2 LAST Datasheet - FIREFLEX Blast/Datasheet/N2...The activation of the detection condition alone...

Transcript of 2 LAST Datasheet - FIREFLEX Blast/Datasheet/N2...The activation of the detection condition alone...

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

1 of 16 FM-076D-0-127C

(System shown is a self contained unit)

FireFlex® N2 Blast® description The FIREFLEX® N2 Blast® integrated system consists of an integrated Firecycle®III single interlock preaction automatic sprinkler system combined with a Nitrogen generating system, factory-assembled in a single cabinet. All the necessary components are integrated. The FIREFLEX® N2 Blast® is fully tested at factory. The FIREFLEX® N2 Blast® System uses the N2 Blast® Nitrogen generator system Type 1 FPS-250 or FPS-750 system, made by South-Tek Systems.

All the deluge valves are rated up to a maximum of 250 psi WWP (1724 kPa) max. and are available in the following diameters:

1½" (40 mm) 2" (50 mm) 3" (80 mm) 4" (100 mm) 6" (150 mm)

Warning: 6" (150 mm) available with N2 Blast® Type 1 FPS-750 only.

Features Inhibits corrosion with 98%+ pure Nitrogen Trouble-free design for safe and easy application Available in 2 cabinet sizes Uses South-Tek N2 Blast® Best value in nitrogen generation technology Limits the liability of early pipe replacement Uses the Viking flow control valve Trim is fully assembled and tested at the factory All trims are galvanized steel, Listed and Approved

for 250 psi (17.2 bar) service maximum Quick connections to water supply and drain on

left side, and sprinkler riser on top of unit, all available with grooved end or flanged fittings

No open drain cup inside unit Separate unlocked access hatch to emergency

manual release Compact, aesthetic and easy to move User-friendly standardized owner's manual with

every unit Unique serial number on every unit Uses UL, ULC and/or FM Approved components Designed in accordance with NFPA Standards Sturdy 14 gauge steel cabinet painted fire red with

oven baked polyester powder on phosphate base Textured rust proof finish Neoprene gasket on all doors to eliminate

vibrations Manufactured under ISO-9001 quality control

procedures Prewired to the Viking VFR-400 releasing control

panel

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 2 of 16

System configurations

□ Firecycle®III Single Interlock Preaction combined with N2 Blast® Type 1 FPS-250 (250 gallons system)

□ Firecycle®III Single Interlock Preaction combined with N2 Blast® Type 1 FPS-750 (750 gallons system) Systems hydraulic limitations The information contained herewith is for estimation and evaluation purposes only. Its use remains the responsibility of the designer. Designers should refer to the appropriate NFPA Standards and any other applicable codes for their final design. Also refer to FireFlex Systems Inc. appropriate user manuals and to manufacturer's data sheets for additional details. Systems limitations indicated below are nominal flow limitations.

System size (in.)

Usage Range (gpm)

Piping Equivalent Lengths w/o shut off valve

Piping Equivalent Lengths c/w shut off valve

Drain flow @ 250 PSIG w.p.

(m.) (ft.) (m.) (ft.) GPM 1½ 0 – 210 8.3 27.2 8.5 27.9 272 2 0 – 360 11.65 38.2 11.85 38.9 272 3 100 - 700 16.8 55.1 20.33 66.7 762 4 200 – 1400 21.89 71.8 25.33 83.1 1597 6 400 - 3500 33.28 109.15 37.28 122.3 1597

Sequence of operation Firecycle®III operation

1. The activation of at least one FireCycle® III detector is necessary to cause the flow control valve actuation.

2. The activation of the detection condition alone will activate the solenoid valves (F1) and (F2), causing the flow control valve to open and allowing water to enter the system piping. The alarm pressure switch (C1) will activate. Water will not discharge into the protected area since all sprinkler heads are closed. The opening of an automatic sprinkler will cause the water to flow out of the system. Water will flow in the protected area until all FireCycle® III detectors have reset (cooled below their set point) After all detectors have been reset, the Firecycle® lll control panel activates the soak timer, allowing the system to discharge water for a pre-determined period of time. When the soak timer has elapsed, the control panel de-energizes the normally closed solenoid valve (F1), allowing the flow control valve to re-prime and close, stopping the flow of water through the piping system. Should a FireCycle® III detector go into alarm, the control panel re-energizes the normally closed solenoid valve and the entire cycle repeats.

