1965 Corvette FI Restored Hemmings February Part 1

description

Transcript of 1965 Corvette FI Restored Hemmings February Part 1

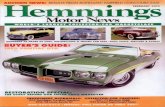

Feature Articles CARFEATURE:18 1970DodgeSuperBee HighImpactpaint,low-impactlifemakesforapamperedBee

CARFEATURE:24 1966FordMustang ShelbyG.T.350H Arentalracerthatescapedtheravagesofthestreets

DRIVEREPORT:30 1968Oldsmobile4-4-2W30 “Factory”meansfunwhenyou’recruisinginanoriginal

contentsHemmings Muscle Machines • Volume 8 • Number 5

Technical Reviews BUYER’SGUIDE:52 1973PontiacGTO SamplethatColonnademagic

TECH/PERFORMANCE:76 FusedandAbused Takechargeofyourelectricalsystem

RESTORATIONPROFILE:58 1965ChevroletCorvetteroadster Part One: Outofthefire,intotherestoshop

ONLOCATION:36 KirklandConcours PerformancemeetsperfectionataFord-focusedevent

HISTORICRACING:40 DragDays DonHunterdocumentedthebestofProStock

MODIFIEDMUSCLE:70 1965RamblerMarlingasser Buildinganhomagetoafamouscrowd-pleaser

4 Hemmings MUSCLE MACHINES | February2011 | hemmings.com4

restoration profile

1965 Chevrolet Corvette roadsterBy Mike McNessorPhotography by Terry McGean • Restoration photography courtesy of Prestige Motor Car • Studio photography by Dino Petrocelli

Years ago, Joe started out as a new-car prep person for the now-defunct Hedley Cadillac in Troy, New York, then gradu-ated to a mechanic’s job at (the also now-defunct) Sibley Chevrolet in Mechanicville, New York. In 1975, Joe struck out on his own and opened a small used car business, Classic Auto Sales and Service, with an emphasis on Corvettes and Firebirds, eventually branching out into bodywork and collision repair.

Then, in 1981, the Verrillos dipped their toes into restora-tion work with a 1966 Corvette—a former race car, which they endeavored to put back to stock.

“It had been a drag car. We restored it back to what it origi-nally was and sold it. When we got it, it had three taillamps on each side, flared fender wells and a roll bar welded to the frame,” Joe said.

So this fledgling project was profitable enough to base a Corvette restoration business on?

“We put in a lot of hours and effort and came out with pen-nies in our pockets,” Joe said. “I think the buyer did better than we did.”

In the mid-’80s, the Verrillos bought another mid-year Corvette project , with a highly desirable big-block drivetrain —right around the start of ’60s muscle-car craze version 1.0. It was this car that started a little momentum building.

“In 1985, we bought a ’67 427/435hp—we restored it, took it to Bloomington, got a Gold Award and sold the car,” Joe said. “Then we bought a ’67 435hp convertible. From then on, it’s been one after the other.”

Looking for a reputable Corvette expert, restoration shop or dealer? Well, you’re in luck. In the U.S., Corvettes are as popular as baseball, hot dogs, apple pie and Dancing With the Stars—so there’s no shortage of support out there.

That’s a good thing for Corvette enthusiasts. But what if you happen to be one of the many Corvette experts, restoration shops or dealers? How do you get your head above the crowd and scream out to potential clients, “Hey, I’m not a poseur!”

Dragging the charred 1965 Corvette roadster carcass pictured on the opposite page into your shop and restoring it to NCRS Top Flight standards would be a good start. But why not raise the bar? Why not insist that the car be rebuilt using only origi-nal, NOS or used/reconditioned factory components?

That’s what Joe Verrillo of Prestige Motor Car Co. in Clifton Park, New York, set out to do 10 years ago when he discovered this catastrophe of a Corvette in Stillwater, New York, about 15 miles north of his showroom. Initially a side project for his crew (it was finished in a flurry of work last year), the car is a rolling showcase of what the Verrillos and their in-house restorers can accomplish.

Joe and his wife, Sunday, have been in the Corvette game—building, buying and selling classic American iron—for almost 30 years, and in that time, they have quietly become one of the more successful Corvette shops you’ve never heard of. Last year, they opened the doors on a new 18,000-sq.ft. building with room for 80 vehicles, and they typically have 30 to 35 Corvettes of all vintages in stock.

