(2) Fermentation Booklet

-

Upload

leandro-e-criis -

Category

Documents

-

view

232 -

download

0

Transcript of (2) Fermentation Booklet

Cairo University

Faculty of Science Biotechnology/Biomolecular Chemistry Program

(BioT 405)

Prof. Zeinat Kamel &

Dr. Sherif Elnagdy

Faculty of Science, Cairo University

1

Cairo University

Faculty of Science Biotechnology/Biomolecular Chemistry Program

Practical Fermentation Technology

(BioT 405)

Prof. Zeinat Kamel Prof. of Microbiology and Biotechnology

Faculty of Science, Cairo University

&

Dr. Sherif Elnagdy Lecturer of Microbiology and Molecular Genetics

Faculty of Science, Cairo University

2

Introduction

This practical handout is a collection of practical activities aimed at introducing the user

to a range of interesting and thought provoking fermentations. The investigations have

been designed so that on completion they will give the user a new insight into

fermentation. It is also hoped that the extension activities will lead on to other more

demanding investigations designed by the students themselves. Many of the extensions

activities focus on activities that allow the application of statistical analysis.

The authors hope that that the practical will not only form the basis for the class activities

but also the stimulus for individual invitations into fermentation.

The Authors

3

Safety Guidelines

All investigations should be carried out using good laboratory practice. Given here are a

few brief notes and hints to help those involved in the various activities to carry them out

safely. Remember that before any practical activity is undertaken a risk assessment

should be performed to ensure there is minimal hazard to all concerned. If there is any

doubt about the assessment of the risk, reference must be made to safety texts or expert

advice taken.

Safe microbiology

The practical activities selected in this package and the microorganisms suggested

present minimum risk given good practice. It is therefore essential that good

microbiology laboratory practice is observed at all times when working with any

microbes.

There are five areas for consideration when embarking on practical microbiology

investigations which make planning ahead essential.

1. Preparation and sterilization of equipment and culture media.

2. Preparation of microbial cultures as stock culture for future investigations and

inoculum for current investigation.

3. Inoculation of the medium with the prepared culture.

4. Incubation of cultures and sampling during growth.

5. Sterilization and safe disposal of all cultures and decontamination of all contaminated

equipment.

Good organizational skills and a disciplined approach ensure that every activity is

performed both safely and successfully.

4

Protection

Food or drink should not be stored or consumed in a laboratory that is used for

microbiology. One should not lick labels, apply cosmetics, chew gum, suck pens or

pencils or smoke in the laboratory. Hands should be washed with disinfectant soap after

handling microbial cultures and whenever leaving the laboratory. If hand contamination

is suspected then the hands should be washed immediately with disinfectant soap. To

ensure that any wounds, cuts or abrasions do not get infected or infection is passed on,

protect them by the use of waterproof dressings or wear disposable surgical gloves.

General personal safety

Each individual embarking on these or any other microbial investigation is responsible

for their own safety and also form the safety of others affected by their work (other

students, technicians, teachers). The individual must include in the planning and

performance of the investigation a risk assessment to assess any hazard that the

investigation may pose and ways of minimizing it. Points to consider include safe storage

and culturing of microorganisms, emergency procedures such as dealing with spillages

and safe disposal of all contaminated material. No one should perform any

microbiological procedures without receiving appropriate training from a competent

person. To minimize the chance of contamination of the user, any other individual, the

environment or the microbial culture good laboratory practice is required. Safety

principles require us to consider all cultures as potentially pathogenic.

Aseptic technique

Sterile equipment and media should be used to transfer and culture microorganisms.

Aseptic technique should be observed whenever microorganisms are transferred from one

container to another. Contaminated equipment should preferably be heat sterilized by

either incineration or autoclaving. A suitable chemical disinfectant can be used but this

may not ensure complete sterilization.

5

1. Fermentation processes and growth

Two general processes: the batch technique and the continuous flow technique are used

in industry for large-scale cultivation of microorganisms.

The batch technique; employs a huge tank with a volume of upto 100,000 gallons of

medium. The tank is often called a fermentor because industrial microbiologists use the

word fermentation to refer to any aerobic or anaerobic process catalyzed by

microorganisms. The medium is sterilized with steam or with a gas such as sulfur

dioxide, and enough microorganisms are allowed to grow for days, weeks or months,

then they are removed and the product is isolated from the materials in the tank. In some

cases, the organisms may be used as feed for animals.

In the continuous flow technique (Figure 2),

medium is continually added to replace that

which has been fermented. An instrument

called a chemostate is used to provide a

constant flow, and the microorganisms are

kept in the logarithmic stage of growth.

6

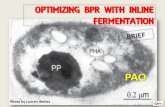

2. Principles of a bioreactor

Before a bioreactor can be used for microbial growth investigations the vessel and its

contents must be sterilized by autoclaving. Autoclaving involves using steam under

pressure and ensures the complete destruction of microorganisms and their spores. The

bioreactor must be correctly prepared to ensure successful sterilization. The individual

components of the bioreactor must be clean and then carefully assembled. Care should be

taken to ensure the correct vents are fully open or closed for autoclaving. The assembled

bioreactor should be filled with broth just before autoclaving. The autoclave time is

worked out by choosing a temperature (e.g. 121°C) and calculating total sterilization

time. The total time consists of (a) heat penetration time, (b) holding time to kill all

organisms and (c) safety margin (e.g. 5+10+5 = 20 min). It is important to close the

addition/ inoculation port immediately after autoclaving so that the bioreactor remains

sterile.

7

8

3. Growth Curve

Microbial growth is an orderly increase in cellular components that is usually followed

by cell division. Under optimal conditions growth is an orderly increase or doubling of all

cellular components and is termed balanced growth.