3. The opening of an automatic sprinkler OR damage to system piping without the detection condition satisfied will activate the low air supervisory and “very low air” alarm switch (E4) contacts but water will not to enter the system piping. The solenoid valve (F2) will be activated.

4. Operation of the emergency manual release will depressurize the priming chamber, causing the deluge valve to open and allowing water to enter the system piping and water will discharge through any open sprinklers.The alarm pressure switch (C1) will activate.

5. When AC Power and DC power supplied by the back up batteries is lost, the system shall “fail-safe” and function as a dry pipe system. The normally open solenoid will remain open, and the pneumatic actuator is the only device holding the priming water in the priming chamber. When a sprinkler operates, air pressure is lost and the pneumatic actuator opens. Priming water is drained from the priming chamber, causing the flow control valve to open and allowing water to enter the system piping. The alarm pressure switch will activate. Water will flow out of any open sprinklers and/or any openings on the system. The cycling function of the system will not operate in this condition, and the system must be manually shut-off.

6. Trouble condition on FireCycle® III detection zone, or "very low air" alarm zone, or the normally closed solenoid output, disables the normally open solenoid and the pneumatic actuator is the only device holding the priming water in the priming chamber. When a sprinkler operates, air pressure is lost and the pneumatic actuator opens. Priming water is drained from the priming chamber, causing the flow control valve to open and allowing water to enter the system piping. The alarm pressure switch will activate. Water will flow out of any open sprinklers and/or any openings on the system.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

3 of 16 FM-076D-0-127C

N2 Blast® Nitrogen generator system operation 1. The initial air supply fill of the piping system within 30

minutes as per NFPA 13 is accomplished using the “initial fill” air compressor. This compressor is equipped with a factory-adjusted ON/OFF pressure switch which is tied into the sprinkler system piping. It is factory-set at 20 and 35 psi for the cut-in and cut-out pressures respectively. There is a "low air" supervisory pressure switch which monitors system piping air/nitrogen pressure at all times. It is factory-set at 25 psi to provide a "low air" supervisory signal and 23 psi to provide a "very low air" supervisory signal.

2. The nitrogen generation/maintenance air compressor is supplied as an integral part of the STS N2-Blast® Nitrogen Generation System. It is equipped with a factory-adjusted ON/OFF pressure switch which is tied into the nitrogen storage tank. It is factory-set at 65 psi and 75 psi for the cut-in and cut-out pressures respectively. The Viking D-2 Air Pressure Maintenance Device is installed and factory-adjusted to 35 psi (normal system air/nitrogen pressure) downstream of the nitrogen storage tank. As the system continually purges with Nitrogen, the APMD will continually draw from the Nitrogen storage tank to maintain supervisory pressure (35 psi). Should the N2-Blast® generator run for more than 6 hours consecutively, the Leak Detection System (LDS) will automatically shut it down and activate a trouble contact.

3. The air and nitrogen supply systems are fully integrated and fully automatic in the FireFlex - N2-Blast®. No shut-off or bypass valve is required. The nitrogen generator is equipped with a BlastOff® Leak Detection System (LDS). Should the nitrogen generator compressor fail or a leak occur that can not be compensated by the nitrogen generating system, the preaction system air compressor will act as a back-up and start-up at 20 psi system pressure.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 4 of 16

Standard equipments Releasing control panel

120 VAC / 60 Hz, 165VA. 12VDC / 12Ah batteries. (factory installed) 12VDC / 18Ah batteries. (optional)

The releasing control panel integrated into the TOTALPAC®3 cabinet is Viking's Model VFR-400. This panel includes four Class B, programmable detection zones (optional Class A); two Class B supervisory zones and four Class B, programmable output circuits (optional Class A). It is also provided with menu driven programming, including a specific program assigned at the factory. The panel is compatible with many types of fire alarm & supervisory devices such as linear heat detectors, spot-type heat and smoke detectors, water flow and release indicators, low and high air pressure switches, manual pull stations.