A garage fire in the 1970s left this 1965 roadster—originally equipped with a 375hp fuel-injected 327 and some other rare options—a charred, ugly mess. Corvette specialist Joe Verrillo saw an opportunity to build an award-winning ’Vette.

58 Hemmings MUSCLE MACHINES | February 2011 | hemmings.com58 59hemmings.com | February 2011 | Hemmings MUSCLE MACHINES 59

restoration profile

1965 Chevrolet Corvette roadsterBy Mike McNessorPhotography by Terry McGean • Restoration photography courtesy of Prestige Motor Car • Studio photography by Dino Petrocelli

Years ago, Joe started out as a new-car prep person for the now-defunct Hedley Cadillac in Troy, New York, then gradu-ated to a mechanic’s job at (the also now-defunct) Sibley Chevrolet in Mechanicville, New York. In 1975, Joe struck out on his own and opened a small used car business, Classic Auto Sales and Service, with an emphasis on Corvettes and Firebirds, eventually branching out into bodywork and collision repair.

Then, in 1981, the Verrillos dipped their toes into restora-tion work with a 1966 Corvette—a former race car, which they endeavored to put back to stock.

“It had been a drag car. We restored it back to what it origi-nally was and sold it. When we got it, it had three taillamps on each side, flared fender wells and a roll bar welded to the frame,” Joe said.

So this fledgling project was profitable enough to base a Corvette restoration business on?

“We put in a lot of hours and effort and came out with pen-nies in our pockets,” Joe said. “I think the buyer did better than we did.”

In the mid-’80s, the Verrillos bought another mid-year Corvette project , with a highly desirable big-block drivetrain —right around the start of ’60s muscle-car craze version 1.0. It was this car that started a little momentum building.

“In 1985, we bought a ’67 427/435hp—we restored it, took it to Bloomington, got a Gold Award and sold the car,” Joe said. “Then we bought a ’67 435hp convertible. From then on, it’s been one after the other.”

Looking for a reputable Corvette expert, restoration shop or dealer? Well, you’re in luck. In the U.S., Corvettes are as popular as baseball, hot dogs, apple pie and Dancing With the Stars—so there’s no shortage of support out there.

That’s a good thing for Corvette enthusiasts. But what if you happen to be one of the many Corvette experts, restoration shops or dealers? How do you get your head above the crowd and scream out to potential clients, “Hey, I’m not a poseur!”

Dragging the charred 1965 Corvette roadster carcass pictured on the opposite page into your shop and restoring it to NCRS Top Flight standards would be a good start. But why not raise the bar? Why not insist that the car be rebuilt using only origi-nal, NOS or used/reconditioned factory components?

That’s what Joe Verrillo of Prestige Motor Car Co. in Clifton Park, New York, set out to do 10 years ago when he discovered this catastrophe of a Corvette in Stillwater, New York, about 15 miles north of his showroom. Initially a side project for his crew (it was finished in a flurry of work last year), the car is a rolling showcase of what the Verrillos and their in-house restorers can accomplish.

Joe and his wife, Sunday, have been in the Corvette game—building, buying and selling classic American iron—for almost 30 years, and in that time, they have quietly become one of the more successful Corvette shops you’ve never heard of. Last year, they opened the doors on a new 18,000-sq.ft. building with room for 80 vehicles, and they typically have 30 to 35 Corvettes of all vintages in stock.

A garage fire in the 1970s left this 1965 roadster—originally equipped with a 375hp fuel-injected 327 and some other rare options—a charred, ugly mess. Corvette specialist Joe Verrillo saw an opportunity to build an award-winning ’Vette.

58 Hemmings MUSCLE MACHINES | February 2011 | hemmings.com58 59hemmings.com | February 2011 | Hemmings MUSCLE MACHINES 59

restoration profile

The original inner fender skirts were used, as was the original radiator support. The top bonding brace and the headlamp buckets are NOS.

A former Prestige Corvette employee uses a D-A sander to shape the adhesive used to bond the panels to the rear of the car.