Microbial growth under conventional conditions follows it predictable course. Upon

inoculation into a fresh medium, the culture exhibits an initial lag in the increase in cell

numbers. During this period cells are increasing in size while adapting their synthetic

capacity (that is. DNA. RNA. And protein synthesis) for optimal growth this phase is

followed by a period of exponential growth during which the culture is in balanced

growth and the growth rate is constant. In time, the culture exhausts essential nutrients in

the environment. And toxic wastes build up eventually slowing the growth rate. As

adverse environmental conditions worse. The increase in cell numbers stops. And with

time, the cell population begins to decline.

One can follow the growth of a microbial culture by measuring changes in cell mass,

viable counts, or any chemical constituent of the cell (for example. RNA or protein). In

this experiment you will follows the growth of a microbial culture by measuring two

parameters: cell mass and viable count. This gives you the opportunity to compare the

relationship between the two methods.

The bacterium used in this exercise is Beneckea natriegens. It is a gram-negative rod

related to the pseudomonads. Because of its rapid growth rate, this species is ideally

suited for this exercise. It is an obligate halophilic organism. And all media and dilution

blanks will be supplemented with 1.5% Na Cl.

9

Procedure

You will work in pairs to perform this experiment. Initially you will inoculate a tube of

brain heart infusion broth containing 1.5% NaCI with R. natriegens (your instructor will

indicate the Inoculum size to be used).

1. Immediately after inoculating, read and record the absorbance of the culture tube

at 650 nm using the photometer or spectrophotometer provided. Following these

absorbance measurements. Immediately incubate the culture at 37 oC on the

shaker provided.

2. Continue taking absorbance readings at 15 minute intervals until the absorbance

no longer the culture.

The Bacterial Growth Curve

In the laboratory, under favorable conditions, a growing bacterial population doubles at

regular intervals.

Growth is by geometric progression: 1, 2, 4, 8, etc. or 20, 21, 22, 23.........2n (where n = the

number of generations). This is called exponential growth. In reality, exponential

growth is only part of the bacterial life cycle, and not representative of the normal pattern

of growth of bacteria in Nature.

When a fresh medium is inoculated with a given number of cells, and the population

growth is monitored over a period of time, plotting the data will yield a typical bacterial

growth curve

10

Figure 1 The typical bacterial growth curve. When bacteria are grown in a closed system (also called a

batch culture), like a test tube, the population of cells almost always exhibits these growth dynamics: cells

initially adjust to the new medium (lag phase) until they can start dividing regularly by the process of

binary fission (exponential phase). When their growth becomes limited, the cells stop dividing (stationary

phase), until eventually they show loss of viability (death phase). Note the parameters of the x and y axes.

Growth is expressed as change in the number viable cells vs time. Generation times are calculated during

the exponential phase of growth. Time measurements are in hours for bacteria with short generation times.

Four characteristic phases of the growth cycle are recognized:

1. Lag Phase. Immediately after inoculation of the cells into fresh medium, the

population remains temporarily unchanged. Although there is no apparent cell division

occurring, the cells may be growing in volume or mass, synthesizing enzymes, proteins,

RNA, etc., and increasing in metabolic activity.

The length of the lag phase is apparently dependent on a wide variety of factors including

the size of the inoculum; time necessary to recover from physical damage or shock in the

transfer; time required for synthesis of essential coenzymes or division factors; and time

required for synthesis of new (inducible) enzymes that are necessary to metabolize the

substrates present in the medium.

2. Exponential (log) Phase. The exponential phase of growth is a pattern of balanced

growth wherein all the cells are dividing regularly by binary fission, and are growing by

geometric progression. The cells divide at a constant rate depending upon the

composition of the growth medium and the conditions of incubation. The rate of

exponential growth of a bacterial culture is expressed as generation time, also the

doubling time of the bacterial population. Generation time (G) is defined as the time (t)

11

per generation (n = number of generations). Hence, G=t/n is the equation from which

calculations of generation time (below) derive.

3. Stationary Phase. Exponential growth cannot be continued forever in a batch culture

(e.g. a closed system such as a test tube or flask). Population growth is limited by one of

three factors: 1. exhaustion of available nutrients; 2. accumulation of inhibitory

metabolites or end products; 3. exhaustion of space, in this case called a lack of

"biological space".

During the stationary phase, if viable cells are being counted, it cannot be determined

whether some cells are dying and an equal number of cells are dividing, or the population

of cells has simply stopped growing and dividing. The stationary phase, like the lag

phase, is not necessarily a period of quiescence. Bacteria that produce secondary

metabolites, such as antibiotics, do so during the stationary phase of the growth cycle

(Secondary metabolites are defined as metabolites produced after the active stage of

growth). It is during the stationary phase that spore-forming bacteria have to induce or

unmask the activity of dozens of genes that may be involved in sporulation process.

4. Death Phase. If incubation continues after the population reaches stationary phase, a

death phase follows, in which the viable cell population declines. (Note, if counting by

turbidimetric measurements or microscopic counts, the death phase cannot be observed.).

During the death phase, the number of viable cells decreases geometrically

(exponentially), essentially the reverse of growth during the log phase.

Growth Rate and Generation Time

As mentioned above, bacterial growth rates during the phase of exponential growth,

under standard nutritional conditions (culture medium, temperature, pH, etc.), define the

bacterium's generation time.

Generation times for bacteria vary from about 12 minutes to 24 hours or more. The

generation time for E. coli in the laboratory is 15-20 minutes, but in the intestinal tract,

12

the coliform's generation time is estimated to be 12-24 hours. For most known bacteria

that can be cultured, generation times range from about 15 minutes to 1 hour. Symbionts

such as Rhizobium tend to have longer generation times. Many

lithotrophs, such as the nitrifying bacteria, also have long generation times. Some

bacteria that are pathogens, such as Mycobacterium tuberculosis and Treponema

pallidum, have especially long generation times, and this is thought to be an advantage in

their virulence.