The releasing control panel also includes an alphanumeric display with 2 lines of 16 characters describing all the system conditions, as well as a set of red and yellow LED lamps individually indicating each of the alarm and trouble conditions of the system

Easy to operate control buttons are also provided to activate and operate the system's various functions.

Releasing circuit disconnect switch

The releasing circuit disconnect switch is used to disable the releasing solenoid. When the key is set to “Disable”, the releasing solenoid will be disconnected from the control panel’s releasing circuit, causing a trouble signal and preventing accidental discharge during maintenance or inspection.

Flow control valve The Viking flow control valve is a quick opening, differential type flood valve with a spring loaded rolling diaphragm clapper. The flow control valve can be used to facilitate manual or automatic on/off control. The Viking flow control valve is an integral part of the Viking Firecycle® System.

The valve is held closed by system water pressure trapped in the priming chamber, keeping the outlet chamber and system piping dry. In fire conditions, when the releasing system operates, pressure is released from the priming chamber. The flow control valve clapper opens to allow water to flow into the system piping.

Water supply control valve The water inlet control valve is a supervised, indicating butterfly valve. Purpose of this vale is to manually shutoff the preaction system.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

5 of 16 FM-076D-0-127C

Standard equipments (continued) Preaction riser check valve

The Viking 1-½” and 2” spring loaded In-Line check valve is a general purpose rubber-faced check valve approved for use in fire-service systems. The Spring Loaded In-Line check valve is manufactured with a brass body, brass seat, and a rubber-faced clapper assembly. The Viking 3”, 4” and 6” Easy Riser® Swing check valve is a general purpose rubber-faced check valve approved for use in fire service systems. The valve is for use in preaction system risers.

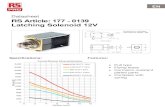

Solenoid valve The high pressure solenoid valve is a two-way type with one inlet and one outlet. It is a packless, internal pilot operated valve, suitable for use in releasing water pressure from the priming chamber of Viking Deluge Valves. The solenoid valve has floating diaphragm construction, which requires a minimum pressure drop across the valve to operate properly.

IN OUT

Low air supervisory switch

The low pressure switches monitors the pressure within the sprinkler piping should a loss pressure of the air below 25PSI occurs, the pressure switch contacts transfer indicating low air supervisory signal. Should a loss pressure of the air below 23PSI occurs, the pressure switch contacts transfer indicating low air alarm signal.

POTTERPS40-2A

Alarm pressure switch

The alarm pressure switch monitors the water flow within the sprinkler piping. Should the Deluge Valve clapper opens to allow water to flow into the sprinkler piping. The alarm pressure switch will activate, indicating a water flow signal

POTTERPS10-1A

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 6 of 16

N2 Blast® Nitrogen generator

South-Tek Systems utilizes Membrane technology in the N2-Blast® Corrosion Inhibiting Systems in order to efficiently separate Nitrogen molecules from the air we breathe. Membrane technology, used in our smaller applications, has a simple air flow design, is wall-mounted and easy to service. PSA technology is more cost effective and energy efficient in larger Fire Protection Systems, those requiring more Nitrogen to compensate for the NFPA “acceptable leak rate”.

BlastOff™ Leak detection system

Unless the leak rate is catastrophic, the supervisory low pressure alarm on the FPS will not activate. Minor leaks cause the air compressor and N2-Blast® to run excessively in order to maintain supervisory pressure. The unnecessary additional run-time decreases the lifespan of the equipment. The Patent Pending BlastOff™ - Leak Detection System is designed to detect significant leaks before they compromise the FPS and the Nitrogen Generation System. It has an internal audible alarm and dry contact for wiring into the Building Monitoring System (BMS) and will also alarm if the air compressor or the N2-Blast® is not working properly.

Nitrogen generator storage cylinder

Type 1 Nitrogen Generation Systems include a 16 gallon Nitrogen receiver tank (12.2”dia x 44.8”H). Nitrogen generated by the N2-Blast® is stored in the tank, and then sent to the sprinkler system through the Nitrogen air pressure maintenance device.