All of the front-end components that were used to recreate the nose of the burned-out Corvette were new-old-stock finds.

The driver’s door was sourced from another car, selected for its fit, then later media-blasted to remove the worn original paint.

Fast-forward to a rainy day in 2001 when Joe was following up on rumors of a torched 1965 Corvette convertible stashed behind a small independent body shop. The ’Vette was said to have its original fuel-injected engine and the whole pile was located no more than 20 minutes away. It was worth a look.

“Someone in passing mentioned to me in 2001 or late 2000 that they knew of a real fuel-injected ’65 Corvette—the guy had the original engine and so on. I found out it was in Stillwater at a body shop. The owner told me it was a parts car and the body was rough. Not many good body panels, but he told me I was welcome to look.”

Joe recalls that the guys working at the shop had nicknamed the car Chia ’Vette because, during its semi-outdoor storage, the car’s body tub had become a planter for indigenous weeds and wild plant life.

“The body was under a makeshift tent. Weeds were all around it, stuff was grow-ing in it and up through it. It had sat out-side after the fire for 15 years, anyway.”

Meanwhile, the original fuel-injected engine was also starting to revert back to its base elements.

“I went to his house, where the engine was. It was a bare block and heads—it looked like three pieces of scrap metal.”

Under the patina of rust, however, the numbers and markings added up to the engine being a 375hp 327. So Joe persisted: “It was the original engine and the block had never been decked,” he said. “So I asked if he could take them to a machine shop to have them magna-fluxed.”

The castings passed the crack test, so Joe struck a deal and hauled the remains of the burned Corvette back to his shop.

“One of my guys laughed that I had

any intention of fixing the car,” Joe said. “But it got more exciting the more I dug into it.”

The person from whom Joe purchased the Corvette wasn’t responsible for the fire that nearly destroyed the car. But Joe was able to contact the previous owner, who owned the car at the time of the blaze, and who had stashed away some of the car’s original components and documentation.

“He lived in Fort Ann, New York,” Joe said. “He bought the Corvette in California and drove it across the country in 1966 after being discharged from the service.”

The beginning of the car’s end came during the winter in the early 1970s: The Corvette’s engine grenaded while the driver spun the skinny rear tires uselessly at the base of an ice-slicked hill some-where in upstate New York. Out came

1965 chevrolet corvette roadster

Amazingly, the once-charred Corvette looks whole again after just a coat of polyester primer/surfacer, proving what a good shop can do.

The parking lamp panel and headlamp buckets are being sized up with the panels that comprise the car’s nose, now clamped in place.

Once primed, the body was block- and stick-sanded to get everything straight for the black finish coat, using DuPont products.

With the body work completed, the Corvette was rolled into the paint booth for a coat of primer. Afterwards, it sat for nearly two years.

is new-old-stock. The side fenders, I had been holding onto for years, while the upper and lower grille panel are also NOS. The whole back top-surround is an NOS piece, and then we were able to find NOS quarter panels, as well as a new exhaust panel in the back.”

The driver’s door was selected from several used doors based on the way it fit the car, while the car’s original passen-ger’s door was re-skinned and reinstalled.

“The driver’s door was a perfect shell from another car that we stripped by so-da-blasting,” Joe said. “We had a couple to choose from, but picked this because it fit best. For the right door, we used the original door and changed the door skin to a used panel.”

The car’s headlamp buckets were melted, so they, too, were replaced; the bumpers were bent during a towing mishap—apparently when the car was

the engine, which was subsequently disassembled. Shortly after, the owner accidentally set fire to his motorcycle while working inside his garage. The garage and its contents—including the Corvette—were all burned to a large, ugly crisp.

Though that owner eventually sold the Corvette, he held onto the California reg-istration and sales receipts, as well as the 1971 New York State registration. He also had the car’s rare and valuable original exhaust manifolds , among some other original parts —all of which Joe was able to purchase.

The damage to the car was consider-able. All of the fiberglass was savaged by the fire, leaving the car looking like it had grown a coat of fire-blackened fur. The upholstery, any soft parts, and the wiring were, of course, all lost. The steel parts of the car had been burned bare and

then left out to rust. The glass was ruined as well.