Growth kinetics and Generation time

1- Add 5 cm3 of the culture of Vibrio natriegens to 95 cm3 of sterile broth in the flask,

swirl and immediately take a 2 - 3 cm3 sample and place in a sterile Universal bottle.

Label and store at 4°C.

2- Incubate the flask in the water bath at 30°C for the next two to three hours and take

samples every twenty minutes for growth measurements using aseptic technique.

The spread plate method is used for determining cell numbers:

3- Aseptically add 1.0 cm3 of the broth culture to 9.0 cm3 of saline to obtain the first

dilution (10-1).

4- Take 1.0 cm3 of the diluted broth culture to 9.0 cm3 of saline to obtain the second

dilution (10-2).

5- A series of dilutions should be made in a similar way to give dilutions in the range of

10-6 to 10-8.

6- Using a sterile spreader spread 0.1 cm3 of one dilution evenly over the surface of a

saline agar.

7- Incubate the plates overnight at 30°C.

8- Examine all plates and select the most appropriate (30 - 300 colonies) and count the

number of colonies on each. Calculate the number of bacterial cells per cm3 of each

sample. Plot a growth curve of log number against time and calculate the mean

generation time.

13

Calculation of Generation Time

When growing exponentially by binary fission, the increase in a bacterial population is by

geometric progression. If we start with one cell, when it divides, there are 2 cells in the

first generation, 4 cells in the second generation, 8 cells in the third generation, and so on.

The generation time is the time interval required for the cells (or population) to divide.

G (generation time) = (time, in minutes or hours)/n(number of generations)

G = t/n

t = time interval in hours or minutes

B = number of bacteria at the beginning of a time interval

b = number of bacteria at the end of the time interval

n = number of generations (number of times the cell population doubles during the time

interval)

b = B x 2n (This equation is an expression of growth by binary fission)

Solve for n:

logb = logB + nlog2

n = logb - logB

log2

n = logb - logB

.301

n = 3.3 logb/B

G = t/n

Solve for G

G = t

3.3 log (b/B)

14

Example: What is the generation time of a bacterial population that increases from

10,000 cells to 10,000,000 cells in four hours of growth?

G = t

3.3 log b/B

G = 240 minutes

3.3 log 107/104

G = 240 minutes

3.3 x 3

G = 24 minutes

4. Relation of free O2 to microbial growth

Gaseous Requirements

The principal gases that affect bacterial growth are – O2 – and CO2. On the bases of

their O2 relationship, bacteria one divided into four groups:

a. Aerobic bacteria: require O2 for growth and can grow when incubated in an

atmosphere (21% O2).

b. Anaerobic: do not use O2 to obtain energy; moreover, oxygen is toxic for then

and they cannot grow when incubated in an air atmosphere. Some can tolerate low

levels of O2 (non-stringent anaerobes) but others (stringent or strict anaerobes)

cannot tolerate. Even low levels and may, upon brief exposure to air.

15

c. Facultative anaerobic bacteria: do not require O2 for growth although they

may use it for energy production of it is available. They one not inhibited by O2

and usually grow as well in presence or absence of O2.

d. Aerotolerant anaerobes: Cannot use but tolerate it though their growth may

be enhanced by.

e. Microaerophilic bacteria: require low levels of O2 for growth but cannot

tolerate the level of O2 present in an air atmosphere.

Procedure:

1- Melt three tubes of yeast extract agar and hold at 100 O C for 10 minutes to expel

the dissolved O2.

2- Cool to a temp. of 45O C and inoculate each with one of the cultures E. Coli,

Micrococcus and Clostridium. Gently shake.

3- Solidify the agar.

4- Incubate at 37 O C for 2 days and observe the location and appearance of growth.

Anaerobic culture:

Anaerrobsis can be achieved by several methods:

1, The use of deep medium:

Deep agar supports the growth of anaerobic bacteria.

16

2-The use of special anaerobic media:

Several media containing reducing substances could be used for anaerobic bacteria:

a- Thioglycolate broth:

Strict aerobes grow in the surface region of thioglycolate broth where more oxygen is

present, while: obligate anaerobes grow throughout the depths of the broth.

Microaerophils grow in the region between the oxygenated surface and the anaerobic

depth.

b. Robertson cooked meat medium:

It consists of slices of meat in broth the meat particles contain hematin, glutathione

and lipids which are reducing agents.

3. Removal of oxygen and replacing it will an inert gas.

5. Antibiotic Production by Fermentation

5.1. Isolation and purification of antibiotic producing organisms

- Different soil samples collected from different cultivated area are used for

isolation of Streptomyces colonies.

- Isolation is performed by soil dilution plate technique using either starch nitrate

agar or chitin-casein agar as selective media for isolation.

- Ten gram of each soil was taken in 100ml of water or isotonic saline solution and

agitated vigorously.

- Different aqueous dilutions in the range of 10-2 to 10-7 of the suspension are

applied onto plates and 20 ml of melted agar medium at 50OC was added to each

dilution after gently rotating the plates are incubated at 30 OC for 7-10 days.

17

- Selected colonies (rough, chalky) of actinomycetes are transferred from mixed

culture of the plates onto respective agar plate and incubated at 28 OC – 30 OC for

7 days.

- The selected isolates were preserved in glycerol 20% and stored at 4 OC for

further investigation.