N2 Blast® AutoPurge System™

High purity Nitrogen must be equally distributed throughout the entire sprinkler piping system in order to effectively inhibit corrosion. The Patent Pending AutoPurge System™ provides a low volume, constant purge of Nitrogen within sprinkler piping. The rate in which gas is evacuated from the sprinkler piping is within NFPA guidelines and allows breathing to occur. The AutoPurge System™ also assists in drying out the residual water from a hydro test. Computational Fluid Dynamics modeling proves that this is the most effective way to ensure that high purity Nitrogen reaches all branches within the sprinkler piping. Install one AutoPurge System™ per system at a high point .

There is a Label on one side of the housing that lists the proper setting for a variety of zone sizes. The Label list: Gallons in Zone, and APS Flow Setting. The Flow Setting is labeled from A-E and has three Settings in between each letter.

Nitrogen generator air pressure maintenance device

FIREFLEX® N2 Blast® use the Viking Model D-2 Air Pressure Maintenance Device (APMD) which is a pressure regulator that automatically reduces the supply air pressure to a preset requirement when connected to a constantly maintained air supply.

The APMD is used to regulate the nitrogen pressure to 35 psi in the sprinkler piping at the specified system pressure for FIREFLEX N2 Blast®.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

7 of 16 FM-076D-0-127C

Optional preaction equipments Shut-off valve & sight glass (optional)

The Shut-off Valve & Sight Glass Option is intended to be used for applications where testing of the system operation without filling the sprinkler piping network is desirable and where it is critical that all functions of the preaction system be tested under actual discharge conditions.

Mainwater supplycontrol valve

Deluge valve

Shut-off valve

Riser check valve

Main drain valve

Sight glassassembly

Point flashlightHERE

FM-076Z-0-4B-1

Anti-column device option The model LD-1 anti-column device is an optional trim component designed for use with preaction sprinkler systems. The anti-column device automatically prevents an unwanted water column from establishing within the system riser. On preaction sprinkler systems the anti-column device prevents water from columning downstream of the easy riser check valve.

From Sprinkler Riser

FM-061H-0-146ATo Drain Collector

Semi-flanged inlet / outlet (optional) When required by the user, FIREFLEX N2 Blast® units can be provided in a semi-flanged configuration. The semi flanged option provides flanged fittings only on the water inlet pipe (left side) and on the system riser outlet. The drain manifold is provided with a threaded connection (left side). The rest of the fittings are the same as usual with the main components being provided in the standard flanged / grooved configuration.

Deluge valve

Flange fittingoutside cabinet

Flange fittingoutside cabinet

Riser check valve

Threadeddrain output

FM-076Z-0-4B-2

Mainwater supplycontrol valve

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 8 of 16

Preaction system - Air supply

Direct air compressor (Style “A”) Used only for the sprinkler piping network of the preaction system. Air supply style "A" includes the air compressor mounted inside the FIREFLEX N2 Blast® cabinets with its supervisory trim and options. Compressors are of the tankless, oiless piston type and are factory piped to the sprinkler system riser, all within the FIREFLEX N2 Blast® cabinets.

Compressors are available in four (4) sizes: 1/6HP 1/2HP 1/3HP 1HP

FM-061H-0-118C

1

CONTRACTOR'SHYDROSTATIC TEST PORT(system side)

2 TO DRAIN COLLECTOR

TO SPRINKLER RISER

Copper tubing

This section replacedby Dehydrator option(when used)

TO OPTIONAL ACCELERATOR(plugged when not used)

3TO PNEUMATIC ACTUATOR(plugged when not used)

E4(plugged withSureFire trim)

Pressure relief valve

Air Pressure Maintenance Device (Style “B”)

Used only for the sprinkler piping network of the preaction system, when an external air supply is provided by others (tank mounted compressor or plant air) and piped to the air inlet port of the unit. Air supply style "B" provides an Air Pressure Maintenance Device (APMD) trim, factory mounted in the FIREFLEX N2 Blast® cabinets.

FM-061H-0-119B

1

CONTRACTOR'SHYDROSTATIC TEST PORT(system side)

TO SPRINKLER RISER

TO OPTIONAL ACCELERATOR(plugged when not used)

E4(plugged with SureFire trim)

This section replacedby Dehydrator option(when used)

Contractor external Airor Nitrogen connection

3TO PNEUMATICACTUATOR(plugged whennot used)

Compressor Service Factor Amp (S.F.A) rating Compressor

Size (HP) 115Vac / 60Hz 230Vac / 60Hz

1/6 5.0 Amp. 2.5 Amp. 1/3 7.4 Amp. 3.7 Amp. 1/2 10.0 Amp. 5.0 Amp. 1 18.0 Amp. 9.0 Amp.

