2 pulleys and belt drives

Transcript of 2 pulleys and belt drives

FUNDAMENTAL UNDERSTANDING FUNDAMENTAL UNDERSTANDING OF OF

PULLEYS AND BELTDRIVESPULLEYS AND BELTDRIVES

ELEMENTS OF TECHNOLOGYELEMENTS OF TECHNOLOGY

WHAT ARE BELT DRIVESWHAT ARE BELT DRIVES A belt drive is a method of transferring rotary motion between A belt drive is a method of transferring rotary motion between

two shafts.two shafts.

A belt drive includes one pulley on each shaft and one or more A belt drive includes one pulley on each shaft and one or more

continuous belts over the two pulleys.continuous belts over the two pulleys.

The motion of the driving pulley is, generally, transferred to the The motion of the driving pulley is, generally, transferred to the

driven pulley via the friction between the belt and the pulley.driven pulley via the friction between the belt and the pulley.

Generally belt drives are friction drives.Generally belt drives are friction drives.

A Belt is a looped strip of flexible material, used to A Belt is a looped strip of flexible material, used to

mechanically link two or more rotating shafts.mechanically link two or more rotating shafts.

A pulley is a wheel with a groove between two flanges around A pulley is a wheel with a groove between two flanges around

its circumference. Pulleys are keyed to the shafts.its circumference. Pulleys are keyed to the shafts.

TYPES OF BELTSTYPES OF BELTSThere are 4 types belts used in belt drives they are as follows:

Flat beltsshaft distance 5 to 10 meters, low power, high speed

Round belts smaller initial tension, absence of vibration and noise, high power, shaft distance > 5 meters

V belts shaft distance < 2 meters, high power, moderate speed

Timing Belts positive drives, precise, reliable

ROUND BELTROUND BELT Round belts are a circular cross section belt Round belts are a circular cross section belt

designed to run in a pulley with a circular (or designed to run in a pulley with a circular (or

near circular) groove.near circular) groove.

The circular belt or rope is mostly used in the The circular belt or rope is mostly used in the

factories where a great amount of power is to factories where a great amount of power is to

be transmitted from one pulley to another, be transmitted from one pulley to another,

when the two pulleys are more than 5 meters when the two pulleys are more than 5 meters

apart.apart.

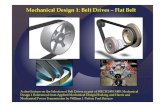

FLAT BELTSFLAT BELTS Flat belts find their widest application Flat belts find their widest application

where high-speed motion, rather than where high-speed motion, rather than

power, is the main concern.power, is the main concern.

Flat belts are made from leather, woven Flat belts are made from leather, woven

cotton, rubber, balata (wood gum).cotton, rubber, balata (wood gum).

‘‘V’ BELTSV’ BELTS The strength of these belts is obtained by The strength of these belts is obtained by

reinforcements with fibers like steel, reinforcements with fibers like steel,

polyester.polyester.

V-belts are far superior to flat belts at V-belts are far superior to flat belts at

small center distances and high reduction small center distances and high reduction

ratios. ratios.

Require larger pulleys than flat belts Require larger pulleys than flat belts

because of their greater thickness. because of their greater thickness.

The The "V""V" shape of the belt tracks in a shape of the belt tracks in a

mating groove (or sheave) in the pulley, mating groove (or sheave) in the pulley,

with the result that the belt cannot slip off.with the result that the belt cannot slip off.

TIMING BELTSTIMING BELTS Also known as Also known as ToothedToothed, , NotchNotch or or CogCog

belts are a belts are a positivepositive transfer belt and can transfer belt and can

track relative movement. track relative movement.

These belts have teeth that fit into a These belts have teeth that fit into a

matching toothed pulley .matching toothed pulley .

They are often used to replace chains or They are often used to replace chains or

gears, reducing noise and avoiding the gears, reducing noise and avoiding the

lubrication bath or oiling system lubrication bath or oiling system

requirement. requirement.

Requires the least tension of all belt drives Requires the least tension of all belt drives

and are among the most efficient. and are among the most efficient.