5.2. Screening antimicrobial activity of the isolates

5.2.1 Antagonistic properties of solid agar cultures (Cork-borer method)

The studied isolates are grown on starch nitrate agar, sucrose nitrate agar, glycerol

asparagines agar oat meal agar and fish meal extract agar. After 7 days of incubation, at

28 OC, agar discs, 6 mm in diameter, were cut off by a cork borer and transferred to the

surface of agar plates freshly inoculated with the test organisms, the bacterial test

organism are cultivated on nutrient agar whereas yeasts and fungi are cultivated on malt

extract agar and sucrose Czapek Dox agar respectively, the diameter of the inhibition

zone of the test – organism are measured after 24 hours for bacteria and 48 hours for

yeast and fungi.

5.2.2 Antagonistic properties of liquid shaken cultures

• Agar well method:

Erlenmeyer flasks - 250 ml, capacity containing 50ml liquid medium are inoculated with

the experimental isolates and kept at 28 OC on a rotary shaker “200 r.p.m” for 5 days.

Aliquots of 0.2ml of the fermented broth were transferred to wells bored in agar plates,

previously inoculated with the test organisms. The Petri dishes were kept in a refrigerator

for diffusion for two hours just before incubation at 37 OC for 24 hours, for bacteria, at 30

18

OC for 48 hours for yeast and 72 hours at 25-30 OC for filamentous fungi. The diameters

of inhibition zones around the well are measured after 24 or 48 hours of incubation

periods. The inhibition zones are an indication of the antimicrobial activity of isolates.

• Paper disk method :

Analytical paper disk (10 mm in diameter) are saturated with fermentation broth and

aseptically placed onto the surface of the inoculated pates with different test organisms.

The Petri dishes were kept in a refrigerator for diffusion for two hours just before

incubation at 37 OC for 24 hours for bacteria, at 30 OC for 48 hours for yeast and 72 hours

at 25-30 OC for fungi. The diameter of inhibition zones around the filter paper discs is

measured.

5.3. Separation and detection of different antibiotics by bio-

autography

This method enables the separation and detection of different antibiotics if more than one

active substances present in the culture filtrate. Bio-autography is used also for the

identification of the antibiotics procedure.

Procedure

The clear broth was concentrated, in vaccuo, and either extracted by different solvents

(e.g. chloroform, ethyl acetate, diethyl ether) or applied directly to the paper. 50mg of the

antibiotic solution is applied to a chromatographic paper strip (2cm X 30cm) using a

micropipette. Different developing solvent systems are used for ascending paper

chromatography:

- Petroleum ether saturated with water.

- Diethyl ether.

- Chloroform.

19

- Ethyl acetate.

- Butanol – acetic acid – water (2: 1:1 v/v).

- Acetone.

The antibiotic spots are detected by bio-autography against Bacillus cereus as a test

organism:

Chromatograms of the investigated antibiotic previously developed in appropriated

solvent systems are dried and placed on the surface of nutrient agar plates freshly

inoculated with sensitive test organism e.g. B. cereus. The width of inhibition zones is

determined.

The Rf values, in different developing solvents are recorded.

The classes of the antibiotic are determined by comparing its Rf values in different

solvents with those obtained by authentic or known antibiotic.

5.4. Fermentation, extraction, isolation and separation of the

antibiotic from culture broth

5.4.1 Fermentation

For the process of antimicrobial agent (s) biosyntheses by the submerged fermentation

conditions used, in which conical flasks of 250 ml capacity charged with 100mml of

inorganic salt-starch agar medium (g/l) (soluble starch 20g; K2HPO4 (anhydrous), 1g;

MgSO4.7H2O, 1.5g; NaCl, 1g; (NH4)2SO4, 2.5g; CaCO3.H2O, 2.0g; distilled water,

1000ml and trace salt, 1.0ml). pH of the media was adjusted at 7, then the emdia

autoclaved. 3 discs of the culture were inoculated to each flask and incubated at 30OC for

7 days on a rotary shaker at 250 r.p.m.

20

5.4.2 Isolation of the antimicrobial agent(s)

At the end of incubation period, filtration was carried out first through cotton wool and

then centrifugation was performed at 5000 r.p.m. for 15 minutes. Clear filtrate was tested

for its antimicrobial activity. Many trials were carried out for extraction of the

antimicrobial substances produced by Streptomyces, in a cell-free filtrate. Various

organic solvents were used in this respect in alkaline, acidic and at neutral pH. Organic

solvents used for extraction were:

1. Ethyl acetate

2. Chloroform

3. Diethyl ether

4. N-Butanol

5. Ethyl acetate + chloroform

6. Benzen

7. Chloroform+ n-Butanol

8. Ethyl acetate+ n-Butanol

The extracts were tested for their antimicrobial agnet activity using paper disc method

(table)

5.4.3. Extraction

The cell free filtrate was adjusted at pH 7 and extracted by chloroform as the suitable

solvent. The solvent was added to the fermentation broth at the level of 2:1 (V/V)

respectively. The organic phase was collected evaporated under reduced pressure by

using a rotary evaporator, the evaporation was continued until viscous syrup was

dissolved in the least amount of solvent and filtered through whatman No.1 filter paper

and then tested for its antimicrobial agent activity.

21

Table: Showing data of the isolation procedure of the produced antimicrobial agents

produced by Streptomyces sp.