115 / 220 Vac – 60Hz Compressor selection Table:

H.P CFM

@ 40 PSI

System capacity to fill system to 35 PSI

in 30 minutes *

1/6 1.33 142 gal. 1/3 2.61 285 gal. 1/2 4.06 417 gal. 1 7.40 702 gal.

* For systems with maximum water supply pressure up to 250 PSI (1724 kPa)

WARNING The information contained herewith is for estimation and evaluation purposes only. Its use remains the responsibility of the designer.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

9 of 16 FM-076D-0-127C

Details & field wiring diagrams P & ID

Tank Providedwith brackets and Strap

Riser towards the nozzles

N2 Blast

Compressor

Air Maintenance Device/s(AMD/s) Supplied by Fireflex

PreactionCompressor

PreactionAir Kit

PreactionSystem

Low AirPressure Switch

Autopurge System

Sprinkler

NitrogenAir

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 10 of 16

Cabinet with main components, shown without door(s)

FM-06LM-0-1A-4FM-06LM-0-1A-4

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

11 of 16 FM-076D-0-127C

Trim diagram

D1

B6

F2D3

A2

FM-076Z-0-65A

FIELD CONNECTIONTO OPEN DRAIN

(left side only)

FIELD CONNECTIONTO WATER SUPPLY

(left side only)

C1

B5

B7

F1

B1

B2

B4B3

D2

B13

C2B11

B12

B10

2

CONTRACTOR'SHYDROSTATICTEST PORT(water supply side)

1To Air Supply System Trim

FIELD CONNECTION TOSPRINKLER PIPING NETWORK

TotalPac Base(shown without enclosure)

To Air SupplySystem Trim

B8F3

3 To Air Supply System Trim

B9

Trim Components: A2 Flow control valve B1 Priming valve B2 Strainer B3 1/8" Restricted orifice B4 Spring loaded check valve B5 Alarm test valve B6 Flow test valve B7 Drip check valve B8 Drain check valve B9 Pressure operated relief valve (PORV) B10 Emergency release valve B11 Priming pressure water gauge & valve B12 Water supply pressure gauge & valve B13 Clapper check valve

C1 Alarm pressure switch C2 Connection to water motor gong (strainer supplied by contractor) D1 Water supply control valve D2 Riser check valve D3 Main drain valve F1 N.C. Solenoid valve – 24Vdc F2 N.O. Solenoid valve – 24Vdc F3 Pneumatic actuator

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 12 of 16

Wiring diagram

5 6 7 8

MAN

UAL

PULL

STA

TIO

NS

ZON

E 4

FM-061H-0-239A

TBA

1234

TBB

56

TBA

WIRING INCLASS B / STYLE B

OPTIONAL WIRING INCLASS A / STYLE D

WIRING INCLASS B / STYLE Y

1

TBC

2 3 4 5

120

24VD

C N

ON

SH

IELD

RE

SE

TTAB

LE

RS485

LINENEUTRALGROUNDGROUNDNEUTRALLINE

CONTROL PANEL100VA MAX

N²BLAST UNIT20A MAX

WIRING OF INPUT POWER SOURCE

Branch circuit for air compressor shall not be the sameas the control panel power source.

6 7 8 9 10 11

C NO

NC

MA

IN V

ALVE

C NO

NC

SH

UT-

OFF

VA

LVE

Contact provided for connection tothe building's central Fire Alarm Panel.

OPTIONAL

LOS ANGELES OPTION

CHICAGO OPTION

NOTE:

Class A / Style D requires CA2Z modules.NOTES:

All devices are shown in their normal supervisory state.

NOTES:

Use dry contacts with power limited circuits only.

CONTACTS RATED:5A, 1/6HP, 125/250VAC0.5A, 250VDC 0.25A, 250VDC

HEAT DETECTOR

SMOKE DETECTOR

MANUAL RELEASE

DRY CONTACT

END OF LINE RESISTOR

LEGEND

BELL OR HORN

End-of-line devices are not required forClass A / Style D wiring.