Types of Belt drives based on the arrangement are as follows

• OPEN BELT DRIVES

• CROSSED OR TWIST BELT DRIVES

• BELT DRIVE WITH IDLER PULLEYS

• COMPOUND BELT DRIVE

TYPES OF BELT DRIVES TYPES OF BELT DRIVES BASED ON BASED ON

ARRANGEMENTARRANGEMENT

OPEN BELT DRIVEOPEN BELT DRIVE The Open belt drive is arranged with The Open belt drive is arranged with

shafts arranged parallel and rotating in shafts arranged parallel and rotating in

the same direction.the same direction.

The driver pulls the belt from one side The driver pulls the belt from one side

and delivers it to the other side thus the and delivers it to the other side thus the

tension in the one side belt will be more tension in the one side belt will be more

than that in the other side belt.than that in the other side belt.

X

d1 d2

21

1dr

22

2dr

xx

dd rr )22(2

2

)( 2121

Length of the open belt=Length of the open belt=

CROSSED OR TWIST BELT DRIVECROSSED OR TWIST BELT DRIVE The crossed or twist belt drive is The crossed or twist belt drive is

used with shafts arranged parallel used with shafts arranged parallel and rotating in the opposite and rotating in the opposite directions.directions.

The tension in the tight side will be The tension in the tight side will be more than the slack side. The more than the slack side. The point where the belts rubs against point where the belts rubs against each other and there will be each other and there will be excessive wear and tear.excessive wear and tear.

To avoid this the shafts should be To avoid this the shafts should be placed at a maximum distance of placed at a maximum distance of 20b where b is the width of the 20b where b is the width of the belt and the speed should be less belt and the speed should be less than 15 m/s.than 15 m/s.

X

21

1dr

22

2dr

Length of the cross belt=x

rrx

dd )22(2

2

)( 2121

Velocity of Belt (V)=60

dNWhere ( d=diameter of pulley (mts), N=Revolutions per minute (RPM), V=velocity of belt in

mts/sec )Effective Tension in the belt (T) = (T1-T2)

Power (P) = T x V =60

)()( 21 dNTT

Power (P) =45000

dNTHere ( d=diameter in meters, N=Speed in RPM, P=power in HP (Horse Power), T= Tension in the belt in Kgs )

Power (P) =60

11NdT Here ( d1=diameter in meters, N1=Speed in RPM, P1=power in Watts, T= Tension in the belt N )

COMPOUND BELT DRIVECOMPOUND BELT DRIVE

A compound belt drive is used A compound belt drive is used

when power is transmitted from when power is transmitted from

one shaft to another through a one shaft to another through a

number of pulleys.number of pulleys.

The belts are connected in such The belts are connected in such

a way that the driver moving one a way that the driver moving one

system of drives is system of drives is

simultaneously moving the other simultaneously moving the other

connected system.connected system.

IDLER PULLEY

1) Adjust tension and slack in the belt

2) Increase the belt contact area with pulley

3) To make drive compact

APPLICATIONSAPPLICATIONS

DRILLING MACHINE DRILLING MACHINE WITH SPEED CONE WITH SPEED CONE PULLEYSPULLEYS

A OPEN BELT DRIVE IN A A OPEN BELT DRIVE IN A JIG-SAW MACHINEJIG-SAW MACHINE

LATHE MACHINE LATHE MACHINE WITH SPEED CONES WITH SPEED CONES AND TIMING BELTAND TIMING BELT

SKIVING MACHINESKIVING MACHINE

A PLANAR MACHINE A PLANAR MACHINE WITH GUIDE PULLEYSWITH GUIDE PULLEYS

A GUIDE PULLEY BELT DRIVE A GUIDE PULLEY BELT DRIVE IN SPINDLE MOULD MACHINEIN SPINDLE MOULD MACHINE

A FLAT BELT IN A CIRCULAR A FLAT BELT IN A CIRCULAR SAW MACHINESAW MACHINEA TIMING BELT IN LATHE MACHINEA TIMING BELT IN LATHE MACHINE

TIMING BELT OF AN AUTOMOBILESTIMING BELT OF AN AUTOMOBILES

IN SEWING MACHINEIN SEWING MACHINE

IN TREADMILLSIN TREADMILLS