2 4b Energy - PSI Metals

Transcript of 2 4b Energy - PSI Metals

© PSI Metals 2011Slide 2

PSI: Process Control and Information Systems

PSI is the leading German supplierof control system software solutions

for energy utilities and industry.

© PSI Metals 2011Slide 4

PSImetals Energy: general tasks and aims

Collect and display data of power producing and power consuming plants

Control of energy consumption and production

Forecast for power consumption and production for different time periods

Integration of production scheduling and real time production events

Avoiding the violation of contract limits

Optimization of steel production respecting energy costs.

© PSI Metals 2011Slide 5

PSImetals Energy: Energy Management System

Important features:Steel-specific:A standard system tailored to the needs of the steel industry.

Proven and tested: High stability, available to use in 7*24h operations.

Flexible:Highly parametrizable and adaptable to changing requirements at any time.

Learning:Permanent, automatic optimization thanks to adaptive algorithms.

Modular:Modular system architecture enables integration of further media without any problems.

© PSI Metals 2011Slide 6

PSImetals Energy: Energy Management System

Components

• EBF – Basic functions

• ECF – Electrical energy

• PDC – Load management

• GCF – Gas and other media

© PSI Metals 2011Slide 7

PSImetals Energy: System Components

EBF Energy Basic Functions

PSIintegration

ECFElectrical Energy

Consumption Forecast

PDCPower Demand

Control

GCFGas Consumption

Forecast

© PSI Metals 2011Slide 8

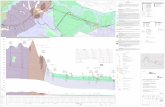

PSImetals Energy at ArcelorMittal Eisenhüttenstadt

History of Energy cooperationbetween AM Eisenhüttenstadt and PSI

Requirement specification for Load Management System (LMS) in 2000

Implementation and going live of Load Management System in 2001

Requirement specification for Gas Management System in 2002

Implementation and going live of Gas Management System (GMS) in 2003/2004, close partnership with BFI (VDEH)

Further enhancements in 2005 and 2006

© PSI Metals 2011Slide 9

PSImetals Energy at ArcelorMittal Eisenhüttenstadt

Realized interfaces with

MES system for planning and scheduling

Electricity counting system for measurements

Steel mill control system (LF integration)

HRM control system via MES

CRM control system via MES

Designed computer interface to

Power supply company

© PSI Metals 2011Slide 10

PSImetals Energy: EBF - Energy Basic Functions

EBF Energy Basic Functions

PSIintegration

ECFElectrical Energy

Consumption Forecast

PDCPower Demand

Control

GCFGas Consumption

Forecast

© PSI Metals 2011Slide 11

PSImetals Energy: EBF - Energy Basic Functions

Collecting Data - Creating TransparencyMeasured-value acquisition and compression

Plausibility checks for all data, Marking / highlighting of invalid data

Automatic measured-value correctionMarking / highlighting of corrected measured values,the original measured values are retained

Check of overall measurements vs. the sum of individual measurements

Definition of software measuring points

Compression of momentary measured values gathered, for example, at a second‘s interval

Archiving of historical data:online database, archive database and reproduction database

Plant downtime scheduling and planning

Contract updating

© PSI Metals 2011Slide 13

Managing supply contractsVariable accounting / billing interval

Several supply contracts per accounting / billing interval

Different supply volumes per accounting / billing interval and supply contract

Contracts for the supply of electrical energy:

Energy costs for the electrical energy actually consumed

Costs for the provision of power station capacity (provision of standard energy)

Penalties for upper (or lower, if applicable) deviations from the agreed power limits

PSImetals Energy: EBF - Energy Basic Functions

© PSI Metals 2011Slide 14

PSImetals Energy: Supply contracts

Screen showing detailsof a specific energy contract.

