development would additionally include the following elements:

• A systematic evaluation, understanding and refining of the formulation and manufacturing process, including;

o Identifying, through e.g., prior knowledge, experimentation, and risk assessment, the material attributes and process parameters that can have an effect on product CQAs;

o Determining the functional relationships that link material attributes and process parameters to product CQAs;

• Using the enhanced product and process understanding in combination with quality risk management to establish an appropriate control strategy which can, for example, include a proposal for a design space(s) and/or real-time release testing.

As a result, this more systematic approach could facilitate continual improvement and innovation throughout the product lifecycle (See ICH Q10).

9PROTAFFIN

Process Risk Assessment

• Despite no formal Regulatory requirement, Failure Mode Effect Analysis (FMEA) is the tool the most used in Pharmaceutical Industry

• Ishikawa diagrams largely utilized as starting point

Chemicals Water

Buffers Batch record

Technical staf Chromatographic media

Starting Material Semi purified product

SOP External supply

Equipment Compressed air Electricity Waste

Chromatographic Column system

10PROTAFFIN

FMEA

• Identification of all potential Hazard/failure (what can go wrong)

• What may be the effect of each hazard/failure and severity (S)

• Possible cause and the probability associated (P)

• Way to reduce the Risk to an acceptable level and the change of detecting it (D)

• Ranking of the potential hazards according to their Risk Priority Number

RPN = S x P x D

11PROTAFFIN

FMEA : easy but

• How many level ?

• Which Risk Level is acceptable ?

• Bioprocess are complex : classical FMEA usually 300 – 400 sheets

How to review it regularly during the life cycle of the product ?

• Lack of Homogeneity in term of both wording and scoring

• Solutions may be found in other industries (automobile,...) or closer in Medical Device (ISO 13485 and 14971)

12PROTAFFIN

FMEA : example

PA401 FMEA analysis of Down Stream in 19 sheets

13PROTAFFIN

Second part of QbD : Statistics

• Design of Experiment (DoE) and multivariate analysis

• Monte Carlo simulation and Baysian statistics

• Neuronal network

•Six Sigma

ii

iii h1

var)var( ,

et

ii

i

ii

iii

ii

ii

hh

h

s

1)1/(

1/(

)(. 2

)

,

,

14PROTAFFIN

Statistics in Industry

• 1940 : World war II Bullets manufactured in one state must fit with Rifles assembled in other states

• Manual inspection of all products

• Statistical analysis of samples

• 1945 : end of WWII, reconstruction of Japan economyVery disappointing results

• Japonese product = poor quality = gadget

Deming/Juran (US citizen) build new Quality Systems (Total Quality Management)• Quality results from organisational process

• Successfully used for automobile, electronic,

• …

• Success of Japanese industry became a serious threat for US Economy

– If Japanese can, why can’t we ?

15PROTAFFIN

Statistics in Industry

• 1986 : Methodology Six Sigma (Motorola) : DMAICBased on customer’s satisfaction

< 3.4 defect/1 000 000

• 1987 : Release of Iso 9000 Reaction against Japanese success

Reviewed in 2000 (Iso9000:2000)

• 1987- Evolution of Six Sigma and ISO (alone or combined)DFSS, Lean Six Sigma, Toyota Way,, …to Process Ninja

16PROTAFFIN

Statitics in Pharmaceutical industry

18th century 1946 1985

(De Moivre) (Placket Burman) FMEA

Normal Law DoE

1944 1960 1988

Monte Carlo Simulation Bayesian Statistics (Harry)

Six Sigma

2000

Neuronal Network

2005 2006 2009(?)

ICH Q8 ICH Q9 FDA

validation

QbD

Regulatory

Pharmaceutical development becomes a modern Science

17PROTAFFIN

Design of Experiments

• Design of Experiment (DoE) and multivariate analysis

Classical approach DoE Process understanding

18PROTAFFIN

• Interactions • Real optimum• Quality of information

Design of Experiments

Design of Experiment (DoE)

19PROTAFFIN

But also

Decrease of the number of experiments

Faster and cheaper development (time, manpower, reagents,...)