Control panel AC power source is supervised and non-power limited.

Refer to Local Electrical Codes for wiring size.

789 GROUND

NEUTRALLINE

AIR COMPRESSOR1HP MAX

WITH AIR OPTION "A" ONLY

120VAC, 60Hz

1 2

EOLR5.1K EOLR

5.1KEOLR5.1K

24V

DC

RES

ETTA

BLE

C NO

NC

C NO

NC

C NO

C NO

ALA

RM

TRO

UBL

E

SU

PE

RV

ISO

RY

WAT

ER F

LOW

MAN

UA

L PU

LLS

TATI

ON

SZO

NE

4

NAC

1S

ILEN

CE

ABLE

ALA

RM

NAC

2N

ON

SIL

ENC

EAB

LEW

ATER

FLO

W

CONTACTS RATED 3A, 30VDC RESISTIVE

EOLR5.1K

DET

ECTI

ON

ZON

E 1

3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

Power Limited (supervised) Initiating Device Circuits Detection Zone 1, 2, 3, and 4. Max. loop resistance: 100 ohms End of line: 5.1K ohms, 1/4W Leave ELR (provided) on all unused circuits. Refer to Device Compatibility in the VFR-400 Releasing control panel Manual.

Power Limited (supervised) Initiating Device Circuits Supervision Zone 1, and 2. Max. loop resistance: 100 ohms End of line: 5.1K ohms, 1/4W Leave ELR (provided) on all unused circuits. For dry contact supervisory devices such as tamper, low air, or high air switches. (Class-B only)

Power Limited (supervised) Notification Appliance Circuits Output Circuit 1, 2, 3, and 4 Maximum operating voltage: 27Vdc (ripple: 0.3Vdc) Maximum usable current per circuit: 1.0A Total current available (all circuits): 2.5A Polarity is reversed in supervisory condition. Leave ELR (provided) on all unused circuits. Refer to Device Compatibility in the VFR-400 Releasing control panel Manual.

Auxiliary Power 24Vdc Regulated Source Total current available: 0.2A Resettable for 4 wires smoke detectors

WARNING Releasing control panel shall be supplied by a dedicated circuit breaker, as per NFPA 70, Section 760 and Canadian Electrical Code, Section 32.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

13 of 16 FM-076D-0-127C

Optional electrical equipment's

Relay module ARM-44

The ARM-44 is an auxiliary relay module designed to operate with the Viking VFR-400 releasing control panel to provide 4 independent form C relay outputs. The 4 output circuits each have a dedicated relay. Each relay is rated for 3 amps at 24 volts DC resistive load. The relay module mounts directly to the back of the cabinet and is connected to the main board. All of the relay terminals are wired back to the field wiring junction box. A disable switch is available for disabling the relays when the system is being tested or serviced.

24Vdc RS-485

Remote Annunciator RA-4410-RC

The RA-44410-RC remote annunciator is designed to operate with the Viking VFR-400 releasing control panel. There are 34 LED's to indicate a change in panel status. There is a buzzer on the annunciator that sounds for any trouble or supervisory condition. The release control panel supervises and communicates with the annunciator via separate connections for the RS-485 communication and the 24VDC power requirement of the RA-4410-RC. Separate cables should be used for power and communication. Shielded cable MUST be used for the RS-485 communication line.

RA-4410-RCOUTPUT 1ZONE 1

OUTPUT 2ZONE 2

OUTPUT 3ZONE 3

OUTPUT 4ZONE 4

ZONE 1

ZONE 2

ZONE 3

ZONE 4

OUTPUT 1

OUTPUT 3

OUTPUT 4

OUTPUT 2

AC POWER

POWER TROUBLESYSTEMTROUBLEGROUNDFAULT

SUPERVISORYTROUBLE

STEADY : DISCHARGEDFLASHING : PRE-DISCHARGE

SUPERVISORY

COMMON ALM.ALM. SILENCE

LAMP TEST

SILENCE

Class A initiating device module CA2Z

The Model CA2Z Class A Module is designed to be used with the Viking VFR-400 releasing control panel to convert from two (Class B) initiating device circuits to two (Class A) circuits. The module is to be mounted in the upper right hand corner of the panel. All the connections are wired back to the field wiring junction box.