PSImetals Energy: EBF - Energy Basic Functions

© PSI Metals 2011Slide 15

Integration of new plants

and worksPSImetals Energy manages works and, within the works, individual plants

Integration of new works orplants is possible withoutprogramming

General rule:All controlling parametersof the system are stored asvariables which can bechanged by the user

PSImetals Energy: EBF - Energy Basic Functions

© PSI Metals 2011Slide 16

Benefits of the basic functions

Acquisition of all measured values –

therefore reproducibility of consumption possible

Assignment of consumption to plant and/or works –

therefore assignment of costs is possible

Correlation of the actual consumption to energy contracts becomes evident –

therefore improved transparency

Data archiving – enabling future analyses even of parameters which are

subject to low change rates

PSImetals Energy: EBF - Energy Basic Functions

© PSI Metals 2011Slide 17

PSImetals Energy at ArcelorMittal Eisenhüttenstadt

5 main consumers:

• REW = hot metal plant with 2 blast furnaces

• KSW = steel mill with 2 BOF, 1 LF

• WWW = hot rolling mill

• KWW = cold rolling mill

• the town Eisenhüttenstadt

About 20 important consumers with single measured values

A power station with 5 steam boilers for blast furnace gas, converter gas, natural gas and 1 natural gas turbine

Power supply contract

© PSI Metals 2011Slide 18

LMS at ArcelorMittal Eisenhüttenstadt

Five main plants are divided into important single consumers

Planned downtimes are integrated via interface with planning and scheduling system and MES,combined with automatic detection of downtimes

Interface with measurement systems.

LMS gets measured values every 5 seconds for each consumer.

Measured values are consolidated and stored into the LMS system.

Consolidated values are stored up to 10 years in special archiving database.

Integrated breakdown recognition module using measured values

© PSI Metals 2011Slide 19

EBF Energy Basic Functions

PSIintegration

ECFElectrical Power

Consumption Forecast

PDCPower Demand

Control

GCFGas Consumption

Forecast

PSImetals Energy: ECF - Energy Consumption Forecast

© PSI Metals 2011Slide 20

PSImetals Energy: ECF - Energy Consumption Forecast

Looking to the future

Different forecasting methods for different applications included

Free assignment of one or more forecasting methods to the plants

Automatic weighting of the different forecasting methods

Import of plan data and integration thereof into forecasts

Automatic unplanned downtime detection

Preparation of a time schedule for the utility company

Evaluation of the forecast precision

Internal power generation, if any, by the consumer is considered

© PSI Metals 2011Slide 21

Hot rolling mill

Cold rolling mill

Utility Power station

Small loads

Internally produced gas (blast furnace gas)

Consumption of electrical energyExternally supplied electrical energyElectrical energy fed back into the grid

Externally supplied gas (natural gas)

Gas supply company Steelworks

Blast furnace

Baseload

None

EAF, LF

Rolling stands

Rolling stands

City load curveSwitchable loads

PSImetals Energy: ECF - Energy Consumption Forecast

© PSI Metals 2011Slide 22

Forecasting methods

Forecast on the basis of production planning data, production forecast

• Forecast on the basis of a (constant or variable) baseload, baseloadforecast

• Forecast based on present measured values,measured-value forecast

Integration of plant-specific forecasting models, for example, for electric furnaces, taking the heat sequence into consideration, model forecast

Total forecast with adaptive weighting

PSImetals Energy: ECF - Energy Consumption Forecast

© PSI Metals 2011Slide 23

PSImetals Energy: Forecast

Forecast based onproduction plans andmaterial parameters

Forecast based on shift plans

Forecast based on current measurements

Forecast based on load patternrecognition

Summarizationto

total forecastValuation

© PSI Metals 2011Slide 24

Forecasting periods

The forecasts are re-calculated for:

the present interval (15 minutes): automatically every 30 seconds

the next 8 intervals (2 hours): automatically every 30 seconds

the next 144 intervals (36 hours): automatically every 15 minutes

the next month: must be explicitly triggered by an authorized user

PSImetals Energy: ECF - Energy Consumption Forecast

© PSI Metals 2011Slide 26

PSImetals Energy: ECF - Energy Consumption Forecast

Forecasting precision

Typical values:

15-minute interval: 2% to 3%

2-hour interval: 3% to 6%

36-hour interval: approx. 8%

The forecasting precision is automatically calculated in the ECF and stored in the database.