Solvent used

Antimicrobial agent activity in terms of mean diameter

of inhibition zones (mm)

B. Subtilis

ATCC 6633

S. aureus

ATCC 6538

E. coli

ATCC 8739

C. albicans

ATCC 1023

1- Ethyl acetate

2- Chloroform

3- Diethyl ether

4- n- Butanol

5- Ethyl acetate+ chloroform

6- Benzen

7- Chloroform + n- Butanol

8- Ethyl acetate + n-Butanol

5.4.4. Separation and purification of the active components

Separation of antimicrobial agents into individual components has been carried out by

thin layer chromatography (TLC) using a solvent system composed of n- Butanol +

Pyridine + water (2.0 : 0.6:1.0) (V/V). Thin-layer chromatography of the antimicrobial

agent was carried out by spotting 10 microlitre of the crude antimicrobial agent on each

of the silica gel plates which were developed for 2 hours. Detection of the antimicrobial

agent compounds was accomplished by a microbial procedure. Four plates were seeded

singly with E. coli (as a Gram -ve bacteria), B. subtilis and Staph. aureus (as a Gram +ve

bacteria), and C . albicans. The four thin layer plates were located on the surface of the

four plates of used test organisms and then left for one hour in a cold room. The plates

were then incubated for 24 hour at 37 OC for bacteria and 48 hours for yeast at 30 OC. The

antimicrobial agent compounds were visualized as zones of inhibition (mm) on agar

plates.

22

5.4.5 Determination of minimum inhibitory concentration (MIC)

One mg of the antimicrobial agent under study was dissolved in 1 ml chloroform then

two fold dilutions in the solvent were prepared serially, ten ul of each dilution was loaded

on the filter paper disc (5mm in diameter). The antimicrobial activity was determined by

diffusion method, the inhibition zones that appeared around the discs determined the

activity of the anti microbial agent. The highest minimum concentration of the

antimicrobial agent preventing test organisms is MIC.

23

Isoaltion of Antibiotics from microraginsms

24

25

26

27

28

6. Microbial production of some important industrial

and pharmaceutical enzymes

1. Production of amylase

I) Measurements of amylolytic activity

Starch is a complex carbohydrate of the polysaccharide type. A qualitative test for starch

is the appearance of blue colour upon the addition of a solution of iodine. When starch is

hydrolyzed (decomposed with the addition of water), the cleavage products – dextrins,

maltose and glucose, to list them in descending order of complexity- do not give this

color reaction. The exercise principle is to compare different bacterial isolates for their

potentialities to produce amylase.

Uses and application

It is used in preparing adhesive, clarifying fruits juices, liquefaction of starch in alcohol

fermentation, additive in detergents, manufacturing of pharmaceutical products and for

other products.

Producing organisms

Different bacterial and fungal species can be used, e.g. Bacillus spp., Streptomyces spp.,

and Rhizopus spp.

Procedure

- The medium used contains soluble starch, 5g; yeast extract, 2g; KH2PO4, 1g;

MgSO47H2O, 0.5g and distilled water 1L.

29

- The pH after autoclaving is 7.2

- Three discs (6mm diameter) of each organisms (4-day old) was used as Inoculum.

The flasks are filtered and amylolytic activity is determined in culture filtrates as

follows:

1. Agar-cup plate diffusion method:

- Amylase activity of each culture filtrate is determined by pipetting 0.1 ml of the

filtrate into activity bored in a starch assay medium in Petri-dishes using sterile

cork borer

- The assay agar medium used is:

Soluble starch 5g

Distilled water 1L.

- The dishes were incubated at 30˚c for 24 hrs and then the assay agar medium is

flooded with iodine solution. Uninoculated medium did not show any amylase

activity.

- The width of clear non – blued zone around the activity is measured in mm after

24 hr.

II) Assay of amylolytic activity by estimation of released reducing

sugars:-

3 ml enzyme solution + 0.5% starch in 0.2 m phosphate buffer, PH 6.5.

Similar reaction mixtures using heated inactive enzyme solution are also prepared as

control. The reaction mixture is incubated in water bath at 37˚c for 30 min. The released

reducing sugars due to the amylolytic activity are determined.

30

2- Production of Protease

The term protease refers to a mixture of enzymes that break down proteins.

Proteins peptides amino acids

Uses and application

Protease is used in classifying juices and drinks, is component of detergents, in medicine

as blood clotting, in leather manufacturing improve product quality in cheese making,

also is used to clean dead tissues from wounds.

Producing organisms

Many bacteria can degrade a variety of proteins. Most Streptomyces spp., Bacillus

subtilis and other Bacillus species, Aspergillus oryzue.

Procedure

1- Obtain two Petri plates of skim milk agar.

2- Inoculate one plate with E.coli and the other with B. subtilis using a loop to place cells

in the center only.

3- Incubate at 37˚C until the next laboratory period.

Colonies of organisms that digest casein (Proteolytic microbes) will be surrounded by

clear zones. Areas in which the casein has not been attacked will remain slightly opaque.

You can usually see the clear zones best against a black background.

Proteolytic Enzymes

31

3- Production of cellulase

Cellulose is one of the most abundant naturally occurring organic materials on earth.

The vast quantities of available cellulosic materials have great potentialities as a

reservoir for energy and chemical resource.

Cellulose is a linear homopolymer of glucose units linked together by 1.4 – glucosidic

bonds of indefinite length, complete hydrolysis yields the monosaccharide glucose

while partial hydrolysis yields the disaccharide cellobiose.

Screening of microorganisms for cellulase production

a- On solid media :

The ability of different Strep. sp. to produce cellulose enzymes can le tested by the

agar plate method. Microbial strains are cultured on agar plates containing 4 g/L of

other cellulose or carboxy methyl cellulose as a sole c source mixed with mineral

salts.

Estimation of cellulytic activity is made from the clears zone around the colonies on

cellulose plates.

b- In liquid cultures :

In this experiment different actinomycetes isolates are tested for their ability to

produce cellulase enzyme cultivation is in 250 ml conical flasks each containing 50

ml of sterile medium containing 4/g /L cellulose or carboxy methyl cellulose as a sole

c source mixed with mineral salts.