P

Class A Indicating Appliance Circuit Module The Model CAM Class A Module is designed to be used with the Viking VFR-400 releasing control panel to convert a single (Class B) indicating appliance circuit to a (Class A) circuit (one module is required for each indicating appliance circuit). After installing the CAM, the indicating circuit should be activated to ensure proper operation and connections. The module is provided with double-sided foam tape and should be mounted in the field wiring junction box so that the terminals are accessible.

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single c/w N2 Blast® Nitrogen generating system Self contained unit

FM-076D-0-127C 14 of 16

Cabinet The FIREFLEX N2 Blast® cabinet is made of sturdy 14 gauge steel. Refer to figure 4 for dimensions. All surfaces are rust proof coated, inside and outside, with fire red, oven baked polyester powder on phosphate base. Cabinet is provided with two doors, all provided with a neoprene gasket to avoid vibrations, giving the access to the pressure gauges reading and the manual emergency release. The cabinet assembly is pre-assembled, pre-wired, and factory tested under ISO-9001 conditions. Refer to figures 2 & 3 for installation and clearances details. Electrical junction boxes are integrated inside the cabinet for connection of the supervisory and alarm devices contacts. Knockouts are pre-punched for the installing contractor as indicated on figure 1.

Figure 1 - knockouts details

3"

8½"

Top of Cabinet

FM-061H-0-68B-12

2½" Typ.3¾"

2½"

High voltage

Low voltage

Figure 2 - Floor anchoring template

5''

E

G

Ø3/4"

F

FM-061H-1-49B-6

Size E F G

46" 15" 48" 25"

54" 21" 56" 27"

Figure 3 - Required clearance

FM-061H-1-49B-7

12''MIN

12''MIN

22''MIN

Size A 46" 24"

54" 32"

® N2 BLAST® Datasheet Preaction FIRECYCLE® III single interlock c/w N2 Blast® Nitrogen generating system Self contained unit

15 of 16 FM-076D-0-127C

Figure 4 - Cabinet dimensions

WATER INLETSCH.40 GROOVED OUTLET

DRAIN - SCH.40 GROOVED OUTLET

SP

RIN

KLE

R R

ISE

RS

CH

.40

GR

OO

VE

D O

UTL

ET

TBB TBA & TBC

CONTROLPANEL

(except for RemoteControlled Unit)

SP

RIN

KLE

R R

ISE

RS

CH

.40

GR

OO

VE

D O

UTL

ET

T

R

G

M

D

P

F

S

FM-06LM-0-2A

OPTIONALSHUT-OFF VALVE

CO

NTR

OL

PA

NE

L

TBA, TBB & TBC

N

Q

ØC

ØA

ØB

System Size A B C D E F G H J K L M N P Q R S T 1½" 2" 1½" 2" 46" 25" 77¼" 4" 8¾" 11½" 13¾" 3¾" 2¾" 2¾" 15" 11½" 37½" 44¾" 50"

2" 2" 2" 2" 46" 25" 77¼" 4" 8¾" 11½" 13¾" 3¾" 2¾" 2¾" 15" 11½" 37¾" 45" 50"

3" 4" 3" 2" 46" 25" 77¼" 4" 10" 11½" 13¾" 3¾" 2¾" 2¾" 15" 11½" 44" 47¾" 50"

4" 4" 4" 2" 54" 31" 81¼" 4" 10" 11½" 13¾" 3¾" 2½" 2½" 23¾" 11½" 48½" 53" 58"

6" 6" 6" 2" 54" 31" 81¼" 4" 11" 13" 13¾" 5¼" 2¾" 2¾" 25" 13" 59¼" 65¼” 58"

Dimensions are nominal and may vary by ¼”

FM-076D-0-127C 16 of 16

1935, Lionel-Bertrand Blvd. Boisbriand QC Canada J7H 1N8 Tel.: 450-437-3473 • Fax: 450-437-1930 Toll Free: 866-347-3353 Email: [email protected] • Web: www.fireflex.com