© PSI Metals 2011Slide 27

Benefits of the forecasting function

Different forecast calculations

• therefore reliable consumption monitoring possible

Comparison of actual values with the power supply contracts

• therefore a possibility to reduce the price per kilowatt, avoidance of

penalties due to limit-value violations

Preparation of timetables

• therefore better coordination with the utility company is possible

PSImetals Energy: ECF - Energy Consumption Forecast

© PSI Metals 2011Slide 28

EBF Energy Basic Functions

PSIintegration

ECFElectrical Power

Consumption Forecast

PDCPower Demand

Control

GCFGas Consumption

Forecast

PSImetals Energy: PDC - Power Demand Control

© PSI Metals 2011Slide 29

Load management functions and goals

The agreed maximum value may not be exceeded under any circumstances.

Monitoring and control of switchable loads for the safe avoidance of load peaks

Minimum interference with production, and hence avoidance of intervention and shutting down of plants/units whenever possible

Controlling the energy consumption by electric arc furnaces and ladle furnaces by:

• reducing power consumption (changing the transformer voltage)

• complete shut-down, if necessary

Disabling the activation of non-switchable loads

PSImetals Energy: PDC - Power Demand Control

© PSI Metals 2011Slide 30

Benefits of load managementReliable adherence to the lowest maximum value possible

The energy available during an interval is utilized to the maximum extent possible

Minimum interference with production because the number of operator interventions is reduced

Power reduction and/or shutting down is avoided as long as possible

Priority-controlled energy distribution, depending on the progress of production in the case of several switchable loads

Creating transparency

PSImetals Energy: PDC - Power Demand Control

© PSI Metals 2011Slide 31

Control principle

Calculation of setpoints and limit values

Filter

PGS

_

POS

Priorities

Powercontrol

PO

PB

PG

TW

G< W

V

PSImetals Energy: PDC - Power Demand Control

© PSI Metals 2011Slide 32

*) Pre-set by an energymanagement system, if applicable

Setpointvoltage level

Setpoint of maximum value *)Actual value of baseload

Actual valuespower, energy

Load management

Connection to aprocess management system

Operation diagram

Default power

Energy demand(desired power, energy)

Process controlPSImetals

Production&Quality

PSImetals Energy: PDC - Power Demand Control

© PSI Metals 2011Slide 33

PSImetals: Energy und Online Heat Scheduling

Visualizing the process flow

In-time planning and production control

Forecast of energy consumption

Allows simple solving of conflicts

Home - Index - PSImetals PES: Online Scheduling

© PSI Metals 2011Slide 34

Benefits of the power demand control system

Safe avoidance of exceeding power limits

Effective utilization of the energy quota made available

Increased productivity by minimizing shut-down time

Long-time archiving of the relevant data and hence:

• Creation of more transparency of the loads and processes concerned

• Possibilities for analyzing consumption patterns and hence

• Possibility to optimize power supply contracts

PSImetals Energy: PDC - Power Demand Control

© PSI Metals 2011Slide 35

PSImetals Energy - Smart Grid for Metals

Smart grid is a type of elctrical grid which attempts to predict and intelligently respond to the behaviour and actions of all electric power suppliers and consumers connected to it - in order to efficiently deliver reliable, economic, and sustainable electricity services.

Production planning

Contract- and procurement management

Production execution Process- control

and models

© PSI Metals 2011Slide 36

PSImarket

Procurement Plan,Scenarios

Energy Market

Procurementand Proprietary Trading

Historical andPlanned Salesand Profiles

Market Prices,Products

IntegratedRisk- and Portfolio Management

HedgedProcurementCosts

Sales

© PSI Metals 2011Slide 37

Reacting to buying conditions

Paradigm change cause of regenerative energy production

Today: “energy production follows consumption”

Tomorrow:“consumption follows energy production”