After autoclaving, the medium is adjusted to pH 7.5 with 5 N sterile NaOH.

32

- Flasks incubation, the culture medium from each flask is filtered to separate the

mycelium from the culture filtrate.

- In the clear supernatant, the cellulytic activity is determined.

a- Estimation of cellulytic activity by agar plate method:

The procedure consists of incorporation of 1% of cellulose or carboxy methyl

cellulose in 2% agar solution, poured in Petri dishes to give 4 – mm layer. Enzyme

activity of each culture filtrated is determined by pipetting 0.1 ml of the filtrate into a

well bored in cellulose assay medium in Petri dishes the dishes are incubated at 28 C

for 18-24 hours. Estimation of cellulose is made from the clear zones produced a

around the pores. Zone diameter is measured and the activities are calculated from the

standard.

b- Quantitative estimation of cellulase.

The reducing sugars liberated by cellulase in the culture broth are estimated.

Assay of cellulase mixture consisted of 2.0 ml of the culture filtered and 18 ml citrate

phosphate buffer (pH 5) containing the substrate carboxy methyl cellulose (CMC) the

reducing sugars released from cellulose substrate are determined as glucose using

Somegy`s methods .

4. Production of lipase

Purpose

- To demonstrate the fat-splitting action of microorganism. i.e. the presence of

lipolytic enzymes.

- To indicate the reaction of these enzymes to problems of food spoilage.

Especially those rich in fatty substances.

33

Materials

1. Cultures (broth- 24 hours).

a. Peseudomonas florrescens. C. Bacillus subtilis.

b. Escherichia coli. D. Serratia narcescens.

2. Nutrient agar for plating (M-xx1) (2 tubes).

3. Fresh vegetable fat.

4. Copper sulfate solution (rp-VII).

5. Sterile Petri dishes (2). Sterile pipette. 1-ml.(1)

NOTE: If the plates are prepared by the instructor. A more even distribution may be

obtained by the use of a homogenizer.

Procedure

1. To each of two tubes of melted agar, add about 0.2 or 0.3 ml of a vegetable fat

(cottonseed or coconut oil), using a sterile pipette.

2. Rotate the tubes thoroughly between the palms of the hands until the fat is

well distributed in the agar.

3. Pour contents of each table into a sterile Petri dish, and allow the agar to

solidify.

4. Inoculate one plate by making a short (streak with P. fluorescens and a second

streak with S. marcescens, labeling both. Do likewise with E. coli: and B.

subtilis on the second plate.

34

5. Incubate in an inverted position at 30o C. or room temperature for 4 days.

6. After Incubation, flood both plates with the copper sulfate solution permitting

it to remain in contact for 10 to 35 minutes. Pour off the excess.

7. Examine plates for a greenish sheen along and under of growth this is best

done in reflected light.

Record of Results

Tabulate as follows:

Organism Lipolytic Activity

5- Keratinase:

Some microorganisms are known for their ability to hydrolyze febrile proteins e.g keratin

of hair wool horns and feather yielding a mixture of peptides and amino acids.

Uses

Keratinase is used for unhairing of hides, leather industry, skin treatment and cosmetics

and in pharmaceutical chemical. Production of protein and peptides from wastes for

animal feed.

Producing organism: Some Streptomyces species.

35

Procedure

-8 flasks (250 ml) containing 50 ml inorganic salt broth media without nitrogen source.

-Add 50 g of each keratin to two flasks including sterile feather, hairs, wool. Three discs

of each organism were used as at 28 – 30 for 15 days. The activity is determined by

measuring the filtrate by Folin reagent for detection of peptides.

7. Production of Organic acids

1- Lactic acid Production by bacteria:

Fermentation is one of the oldest means of food preservation. Lactic acid fermentation

plays an important role in dairy and pickles industries.

Most fermented foods require the growth and activity of one or more species of lactic

acid bacteria (Lactobacillus, Pediococcus, Leuconostoc, Streptococcus). These bacteria

ferment sugars to organic acids, mainly lactic acid, which act as preserving a gents and

prevents the action of putrefactive bacteria (Spoilage).

Fermentation not only preserves certain food but also improves the flavor and nutritional

value of some.

C H O CH COCOH CH CHOHCOOH

Glucose Pyruvic acid Lactic acid

• Lactic acid bacteria are Gram +ve rods or cocci; microaerophilic or

facultative anaerobes that are common in dairy products, fermented food,

mouth and gastrointestinal tracts of human and animals.

6 12 3 3 6

36

• Lactic acid bacteria are responsible for the souring taste of pickles and

yogurt.

• The drop in pH of the medium is unfavorable for the growth of other

bacteria.

Production of lactic acid:

Lactobacillus species are used in lactic acid production L.bulgricus is a commonly used

species because it produce lactic acid only (homofermentative).

- Lactic acid fermentation is anaerobic fermentation.

- Conical flasks containing sterile whey as a fermentation medium is inoculated

with the bacterium and incubated at 43 C. Ca is added to convert lactic acid to

calcium lactate.

- After some days test for the presence of lactic acid in the fermented solution

as follow:

- Transfer 1m1 of the inoculated solution is a test tube, add few drops of 10%

Na OH until the solution is just alkaline to litmus.

- Add 5 ml of 15% potassium iodide.

- Add 5 ml of sodium hypochlorite solution, mix well, a yellow ppt is formed

immediately on cooling.

- Determine the amount of lactic produced by titration with NaOH.

Quantitative estimation if lactic acid

a. To 10 ml inoculated cheese whey culture, add 10 ml distilled water.

37

b. Boil for 1-2 minutes to get rid of all Co2/

c. Titrate against 0.1N: NaOH using phenolphthalein indicator.