So why would anyone even consider such a project? The frame was unrusted and unbent, and the car had its original drivetrain. In addition to the fuel-injected engine, the Corvette had been ordered with a 4.11:1 gear, a Teakwood steering wheel and F40 suspension, making it increasingly rare. The last year for fuel in-jection in a mid-year Corvette was 1965, and only 771 cars were so equipped that year.

As a restorer, Joe had amassed a trove of spare Corvette parts, from major pan-els down to hard-to-find correct fasten-ers. He owned a set of NOS fenders for the car and was able to track down NOS quarter panels, an NOS rear upper deck, taillamp and exhaust panels.

“We used original inner fender skirts while the rest of the front end fiberglass

1

2

3

4

5

6

7

8

60 Hemmings MUSCLE MACHINES | February 2011 | hemmings.com60 61hemmings.com | February 2011 | Hemmings MUSCLE MACHINES 61

restoration profile

The original inner fender skirts were used, as was the original radiator support. The top bonding brace and the headlamp buckets are NOS.

A former Prestige Corvette employee uses a D-A sander to shape the adhesive used to bond the panels to the rear of the car.

All of the front-end components that were used to recreate the nose of the burned-out Corvette were new-old-stock finds.

The driver’s door was sourced from another car, selected for its fit, then later media-blasted to remove the worn original paint.

Fast-forward to a rainy day in 2001 when Joe was following up on rumors of a torched 1965 Corvette convertible stashed behind a small independent body shop. The ’Vette was said to have its original fuel-injected engine and the whole pile was located no more than 20 minutes away. It was worth a look.

“Someone in passing mentioned to me in 2001 or late 2000 that they knew of a real fuel-injected ’65 Corvette—the guy had the original engine and so on. I found out it was in Stillwater at a body shop. The owner told me it was a parts car and the body was rough. Not many good body panels, but he told me I was welcome to look.”

Joe recalls that the guys working at the shop had nicknamed the car Chia ’Vette because, during its semi-outdoor storage, the car’s body tub had become a planter for indigenous weeds and wild plant life.

“The body was under a makeshift tent. Weeds were all around it, stuff was grow-ing in it and up through it. It had sat out-side after the fire for 15 years, anyway.”

Meanwhile, the original fuel-injected engine was also starting to revert back to its base elements.

“I went to his house, where the engine was. It was a bare block and heads—it looked like three pieces of scrap metal.”

Under the patina of rust, however, the numbers and markings added up to the engine being a 375hp 327. So Joe persisted: “It was the original engine and the block had never been decked,” he said. “So I asked if he could take them to a machine shop to have them magna-fluxed.”

The castings passed the crack test, so Joe struck a deal and hauled the remains of the burned Corvette back to his shop.

“One of my guys laughed that I had

any intention of fixing the car,” Joe said. “But it got more exciting the more I dug into it.”

The person from whom Joe purchased the Corvette wasn’t responsible for the fire that nearly destroyed the car. But Joe was able to contact the previous owner, who owned the car at the time of the blaze, and who had stashed away some of the car’s original components and documentation.

“He lived in Fort Ann, New York,” Joe said. “He bought the Corvette in California and drove it across the country in 1966 after being discharged from the service.”

The beginning of the car’s end came during the winter in the early 1970s: The Corvette’s engine grenaded while the driver spun the skinny rear tires uselessly at the base of an ice-slicked hill some-where in upstate New York. Out came

1965 chevrolet corvette roadster

Amazingly, the once-charred Corvette looks whole again after just a coat of polyester primer/surfacer, proving what a good shop can do.

The parking lamp panel and headlamp buckets are being sized up with the panels that comprise the car’s nose, now clamped in place.

Once primed, the body was block- and stick-sanded to get everything straight for the black finish coat, using DuPont products.

With the body work completed, the Corvette was rolled into the paint booth for a coat of primer. Afterwards, it sat for nearly two years.

is new-old-stock. The side fenders, I had been holding onto for years, while the upper and lower grille panel are also NOS. The whole back top-surround is an NOS piece, and then we were able to find NOS quarter panels, as well as a new exhaust panel in the back.”

The driver’s door was selected from several used doors based on the way it fit the car, while the car’s original passen-ger’s door was re-skinned and reinstalled.