Quelle: DER SPIEGEL Nr. 38 2010

37

Unsettled powerPower consumption and wind power in Germany, Dec. 2009

Power consumption

Wind power

© PSI Metals 2011Slide 38

Optimizing the portfolio

Analyse, Information, Recommendations

PSImetals Energy in futureforecast of renewable

energy production

forecast of energy-intensive consumers

Optimized production

© PSI Metals 2011Slide 39

PSImetals Energy – Overall Optimization

Planning and Scheduling

Energy Forecast

Optimized Schedule and Line Sequences

Optimized Energy Costs and Production Results

Real Time Event Handling

Cost Evaluation

Home - Index - PSImetals EMS – Energiekosten über den Produktionsplan optimieren

© PSI Metals 2011Slide 40

PSImetals Energy together with Planning

Orders

Energy

Portfolio and demand

Rules, technicalconstraints & standard practices

Inventories levels

© PSI Metals 2011Slide 43

Contact

Peter Bergfort

Sales Manager

PSI Metals GmbHHeinrichstraße 83-85

40239 DüsseldorfGermany

phone:+49/211/602 19-588mobile:+49/172/23 23 482

fax:+49/211/602 19-240

email: [email protected]

FOTO Franz

www.psimetals.com

© PSI Metals 2011Slide 44

Copyright 2011 PSI AG.Weitergabe und Vervielfältigung dieser Publikation oder von Teilen daraus sind, zu welchem Zweck und in welcher Form auch immer, ohne die ausdrückliche schriftliche Genehmigung durch die PSI AG nicht gestattet. In dieser Publikationenthaltene Informationen können ohne vorherige Ankündigung geändert werden.

PSImetals, PSIintegration und andere in diesem Dokument erwähnte PSI-Produkte und Services sind Marken odereingetragene Marken der PSI AG und der PSI Metals GmbH in Deutschland und in mehreren anderen Ländern weltweit. Alleanderen in diesem Dokument erwähnten Namen von Produkten und Services sowie die damit verbundenen Firmenlogossind Marken der jeweiligen Unternehmen. Die Angaben im Text sind unverbindlich und dienen lediglich zuInformationszwecken. Produkte können länderspezifische Unterschiede aufweisen.

Die in diesem Dokument enthaltenen Informationen sind Eigentum von PSI. Dieses Dokument unterliegt nicht IhrerLizenzvereinbarung oder einer anderen Vereinbarung mit PSI. Dieses Dokument enthält nur vorgesehene Strategien, Entwicklungen und Funktionen des PSI-Produkts und ist für PSI nicht bindend, einen bestimmten Geschäftsweg, eineProduktstrategie bzw. -entwicklung einzuschlagen. PSI übernimmt keine Verantwortung für Fehler oder Auslassungen in diesen Materialien. PSI garantiert nicht die Richtigkeit oder Vollständigkeit der Informationen, Texte, Grafiken, Links oderanderer in diesen Materialien enthaltenen Elemente. Diese Publikation wird ohne jegliche Gewähr, weder ausdrücklich nochstillschweigend, bereitgestellt. Dies gilt u. a., aber nicht ausschließlich, hinsichtlich der Gewährleistung der Marktgängigkeitund der Eignung für einen bestimmten Zweck sowie für die Gewährleistung der Nichtverletzung geltenden Rechts.

PSI übernimmt keine Haftung für Schäden jeglicher Art, einschließlich und ohne Einschränkung für direkte, spezielle, indirekte oder Folgeschäden im Zusammenhang mit der Verwendung dieser Unterlagen. Diese Einschränkung gilt nicht beiVorsatz oder grober Fahrlässigkeit. Die gesetzliche Haftung bei Personenschäden oder die Produkthaftung bleibt unberührt.

Die Informationen, auf die Sie möglicherweise über die in diesem Material enthaltenen Hotlinks zugreifen, unterliegen nichtdem Einfluss von PSI, und PSI unterstützt nicht die Nutzung von Internetseiten Dritter durch Sie und gibt keinerleiGewährleistungen oder Zusagen über Internetseiten Dritter ab.

Alle Rechte vorbehalten.