Lactic acid ( 9%) = X 100 X

A. volume of Na CH B Normality of NAOH

C. Eq. Wt. Of lactic acid 90 D volume of sample

2. ACETIC ACID AND VINEGAR

Although acetic acid is produced by many fermentative bacteria, only members of a

special group, the acetic acid bacteria, are used in commercial production. The acetic

acid, bacteria can be divided into 2 genera, Gluconobacter and Acetobacter. Over a

hundred types of both genus have been used for production.

Vinegar contains about 3 to 5% acetic acid, Production of vinegar, involves two types of

biochemical changes:

1. An alcoholic fermentation of a carbohydrate by yeast (anaerobic fermentation).

2. Oxidation of the alcohol to acetic acid by acetic acid bacteria (aerobic process).

There are several kinds of vinegar and the differences among them are primarily

associated with kind of material used in the alcoholic formation, e.g. fruit juices, sugar

syrups and hvdrolyzed starch materials.

A X B X C D

1 1000

38

CH3 CH 2 OH CH3 CHO CH3 COOH

Ethyl alcohol acetaldehyde acetic acid

Productions process in industry is aerobic and involves the adsorption of acetic acid

bacteria (Acetobacter on to wood chips that are packed into column, an aerated solution

of ethereal is passed through the column, ethanol is converted to acetic acid.

Acetic acid production can be detected by inoculating conical flasks containing 10-13%,

ethanol by Acetic acid bacteria. Shake the ethanol solution well. After incubation for 2-3

days smell the sample of the culture and smell of acetic acid.

Add 2 drops of phenol phethaline indicator to 10 drops sample. Titrate with NaoH until

the first sign of pink appears, record the amount of NaOH added. Calculate the amount of

acid produced subtracting the volume for the original substrate.

3. CITRIC ACID PRODCUTION

Production of citric acid is aerobic process.

Uses

• In pharmaceutical industry (10% of the total usage)

- Iron citrate is used as a source of iron.

- Because citric acid is an anticoagulant, it is used as a preservative for stored

blood.

- It is used in ointments and in cosmetic preparations.

• In chemical industry (25% of the total usage)

- It is used as antifoam agent.

- It is used in inks and dyes.

- It is used as a softener and for the treatment of textiles.

- Citric acid is used in the detergent industry because it can replace polyphosphates.

• In food industry (60% of the total)

39

Citric acid is used in the food and beverage industry. The flavor of fruit juices, candy,

ice cream and marmalade is enhanced or preserved by the addition of citric acid.

• In metal industry

Pure metals are produced as metal citrate.

Procedure

In one L flat bottle add 200 ml of salt medium containing sucrose or molasses as carbon

source then sterilize.

Inoculate the surface of the medium with spores from the slant culture of A. niger.

After incubation, titrate a 5 ml sample of the medium using 0.1N NaOH and phenol

phthalein as indicator.

Calculate the amount of NaOH required to neutralize the acid present from your titration

later calculate the percent of acid formed.

8. Sauerkraut- a natural traditional fermentation

The production of sauerkraut is a traditional fermentation in which the sugars in the

cabbage are fermented to acids by the naturally occurring bacteria that are found of the

leaves. The cabbage is shredded and salted and under anaerobic conditions the sugar are

converted to acids, ethanol, mannitol, esters and carbon dioxide. Lactacillus plantarum is

one of the important bacteria involved in the conversion of sugars and mannitol to lactic

acid. The removal of mannitol is especially important as it imparts a bitter flavour to the

sauerkraut.

40

Equipment and materials:

300 g finely shredded cabbage 300 cm 3% w/v sodium chloride solution 1 dm glass

beaker PH electrode and meter temperature electrode (optional) 15 cm bent glass l pipette

with 3 cm rubber tubing Restriction clip (Hoffman clip) large plastic bag (approx. 34 cm

X 26 cm) Scissors Adhesive tape Elastic bands small metal weights 3X00 cm sterile

water for each population count Rogosa agar and GYLA plates (3 of each per count)

(GYLA= Glucose Yeast Lemco Agar). Sterile 1 cm , 2 cm , 5 cm and 10 cm syringes

sterile spreader, and a capped beaker of IMS for flaming spreader Burette containing

0.1.M sodium hydroxide solution flasks containing 10 cm deionised water sterile

spreader, and a capped beaker of IMS for flaming spreader Burette containing 0.1M

sodium hydroxide solution flasks containing 10 cm deionised water. Phenolphthalein

indicator solution and dropping pipette.

Procedure:

1. Place 300 g of finely shredded cabbage in the 1 dm beaker. Add sufficient

sodium chloride solution to just cover the cabbage.

2- Cut three sides of the plastic bag to give a single sheet of approximately 300

mm x 500 mm. Cut two small holes for the PH probe and modified pipette,

approximately 150 mm in from each side on the central fold of the sheet. (A third

hole will have to be cut if a temperature probe is used).

3. Place plastic over the surface of the cabbage and insert probes and pipette

through holes. Make as airtight a seal as possible around each probe with the

adhesive tape. Secure the plastic around the beaker with tow elastic bands, Press

down with weights to exclude as much air as possible.

4. Record initial pH (and temperature) and continue to record daily for two weeks.

41

5- During this period, samples of the liquid should be taken for making bacterial

population counts.

6- Samples should also be taken for the calculation of acid content.