20PROTAFFIN

DoE in Production Process for BioPharmaceuticals

W C B

L B

A c id

B a se

A n t if o a m

I n o c ulum

M e dium

Sup e r n a t a n t

C e ll p a st e

S h ak e F las kS F -1 0 1

F erm en to rF E R -1 0 2

C en t ri fu g eC C -1 0 3 & 1 0 4

H ig h P res s u reH P -1 0 4

C en t ri fu g eC C -1 0 4

P e lle t

St o r a ge

St o r a ge

A c id p r e c ip it a t io n

C en t ri fu g eC C -1 0 4

A c id

H ig h P res s u reH P -1 0 4C en t ri fu g e

C C -1 0 4

P e lle tP e lle t

So luble p r o t e in s

F i l t rat io nD E -1 0 6

C I P buf f e r

B uf f e r A

B uf f e r B

W a st e

C I P buf f e r

D ilut io n buf f e r

W a st e

C I P buf f e r

B uf f e r A

B uf f e r B

T an kD P -1 0 5

C o lu m ,C o l -2 0 1

D iafi l t rat io nD F -2 0 2

C o lu m ,C o l -2 0 3

C o lu m ,C o l -2 0 5

C o n cen t rat io nD F -2 0 4

C I P buf f e rC I P buf f e r

B uf f e r A

St o r a geC I P buf f e r

B uf f e r A

D iafi l t rat io nD F -2 0 5

D i lu t io nD F -2 0 6

B uf f e r A

F i l t rat io nD E -2 0 7

W a st e

W a st e

W a st e W a st e

21PROTAFFIN

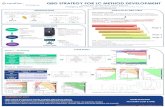

DoE in BioPharmaceutical Life Cycle

Discovery Preclinical Phase I Phase II Phase III Commercial

R IV Factorial Design : identification of Critical Factor

RSM : Optimisation

R III Factorial Design

(Design Space and

Proven Acceptable Range)

Multivariate Analysis

Process Design Process Continued Process

Qualification Verification

CTD

22PROTAFFIN

DoE – 1 : Define

•Define the goal/target of the experiment :

Identification of critical factors (and interactions), optimisation, characterisation,...

Minimal level of improvement

Justification of the step and analytical procedure to be used

Use of the product : screening, reagent, pharmaceutical development

Ressource (Man power, timelines,...)

What is possible (number of experiments and analysis,...)

Prior knowledge (patents, publication, existing process,...)

23PROTAFFIN

DoE – 2 : Measure

•For existing process :

Mesure current actual performance

Multivariate analysis, principal componant analysis, Matrix chart

Justification of the step and analytical procedure to be used

Use of the product : screening, reagent, pharmaceutical development

Ressource (Man power, timelines,...)

What is possible (number of experiments and analysis,...)

Prior knowledge (patents, publication, existing process,...)

24PROTAFFIN

DoE – 3 : Analyse

3a- Run your experiments

25PROTAFFIN

Design-Expert® SoftwareFVIIam capacity

Error from replicates

Shapiro-Wilk testW-value = 0.997p-value = 0.992A: Contact TimeB: pH loadC: Column VolumeD: ConductivityE: Elution temperature

Positive Effects Negative Effects

Half-Normal Plot

Ha

lf-N

orm

al

% P

rob

ab

ilit

y

|Standardized Effect|

0.00 142.38 284.75 427.13 569.50

010

20

30

50

70

80

90

95

99

C

E

CE

DoE – 3 : Analyse

3b- Identify the critical factor and interactions

Critical factorsPlace for improvement

Reproducibility

Half Normal Plot

26PROTAFFIN

Analysis of variance table [Partial sum of squares - Type III]Sum of Mean F p-value

Source Squares df Square Value Prob > FModel 2502 3 834 24,75 0.0020 significant B-Conductivity sample722 1 722 21,42 0.0057 C-Load 722 1 722 21,42 0.0057 BC 1058 1 1058 31,39 0.0025Curvature 160 1 160 4,75 0.0812 not significantResidual 168,5 5 33,7Lack of Fit 156 4 39 3,12 0.3984 not significantPure Error 12,5 1 12,5Cor Total 2830,5 9

Factors Variation degree of SS/df MS/residual associated

selected associated freedom probability

DoE – 3 : Analyse

3c- Statistical significance of selected factors and interactions

27PROTAFFIN

DoE – 3 : Analyse

3c- Controls of the models

Design-Expert® SoftwareHCP peak

Color points by value ofHCP peak:

519.2

2.5

Internally Studentized Residuals

No

rma

l %

Pro

ba

bil

ity

Normal Plot of Residuals

-1.43 -0.71 0.00 0.71 1.43

1

5

10

20

30

50

70

80

90

95

99

Design-Expert® SoftwareRP cor pic 2

Color points by value ofRP cor pic 2:

97.4616

0

Internally Studentized Residuals

No

rma

l %

Pro

ba

bil

ity

Normal Plot of Residuals

-2.56 -1.03 0.50 2.03 3.56

1

5

10

20

30

50

70

80

90

95

99

If all factors affecting the process are identified, residuals are random and distributed according a normal law

28PROTAFFIN

DoE – 3 : Analyse

3c- Controls of the models

Design-Expert® SoftwareHCP peak

Color points by value ofHCP peak:

519.2

2.5

Predicted

Inte

rna

lly

Stu

de

nti

ze

d R

es

idu

als

Residuals vs. Predicted

-3.00

-1.50

0.00

1.50

3.00

3.10 128.59 254.08 379.56 505.05

Design-Expert® Softwareyield

Color points by value ofyield:

5769

275

Predicted

Inte

rna

lly

Stu

de

nti

ze

d R

es

idu

als

Residuals vs. Predicted

-3.00

-1.50

0.00

1.50

3.00

568.13 1534.59 2501.06 3467.53 4434.00

OK Will requires data transformation

29PROTAFFIN

DoE – 3 : Analyse

3c- Controls of the models

30PROTAFFIN

DoE – 3 : Analyse

Load Flow rate Gradient pH Particle size% cm/h CV µm ppm50 50 15 8 30 450 150 15 6 30 350 50 5 8 90 211

150 150 5 8 30 491150 50 5 6 30 519100 100 10 7 60 157150 150 15 8 90 43150 50 15 6 90 950 150 5 6 90 249

100 100 10 7 60 143

HCP contamination

Design-Expert® Software

HCP peakDesign points below predicted value519.2

2.5

X1 = A: LoadX2 = C: Gradient

Actual FactorsB: Flow rate = 100.00D: pH = 7.00E: Particle size = 60.00

50.00

75.00

100.00

125.00

150.00

5.00

7.50

10.00

12.50

15.00

-70

60

190

320

450

H

CP

pe

ak

A: Load C: Gradient

31PROTAFFIN

DoE – 4 : Improve

• 4- Optimize significant factors even with complex/contradicory results

X

X

32PROTAFFIN

DoE – 4 : Improve

• 4- Optimize significant factors even with complex/contradicory results

X

X

33PROTAFFIN

DoE – 5 : Control

Current conditionsCurrent conditions Optimised conditionsOptimised conditions

Wash 1 : 25 % A 0.2 M B in 8 % A

Wash 2 : 0.5 M B

Elution : 0.5 M B in 25 % A 0.75 M B in 22.5 % A

Only a mathematical model, results must be controled

Yield : 68 – 85 % 85 %

HCP Clearance : 2.9 – 3.1 Log 4.1 Log

34PROTAFFIN

Not only DoE :

• Define

• Mesure

• Analyse

• Improve

• Control

DMAIC : Six SigmaNot anymore sufficient : ICH Q8(R2)

The multidimensional combination and interaction of input variables (e.g., material attributes) and process parameters that have been demonstrated to provide assurance of quality

Baysian statistics and Monte Carlo simulation

35PROTAFFIN

Monte Carlo Simulations

36PROTAFFIN

Monte Carlo simulation for initial specifications

• 10 000 calculations with A and B randomly chosen within initial target specifications

• Nearly 20 % of failure

37PROTAFFIN

How to improve the process robustness?

AB

A B

38PROTAFFIN

Optimized specifications

No Failure (< 3.4/106 : Six Sigma robust process)

39PROTAFFIN

Neuronal Network

• DoE has been developped 100 years ago

• DoE, despite serious improvment is now an ‘’old’’ technique and suffers from many disadvantages

– Number of experiments may be further reduced

– Model may be wrong in the real world

– Difficulty to select the best model (complexity)

– Predictability of model difficult to estimate

40PROTAFFIN

Number of experiments may be further reduced

• DoE : With n experiments, you can calculate the coefficients for SIGNIFICANT n-1 factors and interactions

• Exemple : 5 factors tested : – Factorial : 2^5 = 32 experiments– Half Factorial : 16 experiments– If only A, B and interaction AB are found significant, evaluation of their

parameter would have required only 4 experiments

41PROTAFFIN

Number of experiments may be further reduced

• RSM model with interactions may required a lot of expirements.

• Yi = naaa*A3+ nbbb*B3+ naab*A2B + nabb*AB2 + naa*A2+ nbb*B2+ nab*AB + na*A+ nb*B + ……..