“The driver’s door was a perfect shell from another car that we stripped by so-da-blasting,” Joe said. “We had a couple to choose from, but picked this because it fit best. For the right door, we used the original door and changed the door skin to a used panel.”

The car’s headlamp buckets were melted, so they, too, were replaced; the bumpers were bent during a towing mishap—apparently when the car was

the engine, which was subsequently disassembled. Shortly after, the owner accidentally set fire to his motorcycle while working inside his garage. The garage and its contents—including the Corvette—were all burned to a large, ugly crisp.

Though that owner eventually sold the Corvette, he held onto the California reg-istration and sales receipts, as well as the 1971 New York State registration. He also had the car’s rare and valuable original exhaust manifolds , among some other original parts —all of which Joe was able to purchase.

The damage to the car was consider-able. All of the fiberglass was savaged by the fire, leaving the car looking like it had grown a coat of fire-blackened fur. The upholstery, any soft parts, and the wiring were, of course, all lost. The steel parts of the car had been burned bare and

then left out to rust. The glass was ruined as well.

So why would anyone even consider such a project? The frame was unrusted and unbent, and the car had its original drivetrain. In addition to the fuel-injected engine, the Corvette had been ordered with a 4.11:1 gear, a Teakwood steering wheel and F40 suspension, making it increasingly rare. The last year for fuel in-jection in a mid-year Corvette was 1965, and only 771 cars were so equipped that year.

As a restorer, Joe had amassed a trove of spare Corvette parts, from major pan-els down to hard-to-find correct fasten-ers. He owned a set of NOS fenders for the car and was able to track down NOS quarter panels, an NOS rear upper deck, taillamp and exhaust panels.

“We used original inner fender skirts while the rest of the front end fiberglass

1

2

3

4

5

6

7

8

60 Hemmings MUSCLE MACHINES | February 2011 | hemmings.com60 61hemmings.com | February 2011 | Hemmings MUSCLE MACHINES 61

restoration profile

An NOS upper control arm, hanging in preparation for paint, was used to make the front end of the car as correct as possible.

A coat of tinted sealer was applied over the primer before the black basecoat/clearcoat paint went on.

After the pits in the frame were smoothed with body filler, the frame was primed, then sanded, sealed and painted.

The chassis was stripped of its original components and the pieces sent out for media-blasting and reconditioning, where necessary.

are more durable than the original lac-quer. But we apply it with some orange peel and satin the jambs to replicate the original lacquer look. It’s glitzier than new, but similar.”

Once the body was finished, it was removed from the chassis and set aside. Then the chassis and drivetrain were disassembled. Various pieces were sent out to be rebuilt and reworked while the frame rails were blasted, and then brought back to the body shop.

“After the frame comes back from the sandblaster, it goes on a rotisserie and we evaluate what it needs,” Joe said. “It had a lot of pits from sitting, so we sanded it with a D-A sander from front to back. It wasn’t dented or rusted, so we skim-coated it with body filler and then sanded it. Then it was re-primed, sealed and painted with DuPont paint with a flattening agent added.”

stuck in the snow with a blown engine. Joe exchanged them for a set of used, reconditioned bumpers.

The Corvette’s body was left on the chassis while it was restored. The fire-damaged fiberglass panels were cut off, the steel “bird-cage” of the car was sandblasted and then, working from the rear to the front, the new panels were bonded to the substructure with Evercoat ’Vette Panel Adhesive/Filler. The inside of the cage was coated with zinc-chromate primer to replicate the original look.

“We build [Corvettes] from back to front, fitting the backs of the doors, then straightening the seams all out. We then apply a final coat of plastic to the body and rough all of that out with 80-grit paper. Once it’s roughed in and once the back and doors are built, we hang the front panels. When those panels are on, the doors come off, we grind out the ex-

cess panel adhesive, finish it all and then spray it with polyester.”

Normally the body would sit in primer for about a month to allow the primer/surfacer to shrink. But other projects and a business to run meant that the Corvette sat from 2006 until 2008.

“In 2008, we took the car back out and began working on it as a filler proj-ect,” says Joe of the Corvette’s status in the shop.