Sampling for population counts:

a. Prepare plates (Rogosa and Glucose Yeast Lemco Agar).

b. The bent arm pipette provides safe and accurate sampling from the

fermentation vessel.

c. As aseptically as possible take 1 cm of liquid from the bottom of the

sauerkraut container using a sterile 5 cm bottom of the sauerkraut

container using a sterile 5 cm syringe attached to the bent arm pipette with

the tubing.

d. Add the sample to 99 cm of sterile water (10). Mix thoroughly and then

aseptically remove 1 cm of the 10 thoroughly and then aseptically remove

1 cm of the 10 dilution and add to a second bottle of sterile water (10)

Aseptically remove 1cm of the second diluted solution and add to a third

bottle of sterile water (10).

e. Make lawns on both types of agar plates with 0:1 cm of each of the

dilutions using three new sterile syringes. Flame the spreader with alcohol

between each spreading.

f. After incubation of the plates for 24-48 hours (25 C).count the colonies

and calculator the population of organisms present in the fermentation

(number per cm)

42

Sampling for acid content

1. Aseptically remove 5 cm liquid from the fermentation and add to 10 cm

deionised water. Titrate against 0. 1 M sodium hydroxide solution using a

few drops of phenolphthalein solution as an indicator. (Good laboratory

practice must be observed when using the indicator solution).

2. Calculate the percentage of acid by applying the formula:

% lactic acid=

Assuming no acetic acid is present this value can be used as the amount of lactic acid

produced by the fermentation. Care will need to be taken when determining the end point

of each of the titrations consider how many replicated should be carried out to obtain a

meaning ful set of results.

9. Production of fermented food

Yoghurt

Yoghurt is manufactured by fermenting milk with lactic acid bacteria. The final product

is a viscous gel, which will keep for several days. The concentration of non-fat solids,

which determine the consistency of finished products, is increased to between 14 and 15

g/100 ml. This is done either by adding powdered, milk or by concentrating the milk by

vacuum evaporation. The fat content can be reduced by skimming it off the surface of the

milk. A variety of materials (plant guns, seaweed extracts, Starch, gelatin and cellulose

derivatives) can be added to improve the texture.

titer, cm X morality of Na OH X mol. Mass of lactic acid cm3 sample X 10

43

Procedure

The milk is vigoursly mixed at a temperature between 50 and 760oC to reduce the size of

the fat globous and distribute them evenly throughout the fluid. This step increases the

viscosity by causing casein micelles to interact with fat globules and denaturated why

proteins. Pasteurization or sterilization follows to kill unwanted bacteria, and the milk is

then cooled to fermentation temperature, and inoculated with starter culture.

Bacterial fermentation produces lactate from lactose and the resulting drop in pH causes

casein to precipitate and the product becomes a gel. Yoghurt is naturally flavored by

lactic acid, acetaldehyde, diacetyl and other bacterial metabolites but most yoghurt in

western countries has fruits or flavorings added.

Optimization of incubation temperature

Procedure:

1- Fill 8 measuring cylinders with a mixture of 10% sucrose and 2% yeast cells.

2- Cover the opening of measuring cylinders with Parafilm and invert each one in beaker

contain the same mixture.

3- Poke a tiny hole in the Parafilm with a dissecting needle (to release the pressure).

4- Incubate each beaker in 0, 10, 20, 30, 40, 50, 60 or 70 °C water bath for 45 minutes.

5- Measure the volume of carbon dioxide gas in each cylinder at 5 minutes intervals.

6- Record your values in a table and determine the optimum temperature for

fermentation.

Suitability of different sugars from yeast fermentation

1- Fill 7 measuring cylinders with a mixture of 2% yeast cells and 10% of glucose,

galactose, fructose, maltose, sucrose, lactose or starch.

2- Cover the opening of measuring cylinders with Parafilm and invert each one in beaker

contain the same mixture.

3- Poke a tiny hole in the Parafilm with a dissecting needle (to release the pressure).

44

4- Incubate each beaker in 40°C water bath for 45 minutes.

5- Measure the volume of carbon dioxide gas in each cylinder at 5 minutes intervals.

6- Record your values in a table and determine the best sugar for fermentation.

10. Co- Immobilization of yeast and lactase

Although the brewing yeast Saccharomyces cerevisiae is able to ferment many simple

sugars, such as the monosaccharide glucose and the disaccharide sucrose, to alcohol

and carbon dioxide, it does not have an enzyme system to allow fermentation of the

disaccharide lactose. However, by co-entrapping the yeast and the enzyme lactase (β-

galactosidase), the yeast is able to ferment the sugars formed from the enzymatic

hydrolysis of lactose. In this investigation yeast cells and enzyme are immobilized

together in a calcium alginate matrix.

Procedure

1-Place 50 cm3 water into a small beaker and add 5 g dried yeast.

2- Carefully stir the yeast into the water with a glass rod to ensure a thorough mix. Try

not to mix air into the slurry.

3- Pour 50 cm3 4% sodium alginate solution into the yeast slurry.

4- Carefully stir the sodium alginate solution into the yeast slurry to ensure a thorough

mix. Again try not to stir air into the mixture.

5- For investigations involving co-immobilization of the enzyme lactase with the yeast

cells add 10 cm3 of lactase to the yeast slurry and sodium alginate solution. For

control investigation, Do not use the enzyme lactase but add a further 10 cm3 of

water to the slurry.

6- Place 200 cm3 2% calcium chloride solution into one of the flasks that is to be used

for the fermentation. Add a magnetic follower and place on a magnetic stirrer and

start stirring gently or mix by gently swirling the flask by hand.

7- Draw the yeast-alginate mix up into a 10 cm3 syringe. Add the mixture drop by drop

45

into the calcium chloride solution so that it forms small regular beads. To ensure the

beads set fully, leave them in the calcium chloride solution for about ten minutes.

8- Separate the beads from the calcium chloride solution by using a tea strainer.

9- Examine the ability of these beads for lactose fermentation.

GOOD LUCK

PROF. ZEINAT KAMEL

DR. SHERIF ELNAGDY