• 9 parameters for only 2 factors

42PROTAFFIN

Model may be wrong in the real world

• 3 Factors : A, B, C, RSM• Real = 3A2 + 2 B2 + C + AB + AC

Run A B C Real Alea Real1 0,0 2,0 1,0 11,0 2,7 13,72 5,0 2,0 1,0 96,0 18,2 114,23 5,0 4,0 1,0 132,0 10,2 142,24 0,0 4,0 1,0 37,0 4,7 41,75 2,5 3,0 3,5 58,3 -14,3 43,96 2,5 3,0 -0,7 41,4 -17,4 24,07 2,5 3,0 3,5 58,3 17,1 75,38 2,5 1,3 3,5 33,6 2,0 35,79 2,5 3,0 3,5 58,3 -0,9 57,3

10 6,7 3,0 3,5 187,0 -4,5 182,511 2,5 3,0 3,5 58,3 -12,5 45,812 5,0 2,0 6,0 111,0 6,1 117,113 2,5 3,0 3,5 58,3 -13,0 45,314 2,5 3,0 3,5 58,3 -8,3 49,915 0,0 4,0 6,0 62,0 -7,0 55,016 2,5 4,7 3,5 94,2 -2,4 91,817 5,0 4,0 6,0 157,0 -18,9 138,118 -1,7 3,0 3,5 35,6 -6,7 28,919 0,0 2,0 6,0 26,0 11,2 37,220 2,5 3,0 7,7 75,1 8,3 83,4

Equation CoefficientFactor EstimateInterceptA-AB-BC-C 1 1,0AB 1 1,1AC 1 1,0BCA^2 3 3,1B^2 2 1,8C^2

43PROTAFFIN

Model may be wrong in the real world

• Real world + 20% (precision of the process / analytics)

Run A B C Real Alea Real1 0,0 2,0 1,0 11,0 2,7 13,72 5,0 2,0 1,0 96,0 18,2 114,23 5,0 4,0 1,0 132,0 10,2 142,24 0,0 4,0 1,0 37,0 4,7 41,75 2,5 3,0 3,5 58,3 -14,3 43,96 2,5 3,0 -0,7 41,4 -17,4 24,07 2,5 3,0 3,5 58,3 17,1 75,38 2,5 1,3 3,5 33,6 2,0 35,79 2,5 3,0 3,5 58,3 -0,9 57,3

10 6,7 3,0 3,5 187,0 -4,5 182,511 2,5 3,0 3,5 58,3 -12,5 45,812 5,0 2,0 6,0 111,0 6,1 117,113 2,5 3,0 3,5 58,3 -13,0 45,314 2,5 3,0 3,5 58,3 -8,3 49,915 0,0 4,0 6,0 62,0 -7,0 55,016 2,5 4,7 3,5 94,2 -2,4 91,817 5,0 4,0 6,0 157,0 -18,9 138,118 -1,7 3,0 3,5 35,6 -6,7 28,919 0,0 2,0 6,0 26,0 11,2 37,220 2,5 3,0 7,7 75,1 8,3 83,4

Equation CoefficientFactor EstimateIntercept 56,7A-A 44,1B-B 17,6C-C 1 11,0AB 1 3,8AC 1 -4,1BC 4,0A^2 3 20,0B^2 2 3,6C^2 -0,4

44PROTAFFIN

Best Model and Predictibility

• Real model : A, linear , tested at 4 levels

0123456789

10

0 1 2 3 4 5

Theoretical Real Mean Linear cubic

0123456789

10

0 1 2 3 4 5

Real cubic Next time

If complexity of model increase, precision to data increase (diminution of Sum of Square) but predictibility to other results decrease (increase of bias)

45PROTAFFIN

Bayes limit : Bias/variance dilemna

0

20

40

60

80

100

120

0 2 4 6 8

Complexity of model

Sum of Square Bias Bayes Limit

Best Model

46PROTAFFIN

DoE models : which is the best ?

47PROTAFFIN

DoE / Neuronal Network

DoE Neuronal Network

Factors

Response

Constant Function

48PROTAFFIN

Functions in Neuronal Network

• Several types of fonctions, only two parameters/function• Reduced number of experiments for modeling (statistical learning)• If classical DoE require 36 experiments for modelisation, neuronal

network may use this number of experiment to– Statistical learning (modelisation), ex : 12 experiments +– Evaluation of the model on other data not used (validation), ex 12

experiments +– Evaluation of the model on final data remaining (test), ex 12

experiments• Allow Bootstrap : instead of a single analysis, perform i.e 200

statistical modeling/validation/testing analysis using each time 12 random experiments for each step

49PROTAFFIN

Conclusions

• Avoid Muri (overworked men or overstrechted equipment)

• Due to Mura (inconsistency, irregular production)

• To decrease Muda (waste, wrong product)

• In a Kaizen (continuous improvement) spirit

Toyota Way ProtAffin Way

50PROTAFFIN

Quality by Design

– Regulatory : to offer flexibility in the Design Space but...

– New for Biopharmaceutical Industry and still only poorly used

51PROTAFFIN

QbD strongly requested by Authorities, lack of implementation may lead not only to a Dossier Assessment Refusal Report but to the discontinuation of GMP authorisation for Manufacturing of Facility