The block-sanding process began to get the car perfect for its black finish coat. To replicate the original lacquer paint on mid-year Corvettes, the Prestige crew intentionally works a little orange peel into the finish and applies a satin fin-ish to the door jambs.

“We use DuPont Performance Coat-ings—they were the original manufac-turer of the Corvette’s paint. We use basecoat/clearcoat finishes because they

The engine, too, was painted in the body shop, using paint color mixed in-house. The lower intake and distributor were masked off in place.

The engine looks factory fresh sitting in the frame with the original rebuilt fuel pump, and original exhaust manifolds.

1965 chevrolet corvette roadster

The artfully finished chassis was rolled into photographer Dino Petrocelli’s studio in Albany, New York, for its close up. Tune in next month for more photos of the build and the completed car.

9

10 12

11

Next Month:Part 2: An award-winning 1965 Corvette rises from the ashes.

13 14

62 Hemmings MUSCLE MACHINES | February 2011 | hemmings.com62 63hemmings.com | February 2011 | Hemmings MUSCLE MACHINES 63

restoration profile

An NOS upper control arm, hanging in preparation for paint, was used to make the front end of the car as correct as possible.

A coat of tinted sealer was applied over the primer before the black basecoat/clearcoat paint went on.

After the pits in the frame were smoothed with body filler, the frame was primed, then sanded, sealed and painted.

The chassis was stripped of its original components and the pieces sent out for media-blasting and reconditioning, where necessary.

are more durable than the original lac-quer. But we apply it with some orange peel and satin the jambs to replicate the original lacquer look. It’s glitzier than new, but similar.”

Once the body was finished, it was removed from the chassis and set aside. Then the chassis and drivetrain were disassembled. Various pieces were sent out to be rebuilt and reworked while the frame rails were blasted, and then brought back to the body shop.

“After the frame comes back from the sandblaster, it goes on a rotisserie and we evaluate what it needs,” Joe said. “It had a lot of pits from sitting, so we sanded it with a D-A sander from front to back. It wasn’t dented or rusted, so we skim-coated it with body filler and then sanded it. Then it was re-primed, sealed and painted with DuPont paint with a flattening agent added.”

stuck in the snow with a blown engine. Joe exchanged them for a set of used, reconditioned bumpers.

The Corvette’s body was left on the chassis while it was restored. The fire-damaged fiberglass panels were cut off, the steel “bird-cage” of the car was sandblasted and then, working from the rear to the front, the new panels were bonded to the substructure with Evercoat ’Vette Panel Adhesive/Filler. The inside of the cage was coated with zinc-chromate primer to replicate the original look.

“We build [Corvettes] from back to front, fitting the backs of the doors, then straightening the seams all out. We then apply a final coat of plastic to the body and rough all of that out with 80-grit paper. Once it’s roughed in and once the back and doors are built, we hang the front panels. When those panels are on, the doors come off, we grind out the ex-

cess panel adhesive, finish it all and then spray it with polyester.”

Normally the body would sit in primer for about a month to allow the primer/surfacer to shrink. But other projects and a business to run meant that the Corvette sat from 2006 until 2008.

“In 2008, we took the car back out and began working on it as a filler proj-ect,” says Joe of the Corvette’s status in the shop.

The block-sanding process began to get the car perfect for its black finish coat. To replicate the original lacquer paint on mid-year Corvettes, the Prestige crew intentionally works a little orange peel into the finish and applies a satin fin-ish to the door jambs.

“We use DuPont Performance Coat-ings—they were the original manufac-turer of the Corvette’s paint. We use basecoat/clearcoat finishes because they

The engine, too, was painted in the body shop, using paint color mixed in-house. The lower intake and distributor were masked off in place.

The engine looks factory fresh sitting in the frame with the original rebuilt fuel pump, and original exhaust manifolds.

1965 chevrolet corvette roadster

The artfully finished chassis was rolled into photographer Dino Petrocelli’s studio in Albany, New York, for its close up. Tune in next month for more photos of the build and the completed car.

9

10 12

11

Next Month:Part 2: An award-winning 1965 Corvette rises from the ashes.

13 14

62 Hemmings MUSCLE MACHINES | February 2011 | hemmings.com62 63hemmings.com | February 2011 | Hemmings MUSCLE MACHINES 63